Claas Lexion 780-760 (C69) Combines Repair Manual EN

$100.00

- Model: Lexion 780-760 (C69) Combines

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 284 MB

File List:

00 0292 664 5.pdf

00 0296 338 1.pdf

00 0296 400 0.pdf

00 0296 507 1.pdf

00 0301 513 1.pdf

00 0302 206 0.pdf

00 0302 218 2.pdf

00 0303 709 0.pdf

00 0303 719 0.pdf

Disassembly and Assembly Perkins 1506D.pdf

Test instructions for output assessment T4i engines.pdf

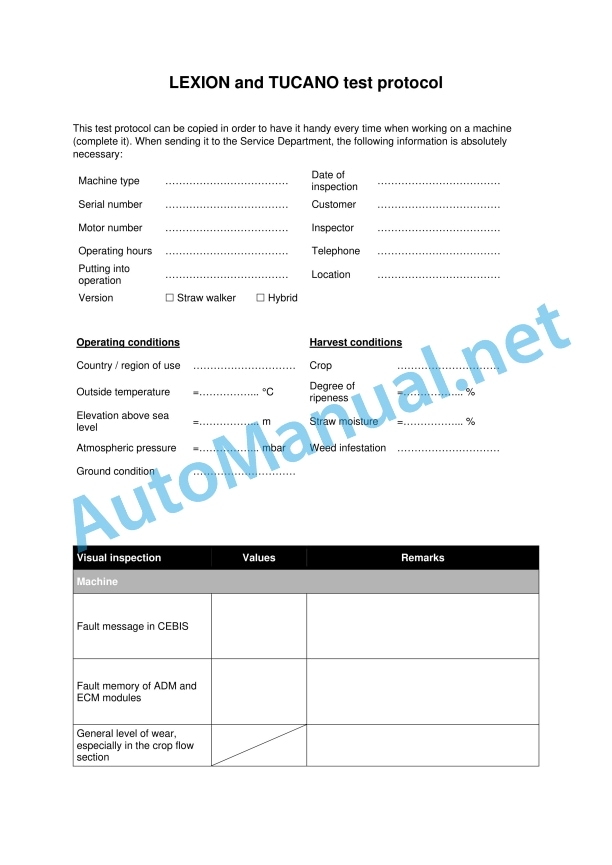

Test protocol LEXION and TUCANO.pdf

00 0296 338 1.pdf:

Mercedes-Benz OM502LA

Table of contents

Introduction

General information

Validity of manual

Handling the manual

Texts and figures

Document structure based on the assembly structure

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on proper repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Taper ring fasteners

Dismounting

Installation

Gib head key joints

Dismounting

Installation

Lock collar bearing

Dismounting

Installation

Adapter sleeve bearings

Dismounting

Installation

Chuck bushing

Dismounting

Installation

Circlips

Ferrule fittings

Screwing in

Non-tight ferrule connection

Sealing cone fittings

Hydraulic hoses

Hose placement

Treatment of sealing faces

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torques for metric fine thread screws

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with sealing cone and O-ring according to DIN 3865

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Tightening torques for SDS hydraulic male connectors

Tightening torques for hydraulic swivel fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for brake line screw fittings

Tightening torques for worm drive hose clamps

Tightening torque for spring-loaded worm drive hose clamps

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Hydraulic system standard

CCN (CLAAS Component Number)

General information

Of special importance

Identification of warning and danger signs

Regulations for avoiding accidents with personal injuries

Testing, adjusting and repair work

Engine operation

Suspended loads

Working on piping and hoses

Working on the electric system

Working on the hydraulic system

Electric welding

Painting work

Working with urea solution

Information on how to avoid damage and premature wear

Liability limitation

Shutting down and storage

Regulations for avoiding health and environmental damage

Precautionary measures for protection against health and environmental damage

Disposal of operating utilities and auxiliary operating utilities

Information for working on the diesel engine

Accident protection

Cleanliness

Installation instructions

Engine overhaul

Putting into operation after an engine overhaul

First aid measures

01 Engine

0102 Complete component

Type design

Engine data

Engine description

Engine components

Ignition order

Cranking the engine

Special tool for built-in engine

Special tools for removed engine

Cranking the engine in built-in condition

Cranking the engine in removed condition

0105 Engine suspension

Lifting eyes

Technical specifications

0110 Engine housing

Oil sump

Special tool

Technical specifications

Installation

Crankshaft front seal

Special tool

Technical specifications

Removing the radial seal

Installing the radial seal

Removing the cassette seal

Installing the cassette seal ring

Crankshaft rear seal

Special tool

Technical specifications

Installation

Crankcase cover

Special tool

Technical specifications

Installation

Timing housing cover

Special tool

Technical specifications

Applies to design type 942.993

Installation

Applies to design type 942.993

Timing housing

Work preparation

Technical specifications

Installation

Timing housing

Work preparation

Technical specifications

Installation

0115 Engine unit

Special tool

Technical specifications

Disassembly

Checking

Assembly

Installation

Installation

Measuring the excess dimension

Connecting rod

Technical specifications

Checking

Installation

Cylinder liner

Special tool

Technical specifications

Checking

Installation

Applies to design type: 458.99x

Measuring the excess dimension

Measuring the cylinder bore

Crankshaft

Special tool

Technical specifications

Checking

Installation

Crankshaft ring

Special tool

Technical specifications

Installation

Oscillation damper

Special tool

Technical specifications

Installation

Flywheel

Special tool

Technical specifications

Checking

Installation

Replace ring gear

Replacing the ring

0120 Cylinder head / Valves / Idler gear

Valve cover

Technical specifications

Cylinder head

Special tool

Technical specifications

Checking

Disassembly

Assembly

Installation

Rocker lever

Special tool

Technical specifications

Installation instructions

Replacing the roller tappets

Special tool

Technical specifications

Installation instructions

Checking the valves

Adjusting the valve lash

Valve springs and valve stem seals

Special tool

Mercedes-Benz

Technical specifications

Installation

Valve guide

Work preparation

Special tool

Technical specifications

Checking

Installation

Camshaft

Special tool

Technical specifications

Checking

Installation

0125 Injection / Fuel system

Fuel system

Cylinder head injection line

Special tool

Technical specifications

Installation instructions

Cylinder head leakage lines

Technical specifications

Nozzle holder combination

Special tool

Technical specifications

Installation

Protective sleeve

Special tool

Technical specifications

Installation instructions

Plug-on pump

Special tool

Work preparation

Technical specifications

Installation

Fuel pump

Work preparation

Technical specifications

Installation

Fuel filter housing

Technical specifications

0130 Lubricating oil system

Lubricating oil system

Special tool

Pre-filling

Oil spray nozzle

Technical specifications

Installation instructions

Oil filter housing

Work preparation

Technical specifications

Installation

Oil cooler

Technical specifications

Installation instructions

Oil excess pressure valve

Technical specifications

Installation instructions

Oil pump

Technical specifications

Installation instructions

0135 Cooling system

Special tool

Technical specifications

Draining

Filling up

Cleaning the coolant circuit

Coolant pump

Special tool

Technical specifications

Disassembly

Assembly

Installation

Coolant thermostat

Work preparation

Technical specifications

Checking

Installation

0140 Exhaust system

Exhaust manifold

Technical specifications

Installation

Exhaust manifold

Technical specifications

Installation

Main exhaust manifold

Technical specifications

Installation instructions

Exhaust turbo charger suction tube

Technical specifications

Installation instructions

Exhaust turbo charger

Special tool

Technical specifications

Installation

Checking

Checking the axial play

Checking the radial play

Exhaust turbo charger

Special tool

Technical specifications

Installation

Checking

Checking the axial play

Checking the radial play

Catalyst

Work preparation

Technical specifications

Installation instructions

0145 Air intake

Intake housing

Technical specifications

Applies to type designs with one exhaust turbo charger

Applies to type designs with two exhaust turbo chargers

Installation

Applies to type designs with two exhaust turbo chargers

Applies to type designs with one exhaust turbo charger

0150 Engine attachment parts

Electric starting motor

Work preparation

Technical specifications

Installation

Removing the solenoid switch

Installing the solenoid switch

Removing the starter pinion

Installing the starter pinion

Alternator

Special tool

Technical specifications

Installation

Removing the pulley

Installing the pulley

Alternator

Special tool

Technical specifications

Alternator (G002)

Alternator (G002)

Alternator (G003)

Alternator (G003)

Alternator (G003)

Installation

Alternator (G002)

Alternator (G002)

Alternator (G003)

Alternator (G003)

Alternator (G003)

Removing the pulley

Installing the pulley

Alternator drive belt tensioner

Technical specifications

Installation instructions

Air compressor

Special tool

Technical specifications

Checking the oil thrown out

Removing the drive wheel

Installing the drive wheel

Removing the cylinder head

Applies to design type 942.993

Disassembling the cylinder head

Assembling the cylinder head

Installing the cylinder head

Applies to design type 942.993

Removing the piston and the cylinder liner

Installing the piston and the cylinder liner

Removing the crankshaft and the connecting rod

Installing the crankshaft and connecting rod

0155 Engine control

MR/PLD control unit

Technical specifications

Installation instructions

0165 Exhaust gas aftertreatment

Exhaust treatment system

Work preparation

Special tool

Technical specifications

Checking the urea solution (purity)

Checking the urea solution (density)

Urea heater valve

Work preparation

Special tool

Technical specifications

Installation

Urea pump

Work preparation

Special tool

Technical specifications

Installation

Removing the pressure accumulator

Installing the pressure accumulator

Removing the dump valve

Installing the dump valve

Removing the intake filter

Installing the intake filter

Checking the electric wiring loom

Filling the accumulator

Urea dosing unit

Work preparation

Special tool

Technical specifications

Installation instructions

Flushing

Urea injector

Technical specifications

Installation instructions

0190 Accessories

Engine insulation

Work preparation

Technical specifications

Engine insulation

Work preparation

Technical specifications

Installation

00 0296 400 0.pdf:

TERRA TRAC track roller unitGeneration II

Table of contents

Introduction

General information

Validity of manual

Handling of this manual

Texts and figures

Document structure based on subassemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on economic repairs

Self-locking bolts

Liquid locking compound

Ferrule fittings

Screwing in

Non-tight ferrule connection

Sealing cone fittings

Hydraulic hose lines

Hose placement

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torque for metric fine threads

Tightening torques for hydraulic screw fittings with ferrule DIN 3861

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with O-ring and sealing cone DIN 3865

Tightening torques for SDS hydraulic male connectors

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for hydraulic swing fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for brake line screw fittings

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

General information

Of special importance

Identification of warning and danger signs

General safety and accident prevention regulations

First aid measures

Risk of injury from hydraulic fluid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjustment and maintenance operations

Hydraulic accumulators

Battery isolating switch

Welding work

03 Chassis

0355 Track roller unit

Overview of TERRA TRAC track roller unit

Removal/Installation

Overview of TERRA TRAC track roller unit

Removal/Installation

TERRA TRAC track roller unit rubber tracks

Work preparation

Installation

TERRA TRAC track roller unit rubber tracks

Work preparation

Special tool

Installation

TERRA TRAC track roller unit support wheels

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit support wheels

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit bearing unit

Work preparation

Installation

TERRA TRAC track roller unit rocker arm

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit gearbox

Work preparation

Special tool

Disassembly

Assembly

Installation

Rubber track tension hydraulic cylinder (3071)

Work preparation

Special tool

Removing the hydraulic cylinder

Installing the hydraulic cylinder

00 0296 507 1.pdf:

LEXION 770 – 620

Table of contents

Introduction

General Information

Validity of manual

Handling the manual

Texts and figures

Document structure based on the assembly structure

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on proper repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Taper ring fasteners

Dismounting

Installation

Gib head key joints

Dismounting

Assembly

Lock collar bearing

Dismounting

Installation

Adapter sleeve bearings

Dismounting

Installation

Chuck bushing

Dismounting

Installation

Circlips

Ferrule fittings

Screwing in

Non-tight ferrule connection

Sealing cone fittings

Hydraulic hoses

Hose placement

Treatment of sealing faces

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torques for metric fine thread screws

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with sealing cone and O-ring according to DIN 3865

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Tightening torques for SDS hydraulic male connectors

Tightening torques for hydraulic swivel fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for brake line screw fittings

Tightening torques for worm drive hose clamps

Tightening torque for spring-loaded worm drive hose clamps

Tightening torques for tyres

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Hydraulic system standard

CCN (CLAAS Component Number)

General Information

Of special importance

Identification of warning and danger signs

General safety and accident prevention regulations

First aid measures

Danger of injury from hydraulic liquid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjustment and maintenance operations

Welding work

03 Chassis

0315 Drive axle

Drive axle

Technical specifications

Axle body

Technical specifications

Installation instructions

Axle rocker

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Wheel hub

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Differential

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Adjusting the axial play of shift dogs

Manual gearbox

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Gearbox shifting hydraulic cylinder (3063)

Technical specifications

Shifter rail installation instructions

Installation instructions for seals

0315 Drive axle

Drive axle

Technical specifications

Axle body

Technical specifications

Installation instructions

Axle rocker

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Wheel hub

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Differential

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Adjusting the axial play of shift dogs

Manual gearbox

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Gearbox shifting hydraulic cylinder (3063)

Technical specifications

Shifter rail installation instructions

Installation instructions for seals

0330 Driven steering axle, rear

Identifying the rear drive axle

Rear drive axle

Technical specifications

Installation

Axle body

Work preparation

Special tool

Technical specifications

Disassembly

Assembly

Installation

Wheel hub

Work preparation

Special tool

Technical specifications

Removing the wheel hub completely

Installing the wheel hub completely

Disassembly

Assembly

Stub axle

Work preparation

Special tool

Technical specifications

Installation

Floating axles

Technical specifications

Installation

Track rods

Work preparation

Special tool

Technical specifications

Installation

Adjusting the track and the steering angle

Axle drive valve block

Technical specifications

Installation

Axle drive hydraulic motor (2003, 2004)

Work preparation

Special tool

Technical specifications

Installation

0330 Driven steering axle, rear

Identifying the rear drive axle

Rear drive axle

Special tool

Technical specifications

Installation

Axle body

Work preparation

Special tool

Technical specifications

Applies to tyre pressure control system

Disassembly

Assembly

Installation

Applies to tyre pressure control system

Wheel hub

Work preparation

Special tool

Technical specifications

Removing the wheel hub completely

Applies to tyre pressure control system

Installing the wheel hub completely

Applies to tyre pressure control system

Disassembly

Assembly

Stub axle

Work preparation

Special tool

Technical specifications

Installation

Floating axles

Work preparation

Special tool

Technical specifications

Installation

Track rods

Work preparation

Technical specifications

Installation

Adjusting the track and the steering angle

Differential

Work preparation

Technical specifications

Disassembly

Assembly

Differential

Work preparation

Technical specifications

Disassembly

Assembly

Installation

Axle drive valve block

Technical specifications

Installation instructions

Four-wheel clutch shifting cylinder (3002)

Technical specifications

Installation instructions

Axle drive hydraulic motor (2068)

Work preparation

Technical specifications

Installation

0330 Driven steering axle, rear

Identifying the rear drive axle

Rear drive axle

Special tool

Technical specifications

Installation

Axle body

Work preparation

Special tool

Technical specifications

Applies to tyre pressure control system

Disassembly

Assembly

Installation

Applies to tyre pressure control system

Wheel hub

Work preparation

Special tool

Technical specifications

Removing the wheel hub completely

Applies to tyre pressure control system

Installing the wheel hub completely

Applies to tyre pressure control system

Disassembly

Assembly

Stub axle

Work preparation

Special tool

Technical specifications

Installation

Floating axles

Work preparation

Special tool

Technical specifications

Installation

Track rods

Work preparation

Technical specifications

Installation

Adjusting the track and the steering angle

Differential

Work preparation

Technical specifications

Disassembly

Assembly

Differential

Work preparation

Technical specifications

Disassembly

Assembly

Installation

Axle drive valve block

Technical specifications

Installation instructions

Four-wheel clutch shifting cylinder (3002)

Technical specifications

Installation instructions

Axle drive hydraulic motor (2068)

Work preparation

Technical specifications

Installation

0365 Tyre pressure control system

Tyre pressure control system

Work preparation

Special tool

Technical specifications

Installation

0370 Slope regulation

Slope control hydraulic cylinder

Work preparation

Technical specifications

04 Brake

0405 Service brake

Brake mechanism

Technical specifications

Installation

Spring accumulator cylinder

Work preparation

Technical specifications

Installation

Cylinder stroke basic adjustment

Checking the cylinder stroke

Deactivating the brake

Activating the brake

05 Steering

0505 Steering

Steering hydraulic cylinder (3023)

Work preparation

Technical specifications

Installation

Steering hydraulic cylinder (3023)

Technical specifications

Installation

0510 Automatic steering

AUTO PILOT steering angle sensor (B006)

Technical specifications

AUTO PILOT steering angle sensor (B006)

Technical specifications

00 0301 513 1.pdf:

TERRA TRAC track roller unitGeneration II

Table of contents

Introduction

General information

Validity of manual

Handling of manual

Texts and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Ferrule joints

Screwing in

Leaky ferrule joints

Sealing cone joints

Hydraulic hoses

Laying of hoses

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torque for metric fine threads

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with sealing cone and O-ring according to DIN 3865

Tightening torques for SDS hydraulic male connectors

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for hydraulic swivel fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for brake line screw fittings

CCN explanation

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

General information

Important

Identification of warning and danger signs

General safety and accident prevention regulations

First aid measures

Danger of injury from hydraulic liquid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjusting and maintenance work

Hydraulic accumulators

Battery isolating switch

Welding work

03 Chassis

0355 Track roller unit

TERRA TRAC track roller unit

Technical specifications

Installation instructions

Rubber tracks

Technical specifications

Work preparation

Special tool

Installation

Drive wheels

Removing the drive wheels

Installing the drive wheels

Support wheels

Technical specifications

Work preparation

Disassembly

Assembly

Installation

Technical specifications

Work preparation

Installation

Rocker arm

Technical specifications

Work preparation

Special tool

Removing the arm

Disassembling the arm

Assembling the arm

Installing the arm

Removing the arm bearing shaft

Installing the arm bearing shaft

Technical specifications

Work preparation

Special tool

Disassembly

Assembly

Installation

Track tension hydraulic cylinder

Technical specifications

Work preparation

Disassembly

Assembly

Installation

00 0302 206 0.pdf:

LEXION 780-620

Table of contents

Introduction

General information

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

Validity of manual

General information

Important

Hazard signs

Signal word

General safety and accident prevention regulations

Combine-harvester safety and accident prevention regulations

First aid measures

Leaving the machine

Adjusting and maintenance work

Danger of injury from hydraulic liquid

Battery isolating switch

Jacking up the machine

Putting the machine out of operation

04 Brake

0415 Parking brake

Parking brake

Technical specifications

Work preparation

Special tool

Removing the brake pads

Installing the brake pads

Removing the brake disc

Installing the brake disc

Remove the floating caliper.

Installing the floating caliper

Checking the residual thickness of brake linings and the piston stroke

Venting the parking brake

Adjusting the parking brake

00 0302 218 2.pdf:

LEXION 780-405

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

Tightening torques

Tightening torques for metric standard threads

Tightening torques for metric fine thread

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

General information

Important

Hazard signs

Signal word

General safety and accident prevention regulations

Combine-harvester safety and accident prevention regulations

First aid measures

Crop / straw discharge

Leaving the machine

Adjusting and maintenance work

Danger of injury from hydraulic liquid

Battery isolating switch

Putting the machine out of operation

08 Drives

0841 Threshing mechanism drive

Driven pulley of belt (R52)

Technical specifications

Work preparation

Special tool

Disassembly

Assembly

Installation

Lubricating interval

0842 Separation drive

Driven pulley of belt (R41)

Technical specifications

Work preparation

Special tool

Disassembly

Assembly

Installation

Lubricating interval

00 0303 709 0.pdf:

Crawler track unit TERRA TRACGeneration IIIon wheels with bolted joints

Table of contents

Introduction

General information

Validity of manual

Handling of this manual

Abbreviations

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Circlips

Hydraulic hoses

Hose placement

Spare parts and technical questions

Tightening torques

Tightening torques for metric ISO screw thread

Tightening torques for metric fine thread

CCN explanation

CCN (CLAAS Component Number)

Electric system standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

General information

Particularly important

Qualification of drivers and maintenance personnel

Identification of warning and danger signs

General safety and accident prevention regulations

Pressurised fluids

Pressure accumulator

Leaving the machine

Putting the machine out of operation

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07