Komatsu PC33E-6 Electric Mini Excavator Shop Manual SEN06975-00

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06975-00

- Format: PDF

- Size: 27.3MB

- Number of Pages: 462

Category: Komatsu Shop Manual PDF

-

Model List:

- PC33E-6 Electric Mini Excavator

- 1. Cover

- 2. Index and Foreword

- 2.1. Index

- 2.2. Foreword, Safety, Basic Information

- 2.2.1. How to Read the Shop Manual

- 2.2.2. Safety Notice for Operation

- 2.2.3. Precautions for Battery Type Compact Hydraulic Excavator

- 2.2.4. Precautions to Prevent Fire

- 2.2.5. Procedures If Fire Occurs

- 2.2.6. Precautions When You Dispose of Waste Materials

- 2.2.7. Precautions When You Handle Hydraulic Equipment

- 2.2.8. Precautions When You Disconnect and Connect Pipings

- 2.2.9. Precautions When You Handle Electrical Equipment

- 2.2.10. Precautions Against High Voltage and High Temperature

- 2.2.11. Procedure for Inspection and Maintenance of High Voltage Parts

- 2.2.12. Procedure to Restore High Voltage Parts

- 2.2.13. Precautions When Machine Falls over and Power Electronics Components Have Damage

- 2.2.14. Precautions for Machine Not to be Put in Water

- 2.2.15. In Cold Weather

- 2.2.16. Practical Use of KOMTRAX

- 2.2.17. Disconnect and Connect PushPull Type Coupler

- 2.2.18. Precautions for Disconnection and Connection of Connectors

- 2.2.19. How to Disconnect and Connect Deutsch Connector

- 2.2.20. How to Disconnect and Connect Slide Lock Type Connector

- 2.2.21. How to Disconnect and Connect Connector with Lock to Pull

- 2.2.22. How to Disconnect and Connect Connector with Lock to Push

- 2.2.23. How to Disconnect and Connect Connector with Housing to Rotate

- 2.2.24. Standard Tightening Torque Table

- 2.2.25. Conversion Table

- 2.2.26. Abbreviation List

- 3. Specifications

- 3.1. Table of Contents

- 3.2. Specifications

- 3.2.1. Specification Drawing

- 3.2.2. Working Range Drawings

- 3.2.3. Specifications

- 3.2.4. Weight Table

- 3.2.5. Lubricant

- 4. Structure and Function

- 4.1. Table of Contents

- 4.2. Bootup System

- 4.2.1. Layout Drawing of Bootup System

- 4.2.2. System Operating Lamp System

- 4.2.3. Special Power Supply for Battery

- 4.2.4. Electric Motor Shutdown Secondary Switch

- 4.2.5. ID Key System

- 4.2.6. Component Parts of BootUp System

- 4.3. Electric Drive System

- 4.3.1. Layout Drawing of Electric Drive System

- 4.3.2. Worker Protection System When You Disassemble Power Electronics Components

- 4.3.3. High Voltage Wiring (Power Cable)

- 4.3.4. Component Parts of Electric Drive System

- 4.4. Electric Motor System

- 4.4.1. Layout Drawing of Electric Motor System

- 4.4.2. Electric Motor Control System

- 4.4.3. AutoDeceleration System

- 4.4.4. Overheat Prevention System

- 4.4.5. Automatic Idle Stop System

- 4.5. Cooling System

- 4.5.1. Layout Drawing of Cooling System

- 4.6. Control System

- 4.6.1. Layout Drawing of Control System

- 4.6.2. Machine Monitor System

- 4.6.3. KOMTRAX System

- 4.6.4. Component Parts of Control System

- 4.7. Hydraulic System

- 4.7.1. Layout Drawing of Hydraulic System

- 4.7.2. CLSS

- 4.7.3. Electric Motor and Pump Combined Control System

- 4.7.4. Component Parts of Hydraulic System

- 4.8. Work Equipment System

- 4.8.1. Layout Drawing of Work Equipment System

- 4.8.2. Structure of Valve Control

- 4.8.3. PPC Lock System

- 4.8.4. Work Equipment and Travel Automatic Lock System

- 4.8.5. Component Parts of Work Equipment System

- 4.9. Swing System

- 4.9.1. Layout Drawing of Swing System

- 4.9.2. Component Parts of Swing System

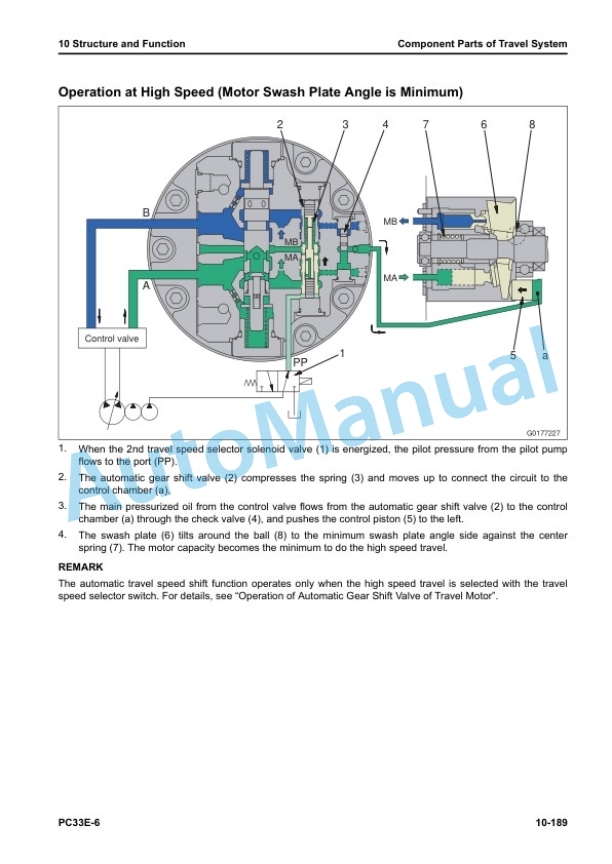

- 4.10. Travel System

- 4.10.1. Layout Drawing of Travel System

- 4.10.2. System Diagram of Travel Control System

- 4.10.3. Component Parts of Travel System

- 4.11. Undercarriage and Frame

- 4.11.1. Layout Drawing of Undercarriage

- 4.11.2. Specifications of Undercarriage

- 4.11.3. Idler Cushion

- 4.12. Work Equipment

- 4.12.1. Structure of Work Equipment

- 4.12.2. Function of Work Equipment

- 4.12.3. Work Equipment Clearance Adjustment Shim

- 4.13. CAB Related Parts

- 4.13.1. Tilt Type Floor

- 5. Maintenance Standard

- 5.1. Table of Contents

- 5.2. Explanation of Terms for Maintenance Standard

- 5.3. Electric Motor and Cooling System

- 5.3.1. Maintenance Standard for Electric Motor

- 5.3.2. Maintenance Standard for Cooling System

- 5.4. Power Train

- 5.4.1. Maintenance Standard for Swing Circle

- 5.4.2. Maintenance Standard for Swing Machinery

- 5.4.3. Maintenance Standard for Sprocket

- 5.5. Undercarriage and Frame

- 5.5.1. Maintenance Standard for Track Frame and Idler Cushion

- 5.5.2. Maintenance Standard for Idler

- 5.5.3. Maintenance Standard for Track Roller

- 5.5.4. Maintenance Standard for Carrier Roller

- 5.5.5. Maintenance Standard for Rubber Shoes

- 5.6. Hydraulic System

- 5.6.1. Maintenance Standard for Hydraulic Tank

- 5.6.2. Maintenance Standard for Main Pump

- 5.6.3. Maintenance Standard for Main Pump Servo Valve

- 5.6.4. Maintenance Standard for PCEPC Valve

- 5.6.5. Maintenance Standard for Swing Motor

- 5.6.6. Maintenance Standard for Travel Motor

- 5.6.7. Maintenance Standard for Control Valve

- 5.6.8. Maintenance Standard for Boom AntiDrop Valve

- 5.6.9. Maintenance Standard for Arm AntiDrop Valve

- 5.6.10. Maintenance Standard for Work Equipment and Swing PPC Valve

- 5.6.11. Maintenance Standard for Blade PPC Valve

- 5.6.12. Maintenance Standard for Boom Swing PPC Valve

- 5.6.13. Maintenance Standard for Travel PPC Valve

- 5.6.14. Maintenance Standard for Center Swivel Joint

- 5.7. Work Equipment

- 5.7.1. Maintenance Standard for Work Equipment Linkage

- 5.7.2. Dimensions of Arm

- 5.7.3. Maintenance Standard for Boom Cylinder

- 5.7.4. Maintenance Standard for Arm Cylinder

- 5.7.5. Maintenance Standard for Bucket Cylinder

- 5.7.6. Maintenance Standard for Blade Cylinder

- 5.7.7. Maintenance Standard for Boom Swing Cylinder

- 6. Others

- 6.1. Table of Contents

- 6.2. Precautions Before Work

- 6.3. Stationary Charger

- 6.3.1. Precautions for Stationary Battery Charger

- 6.3.2. Structure and Operation of Stationary Charger

- 6.3.3. Examine and Adjust Stationary Battery Charger

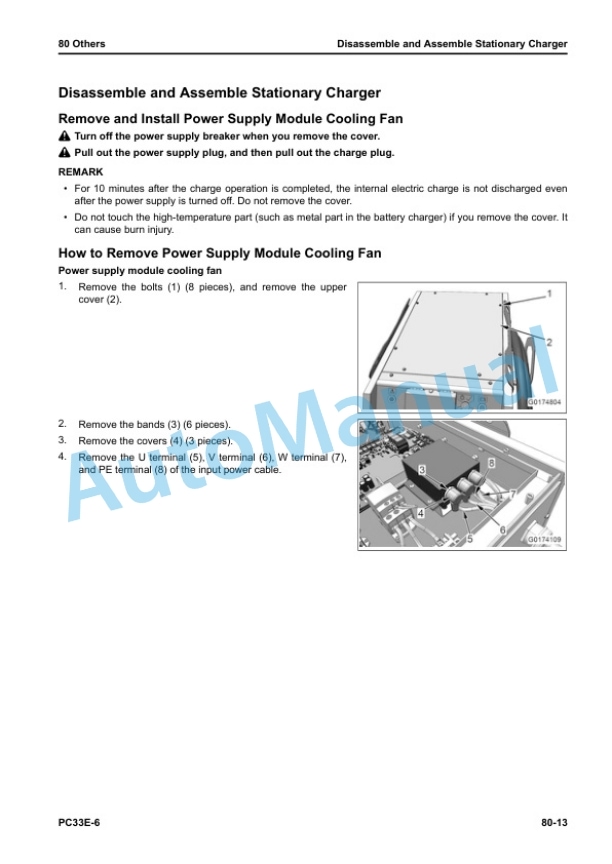

- 6.3.4. Disassemble and Assemble Stationary Charger

- 7. Circuit Diagrams

- 7.1. Table of Contents

- 7.2. How to Read the Codes for Electric Cable

- 7.3. Hydraulic Circuit Diagram

- 7.3.1. Symbols Used in Hydraulic Circuit Diagram

- 7.3.2. Hydraulic Circuit Diagram

- 7.3.3. Hydraulic Circuit Diagram (at Boom Raise Operation)

- 7.3.4. Hydraulic Circuit Diagram (at Left Swing Operation)

- 7.3.5. Hydraulic Circuit Diagram (at Boom Raise and Left Swing Operation)

- 7.4. Electrical Circuit Diagram

- 7.4.1. Symbols Used in Electric Circuit Diagram

- 7.4.2. Electrical Circuit Diagram (1/6)

- 7.4.3. Electrical Circuit Diagram (2/6)

- 7.4.4. Electrical Circuit Diagram (3/6)

- 7.4.5. Electrical Circuit Diagram (4/6)

- 7.4.6. Electrical Circuit Diagram (5/6)

- 7.4.7. Electrical Circuit Diagram (6/6)

- 8. Index

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00