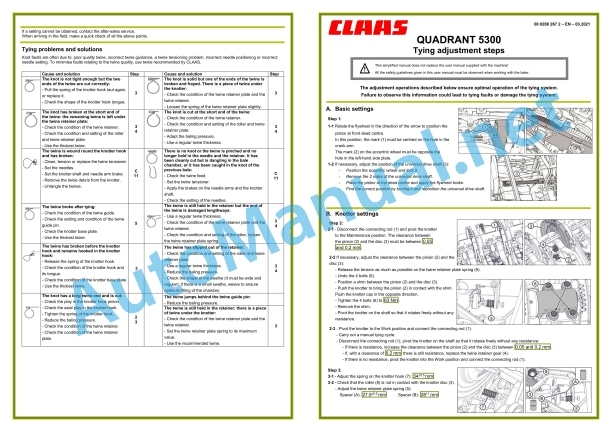

Claas Quadrant 5300 (J32) Balers Operator Manual EN

$50.00

- Model: Quadrant 5300 (J32) Balers

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 120 MB

File List:

00 0288 267 2.pdf

00 0300 208 6.pdf

00 0301 051 0.pdf

00 0304 038 2.pdf

00 0304 158 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0300 208 6.pdf:

QUADRANT 5300 ROTO FEEDQUADRANT 5300 ROTO CUTQUADRANT 5300 FINE CUT

Table of contents

1 Introduction

1.1 General information

1.1.1 Manual validity

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Using in line with intended usage

1.2.2 Reasonably foreseeable improper usage

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Importance of Operator’s Manual

2.2.2 Observe the safety decals and warnings

2.2.3 Requirements for all persons working with the machine

2.2.4 Children in danger

2.2.5 Hazard areas

2.2.6 Presence between tractor and machine

2.2.7 Persons riding on the machine

2.2.8 Hitching the tractor to the machine

2.2.9 Danger of injury from rotating shafts

2.2.10 Structural changes

2.2.11 Optional equipment and spare parts

2.2.12 Controlling the tractor when it is running

2.2.13 Operation only after proper putting into operation

2.2.14 Technical condition

2.2.15 Danger from damage to the machine

2.2.16 Complying with technical limit values

2.2.17 Danger from continued running of machine parts

2.2.18 Keeping the safety devices functional

2.2.19 Personal protective equipment

2.2.20 Wearing suitable clothing

2.2.21 Removing dirt and loose objects

2.2.22 Preparing the machine for road travel

2.2.23 Risks when driving on the road and in the field

2.2.24 Parking the machine safely

2.2.25 Unsupervised parking

2.2.26 Unsuitable operating materials

2.2.27 Safe handling of operating and auxiliary utilities

2.2.28 Environmental protection and disposal

2.2.29 Fire prevention

2.2.30 Lethal electrocution from overhead lines

2.2.31 Electrocution by electrical system

2.2.32 Pressurised fluids

2.2.33 Compressed air

2.2.34 Hot surfaces

2.2.35 Working on machine only after shutting it down

2.2.36 Maintenance work and repairs

2.2.37 Raised machine parts and loads

2.2.38 Risks related to welding work

2.3 Safety decals

2.3.1 Layout of safety decals

2.3.2 Location of safety stickers

3 Machine description

3.1 Existing models

3.1.1 Machine description

3.2 Overview and functions

3.2.1 Left-hand side

3.2.2 Right-hand side

3.3 Safety equipment

3.3.1 Indicator lights

3.3.2 Reflective equipment

Clearance reflectors

3.3.3 Jack stand

3.3.4 Chocks

3.3.5 Parking brake

3.3.6 Flywheel brake

3.3.7 Hydraulic flywheel brake*

3.3.8 Locking the pick-up

3.3.9 Locking the bale ramp

3.3.10 Warning beacon

3.3.11 Extinguisher*

3.4 Working and service areas

3.4.1 General points

3.4.2 Front section of the baler

3.4.3 Upper section of the baler

3.5 Identification plate and serial number

3.5.1 Replacement parts and technical information

3.5.2 Serial number, identification number or VIN code

3.5.3 Identification plate

Identification plate (A)

Identification plate (B)

3.5.4 Drawbar identification plate*

3.5.5 Axle identification plate – Colaert

3.6 General operating principle

3.6.1 Baling cycle

3.7 Information on the machine

3.7.1 Location of information stickers

3.8 Control terminal

3.8.1 CEMIS 700*

3.8.2 ISOBUS connection

3.8.3 EASY on board

3.9 Transmission and drive

3.9.1 Power transmission

3.9.2 Slip clutch

3.9.3 Main drive

3.9.4 Rotor drive

3.9.5 Feed rake drive

3.9.6 Knotter drive

3.10.1 General points

3.10.2 Single axle

3.10.3 Tandem axle

3.10.4 Trailing tandem axle

3.11 Service brake

3.11.1 General points

3.11.2 Pneumatic brakes

3.11.3 Hydraulic brakes

3.11.4 Active hydraulic brakes

3.12 Coupling frame

3.12.1 Types of hitch

3.13 Hydraulic system

3.13.1 Hydraulic oil reservoir

3.13.2 Load-Sensing*

3.14 Crop feeding

3.14.1 Pick-up

3.14.2 Flattening rollers

3.15 Feeder unit

3.15.1 Rotor

3.15.2 Cutting unit*

ROTO CUT knives

FINE CUT knives

Cutting floor with slide

Protection from foreign objects

Dummy knives

Dummy knife holder

3.15.3 Cutting unit control panel*

3.15.4 Precompression chamber

3.15.5 Feed rake

3.16 Baling system

3.16.1 Piston and bale chamber

Hydraulic pressure accumulators

Hydraulic pressure accumulator on bale chamber

Hydraulic pressure compensation accumulator

3.16.2 Regulation of the baling pressure

3.16.3 Maize kit*

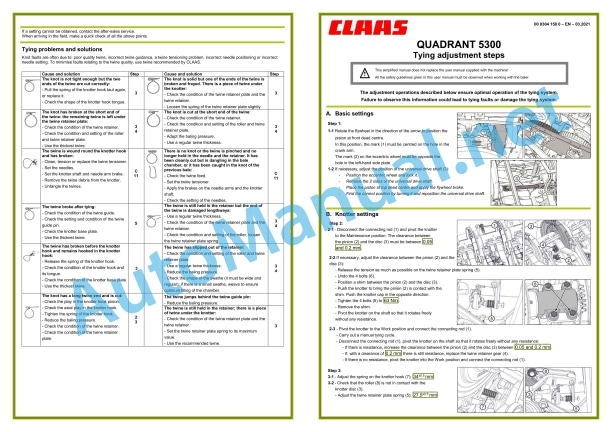

3.17 Tying system

3.17.1 Tying process

3.17.2 Twine boxes

3.17.3 Twine fault warning

3.17.4 Needles

3.17.5 Knotters

3.17.6 Turbofan

3.18 Bale discharge

3.18.1 2-way valve

3.18.2 Bale ramp

3.18.3 Bale ramp position detector

3.18.4 Bale discharge sensor*

3.18.5 Moisture sensor*

3.18.6 Bale weighing device*

3.18.7 Bale ejector

3.19 Central lubrication system

3.19.1 Automatic central lubrication

3.19.2 Automatic chain lubrication*

3.20 Equipment

3.20.1 Ladder

3.20.2 Front ladder support

3.20.3 Storage cabinet*

3.20.4 Work lighting*

3.20.5 Electronic module and diagnosis socket

3.20.6 12 V socket

3.20.7 Anti-theft device*

4 Operating and display elements

4.1 CEMIS 700

4.1.1 Presentation

4.1.2 Description of the CEMIS 700

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0304 038 2.pdf:

QUADRANT 5300 ROTO FEEDQUADRANT 5300 ROTO CUTQUADRANT 5300 FINE CUT

Table of contents

1 Introduction

1.1 General information

1.1.1 Manual validity

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Using in line with intended usage

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Importance of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Requirements for all persons working with the machine

2.2.4 Children in danger

2.2.5 Hazard areas

2.2.6 Presence between tractor and machine

2.2.7 Persons riding on the machine

2.2.8 Hitching the tractor to the machine

2.2.9 Danger of injury from rotating shafts

2.2.10 Structural alterations

2.2.11 Optional equipment and spare parts

2.2.12 Controlling the tractor when it is running

2.2.13 Operation only after proper putting into operation

2.2.14 Technical condition

2.2.15 Danger from damage to the machine

2.2.16 Complying with technical limit values

2.2.17 Danger from continued running of machine parts

2.2.18 Keeping safety devices functional

2.2.19 Personal protective equipment

2.2.20 Wearing suitable clothing

2.2.21 Removing dirt and loose objects

2.2.22 Preparing the machine for road travel

2.2.23 Risks when driving on the road and in the field

2.2.24 Parking the machine safely

2.2.25 Unsupervised parking

2.2.26 Unsuitable operating materials

2.2.27 Safe handling of operating and auxiliary utilities

2.2.28 Environmental protection and disposal

2.2.29 Fire prevention

2.2.30 Lethal electrocution from overhead lines

2.2.31 Electrocution by electrical system

2.2.32 Pressurised fluids

2.2.33 Compressed air

2.2.34 Hot surfaces

2.2.35 Working on machine only after shutting it down

2.2.36 Maintenance work and repairs

2.2.37 Raised machine parts and loads

2.2.38 Risks related to welding work

2.3 Safety decals

2.3.1 Structure of safety decals

2.3.2 Location of safety stickers

3 Machine description

3.1 Existing models

3.1.1 Machine description

3.2 Overview and functions

3.2.1 Left-hand side

3.2.2 Right-hand side

3.3 Safety equipment

3.3.1 Indicator lights

3.3.2 Reflective equipment

Clearance reflectors

3.3.3 Jack stand

3.3.4 Chocks

3.3.5 Parking brake

3.3.6 Flywheel brake

3.3.7 Hydraulic flywheel brake*

3.3.8 Locking the pick-up

3.3.9 Locking the bale ramp

3.3.10 Warning beacon

3.3.11 Extinguisher*

3.4 Working and service areas

3.4.1 General points

3.4.2 Front section of the baler

3.4.3 Upper section of the baler

3.5 Identification plate and serial number

3.5.1 Replacement parts and technical information

3.5.2 Serial number, identification number or VIN code

3.5.3 Machine identification plate

Identification plate for a machine with European certification

Identification plate for a machine without European certification

Identification plate for countries in the Customs Union (Belarus, Kazakhstan, Russia)

3.5.4 Axle identification plate – Colaert

3.6 General operating principle

3.6.1 Baling cycle

3.7 Information on the machine

3.7.1 Location of information stickers

3.8 Control terminal

3.8.1 CEMIS 700*

3.8.2 ISOBUS connection

3.8.3 EASY on board

3.9 Transmission and drive

3.9.1 Power transmission

3.9.2 Friction clutch

3.9.3 Mechanical overload safety

3.9.4 Main drive

3.9.5 Rotor drive

3.9.6 Feed rake drive

3.9.7 Knotter drive

3.10.1 General points

3.10.2 Single axle

3.10.3 Tandem axle

3.10.4 Trailing tandem axle

3.11 Service brake

3.11.1 General points

3.11.2 Pneumatic brakes

3.11.3 Hydraulic brakes

3.11.4 Active hydraulic brakes

3.12 Coupling frame

3.12.1 Types of hitch

3.13 Hydraulic system

3.13.1 Hydraulic oil tank

3.13.2 Load-Sensing*

3.14 Crop feeding

3.14.1 Pick-up

3.14.2 Roller crop press

3.15 Feeder unit

3.15.1 Rotor

3.15.2 Cutting unit*

ROTO CUT knives

FINE CUT knives

Cutting floor with drawer

Protection from foreign objects

Dummy knives

Dummy knife holder

3.15.3 Cutting unit control panel*

3.15.4 Precompression chamber

3.15.5 Feed rake

3.16 Baling system

3.16.1 Piston and bale chamber

Hydraulic pressure accumulators

Hydraulic pressure accumulator on bale chamber

Hydraulic pressure compensation accumulator

3.16.2 Bearing channel knives

3.16.3 Regulation of the baling pressure

3.16.4 Maize kit*

3.16.5 Heavy Duty (HD) kits*

3.17 Tying system

3.17.1 Tying process

3.17.2 Twine boxes

3.17.3 Twine fault warning

3.17.4 Needles

3.17.5 Knotters

3.17.6 Turbofan

3.18 Bale discharge

3.18.1 Bale ramp

Controlling the hydraulic bale ramp from the cab

3.18.2 Bale ramp position detector

3.18.3 Bale discharge sensor*

3.18.4 Moisture sensor*

3.18.5 Bale weighing device*

3.18.6 Bale ejector

Controlling the bale ejector from the cab

3.19 Central lubrication system

3.19.1 Automatic central lubrication

3.19.2 Automatic chain lubrication*

3.20 Equipment

3.20.1 Ladder

3.20.2 Front ladder support

3.20.3 Storage cabinet*

3.20.4 Work lighting*

3.20.5 Camera*

3.20.6 Electronic module and diagnosis socket

3.20.7 12 V socket

3.20.8 Anti-theft device*

3.20.9 Water tank

3.20.10 Special tool

Tying release tool

4 Operating and display elements

4.1 CEMIS 700

4.1.1 Presentation

4.1.2 Description of the

4.1.3 Description of the

4.1.4 Description of the

4.1.5 Description of the

4.1.6 Description of the

4.1.7 Description of the

4.1.8 Description of the

4.1.9 Description of the

4.1.10 Description of the

4.1.11 Description of the

4.1.12 Description of the

4.1.13 Description of the

4.2 ISOBUS terminal

4.2.1 Presentation

4.2.2 General points

4.3 EASY on board

4.3.1 Presentation

4.3.2 General points

5 Technical specifications

5.1.1 Dimensions

5.1.2 Weight

Baler with European certification

Baler with national certification – FRANCE

Baler with national certification – outside of FRANCE

5.1.3 Hitching

5.1.4 Universal drive shaft

5.1.5 Pick-up

5.1.6 Feeder unit

5.1.7 Baling system

5.1.8 Bale discharge

5.1.9 Tying device

5.1.10 Wheels

5.1.11 Braking

5.1.12 Speed – Type of brake / Axle

5.1.13 Hydraulic circuit

5.1.14 Bolt tightening torques

5.1.15 Greasing and lubrication

5.1.16 Noise level

5.2 Safety devices

5.2.1 Shear bolt

5.2.2 Overload safety

5.3 Operating utilities

5.3.1 Lubricants

5.3.2 Twine

5.4 Tractor

5.4.1 Power required

5.4.2 Maximum authorised weight of the towing vehicle

5.4.3 Power take-off

5.4.4 Hitching

5.4.5 Electrical connections

5.4.6 Hydraulic connections

5.4.7 Hydraulic oil and circuit

5.4.8 Braking

6 Machine preparation

6.1 Switching off and securing the machine

6.1.1 Stopping and securing the tractor and machine

6.2 Adapting the tractor

6.2.1 Checking the protective guard on the tractor PTO shaft

6.2.2 Configuring the tractor air brake system

6.2.3 Fitting the CEMIS 700*

6.2.4 Battery cable*

6.2.5 Battery cable* – Tractor without ISOBUS

6.3 Adapting the machine

6.3.1 Universal drive shaft safety advice

6.3.2 Overlap of the universal drive shaft

6.3.3 Adapting the length of the universal drive shaft

6.3.4 Double articulation wide angle universal drive shaft

6.3.5 Adapting clevis hitch / swinging drawbar

6.4 Hitching the machine

6.4.1 Recommendations

6.4.2 Hitching the baler to the tractor

6.4.3 Fitting the universal drive shaft

6.4.4 Connecting the hydraulic hoses

Hose identification

Identifying the hydraulic system on the tractor

General hydraulics for balers equipped with ROTO FEED and tractor equipped with a

Tractor equipped with a

Tractor equipped with a constant output hydraulic system and Tractor equipped with a

Tractor fitted with a hydraulic system with constant pressure

Jack stand and pick-up

Trailing tandem axle*

Hydraulic flywheel brake*

6.4.5 Connecting the brake hoses

Hose identification

Hydraulic brakes*

Active hydraulic brakes*

Pneumatic brake*

6.4.6 Connecting the electrical cables

Identifying the electrical cables

Standard equipment

Power supply for the baler and the CEMIS 700*

Connectors available on the supply cable

Tractor end

Power supply for the baler using the ISOBUS cable*

Connectors available on the supply cable

Tractor end

6.4.7 Connecting the lighting

6.4.8 Connecting the camera*

6.5 Preparing fieldwork

6.5.1 Important

6.5.2 Pick-up wheels

6.5.3 Pick-up height

Pick-up height depending on the crop gathered

6.5.4 Flattening rollers – Head roller position

6.5.5 Mechanical flattening rollers – working height

6.5.6 Removable tines on the full length auger*

6.6.1 Selecting the twine

6.6.2 Preparation

6.6.3 Adjusting the twine tension

6.6.4 Fitting the twine

6.6.5 Fitting the twine in the knotters

6.6.6 Checking the settings

6.7 Cutting unit

6.7.1 Safety advice

6.7.2 Checking

6.7.3 Fitting the knives

6.7.4 Fitting the dummy knives*

6.7.5 Unused knives and dummy knives

6.8 Bale weighing device

6.8.1 Bale weighing device*

6.9 Loading the machine

6.9.1 Raising the baler

6.9.2 Lashing the baler

7 Operation

7.1 General information

7.1.1 Baler user

7.1.2 Opening the flaps and covers

7.2 Travelling with the baler

7.2.1 Checking the equipment

7.2.2 Preparing for transportation

7.2.3 Travelling on the road

7.2.4 Arriving at the field

7.2.5 Driving in fields

7.2.6 Parking

7.3 Before each usage

7.3.1 Reminders

7.3.2 Universal drive shaft

7.3.3 Baler maintenance

7.4 Commissioning in the field

7.4.1 User advice

7.4.2 Starting the machine

Universal drive shaft

Crop conveying system

After a machine stoppage

7.4.3 Hydraulic flywheel brake*

7.4.4 Bale ramp

Manual bale ramp

Hydraulic bale ramp

Controlling the bale ramp from the cab*

7.4.5 Bale ejector

7.4.6 Trailing tandem axle*

7.5 Cutting unit

7.5.1 Cutting unit control panel*

Use in automatic mode

Lowering the cutting frame to the knife changing position

Raising the cutting frame into the working position

Interruption to the automatic cycle

Use in manual mode

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish