Claas Variant 260 Rc (732) Balers Operator Manual EN

$50.00

- Model: Variant 260 Rc (732) Balers

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 52.3 MB

File List:

00 0297 943 6.pdf

00 0299 037 2.pdf

00 0299 439 1.pdf

00 0301 051 0.pdf

00 0304 379 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0297 943 6.pdf:

Introduction

Introduction

Contents

Contents

General notes

Road traffic

Important

Identification plate

Machine-number

Concerning safety

Concerning safety

Marking of warning and danger notes

Intended use

General safety and accident prevention _x0004_regulations

Hitched machines

Power take-off operation

Hydraulic system

Maintenance

Working noise of machines, Information D

Wheel chock

Fire extinguisher (country option)

Protection hood for main transmission

Safety stickers with warning symbol

Technical data

CLAAS Variant 260/280 / Variant 260/280 RC

Intake elements

Cutting device

Compression of bale material

Wrapping facility

Hydraulics

Required tractor hydraulics

Hydraulic pressure

Variant 260/280 / Variant 260/280 RC

Dimensions of the round baler

CLAAS Variant 260/280 / Variant 260/280 RC

Safety installations

Shearing screws

Overload clutch

Design and working principle

Machine overview

Power transmission

Shearing coupling and freewheeling propeller shaft

Cam clutch – propeller shaft

Cutting unit

Blanking knife holder (optional)

Baling chamber

Wrapping the bales

Bale ejector

Storage of round bales

Rotor switch-off clutch

Rotor reversing facility, manually

Twine boxes

Fire extinguisher (country option)

Active hydraulic system

Automatic chain lubrication

Direction indicator (optional)

Control box

Before starting operation

Check and observe the following before operating the machine

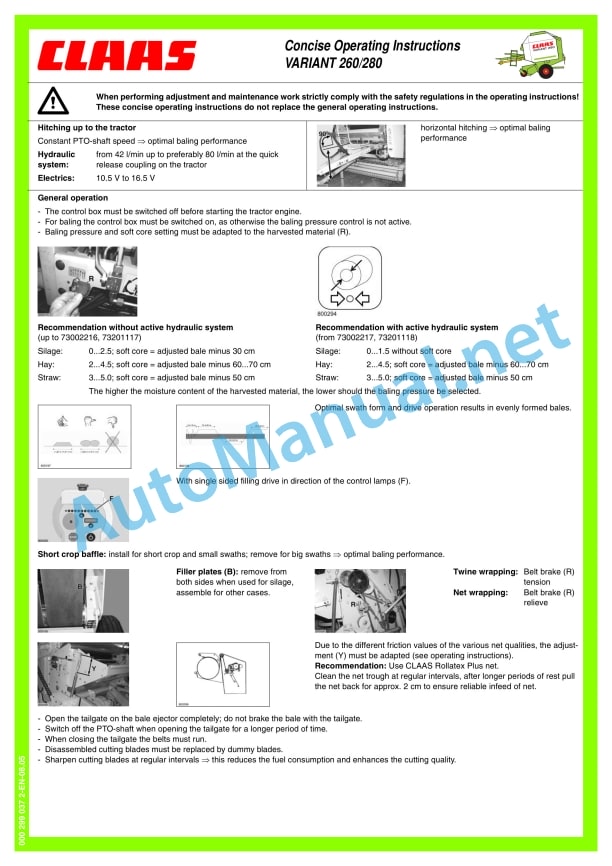

Hitching up the baler

Connecting the universal drive shaft to the baler

Propeller shaft with clamping taper lock

Installing propeller shaft with CC-lock

Parking support

Before hitching the round baler

After hitching the round baler

Hitching to the trailer coupling ring

Greasing the towing eye

Fitting the universal drive shaft to the tractor (for trailer coupling)

Checking the overlap of the universal drive shaft halves:

Shortening the universal drive shaft

Preventing the universal drive shaft guards from rotating with the drive shaft

Hitching to the towing hitch

Fitting the universal drive shaft to the tractor

Attaching to the ball head

Connecting the cables

Control box

Power supply

Travel lights

Connecting the hydraulic hoses

Tailgate opening speed

Before transport

Setting up the baler

Collecting

Height adjustment of pick-up

Adjusting the pick-up working height (Pick-up without supporting wheels)

Pick-up with support wheels

Support wheels

Cutting device (VARIANT 260/280_x0011_RC)

Blank knives

Installing and removing knives

Placing the knives into the dummy knife holder

Locking the knives

Pressing bales

Pressing pressure adjustment

Adjusting the bale diameter

Adjusting the soft core diameter

Wrapping

Net wrapping

Inserting the net

Adjusting the number of net windings

Twine wrapping

Threading the wrapping twine

Adjusting the number of twine windings

Adjusting the twine windings at the outer edges of the bale

Tying with three threads

Preparing the twine eyelet

Threading the three threads

Baler adjustment under severe silage conditions

Disassembly of belt guides

Installation of belt guides

Round baler with twine and net wrapping

Changing to twine wrapping

Adjusting the drive for twine wrapping

Applying the V-belt brake

Changing to net wrapping

Adjusting the drive for net wrapping

Releasing the V-belt brake

Pressing of silage

Installing the blank knife holder (optional) on VARIANT ROTO_x0011_CUT

Operation

Starting operation of the round baler

Filling the baling chamber

Travel direction indicator

Automatic wrapping

Tying delay

Delay function

Twine wrapping: Setting the delay

Net wrapping: Setting the delay

Wrapping and ejecting the bales

Laying down the bales

Ejecting bales without bale ejector

Bale counter

Round baler with net wrapping

Round baler with twine and net wrapping

Round baler with twine wrapping

Manual overload of the automatic wrapping

Triggering early wrapping

Delaying the wrapping process:

Cutting device (ROTO CUT)

Swashing the knives in

Swashing the knives out

Adjusting the volume of the audible warning signal

Blockage of the round baler

Cam clutch – propshaft

Rotor reversing facility (VARIANT_x0011_260/280_x0011_/_x0011_260/280_x0011_RC)

Fault, cause or remedy

Twine wrapping

Net wrapping

After use

Unhitching the baler

Wheel chocks

Parking support

Control box

Hydraulic hoses and electrical wiring

Propeller shaft

Gauge wheels

Cleaning of dirt

Maintenance

Important notes on maintenance

General notes on maintenance

Maintenance and lubricant charts

Maintenance table

Lubricant chart

Shearing bolt main drive

Shearing bolt pick-up drive

Angular gear

Tightening the drive chains

Tightening the pick-up drive chain

Tensioning the drive chain for the feed auger

Adjusting the pressure springs for the pressing roller

Adjusting the clamping device for the net knife

Adjusting the disc brake

Tightening the tension springs for the chain drive (belts and rotor)

Tightening the tension spring for the chain drive in the tailgate

Adjusting the tension springs for top tensioning arm

Adjusting the tension springs for bottom tensioning arm

Tightening the tension spring for the net roll braking bow

Adjusting the spring cylinder for freewheeling drive

Adjusting the tension springs of the bale ejector

Adjusting the linkage to the limit switch of the bale ejector

Drive brake for twine wrapping

Adjusting the pressure springs on the shut-off coupling

Adjusting the pressure springs on the friction clutch (ratchet wheel) (Net wrapping)

Adjusting the twine tensioner

Settings of the inductive sensors

Inductive sensor maximum ball diameter

Inductive sensor closed door

Hydraulic oil filter (Machines with filter system)

Automatic chain lubrication

Adjusting the Linatex guide plate

Fire extinguisher (optional)

Flat belts

Relieving the flat belts

Checking the flat belts

Repairing the flat belt

Installing the flat belt

Belt alignment

Adjusting the scraper, bottom roller

Check tight fit of wheel nuts

Checking wheel hub backlash

Adjusting the backlash

Proposals for winter storage

Lubrication plan

Lubricants and notes

Glossary

Glossary

pdf:

Notice de montage et d’utilisation

Kit lin – lin court and Kit Lin trs court

Introduction

Introduction

Consignes de scurit

Important

Characterization of indications sur les dangers

Consignes gnrales de scurit et de prvention des accidents

Stationnement de la machine

Utilization conforme la destination

Installation notice

Kit lin et lin court

Introduction

Lot de pices (0843 001.0)

Reduction of the number of belts

Dtente des courroies

Coupe des courroies

Ajustage de la longueur des corroies

Agrafage des courroies

Prparation du pick-up

Dmontage du tasseur

Dmontage du carter de protection du pick-up

Montage de la roue chain Kit lin

Dmontage des vis de recentrage

Remontage du carter du pick-up

Dmontage des dents du pick-up

Prparation dtectur de proximit

Graisseur

Montage du kit lin

Fixation du cadre prmont sur la presse

Montage du ski sur le cadre

Fixation du crochet sur la machine

Preparation of the Lin court kit

Variant 260

Perage de la chambre de pressage

Prmontage du kit lin court

Variant 280

Perage de la chambre de pressage

Prmontage du kit lin court

Guides-ficelle et couteau

Montage des guides-ficelle Lin

Montage du knife Lin

Dmontage du couteau d’origine

Montage du knife Lin

lectrique

Montage de l’interrupteur

Prparation de la tle

Fixation de l’interrupteur

Configuration du module pour le lin

Verification of information

Fixation du module lin sur le support

Montage du support sur la presse

Montage du faisce lectrique

Fixing the cable on thetting the proximity Introduction

Lot de pices (0843 592.0)

Prparation du kit lin trs court

Variant 260

Perage de la chambre de pressage

Prmontage du kit lin trs court

Variant 280

Perage de la chambre de pressage

Prmontage du kit lin trs court

Notice d’utilisation

Introduction

Principle and function

Vitesse de la prise de force

Pressage

Sens de pressage

Pressure de pressage

Liage des tiges de lin

Principle

Vitesse davancement et rapport de nappe

Avant utilization

Adjustment of the frame before the kit lin

Hauteur de la roue centrale

Hauteur des guides-fourrage

Hauteur du ski

Adjustment of the press

Nombre de tours de ficelle

Guides-ficelle Lin

Mise en place de la ficelle

Pre Diamtre de balls

pierreux

Rcolte sur terrain pierreux

Utilization pour le pressage du lin court

Generalities

Preparation of the pressing chamber

Montage des glissires sur la paroi – Variant 260

Montage des glissires sur la paroi – Variant 280

Mise en place de la tle lin court

Fixation de la tle lin court

Adjustment of the slide mobile

Rcolte sur terrain non pierreux

Rcolte sur terrain pierreux

Utilization pour le pressing du lin trs court

Generalities

Preparation of the pressing chamber

Montage des glissires sur la paroi – Variant 260

Montage des glissires sur la paroi – Variant 280

Mise en place de la tle lin trs court

Fixation de la tle lin trs court

Adjustment of the slide mobile

Rcolte sur terrain non pierreux

Rcolte sur terUse of the press for other harvests

y and operating instructions

Set linen – short line and set very short line

Introduction

Introduction

Safety instructions

The important information

Description of warning signs

General instructions on safety techniques and accident prevention

Car parking

Use as intended

Assembly instruction

Set for linen and short linen

Introduction

Lot of parts (0843 001.0)

Reducing the number of drive belts

Belt slack

Trimming belts

Belt length adjustment

Belt fastening

Preparing the baler

Dismantling the rammer

Dismantling the baler protection casing

Assembly of stars from the Len set

Dismantling of centering screws

Installation of the baler crankcase

Dismantling fingers with the baler

Preparing the on-board baler

Pre-assembly of the Len set

Installing wheelson a frame

Installation of feed guides on the frame

Setting the proximity detector

Lubrication hole

Assembling the Len set

Fastening the assembled frame to the press

Installing skis on a shoulder

Fixing the grip on the car

Preparation of the set Short linen

Variant 260

Perforating press camera

Pre-assembly of the Short Linen set

Variant 280

Perforating press camera

Pre-assembly of the Short Linen set

String guide and knife

Installation of the guide string of the Len set

Installation of the Len knife

Dismantling the standard blade

Installation of the Len knife

Electronics

Installation of the circuit breaker

Preparation sheet

Mounting the circuit breaker

Cleaning module setting

Check information

Fixation of the Len module on a support

Press support installation

Installation of electrical wiring

Fixing the cable to ng

Setting detector approximations

Hood installation

Assembly instruction

Set very short li592.0)

Preparation of the set Very short linen

Variant 260

Perforating press camera

Pre-assembly of the set Very Short Linen

Variant 280

Perforating press camera

Pre-assembly of the set Very Short Linen

Operating instructions

Introduction

Principle and operation

Power take-off speed

Pressing

Making presses

Pressure presses

Bundle of stems

A principle

Speed advances and layer coefficient

Preparation for use

Adjusting the front frame of the Len kit

Center wheel height

Height of feed guides

Ski height

Press setup

Number of windings

Guide cords Flax

Seasoning strings

Pressure presses

Bundle diameter

Use for pressing flax

Baler picker

Harvesting of non-rocky soil

Harvesting stony soil

Use for pressing short flaxf the press camera

Installation of guides on the wall – Variant 260

Installation of guides on the wall – Variant 280

Installation of welded sheet Short linen

Fixation of welded sheet Short flax

Adjustment of the movable guide

Harvesting of non-rocky soil

Harvesting stony soil

Use for pressing short flax

General information

Preparation of the press camera

Installation of guides on the wall – Variant 260

Installation of guides on the wall – Variant 280

Installation of welded sheet Very short linen

Fixation of welded sheet Very short linen

Adjustment of the movable guide

Harvesting of non-rocky soil

Harvesting stony soil

Using a press for harvesting other crops

Baler picker

Connection

Press camera

ctric current

Technical service

Lubrication hole

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF