Claas Field + Farm Base + Repeater (B88) Digital Solutions Operator Manual EN

$50.00

- Model: Field + Farm Base + Repeater (B88) Digital Solutions

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 89.3 MB

File List:

00 0018 567 2.pdf

00 0018 584 4.pdf

00 0018 647 2.pdf

00 0018 652 1.pdf

00 0019 424 0.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 1400 240 0.pdf

00 1400 243 0.pdf

00 1400 244 0.pdf

00 1400 633 2.pdf

00 1400 638 3.pdf

00 1402 805 1.pdf

00 2348 427 0.pdf

00 0018 567 2.pdf:

RTK FIELD BASE

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of Manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

1.2.3 Legal restrictions and requirements on radio systems

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Requirements made on all persons working with the product

2.2.3 Risk for children

Children at risk

2.2.4 Structural changes

2.2.5 Optional equipment and spare parts

2.2.6 Technical status

2.2.7 Hazard from damage on the product

2.2.8 Personal safety equipment

2.2.9 What to do in the event of lightning

2.2.10 Electrocution by electrical system

2.2.11 Checking and charging the battery

2.2.12 Maintenance and repair work

3 Product description

3.1 Overview and method of operation

3.1.1 RTK FIELD BASE overview

3.1.2 RTK FIELD BASE base station overview

3.1.3 RTK FIELD BASE radio modem

3.1.4 RTK FIELD BASE correction signal overview

3.2 Identification plates and identification numbers

3.2.1 RTK FIELD BASE identification plate

3.2.2 Battery container identification plate

3.2.3 Transmission modem identification plate

3.3 Frequency ranges

3.3.1 Overview of frequency ranges

3.3.2 RTK FIELD BASE 400 radio

3.3.3 RTK FIELD BASE 900 radio

4 Operating and display elements

4.1 RTK FIELD BASE

4.1.1 Controls and display

4.1.2 RTK FIELD BASE modem status display

4.1.3 General menu navigation

4.1.4

4.1.5

4.1.6

4.1.7

4.1.8

5 Technical specifications

5.1 RTK FIELD BASE

5.1.1 Base station

6 Preparing the product

6.1 Switching off and securing the product

6.1.1 Turning off and securing the product

6.2 RTK FIELD BASE

6.2.1 Setting up the RTK FIELD BASE

6.2.2 Dismounting the RTK FIELD BASE

6.2.3 Charging the RTK FIELD BASE

6.2.4 Removing the radio modem

6.2.5 Installing the radio modem

6.3 Initial setup of correction signal

6.3.1 Initial commissioning of the RTK FIELD BASE

7 Operation

7.1 RTK FIELD BASE

7.1.1 Setting up the RTK FIELD BASE

7.1.2 Switching on the RTK FIELD BASE

7.1.3 Operation with external power supply

7.1.4 Switching off the RTK FIELD BASE

7.2 Menu settings

7.2.1 Sub-menu symbol explanation

7.2.2 Setting the language

7.2.3 Naming the position

7.3 Internal radio modem

7.3.1 Configuring the internal radio modem

7.3.2 Setting the radio frequency and channel

7.3.3 Setting the correction data format for the internal radio modem

7.3.4 Setting the transmission power for the internal radio modem

7.3.5 Setting the mode for the internal radio modem

7.4 External radio modem

7.4.1 Setting the baud rate in the external radio modem

7.4.2 Setting the correction data format for the external radio modem

7.5 Configuring the steering system

7.5.1 Configure the RTK FIELD BASE settings in the GPS PILOT steering system

7.6 RTK FIELD BASE base station

7.6.1 Setting the base type

7.6.2 Setting the average time

7.6.3 Reading the current reference position

7.6.4 Naming the current reference position

7.6.5 Selecting the reference position

7.6.6 Renaming the reference position

7.6.7 Deleting the reference position

7.6.8 Re-averaging the reference position

7.6.9 Entering the reference position manually

7.7 Data logging

7.7.1 Exporting the system log

7.7.2 Exporting the GNSS log

7.8 System

7.8.1 Locking sub-menus

7.8.2 Unlocking sub-menus

7.8.3 Changing the PIN

8 Faults and remedies

8.1 Faults and solutions

8.1.1 RTK FIELD BASE

8.1.2 RTK FIELD BASE correction signal

9 Maintenance

9.1 RTK FIELD BASE

9.1.1 RTK FIELD BASE battery

9.1.2 Changing the battery container

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 EC declaration of conformity

11.1 RTK FIELD BASE

11.1.1 EU Declaration of conformity

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Abbreviations

12.1.2 Units

00 0018 584 4.pdf:

EASY on board app

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Information about this Operator’s Manual

1.1.2 Symbols and notes

1.1.3 Notes regarding warranty

1.1.4 Technical requirements

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

1.3 Softwareupdate

1.3.1 Installing updates

1.3.2 Updating the operating system

1.4 Faults and remedies

1.4.1

1.4.2 Fault message: Screen locked

1.5 Technical terms and abbreviations

1.5.1 Technical terms

1.5.2 Units

1.5.3 Abbreviations

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Requirements made on all persons working with the product

2.2.3 Hazard areas

2.2.4 Check interactions with self-propelled machines / tractors and implements

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Technical status

2.2.8 Hazard caused by damage to the product

2.2.9 Visibility of work area

2.2.10 Glare and reflections

2.2.11 Unintentional triggering of functions

2.2.12 Hazards caused by signal tones

2.2.13 Unauthorised use

2.2.14 Use of mobile terminal outside the cab

2.2.15 Follow the safety instructions

2.2.16 Respecting technical limit values

2.2.17 Preparing the product for road travel

2.2.18 Hazards when driving on the road and on the field

2.2.19 Hazards when driving on the road with an ISOBUS implement

2.2.20 Hazards caused by switching off the app while driving

2.2.21 Hazards from disturbance of WLAN environment

2.2.22 Hazards from covering up the App

2.2.23 Hazards caused by malfunctions of the app

2.2.24 Lifted machine parts and loads

3 EASY on board App

3.1 Operating and display elements

3.1.1 Overview of the EASY on board App

3.1.2 Overview of function bar

3.1.3 Cockpit bar overview

3.1.4 Functions of the EASY on board App

3.1.5 Using the number pad

3.1.6 Using the keyboard

3.2 Operation

3.2.1 Selecting a module

3.2.2 Activating or deactivating modules

3.2.3 Activating or changing the licence

3.2.4 Setting the volume

3.2.5 Closing the app

4 Documentation

4.1 Product description

4.1.1 Requirements

4.1.2 Task data

4.1.3 Product options

4.1.4 App operation in the background

4.2 Operating and display elements

4.2.1

4.2.2 Tasks

4.2.3 Fields

4.2.4 Harvesting

4.2.5 Seeds

4.2.6 Consumables

4.2.7 Machines and implements

4.2.8 Persons

4.2.9 Remark

4.2.10

4.2.11 Entering quantities

4.3 Creating a task

4.3.1 Creating a task

4.3.2 Copying a task

4.3.3 Selecting fields

4.3.4 Creating a new field

4.3.5 Selecting the harvest type

4.3.6 Selecting seeds

4.3.7 Select consumables

4.3.8 Selecting machines and implements

4.3.9 Selecting persons

4.3.10 Save task

4.4 Documentation

4.4.1 Starting the task

4.4.2 Stopping the task

4.4.3 Completing the task

4.4.4 Synchronising an task

4.4.5 Exporting data

4.4.6 Deleting settings

5 ISO terminal

5.1 Product description

5.1.1

5.1.2 Connecting the ISO terminal

5.2 Operating and display elements

5.2.1 Overview of the ISO terminal

5.2.2

5.2.3 Controlling the machine without a USB connection to the CWI

5.3 Programmable keys

5.3.1 Assigning a key assignment

5.3.2 Programming the key assignment

5.3.3 Editing a key assignment

5.3.4 Deleting key assignments

6 Adjustments

6.1 Operating and display elements

6.1.1 Settings

6.2 Adjustments

6.2.1 Resetting the data source

6.2.2 Activating ISOBUS communication

6.2.3 Checking the synchronisation status

6.2.4 Sending an error report

7.1 Adjustments

7.1.1 Where do I find the version number?

7.1.2 Can I change to another app while this app is running?

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 1400 240 0.pdf:

Table of contents

1 To this operator’s manual

1.1 Notes on the manual

1.1.1 General instructions

1.1.2 Validity of manual

1.1.3 Handling of manual

1.1.4 Symbols and notes

1.1.5 Equipment

1.1.6 Technical specifications

2.1 Safety rules

2.1.1 Particularly important

2.1.2 Qualification of drivers and maintenance personnel

2.1.3 Intended use

2.1.4 General safety and accident prevention regulations

2.1.5 Hydraulic accumulators

2.1.6 First aid measures

2.1.7 Danger of injury due to hydraulic liquid

2.2 Safety instructions in this manual

2.2.1 Identification of warning and danger signs

2.3 Safety devices

2.3.1 Safety instructions for starting the terminal

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CULTI CAM

3.1.2 Overview of COMMUNICATOR II

Backward compatibility

3.1.3 Overview of camera

3.1.4 Overview of UBM module

3.1.5 Overview of sensors

Working position switch

Travel speed sensor

Steering angle sensor

3.1.6 Overview of hydraulic system

3.1.7 Overview of cables

Main wiring loom

Tractor wiring loom

Camera connecting cable

3.1.8 Function of CULTI CAM

Visual principle

3.1.9 Possible applications and pre-conditions

Pre-conditions for row of plants

Pre-conditions for multiple row

3.1.10 Accuracy and signal quality

Signal quality

Hilly terrain

3.1.11 Plant pre-conditions

Green salad

Cauliflower

Witloof chicory

Strawberries

Sugar beets

3.2 Optional equipment

3.2.1 Optional machine equipment

3.2.2 Video monitor

Invalid signal

Valid signal

3.2.3 Xenon light

3.2.4 Extension cable

3.2.5 Bracket

Aluminium section bracket

Aluminium section

Connector bracket

3.3 Identification plates and identification number

3.3.1 Spare parts and technical questions

3.3.2 Position of identification plate

3.3.3 Explanation of camera identification plate

3.3.4 Explanation of COMMUNICATOR II identification plate

3.3.5 Explanation of UBM module identification plate

4 Operating and control elements

4.1 COMMUNICATOR II

4.1.1 Terminal

4.1.2 Terminal program

4.1.3 Main menu – ���Information���

4.1.4 Main menu – ���Settings���

4.1.5 Main menu – ���Terminal settings�� Cn

4.2.2 Menu cards

4.2.3 Automatic control menu card

4.2.4 Application settings menu card

4.2.5 General settings menu card

4.2.6 Extended settings menu card

4.2.7 Information menu card

5 Technical specifications

5.1 COMMUNICATOR II

5.1.1 Specif 5.2.2 Software version

6 Preparing the product

6.1 General Information

6.1.1 General warnings

6.1.2 Turning off and securing the machine

6.2 Prior to operation

6.2.1 Before commissioning

6.2.2 Every time before putting into operation

6.3 Mounting

6.3.1 Camera

6.3.2 Adjusting the camera position

Adjusting the camera height

Camera height setting valueant row and multiple row

Detecting the camera height

Adjusting the camera angle

Detecting the camera angle

6.3.3 Operation and output

COMMUNICATOR II

6.3.4 Electronics

UBM module

6.3.5 Hydraulic system

6.3.6 Xenon light

6.4 CULTI CAM

6.4.1 Preparing calibration

6.4.2 Perform calibration

Calibration of travel speed sensor

Entering the value manually

Testing the control unit

Alternative:

Calibration of steering angle sensor

Calibration of maximum deflection

Adjusting the steering rate

Sensitivity

Setting the threshold value

Calibration of camera

Performing the camera calibration

6.4.3 Extended calibration

Factory settings

Alarm delay

Simulation speed

Inverting the position switch

Automatic centring

Twin-camera mode

7 Operation

7.1 Driving on the road

7.1.1 Road travel

7.2 Switching COMMUNICATOR II on/off

7.2.1 Engaging COMMUNICATOR II

7.2.2 Selecting an application

7.2.3 Switching COMMUNICATOR II off

7.3 Programmable COMMUNICATOR II keys

7.3.1 Key assignment

7.4 COMMUNICATOR II ISOBUS settings

7.4.1 Administration of applications

7.5 COMMUNICATOR II terminal settings

7.5.1 Setting the screen brightness/volume

7.5.2 Setting the language

7.5.3 Setting the display formats

7.5.4 Setting the date/time

7.5.5 Displaying the COMMUNICATOR II software version

7.6 Fieldwork

7.6.1 General settings

Xenon light

Dual offset

7.6.2 Setting an application

Row of plants

Multiple row

7.6.3 Automatic control

Activating automatic control

Deactivating automatic control

Side shifting

Dual offset

Xenon light

8 Faults and remedies

8.1 Overview of faults

8.1.1 CULTI CAM fault table

Hydraulic system fault

8.1.2 Questions and answers

9 Maintenance

9.1 General Information

9.1.1 General warnings

9.2 Maintenance Information

9.2.1 Maintenance intervals

10 Service

10.1 General Information

10.1.1 Spare parts and technical questions

10.1.2 Service and warranty

Warranty handling

11 Placing out of operation and disposal

11.1 General Information

11.1.1 Putting out of operation and disposal

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Units

12.1.2 Abbreviations

12.1.3 Technical terms

00 1400 243 0.pdf:

AGROCOM MAP quick start guidefor importing a new machine description

! Please note: Please read the manual carefully and follow the instructions.

Step 1: Write data to the memory card on the PC in AGROCOM MAP

Step 2: On MOBILE CEBIS ��� set up the work record with CROP SENSOR

Step 3: Import the machine description on the PC into AGROCOM MAP

00 1400 244 0.pdf:

AGROCOM NET quick startuidefor importing a new machine description

! Please note: Please read the manual carefully and follow the instructions.

Step 1: Write data to the memory card on the PC in AGROCOM NET

Step 2: On MOBILE CEBIS ��� set up the work record with CROP SENSOR

Step 3: Import the machine description on the PC into AGROCOM NET

00 1400 633 2.pdf:

RTK FARM BASINKRTK FARM BASE repeater

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of Manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

1.2.3 Legal restrictions and requirements on radio systems

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meani of Operator’s Manual

2.2.2 Observe the safety decals and warnings

2.2.3 Requirements made on all persons working with the product

2.2.4 Children in danger

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Operation only following proper putting into operation

2.2.8 Technical status

2.2.9 Personal safety equipment

2.2.10 Electrocution by electrical system

2.2.11 Behaviour in case of lightning strike

2.2.12 Safe working on roofs and at high elevations

2.2.13 Maintenance and repair work

3 Product description

3.1 Overview and function of RTK FARM BASE

3.1.1 RTK FARM BASE

3.1.2 Overview of RTK FARM BASE

3.1.3 Overview of RTK FARM BASE control box

3.1.4 Function of RTK FARM BASE

3.2 Overview and function of RTK FARM BASE LINK

3.2.1 RTK FARM BASE LINK

3.2.2 Overview of RTK FARM BASE LINK

3.2.3 Overview of RTK FARM BASE LINK switch box

3.2.4 Function of RTK FARM BASE LINK

3.3 Overview and function of RTK FARM BASE repeater

3.3.1 RTK FARM BASE repeater

3.3.2 Overview of RTK FARM BASE repeater

3.3.3 Overview of RTK FARM BASE repeater control box

3.3.4 Function of RTK FARM BASE repeater

3.4 Overview of components

3.4.1 Overview of GNSS receiver

3.4.2 Overview of radio modem

Motorola modem

RTK FARM BASE radio

RTK Hybrid Kit

3.4.3 Overview of UPS unit

3.5 Optional equipment

3.5.1 Directional beam radio antenna*

3.6 Identification plates and identification numbers

3.6.1 RTK FARM BASE and RTK FARM BASE LINK identification plates

3.6.2 RTK FARM BASE repeater identification plates

4 Operating and display elements

4.1 Components

4.1.1 GNSS receiver

4.1.2 RTK FARM BASE radio

4.1.3 Power supply unit

4.1.4 UPS unit

5 Technical specifications

5.1.1 Correction signal accuracy

5.2 Specification of components

5.2.1 RTK FARM BASE and RTK FARM BASE LINK switch box

5.2.2 RTK FARM BASE repeater control box

5.2.3 GNSS antenna

5.2.4 Omnidirectional radio antenna

5.2.5 Directional beam radio antenna*

5.2.6 GNSS receiver

5.2.7 Motorola modem

5.2.8 RTK FARM BASE radio

5.2.9 UPS unit

6 Preparing the product

6.1 Switching off and securing the product

6.1.1 Turning off and securing the product

6.2 Putting into operation

6.2.1 Prior to initial putting into operation of RTK FARM BASE

6.2.2 Prior to initial putting into operation of RTK FARM BASE LINK

6.2.3 Prior to initial putting into operation of RTK FARM BASE repeater

6.3 Package list

6.3.1 Not included in the shipping package

6.3.2 Shipping package of RTK FARM BASE control box

6.3.3 Shipping package of RTK FARM BASE LINK control box

6.3.4 Shipping package of RTK FARM BASE repeater control box

6.3.5 Shipping package of GNSS antenna

6.3.6 Shipping package of radio antenna

6.3.7 Shipping package of directional beam radio antenna*

6.4 Installing RTK FARM BASE and RTK FARM BASE LINK

6.4.1 Selecting the location

Control box

GNSS antenna

Radio antenna

6.4.2 Installing the radio antenna

Installation

6.4.3 Installing the GNSS antenna

6.4.4 Installing the control box

Fitting the brackets on the control box

Installing the control box

Laying the cable into the control box

6.5 Installation of RTK FARM BASE repeater

6.5.1 Selecting the location

Radio antenna

Control box

6.5.2 Installing the radio antenna

6.5.3 Installing the control box

Fitting the brackets on the control box

Installing the control box

Laying the cable into the control box

6.6 Connecting components

6.6.1 Connecting radio antenna connectors

Installing the radio antenna connector

6.6.2 Connecting the GNSS antenna connector

Installing the GNSS antenna connector

6.6.3 Connecting the power supply

6.6.4 Connecting the UPS unit

6.7 Initial putting into operation of RTK FARM BASE and RTK FARM BASE LINK

6.7.1 Legal provisions for RTK FARM BASE

6.7.2 Performing initial putting into operation of RTK FARM BASE and RTK FARM BASE LINK

Setting a new base

Entering the name

Setting NMEA

Motorola modem

RTK FARM BASE Radio and Hybrid Kit

Initial installation complete

6.7.3 Changing values

6.7.4 Entering and changing characters

6.7.5 Restoring RTK FARM BASE default settings

Setting a new base

Entering the name

Entering the coordinates

Setting NMEA

Motorola modem

RTK FARM BASE Radio and Hybrid Kit

Setting the system configuration

Setting the language

Setting the measuring units

6.8 Initial putting into operation of RTK FARM BASE repeater

6.8.1 Legal requirements for RTK FARM BASE repeater / RTK repeater

6.8.2 Carry out initial putting into operation of RTK FARM BASE repeater

7 Operation

7.1 RTK FARM BASE, RTK FARM BASE LINK and RTK FARM BASE repeater

7.1.1 Operation

8 Faults and remedies

8.1 RTK FARM BASE, RTK FARM BASE LINK and RTK FARM BASE repeater

8.1.1 Fault table

9 Maintenance

9.1 Maintenance interval overview

9.1.1 Monthly maintenance work

10 Putting out of operation and disposal

10.1 General information

10.1.1 Decommissioning and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.2 Units

00 1400 638 3.pdf:

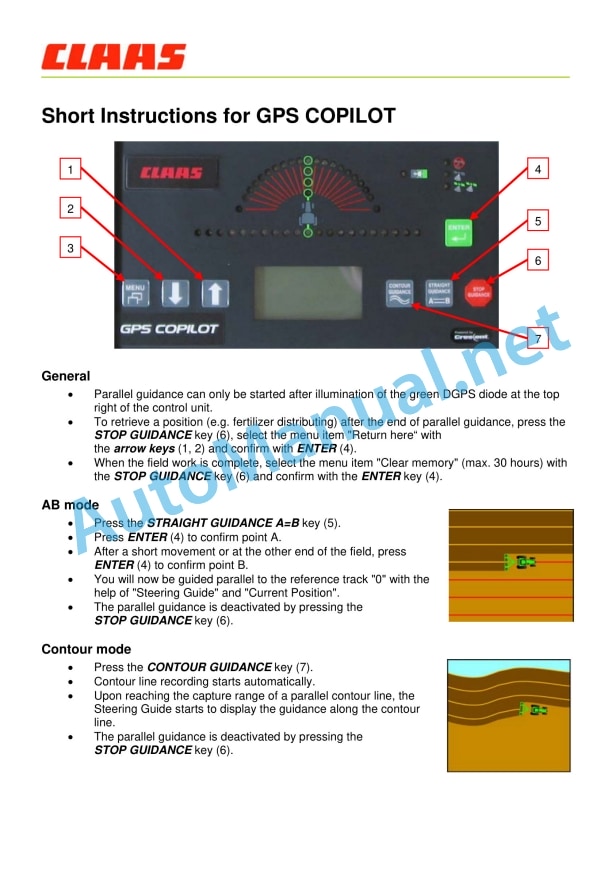

GPS COPILOT S7

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of Manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use of GPS COPILOT

1.2.2 Reasonably foreseeable misuse of GPS COPILOT

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Update of terminal software

2.2.3 Observe the safety decals and warnings

2.2.4 Requirements made on all persons working with the product

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Use of USB devices

2.2.8 Operation only following proper putting into operation

2.2.9 Technical status

2.2.10 Hazards when driving on the road and on the field

Road travel

2.2.11 Electrocution by electrical system

2.2.12 Maintenance operations and repair work

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of GPS COPILOT

3.1.2 Overview of terminal S7

3.1.3 Overview of correction signals

EGNOS/WAAS/MSAS

3.1.4 Overview of antennas

GNSS antenna

3.2 Optional equipment

3.2.1 GLONASS*

3.3 Identification plates and identification numbers

3.3.1 Identification plate of GPS COPILOT S7

3.3.2 Identification plate of terminal

4 Operating and display elements

4.1 Overview of terminal S7

4.1.1 Layout conventions of buttons and displays

4.2 GPS COPILOT menu structure

4.2.1 Start menu

4.2.2 Main menu overview

4.2.3 Overview of DGPS displays

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

4.2.10

4.2.11

4.2.12

4.2.13

4.2.14

4.2.15

4.2.16

4.2.17

4.2.18

4.2.19

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF