Claas Variant 260 Rc (732) Baler Operator Manual ES

$50.00

- Model: Variant 260 Rc (732) Baler

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 10.4 MB

File List:

00 0298 453 6.pdf

00 0299 040 2.pdf

00 0304 379 0.pdf

00 0298 453 6.pdf:

Introduction

Introduction

General indications

Road Traffic

Observe especially

Type indicator plate

Machine number

For security

For security

Warning and indication signs

Proper use

General safety and accident prevention requirements

Trailed machines

Service with PTO shaft

Hydraulic system

Maintenance

Machine working noises, information “D”

wheel chock

Fire extinguisher (Optional depending on country)

Main gear protective cover

Safety stickers with warning symbols

Technical characteristics

CLAAS Variant_x0011_260/280 / Variant_x0011_260/280_x0011_RC

Admission bodies

cutting device

Compaction of the pressed good

Tying mechanism

rolling wheels

Hydraulic system

Tractor hydraulic system required

Hydraulic pressure

Electric system

CLAAS Variant 260/280 /iant 260/280 RC

ensions of the round bale baler

CLAAS Variant 260/280 / Variant 260/280 RC

Safety devices

Cutting screws

Overload clutch

Configuration and way of working

Machine overview

Force transmission

Cutting coupling and free-running articulated shaft

Cam clutch articulated shaft

collecting drum

cutting device

Blind blade support (option)

pressing chamber

Tying the bales

bale ejector

Storage of round bales

Rotor Disengage Clutch

Rotor reverse turning device, manual

yarn drawer

Fire extinguisher (Optional depending on country)

Active hydraulics

Automatic chain lubrication

Address indication (option)

control box

Before commissioning

Check and observe before first start-up

Hook up the baler

Install the drive shaft on the machine side

Transmission shaft with tightening cone closure

Assemble the drive shaft with clamping cone lock

Stop support

Before unhitching the round baler

After attaching the round baler

Hook on the traction pendulum

Grease the traction eye

Mount the transmission shaft on the tractor side (by coupling with a traction pendulum)

Check the meshing of the drive shaft halves:

Reduce drive shaft

Secure the drive shaft protection tubes against simultaneous rotation

Hitch in the hitch mouth

Install the drive shaft on the tractor side

Attachment to the labeled pivot

Splice the pipes

handling box

Power supply

Translation lighting

Splice the hydraulic oil hoses

Back cover opening speed

Before transportation

Arrange the press

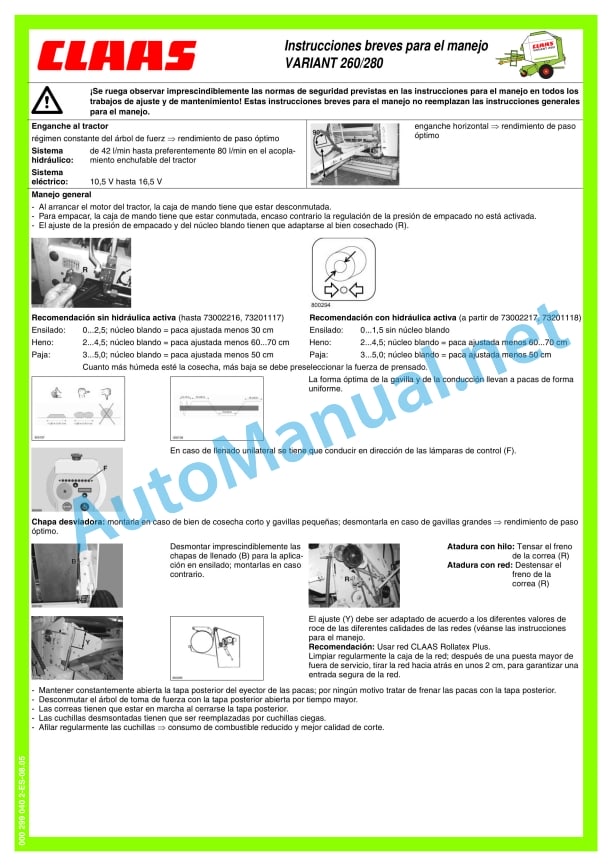

Collected

Pickup height adjustment

Adjust the working height of the pickup (pickup without support wheels)

Pickup with training wheels

Support wheels

Cutting device (VARIANT 260/280 RC)

blind blade

Assembling and disassembling the blades

Insert the blades into the blade holder

Fit the blade

Bale compaction

Pressing pressure regulation

Adjust the diameter of the bale

Adjust the diameter of the soft core

Net binding

Put the network

Regulate the number of network wraps

Tying with thread

Thread the thread

Regulate the number of thread wraps

Adjust the twine wraps on the outer edges of the bale

Tie with three threads

Prepare the eyelet for the thread

Introduce the three wires

Press adjustment for extreme silage cases

Removing the belt guides

Assembling the belt guides

Round bale press with twine and net tying

Switch to thread tying

Drive for tying with thread

Put the V-belt brake on

Switch to net tethering

Adjust the drive for tying with net

Release the V-belt brake

Silage pressing

Mount the blind knife holder (option) on VARIANT ROTO_x0011_CUT

Commissioning the round baler

Filling the pressing chamber

Indication of the direction of travel

Automatic binding

Tether delay

delay function

Thread Tying: Delay Adjustment

Net Tying: Delay Adjustment

Tying and ejecting the bales.

Deposit the bales

Ejecting bales without the bale ejector

bale counter

Round baler with net tying

Baler for round bales with twine and net tying

Round baler with twine tying

Manual overregulation of automatic fastening

Activate the binding process early

Slow down the binding process

Cutting device (ROTO CUT)

Turn the blades inward

Rotate the blades outward

Adjust the volume of the acoustic warning signal

Blockages in the round bale baler

Cam clutch articulated shaft

Rotor reverse turning device (VARIANT_x0011_260/280 / 260/280_x0011_RC)

Fault, reason or solution

Tying with thread

Net binding

After service

Uncouple the baler

wheel chocks

Stop support

control box

Hydraulic oil hoses and electrical connection cables

Transmission tree

Support wheels

Dirt cleaning

Maintenance

Important maintenance instructions

General maintenance instructions

Maintenance and lubrication tables

Maintenance tables

Lubricant table

Cutting screw, main drive

Cutting screw, collector drive

angular gear

Retension drive chains

Tension the collector drive chain

Tension the drive chain of the transverse conveyor thread

Adjust compression springs for pressure roller

Adjust the clamping device for the network meter

Adjust disc brakes

Tension the tension spring for the chain drive (belts and rotor)

Tension the tension spring for the chain drive on the rear cover

Adjust tension springs for clamping arm

Adjust the tension springs for the lower clamping arm

Tension the tension spring of the net roll braking bracket

Adjust spring cylinder for freewheel drive

Adjust the bale ejector tension springs

Adjust linkage to bale ejector end switch

Drive brake on twine tie

Adjust compression springs on disengagement clutches

Adjust the compression springs on the slip coupling (ratchet wheel) (attachment…

Adjust the thread tensioners

Inductive sensor settings

Inductive sensor “maximum ball diameter”

Inductive “door closed” sensor

Hydraulic oil filter (machines with filter installation)

Automatic chain lubrication

Adjust the Linatex guide plate

Fire extinguisher (option)

flat strap

Release the flat belt

Check flat belts

Repair flat belts

Lay the straps flat

Adjust the belt travel

Adjust the lower roller scraper

Check the seat of the wheel nuts

Check the wheel hub bearing clearance

Adjust bearing clearance

Proposals for preparing for winter

Lubrication plan

Lubricants and information

Reference word index

Reference word index

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF