Komatsu 95 Series Engine Shop Manual SEN0440

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN0440

- Format: PDF

- Size: 15.2MB

- Number of Pages: 198

Category: Komatsu Shop Manual PDF

-

Model List:

- 95 Series Engine

- 1. SEN0440800 WA656, WA706, WA806

- 1.1. General assembly drawing

- 1.2. WE5 LEFT SIDE VIEW (WA65HH6)

- 1.3. WE5 RIGHT SIDE VIEW (WA65HH6)

- 1.4. WE5 FRONT VIEW (WA65HH6)

- 1.5. WE5 REAR VIEW (WA65HH6)

- 1.6. S4D95LWE5 LEFT SIDE VIEW (WA80HH6)

- 1.7. S4D95LWE5 RIGHT SIDE VIEW (WA80HH6)

- 1.8. S4D95LWE5 FRONT VIEW (WA80HH6)

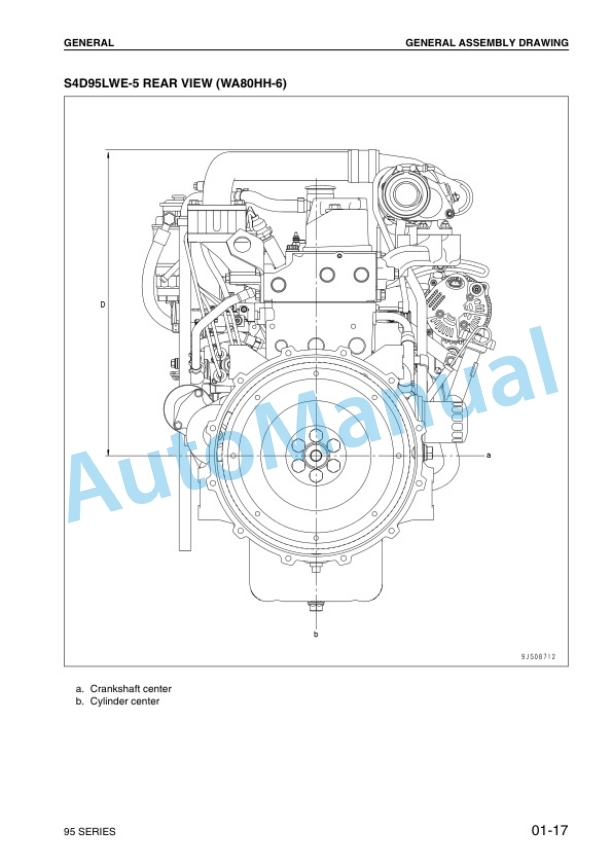

- 1.9. S4D95LWE5 REAR VIEW (WA80HH6)

- 1.10. DIMENSION TABLE

- 1.11. Engine performance curve

- 1.12. WE5 Applicable machine WA65HH6

- 1.13. WE5 Applicable machine WA70HH6

- 1.14. WE5 Applicable machine WA80HH6

- 1.15. Weight table

- 2. STRUCTURE AND FUNCTION

- 2.1. General structure

- 2.2. EXHAUST SYSTEM

- 2.2.1. Turbocharger

- 2.2.2. TD04L

- 2.2.2.1. Outline of waste gate valve

- 2.2.3. Main moving parts

- 2.2.4. Timing gear

- 2.2.5. WITHOUT FRONT PTO TYPE (HELICAL GEAR)

- 2.2.5.1. Front oil seal

- 2.2.6. Valve system

- 2.2.7. Flywheel and flywheel housing

- 2.2.8. WITHOUT REAR PTO TYPE

- 2.3. LUBRICATION SYSTEM

- 2.3.1. Lubrication system chart

- 2.3.2. Oil pump

- 2.3.2.1. Specifications

- 2.3.2.2. Oil pump

- 2.3.2.3. Regulator valve

- 2.3.3. Oil filter

- 2.3.3.1. Relief valve

- 2.4. FUEL SYSTEM

- 2.4.1. Fuel system chart

- 2.4.2. Fuel injection pump

- 2.4.3. Fuel injection nozzle

- 2.4.4. For direct fuel injection type

- 2.4.5. For swirl chamber type

- 2.4.5.1. Fuel injection nozzle

- 2.5. COOLING STSTEM

- 2.5.1. Cooling system chart

- 2.5.2. Thermostat and fan drive

- 2.5.3. THERMOSTAT (WITHOUT JIGGLE VALVE)

- 2.6. ELECTRICAL SYSTEM

- 2.6.1. Starting and charging system electrical circuit diagram

- 2.6.2. Alternator

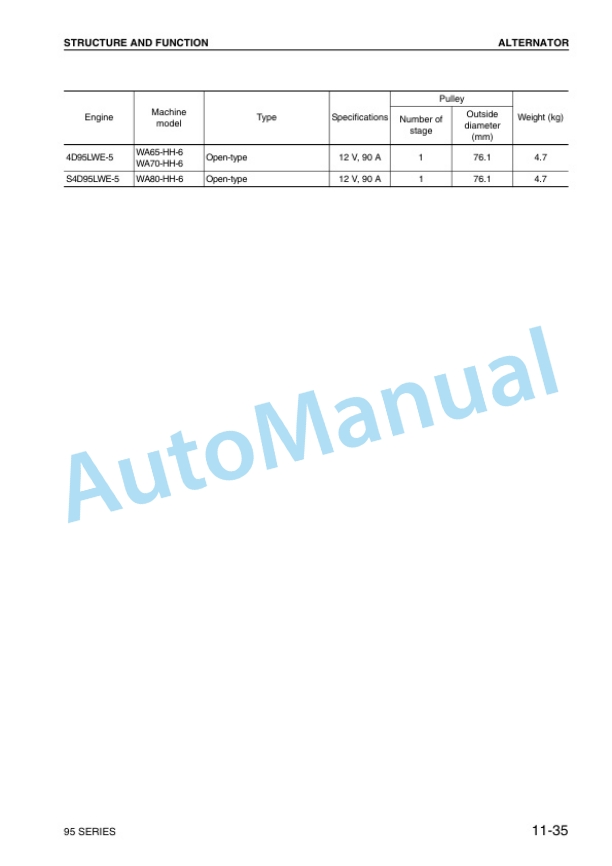

- 2.6.3. ALTERNATOR WITH BUILTIN REGULATOR (Open type, 90A)

- 2.6.4. Starting motor

- 2.6.4.1. For 2.2 kW

- 2.6.5. Engine starting device

- 2.6.6. GLOW PLUG (METAL 2WIRE TYPE GLOW PLUG)

- 2.6.6.1. Connector (round 8pin), (Short 8pin)

- 2.6.6.2. Lead wire

- 2.6.6.3. Case

- 2.6.6.4. Bracket

- 2.6.6.5. Label

- 2.6.6.6. Water temperature sensor

- 2.6.6.7. Glow relay

- 2.6.6.8. Lead wire

- 2.6.6.9. Connector (round 2in)

- 3. TESTING AND ADJUSTING

- 3.1. Performance test

- 3.2. Runin standard

- 3.3. Performance test criteria

- 3.4. Testing and adjusting data

- 3.5. Testing and adjusting tools list

- 3.6. Intake and exhaust system

- 3.7. Adjusting valve clearance

- 3.8. Engine body

- 3.9. Measuring compression pressure

- 3.9.1. Measurement procedure

- 3.10. Fuel system

- 3.11. Adjusting fuel injection pressure (Cracking pressure)

- 3.12. Shim data for adjusting injection pressure

- 3.13. Testing and adjusting fuel injection timing

- 3.14. Table of injection pumps using plunger with stepped lead

- 3.15. Adjusting fuel injection rate

- 3.16. Governor adjustment standard

- 3.17. Troubleshooting

- 3.18. Method of using troubleshooting charts

- 3.19. Points on troubleshooting

- 3.20. S1 Starting performance is poor (Starting always takes time)

- 3.21. S2 Engine does not start

- 3.21.1. Engine does not turn

- 3.21.2. Engine turns but no exhaust gas comes out (Fuel is not being injected)

- 3.21.3. Exhaust gas comes out but engine does not start (Fuel is being injected)

- 3.22. S3 Engine does not pick up smoothly (Followup is poor)

- 3.23. S4 Engine stops during operations

- 3.24. S5 Engine does not rotate smoothly

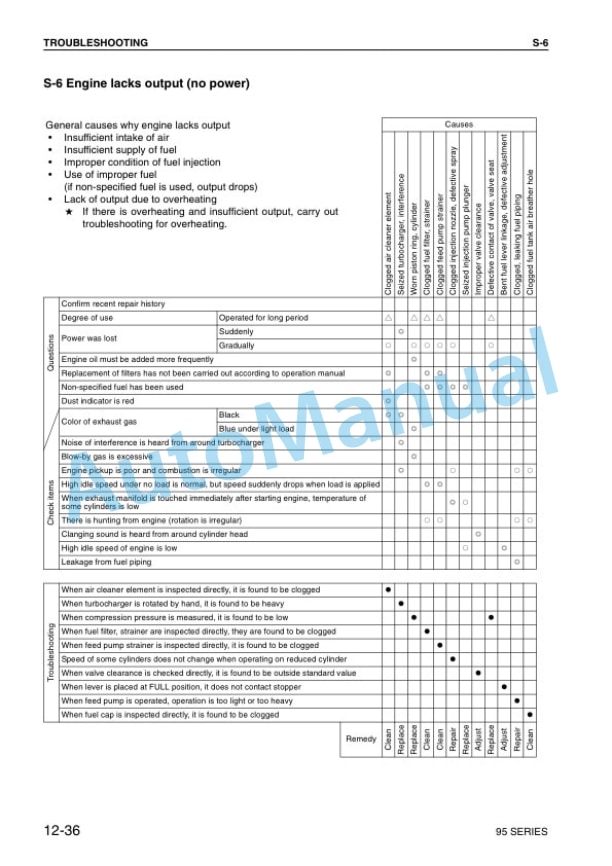

- 3.25. S6 Engine lacks output (no power)

- 3.26. S7 Exhaust gas is black (incomplete combustion)

- 3.27. S8 Oil consumption is excessive (or exhaust gas is blue)

- 3.28. S9 Oil becomes contaminated quickly

- 3.29. S10 Fuel consumption is excessive

- 3.30. S11 Oil is in coolant, or coolant spurts back, or coolant level goes down

- 3.31. S12 Oil pressure lamp lights up (drop in oil pressure)

- 3.32. S13 Oil level rises

- 3.33. S14 Coolant temperature becomes too high (overheating)

- 3.34. S15 Abnormal noise is made

- 3.35. S16 Vibration is excessive

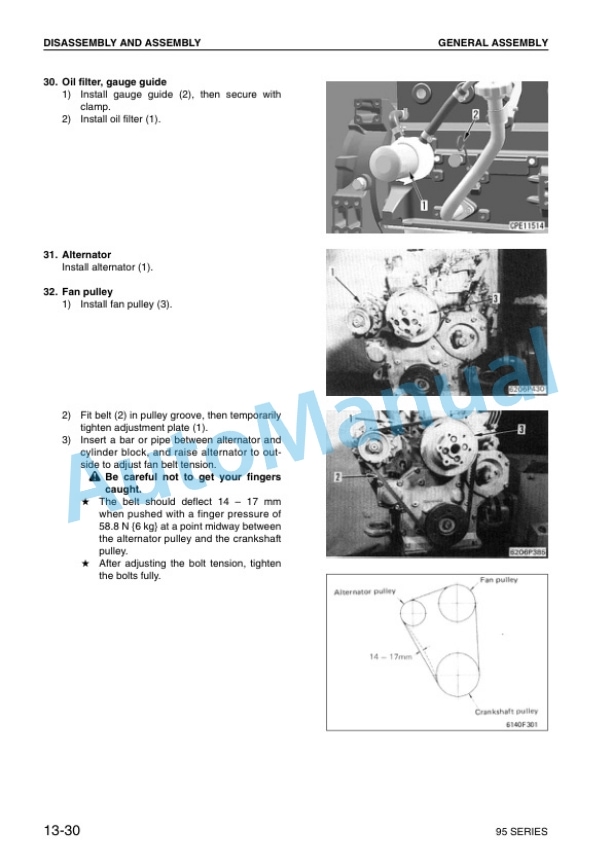

- 4. DISASSEMLY AND ASSEMBLY

- 4.1. General disassembly

- 4.1.1. Special tools

- 4.2. General assembly

- 4.2.1. Special tools

- 5. MAINTENANCE STANDARD

- 5.1. Turbocharger

- 5.2. Cylinder head

- 5.3. Valve, valve guide

- 5.4. Rocker arm shaft, push rod and tappet

- 5.5. Cylinder block

- 5.6. Cylinder

- 5.7. Crankshaft

- 5.8. Camshaft

- 5.9. Timing gear (Helical gear)

- 5.10. Flywheel and flywheel housing

- 5.11. Piston, piston ring and piston pin

- 5.12. Connecting rod

- 5.13. Regulator valve

- 5.14. Water pump and thermostat

- 6. REPAIR AND REPLACEMENT OF PARTS

- 6.1. Grinding cylinder head mounting surface

- 6.2. Replacing valve guide

- 6.2.1. Special tools

- 6.3. Grinding valve

- 6.3.1. Special tool

- 6.4. Replacing camshaft bushing

- 6.4.1. Special tools

- 6.5. Replacing crankshaft gear

- 6.6. Testing and adjusting fuel injection timing

- 6.7. Replacing flywheel ring gear

- 6.8. Procedure for pressure test

- 6.8.1. Special tools

- 6.9. Cylinder liner

- 6.10. (special restoration part)

- 6.10.1. Cylinder liner

- 6.11. Machining drawing for cylinder block bore

- 6.12. Additional machining of cam journal

- 6.13. Grinding crankshaft

- 6.13.1. Applicable crankshaft

- 6.14. Replacing connecting rod small end bushing

- 6.14.1. Special tools

Rate this product

You may also like