Claas Medion 330-310 (932) Combines Operator Manual EN

$50.00

- Model: Medion 330-310 (932) Combines

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 46.4 MB

File List:

00 0293 467 0.pdf

00 0297 764 6.pdf

00 0297 995 1.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 0293 467 0.pdf:

02934670_de.pdf

Instructions for use with CLAAS-Bordinformator

Instructions

Besons on the beach

Kennzeichnung von Warn- und Gefahrenhinweisen

Bestimmungsgeme Verwendung

Functional elements of the Bordinformators

Functions of the Bordinformators on their Program Card

Bordinformator with added programmer card

Bordinformator in Betrieb nehmen

Zugschalter einstellen

Programmieren ohne Programmierkarte

Programmieren mit Programmierkarte

Distanzfaktor

Motoren-Nenndrehzahl

Einstelldaten

Reed contact service an der Vorlegewelle (V)

Induktivgeber an der hinteren Corn-Cracker-Walze (Feldhcksler)

Induktivgeber am Reinigungsgeblse (Mhdrescher)

Induktivgeber am Hauptgetriebe (Feldhcksler)

Induktivgeber Induktivgeber am Motorabtrieb (Feldhcksler)

Induktivgeber am Motorabtrieb (Mhdrescher)

02934670_en.pdf

Operator’s manual CLAAS fieldwork computer

Introduction

Table of contents

Important information

Identification of warning and danger signs

Intended use

Function elements of the fieldwork computer

Functions of the fieldwork computer without programming card

Fieldwork computer with programming card inserted

operating the fieldwork computer

Setting the pull switch

Programming without a programming card

Programming with programming card

Distance factor

Rated engine speed

Setting data

Reed switch on the intermediate drive shaft (V)

Magnetic pickup on the rear corn cracker roller (forage harvester)

Magnetic pickup on the cleaning fan (combine harvester)

Magnetic pickup on the main gearbox (drilling harvester)

Magnetic pickup on threshing drum or cutting cylinder

Magnetic ckup on toutput (drilling harvester)

Magnetic pickup on the engine output (combine harvester)

02934670_fr.pdf

Instructions for use CLAAS on-board informant

Introduction

Contents

Particularly important

Marking of warnings and dangers

Use in accordance with instructions

Function elements of the on-board informant

On-board informant functions without programming card

On-board informant with programming card in place

Switching on the on-board informant

Adjust barrel draw

Program without a programming card

Program with programming card

Distance factor

Rated engine speed

Setting parameters

Reed pressure switch on the intermediate train (V)

Inductive sensor on the rear roller of the Corn-Cracker (forage harvester)

Inductive sensor on cleaning fan (combine harvester)

Inductive sensor on the main gearbox (forage harvester)

Inductive sensor of the beater or blade holder

Inductive sensor on the motor output (forage harvester)

Inductive sensor on motor output (combine harvester)

02934670_it.pdf

CLAAS bordo computer user manual

Introduction

Important news

Warning and pericolo signal

Specific use

Functional elements of the computer on board

Computer functions on board according to the programming schedule

Computer on board with application programming schedule

Messa in use of the computer on board

Regulation of the switch on the strap

Programming according to the programming schedule

Programming with programming schedule

Fattore di distance

Rated engine speed

Regulatory data

Contact reed of the albero di rinvio (V)

Industrial transmission of the rear corn cracker wheel (trincia foraggi)

Industrial fan transmitter of the power fan (mietitrebbia)

Main transmission driver (trinciaforaggi)

Industrial transmission of the battery or the trinciatura drum

Engine power transmission (trimming)

Engine power transmission (lower speed)

02934670_ru.pdf

Engine serial no. PERKINS 1006-6 TA

Engine serial number DAIMLER CHRYSLER OM 906 LA

Cutterbar identification plate

Straw chopper

Cab serial number

Safety Rules

Safety Regulations

Cylinder safety lock

Fire extinguisher

Battery isolating switch

Wheel chock (not for all countries)

Apply a wheel chock

Safety decals with pictorials

Specifications

CLAAS MEDION 340

CLAAS MEDION 340

CLAAS MEDION 340

CLAAS MEDION 330 / 320 / 310

CLAAS MEDION 330 / 320 / 310

CLAAS MEDION 330 / 320 / 310

Safety features

Front attachments – weights and dimensions

Sectional view of machine

Description and function

Cutterbar

Threshing mechanism

Straw walkers

Cleaning unit

Disawning

Basic rules for combining

Prior to operation

Carry out prior to initial operation

Cab with automatic air conditioner

Automatic air conditioner

Operating and display elements

Putting the automatic air conditioner into operation

Setting the cab temperature

Manually setting the evaporator blower speed

Activating ECON operating mode

Deactivating ECON operating mode

REHEAT operation (Dehumidify cab windows)

Displaying the outside temperature

Changing the temperature display to _x001E_Fahrenheit

Floor heating

Display of malfunction: error in thermometer F0 (cab, blue)

Display of malfunction: error in thermometer F1 (exhaust, yellow)

Display of malfunction: error in thermometer F2 (outside, red)

Cab with air conditioner

Cab with fan

Cab with fan and air conditioner

Cab with fan and heater

Floor heating

Reheat system (Dehumidify cab windows)

Malfunction, possible cause or remedy – air conditioner

Opening and closing the cab roof

Opening the cab roof

Closing the cab roof

Operator’s platform

Steering column

Ignition switch

Vehicle information unit

Function of vehicle information unit

Operations display screen

Function of operations display screen

Switch console (up to serial no. …)

Switch console (from serial no. …)

Multifunction lever (up to serial no. …)

Multifunction lever (from serial no. …)

Central terminal compartment

Plug-in type module (P) CLAAS Autopilot

Positioning the cutterbar / maize picker head for road travel

Steering column adjustment

Operators seat air suspension (option)

Height adjustment

Weight adjustment

Seat angle adjustment

Seat depth adjustment

Lumbar suppo

Armrest angle adjustment

Horizontal adjustment of operator’s seat

Operator’s seat, mechanical (option)

Weight adjustment

Height adjustment

Seat angle adjustment

Seat depth adjustment

Lumbar support

Armrest angle adjustment

Horizontal adjustment of operator’s seat

Master safety switch in driver’s seat (from serial no. …)

Access ladder

Front ladder

Access and ladderon

Rear ladder

Driving the combine

Engine speed rotary switch

Start the engine

Adjusting the stiffness of ground speed control lever

Gear ranges

Stopping

Driving behaviour

Steering

Foot brake

Hand brake

Stopping the engine

CLAAS Autopilot

Rear axle

Converting the adjustable rear axle

Changing the rear axle from transport to working position

CLAAS 4-Trac System

Towing a machine with rear wheel drive axle

Cutterbar cylinders

Hydraulic cylinders

Attaching cutterbar hydraulic cylinders

Attaching the right-hand cutterbar cylinder

Third cutterbar cylinder necessary

Towing and catwalk railing

Backwards

Catwalk railing

Tilting the catwalk railing

Cab and lighting

Headlights, worklights and mirrors

Side panels

Opening and closing the side panels

Adjusting the panel locks

Operation – Cutterbar

Installing the cutterbar

Adjusting the stripper angle MEDION 330 – 310

Machine equipped with CLAAS Auto Contour

Align the coupling pin cylinder (up to serial no. …)

Machines without Auto Contour

Levelling the cutterbar

Connecting the universal drive shafts

Connecting the hydraulic hoses

Connecting the cables

Mounting the stands

Adjustments at the cutterbar

Crop dividers

Crop lifters

Removing the knives

Installing the knives

Adjusting the height of the knife head

Adjusting the knife clips

Spare knife

Cutterbar skids

Reel tines

Reel drive

Reel fore and aft adjustment (mechanical)

Reel fore and aft adjustment (hydraulic)

Reel variable speed drive

Intake auger

Adjusting the clearance to the cutterbar trough bottom plate

Adjusting position of auger fingers

Adjusting the stripper bars

Replacing knife sections in the field

Operation – Basic machine

Feed rake conveyor

Feeder chains

Front attachment reverser

CLAAS Auto Contour Automatic cutting height control with cutterbar cross levelling

Preset cutting height control with automatic control (Machines equipped with Auto Contour)

Adjusting the cutterbar floatation springs

Checking the cutterbar floatation springs and checking the feed rake conveyor suspension for smooth movement

Setting the cutting height indicator

Spring pressure indicator

Adjusting the front attachment drop rate (up to serial no. …)

Adjusting the front attachment drop rate (from serial no. …)

Put CLAAS Auto Contour in operation (up to serial no. …)

Put CLAAS Auto Contour in operation (from serial no. …)

Operation with maize picker head

Programming of CLAAS Auto Contour (up to serial no. …)

Programming of CLAAS Auto Contour (from serial no. …)

Setting chart for automatic cutting height control

Putting the cutterbar automatic pre-set cutting height control system into operation (Machines equipped with Auto Contour)

CLAAS Contour System (ground pressure control)

Setting the cutterbar ground pressure

Putting the CLAAS Contour system in operation (up to serial no. …)

Putting the CLAAS Contour system in operation (from serial no. …)

CLAAS Pre-set cutting height control

Putting the preset cutting height control in operation (up to serial no. …)

Putting the preset cutting height control in operation (from serial no. …)

Cutterbar adjusting range

Clearance height

Cutterbar adjusting range without Auto Contour

Clearance height to bottom edge of cutterbar skid

Cutterbar clutch

Engaging the front attachment (up to serial no. …)

Disengaging the front attachment (up to serial no. …)

Engaging the front attachment (from serial no. …)

Disengaging the front attachment / Switch console (from serial no. …)

Disengaging the front attachment / Multi-function handle (from serial no. …)

Threshing mechanism

Stone trap

Engaging and disengaging the threshing mechanism

Engaging the threshing mechanism (up to serial no. …)

Engaging the threshing mechanism (from serial no. …)

Disengaging the threshing mechanism

Concave adjustment

Safety stop bolt for concave adjustment

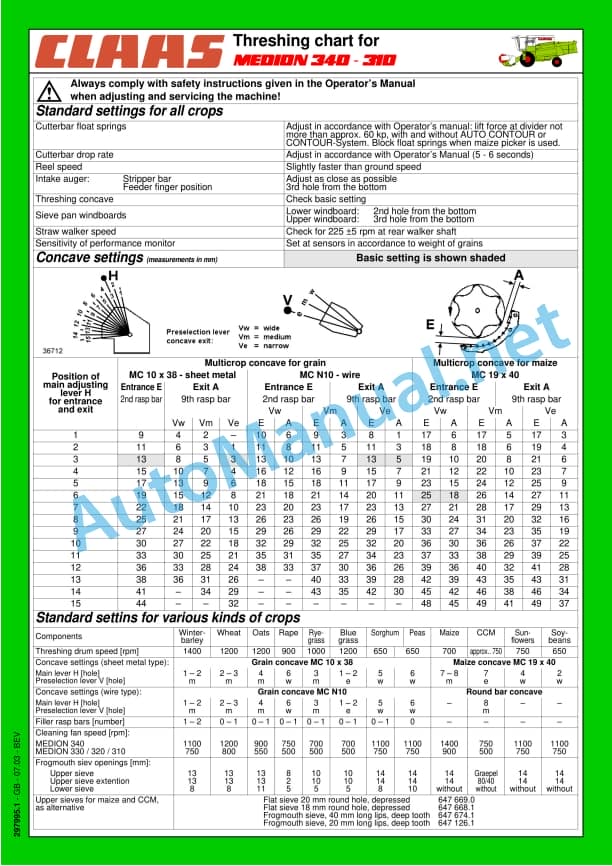

Concave settings

Concave settings

Basic setting with various concaves

Basic rule for concave-to-drum clearance setting

Threshing drum

Cleaning the threshing mechanism

Threshing drum speed

Adjusting the threshing drum speed (up to serial no. …)

Adjusting the threshing drum speed (from serial no. …)

Two-step variable-speed drive

Disawning

Unslugging the threshing drum

Impeller

Deflector curtain

Straw walkers and cleaning

Straw walkers

Intensive separation system

Cleaning the straw walkers

Straw walker risers

Warning signal

Sieve pan

Preparation floor

Cleaning fan

Electrical fan speed adjustment

Adjusting the wind direction

Adjusting the frogmouth sieves

Hillside riser plates (Machines without 3-D cleaning system)

Lower sieves

Removing the upper sieves

Installing the upper sieves

Removing the lower sieves

Installing lower sieves

Tightening torques of axial mountings for the upper and lower sieves

Dynamic slope compensation (3-D cleaning system)

Combine performance monitor

Adjusting the monitor to crop type

Adjusting sensitivity of sensors

Putting the performance monitor into operation

Grain delivery

Augers and auger troughs

Elevators

Grain tank

Grain tank covers

Unloading the grain tank

Rear ladder with safety switch (up to serial no. …)

Grain tank unloading tube

Engaging/disengaging grain tank unloading (up to serial no. …)

Engaging/disengaging grain tank unloading (from serial no. …)

Grain tank unloading tube transport position

Cleaning flap on grain tank unloading tube

Grain tank unloading auger drive

Shear bolt for grain tank unloading

Lateral auger drive

Grain tank fill indicator

Acoustic grain tank fill indicator

Straw chopper / Chaff spreader

Straw chopper

Before using the chopper for the first time, check

Adjusting the length of cut

Adjusting the cross blade

Putting the straw chopper into operation

Adjusting the spreading width

Electric deflector adjustment (option)

Adjusting the deflectors

Putting the chopper out of operation and converting the machine for laying swaths

Hitching the cutterbar trailer to the combine

Changing the chopper speed from grain to maize (MEDION 340)

Replacing the front V-belt pulley

Changing the chopper speed from maize to grain (MEDION 340)

Replacing the front V-belt pulley

Changing the chopper speed from grain to maize (MEDION 330 – 310)

Chaff spreader

Setting the chaff spreader

Sieve chart and suggested combine adjustments

Sieve chart

Suggested combine adjustments

Jacking up the machine

Malfunction, cause and / or remedy – Basic machine

Maintenance – basic machine, cutterbar

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedules

Lubricants charts

Hydraulic system

Hydraulic accumulators

Checking the oil level (Hydrostatic ground drive and working hydraulics)

Changing hydraulic oil (Hydrostatic ground drive and working hydraulics)

Changing the hydraulic oil filter

Changing the return filter (up to serial no. …)

Changing the return filter (from serial no. …)

Filling instructions when carrying out hydraulic oil change

Adjusting the hydrostatic pump

Bleeding the reel cylinders

Venting the cutterbar cross levelling hydraulic cylinder (machines with Auto Contour, up to serial no. …)

Venting the cutterbar cross levelling hydraulic cylinder

Foot brake / brake fluid

Gearboxes

Gear shift control adjustment

Manual gearbox

Checking the oil level

Oil change

Axle drive MEDION 340

Checking the oil level

Oil change

Axle drive MEDION 330 – 310

Checking the oil level

Oil change

Rear wheel drive planetary gears CLAAS 4-Trac System

Checking the oil level

Oil change

Knife drive casing

Checking the oil level / oil change

Threshing drum reduction gearbox

Checking the oil level

Oil change

Angle drive in grain tank MEDION 340

Feed rake conveyor

Tension feeder chains

Elevator chains

Tensioning the grain elevator chain

Tensioning the returns elevator chain

Drive belts / drive chains – basic machine

General Information

Drive system diagram, left-hand side

Drive system diagram, right-hand side

Removing the belt (1)

Installing the belt (1)

Removing the belt (2) (up to serial no. …)

Installing the belt (2) (up to serial no. …)

Removing the belt (3)

Installing the belt (3)

Removing the belt (4) (up to serial no. …)

Installing the belt (4) (up to serial no. …)

Removing the belt (4) (from serial no. …)

Installing the belt (4) (from serial no. …)

Removing the belt (5)

Installing the belt (5)

Removing the belt (6)

Installing the belt (6)

Removing the belt (7)

Installing the belt (7)

Removing the belt (8)

Installing the belt (8)

Removing the belt (9)

Installing the belt (9)

Removing the belt (10)

Installing the belt (10)

Removing the belt (11)

Installing the belt (11)

Removing the belt (12)

Installing the belt (12)

Removing the belt (14)

Installing the belt (14)

Removing the belt (15)

Installing the belt (15)

Removing the belt (16)

Installing the belt (16)

Removing the belt (20)

Installing the belt (20)

Removing the belt (21) (up to serial no. …)

Installing the belt (21) (up to serial no. …)

Removing the belt (21) (from serial no. …)

Installing the belt (21) (from serial no. …)

Removing the belt (22)

Installing the belt (22)

Removing the belt (23)

Installing the belt (23)

Removing the belt (24) (up to serial no. …)

Installing the belt (24) (up to serial no. …)

Removing and installing the belt (24) (from serial no. …)

Removing the belt (25) (without intermediate drive)

Installing the belt (25) (without intermediate drive)

Removing the belt (26) (up to serial no. …)

Installing the belt (26) (up to serial no. …)

Removing the belt (27) (up to serial no. …)

Installing the belt (27) (up to serial no. …)

Removing the belt (28)

Installing the belt (28)

Removing the chain (30)

Installing the chain (30)

Removing the chain (31)

Installing the chain (31)

Removing the chain (32) (MEDION 340)

Installing the chain (32) (MEDION 340)

Removing the chain (33)

Installing the chain (33)

Removing the belt (35) (from serial no. …)

Installing the belt (35) (from serial no. …)

Drive belts / drive chains – cutterbar

General Information

Drive system diagram cutterbar

Tensioning the knife drive belt (40)

Tensioning the intake auger drive chain (41)

Tensioning the reel drive chain (42)

Removing and installing the reel drive belt (43)

Tensioning the reel drive chain (44)

Tensioning the reel drive chain (45)

Cab / air conditioner

Cleaning the filters

Air conditioner

Cleaning the condenser

Checking refrigerant level

Replacing the filter receiver drier

Required refrigerant quantity – refrigerant R 134 a

Maintenance work before the harvest

Fire extinguisher

Have fire extinguisher checked for serviceable condition

Checking the speed of the straw walker shaft

Adjusting the magnetic pick-ups (sensors)

Machines equipped with fieldwork computer

Straw chopper

Changing the free-swinging knives

Removing the knives

Installing the knives

Replacing the stationary knives

Winter storage instructions for combines

Maintenance – Engine

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedule DAIMLER CHRYSLER OM 906 LA

Lubricants chart DAIMLER CHRYSLER OM 906 LA

Maintenance schedule PERKINS 1006-6 TA

Lubricants chart PERKINS 1006-6 TA

Engine maintenance

Engine overview DAIMLER CHRYSLER OM 906 LA (up to serial no. …)

Engine overview DAIMLER CHRYSLER OM 906 LA (from serial no. …)

Engine overview PERKINS 1006-6 TA

Engine access door in grain tank

Access to the engine compartment from the cab

Fuel system

Fuel tank

Fuel shut-off tap

Water separator / fuel prefilter (accessory – small version)

Water separator / fuel pre-filter disassembled:

Fuel pre-filter DAIMLER CHRYSLER OM 906 LA

Fuel pre-filter PERKINS 1006-6 TA (Standard version)

Water separator / fuel pre-filter (accessory – large version)

Water separator / fuel pre-filter disassembled:

Fuel filter DaimlerChrysler OM 906 LA (up to serial no. …)

Cleaning the fuel pre-filter DaimlerChrysler OM 906 LA (from serial no. …)

Replacing the fuel filter DaimlerChrysler OM 906 LA (from serial no. …)

Fuel filter PERKINS 1006-6 TA

Bleeding the fuel system DAIMLER CHRYSLER OM 906 LA

Bleeding the fuel system with an electrical feed pump PERKINS 1006-6 TA

Engine oil level check

Engine oil change

Draining used oil

Oil filter DAIMLER CHRYSLER OM 906 LA

Oil filter PERKINS 1006-6 TA

Topping up engine oil

Tensioning the V-belt PERKINS 1006-6 TA

Tensioning the alternator V-belt DAIMLER CHRYSLER OM 906 LA

Tensioning the alternator / fan drive V-belt PERKINS 1006-6 TA

Cooling System

Water drain plugs on the engine block

Observe coolant type

Identifying the coolant type

Topping up coolant

Changing the coolant

Coolant mixing ratio

Radiator

Topping up coolant (up to serial no. …)

Topping up coolant (from serial no. …)

Overpressure

Frost protection / corrosion protection

Warning sign

Coolant temperature

Shut down the overheated engine

Rotary chaff screen

Cleaning the rotary chaff screen

Folding up rotary chaff screen

Swinging up the oil cooler (up to serial no. …)

Swinging up the oil cooler (from serial no. …)

Cleaning the oil cooler

Cleaning the radiator

Dry-type air filter

Warning device

Cleaning air filter suction screen

Cleaning the air filter

Cleaning the dry-type air filter with dust extractor unit

Removing the air cleaner main cartridge (housing – metal version)

Installing the air cleaner main cartridge (housing – metal version)

Dry air cleaner with safety filter cartridge (housing – metal version)

Removing the air cleaner main cartridge (housing – plastic version)

Installing the air cleaner main cartridge (housing – plastic version)

Safety filter cartridge (housing – plastic version)

Electrical system

Alternator

Engine problems, cause and / or remedy

Engine winter storage

Engine preservation

Lubrication chart

Lubricants and lubrication instructions

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20