Claas Disco 3500 Tc (F52) Mower Operator Manual EN

$50.00

- Model: Disco 3500 Tc (F52) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 37.1 MB

File List:

00 0295 391 2.pdf

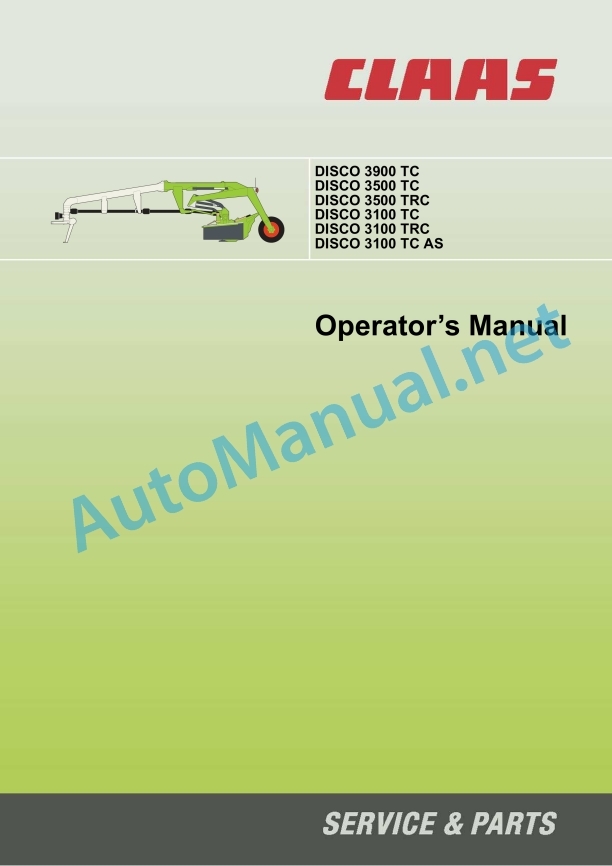

00 1329 399 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0295 391 2.pdf:

Contents

1 Machine description

1.1 DISCO 3900 TC; 3500 TC / TRC; 3100 TC / TRC 9

1.1.1 Designations 9

1.2 DISCO 3100 TC AS 11

1.2.1 Designations 11

2 Introduction

2.1 General Information 13

2.1.1 Using the manual 13

2.1.2 Validity of manual 14

2.2 Identification plates and identification numbers 15

2.2.1 Spare parts and technical questions 15

2.2.2 Identification plate 16

3 Safety

3.1 Basic safety instructions 17

3.1.1 General safety information 17

3.1.2 Intended use 17

3.1.3 Reasonable foreseeable misuse 18

3.1.4 Directives, statutes and standards 18

3.1.5 Technical condition 19

3.1.6 Occupational safety 19

3.1.7 Hydraulics 21

3.1.8 Safety features on the machine 22

3.1.9 What to do in the event of hazardous situations and accidents 22

3.1.10 Decommissioning and disposal 23

3.2 Warning and hazard signs 24

3.2.1 Labels 24

3.3 Safety decals 25

3.3.1 General instructions for warning signs 25

3.3.2 Placement on the machine 26

4 Specifications

4.1 DISCO 3900 TC – Model F53 33

4.1.1 Dimensions and weight 33

4.1.2 Requirements for the tractor 34

4.1.3 Design 34

4.1.4 Tyres 34

4.1.5 Noise level 35

4.2 DISCO 3500 TC / DISCO 3500 TRC – Model F52 36

4.2.1 Dimensions and weight 36

4.2.2 Requirements for the tractor 37

4.2.3 Design 37

4.2.4 Tyres 37

4.2.5 Noise level 38

4.3 DISCO 3100 TC / DISCO 3100 TRC – Model F51 39

4.3.1 Dimensions and weight 39

4.3.2 Requirements for the tractor 40

4.3.3 Design 40

4.3.4 Tyres 40

4.3.5 Noise level 41

4.4 DISCO 3100 TC AS – Model F51 42

4.4.1 Dimensions and weight 42

4.4.2 Requirements for the tractor 43

4.4.3 Design 43

4.4.4 Tyres 43

4.4.5 Noise level 44

5 Prior to initial operation

5.1 General information 45

5.1.1 Checklist for commissioning 45

5.2 Adaptation to the machine 46

5.2.1 Universal drive shaft – check length 46

5.2.2 Universal drive shaft – adjusting length 47

5.2.3 Mounting universal drive shaft on machine 48

5.2.4 Adjusting the lateral offset 50

5.3 Accessories 53

5.3.1 Crop spreader (G03 0010) 53

5.3.2 Swathing plate extension (G03 0060) 53

5.3.3 High-cut skids (B03 0020) 53

5.3.4 Skid extensions (C03 0030) 54

5.3.5 Hydraulic connection for tractor (R03 0030) 54

6 Before putting the machine into operation

6.1 General information 55

6.1.1 Check list for putting into operation 55

7 Attaching / detaching machine

7.1 Hitching the machine 56

7.1.1 General instructions 56

7.1.2 Connecting the hitch bracket 57

7.1.3 Raising the prop stand 57

7.1.4 Fitting the universal drive shaft 58

7.1.5 Coupling hydraulic hose lines 60

7.1.6 Connecting the power supply 65

7.1.7 Cross conveyor belt control terminal 65

7.2 Unhitching the machine 66

7.2.1 General instructions 66

7.2.2 Lowering the prop stand 66

7.2.3 Disconnecting the power supply 67

7.2.4 Cross conveyor belt control terminal 67

7.2.5 Decoupling hydraulic hose lines 68

7.2.6 Removing universal drive shaft 72

7.2.7 Unhitching headstock 72

8 Driving and Transport

8.1 General information 73

8.1.1 Road travel 73

8.1.2 Field driving 76

8.1.3 Handling 76

8.2 Transport position 77

8.2.1 Folding down safety devices 77

8.2.2 Lifting the mower unit 78

8.2.3 Swinging to transport position 79

8.2.4 Lowering the cross conveyor belt to working and transport position 80

8.3 Loading machine 81

8.3.1 Loading / unloading machine 81

9 Setup for work use

9.1 Working position 82

9.1.1 Folding safety devices 82

9.1.2 Adjusting the hitch bracket 83

9.1.3 Adjusting the mower head load relief 83

9.1.4 Adjusting the cutting height 85

9.2 Conditioner of DISCO 3900 TC / 3500 TC / 3100 TC / TC AS 86

9.2.1 Conditioner speed 86

9.2.2 Chicane plate 86

9.2.3 Swathing plates 87

9.2.4 Crop spreader 88

9.3 DISCO 3500 TRC / 3100 TRC conditioner 89

9.3.1 Swathing plates 89

9.3.2 Mowing without conditioner effect 89

9.4 Cross conveyor belt of DISCO 3100 TC AS 91

9.4.1 Adjusting the discharge flap 91

9.4.2 Cross conveyor belt – Adjusting the throwing distance 92

10 Working

10.1 Working in the field 93

10.1.1 General instructions 93

10.1.2 Swinging into working position 95

10.1.3 Lowering the mower unit 96

10.2 Mowing 97

10.2.1 Putting the machine into operation 97

10.2.2 Mowing methods 98

10.2.3 Turning area position 99

10.2.4 Instructions for mowing 100

10.2.5 Difficult conditions of use 101

10.2.6 Recommendation for environmental protection 101

10.3 Mowing with cross conveyor belt DISCO 3100 TC AS 103

10.3.1 Putting the machine into operation 103

10.3.2 Lifting / lowering the cross conveyor belt 104

10.3.3 Starting / stopping the cross conveyor belt 104

10.3.4 Mowing methods 105

11 Maintenance

11.1 General warning signs 107

11.1.1 Bolts 107

11.1.2 Lubrication 107

11.1.3 Wheels / tyres 108

11.1.4 Hydraulic system 109

11.1.5 Electrical system 109

11.1.6 Protective guards 110

11.1.7 Parts 110

11.1.8 Unbalance 110

11.1.9 Cleaning and care 111

11.1.10 Winter storage recommendations 112

11.2 Maintenance schedule 113

11.2.1 Service intervals 113

11.3 Lubricants 115

11.3.1 Lubricants chart 115

11.4 Gearbox / clutch / universal drive shaft 118

11.4.1 Main gearbox 119

11.4.2 Transfer gearbox 122

11.4.3 Angle drive 126

11.4.4 Maintaining universal drive shaft 128

11.4.5 Friction clutch 129

11.4.6 Venting the friction clutch 129

11.4.7 Replacing the friction discs 130

11.5 Transport chassis 131

11.5.1 Wheels and tyres 131

11.5.2 Wheel change 132

11.6 Hitch 133

11.6.1 Adjusting the hitch bracket pressure springs 133

11.7 Hydraulics 134

11.7.1 Hydraulic system 134

11.7.2 Hydraulic hose lines 135

11.7.3 Accumulator 136

11.7.4 Tensioning the hydraulic pump drive belt 137

11.7.5 Replacing the drive belt hydraulic pump 137

11.7.6 Cross conveyor belt hydraulic oil 138

11.8 Mowing unit 139

11.8.1 Mower head gearbox 140

11.8.2 Mower knife box 143

11.8.3 Replacing the knives 144

11.8.4 Knife holder 150

11.8.5 Maintaining the cutting disc 152

11.8.6 Replacing the cutting discs 153

11.8.7 Installing the pinion units 154

11.8.8 Adjusting the safety guard 155

11.8.9 Anti-wrapping guard 156

11.9 Crop processing 157

11.9.1 Tensioning the conditioner drive belt 157

11.9.2 Changing conditioner drive belts 157

11.9.3 Installing/removing the conditioner tines DISCO 3900 TC / 3500 TC / 3100 TC 159

11.9.4 DISCO 3500 TRC / 3100 TRC conditioner rollers 160

11.10 Crop discharge 162

11.10.1 Adjusting the cross conveyor belt 162

11.11 Attachment parts/machine body 166

11.11.1 Adjusting the suspended frame tension springs 166

11.12 Problems and remedies 167

12 Lubrication chart

12.1 Lubrication points 170

12.1.1 Lubricants 170

12.1.2 Lubrication intervals 171

12.1.3 Lubrication points – 8 h 174

12.1.4 Lubrication points – 20 h 175

12.1.5 Lubrication points – 100 h 178

12.1.6 Lubrication points – 250 h 179

1 Machine description

1.1 DISCO 3900 TC; 3500 TC / TRC; 3100 TC / TRC

1.1.1 Designations

1.2 DISCO 3100 TC AS

1.2.1 Designations

2 Introduction

2.1 General Information

2.1.1 Using the manual

Texts and figures

Document structure based on subassemblies

Search and find

Technical specifications

Directions

2.1.2 Validity of manual

2.2 Identification plates and identification numbers

2.2.1 Spare parts and technical questions

2.2.2 Identification plate

3 Safety

3.1 Basic safety instructions

3.1.1 General safety information

3.1.2 Intended use

3.1.3 Reasonable foreseeable misuse

3.1.4 Directives, statutes and standards

3.1.5 Technical condition

3.1.6 Occupational safety

3.1.7 Hydraulics

3.1.8 Safety features on the machine

3.1.9 What to do in the event of hazardous situations and accidents

3.1.10 Decommissioning and disposal

3.2 Warning and hazard signs

3.2.1 Labels

3.3 Safety decals

3.3.1 General instructions for warning signs

3.3.2 Placement on the machine

00 0515 130 0 (2)

00 0515 134 0 (33)

00 0480 462 0 (1)

00 0514 899 0 (8)

00 0515 380 0 (21)

00 0516 039 0 (22)

00 0515 139 1 (50)

00 0514 799 0 (6)

00 0516 038 0 (21)

00 0516 052 0 (25)

00 0514 825 0 (32)

4 Specifications

4.1 DISCO 3900 TC – Model F53

4.1.1 Dimensions and weight

4.1.2 Requirements for the tractor

4.1.3 Design

4.1.4 Tyres

4.1.5 Noise level

A-valuated equivalent permanent sound pressure level

Measuring method

4.2 DISCO 3500 TC / DISCO 3500 TRC – Model F52

4.2.1 Dimensions and weight

4.2.2 Requirements for the tractor

4.2.3 Design

4.2.4 Tyres

4.2.5 Noise level

A-valuated equivalent permanent sound pressure level

Measuring method

4.3 DISCO 3100 TC / DISCO 3100 TRC – Model F51

4.3.1 Dimensions and weight

4.3.2 Requirements for the tractor

4.3.3 Design

4.3.4 Tyres

4.3.5 Noise level

A-valuated equivalent permanent sound pressure level

Measuring method

4.4 DISCO 3100 TC AS – Model F51

4.4.1 Dimensions and weight

4.4.2 Requirements for the tractor

4.4.3 Design

4.4.4 Tyres

4.4.5 Noise level

A-valuated equivalent permanent sound pressure level

Measuring method

5 Prior to initial operation

5.1 General information

5.1.1 Checklist for commissioning

5.2 Adaptation to the machine

5.2.1 Universal drive shaft – check length

Universal drive shaft – shortest operating position

Universal drive shaft – longest operating position

5.2.2 Universal drive shaft – adjusting length

Universal drive shaft without seal on the outer profile tube

Universal drive shaft with seal on the outer profile tube

5.2.3 Mounting universal drive shaft on machine

Locking pin – lock

Draw lock

5.2.4 Adjusting the lateral offset

Adjusting the hydraulic cylinder length

Hydraulic cylinder alignment position

5.3 Accessories

5.3.1 Crop spreader (G03 0010)

DISCO 3900 TC

DISCO 3500 TC

DISCO 3100 TC

5.3.2 Swathing plate extension (G03 0060)

DISCO 3900 TC

5.3.3 High-cut skids (B03 0020)

5.3.4 Skid extensions (C03 0030)

DISCO 3900 TC

DISCO 3500 TC / TRC

DISCO 3100 TC / TRC / TC AS

5.3.5 Hydraulic connection for tractor (R03 0030)

6 Before putting the machine into operation

6.1 General information

6.1.1 Check list for putting into operation

7 Attaching / detaching machine

7.1 Hitching the machine

7.1.1 General instructions

7.1.2 Connecting the hitch bracket

7.1.3 Raising the prop stand

7.1.4 Fitting the universal drive shaft

Wide angle constant-velocity joint

7.1.5 Coupling hydraulic hose lines

Hydraulic hose lines – Lifting

Hydraulic hoses – swivelling

Hydraulic hose line – Load relief

Hydraulic hose – cross conveyor belt

7.1.6 Connecting the power supply

7.1.7 Cross conveyor belt control terminal

7.2 Unhitching the machine

7.2.1 General instructions

7.2.2 Lowering the prop stand

7.2.3 Disconnecting the power supply

7.2.4 Cross conveyor belt control terminal

7.2.5 Decoupling hydraulic hose lines

Hydraulic hose line – Load relief

Hydraulic hoses – swivelling

Hydraulic hose lines – Lifting

Hydraulic hose – cross conveyor belt

7.2.6 Removing universal drive shaft

Locking pin – lock

Draw lock

7.2.7 Unhitching headstock

8 Driving and Transport

8.1 General information

8.1.1 Road travel

Marking the machine for road travel

8.1.2 Field driving

8.1.3 Handling

8.2 Transport position

8.2.1 Folding down safety devices

8.2.2 Lifting the mower unit

8.2.3 Swinging to transport position

8.2.4 Lowering the cross conveyor belt to working and transport position

8.3 Loading machine

8.3.1 Loading / unloading machine

9 Setup for work use

9.1 Working position

9.1.1 Folding safety devices

9.1.2 Adjusting the hitch bracket

9.1.3 Adjusting the mower head load relief

9.1.4 Adjusting the cutting height

9.2 Conditioner of DISCO 3900 TC / 3500 TC / 3100 TC / TC AS

9.2.1 Conditioner speed

DISCO 3900 TC:

DISCO 3500 TC / 3100 TC / 3100 TC AS:

9.2.2 Chicane plate

9.2.3 Swathing plates

9.2.4 Crop spreader

9.3 DISCO 3500 TRC / 3100 TRC conditioner

9.3.1 Swathing plates

9.3.2 Mowing without conditioner effect

9.4 Cross conveyor belt of DISCO 3100 TC AS

9.4.1 Adjusting the discharge flap

9.4.2 Cross conveyor belt – Adjusting the throwing distance

10 Working

10.1 Working in the field

10.1.1 General instructions

10.1.2 Swinging into working position

10.1.3 Lowering the mower unit

10.2 Mowing

10.2.1 Putting the machine into operation

10.2.2 Mowing methods

10.2.3 Turning area position

10.2.4 Instructions for mowing

10.2.5 Difficult conditions of use

10.2.6 Recommendation for environmental protection

10.3 Mowing with cross conveyor belt DISCO 3100 TC AS

10.3.1 Putting the machine into operation

10.3.2 Lifting / lowering the cross conveyor belt

10.3.3 Starting / stopping the cross conveyor belt

10.3.4 Mowing methods

11 Maintenance

11.1 General warning signs

11.1.1 Bolts

11.1.2 Lubrication

11.1.3 Wheels / tyres

11.1.4 Hydraulic system

11.1.5 Electrical system

11.1.6 Protective guards

11.1.7 Parts

11.1.8 Unbalance

11.1.9 Cleaning and care

11.1.10 Winter storage recommendations

11.2 Maintenance schedule

11.2.1 Service intervals

11.3 Lubricants

11.3.1 Lubricants chart

11.4 Gearbox / clutch / universal drive shaft

11.4.1 Main gearbox

Top gearbox

Lower gearbox

Cleaning the breather valve

Checking the oil level

Topping up oil

Draining / changing the oil

11.4.2 Transfer gearbox

Top gearbox

Lower gearbox

Cleaning the breather valve

Checking the oil level

Topping up oil

Draining / changing the oil

11.4.3 Angle drive

Checking the oil level

Topping up oil

Draining / changing the oil

Cleaning the vent valve

11.4.4 Maintaining universal drive shaft

General information about universal drive shafts

11.4.5 Friction clutch

11.4.6 Venting the friction clutch

11.4.7 Replacing the friction discs

11.5 Transport chassis

11.5.1 Wheels and tyres

11.5.2 Wheel change

11.6 Hitch

11.6.1 Adjusting the hitch bracket pressure springs

11.7 Hydraulics

11.7.1 Hydraulic system

11.7.2 Hydraulic hose lines

11.7.3 Accumulator

Check pre-loading pressure

11.7.4 Tensioning the hydraulic pump drive belt

11.7.5 Replacing the drive belt hydraulic pump

11.7.6 Cross conveyor belt hydraulic oil

Checking the oil level

Topping up oil

Draining / changing the oil

11.8 Mowing unit

11.8.1 Mower head gearbox

Checking the oil level

Topping up oil

Draining / changing the oil

11.8.2 Mower knife box

11.8.3 Replacing the knives

Mower knife quick change system

11.8.4 Knife holder

11.8.5 Maintaining the cutting disc

Cleaning the drain opening

Checking the wear bars

11.8.6 Replacing the cutting discs

11.8.7 Installing the pinion units

11.8.8 Adjusting the safety guard

Front safety guard holder

Safety guard holder, left /right

11.8.9 Anti-wrapping guard

11.9 Crop processing

11.9.1 Tensioning the conditioner drive belt

11.9.2 Changing conditioner drive belts

11.9.3 Installing/removing the conditioner tines DISCO 3900 TC / 3500 TC / 3100 TC

11.9.4 DISCO 3500 TRC / 3100 TRC conditioner rollers

Adjusting the tension springs

Adjusting synchronous running

Adjusting the roller clearance

11.10 Crop discharge

11.10.1 Adjusting the cross conveyor belt

11.11 Attachment parts/machine body

11.11.1 Adjusting the suspended frame tension springs

11.12 Problems and remedies

12 Lubrication chart

12.1 Lubrication points

12.1.1 Lubricants

12.1.2 Lubrication intervals

12.1.3 Lubrication points – 8 h

12.1.4 Lubrication points – 20 h

12.1.5 Lubrication points – 100 h

12.1.6 Lubrication points – 250 h

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF