Komatsu PC130-7 Hydraulic Excavator Shop Manual SEBM036301

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM036301

- Format: PDF

- Size: 9.9MB

- Number of Pages: 342

Category: Komatsu Shop Manual PDF

-

Model List:

- PC130-7 Hydraulic Excavator

- 1. .pdf

- 1.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 1.1.1. When carrying out troubleshooting, do not hurry to disassemble the components.

- 1.1.2. Points to ask user or operator

- 1.1.2.1. Have any other problems occurred apart from the problem that has been reported

- 1.1.2.2. Was there anything strange about the machine before the failure occurred

- 1.1.2.3. Did the failure occur suddenly, or were there problems with the machine condition before this

- 1.1.2.4. Under what conditions did the failure occur

- 1.1.2.5. Had any repairs been carried out before the failure

- 1.1.2.6. Has the same kind of failure occurred before

- 1.1.3. Check before troubleshooting

- 1.1.3.1. Check the oil level

- 1.1.3.2. Check for any external leakage of oil from the piping or hydraulic equipment.

- 1.1.3.3. Check the travel of the control levers.

- 1.1.3.4. Check the stroke of the control valve spool.

- 1.1.3.5. Other maintenance items can be checked externally, so check any item that is considered to be …

- 1.1.4. Confirming failure

- 1.1.5. Troubleshooting

- 1.1.5.1. Start from the simple points.

- 1.1.5.2. Start from the most likely points.

- 1.1.5.3. Investigate other related parts or information.

- 1.1.6. Measures to remove root cause of failure

- 1.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 1.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 1.3.1. To maintain the performance of the machine over a long period, and to prevent failures or other t…

- 1.3.1.1. Points to remember when handling electric equipment

- 1.3.1.1.1. Handling wiring harnesses and connectors

- 1.3.1.1.1.1. Defective contact of connectors (defective contact between male and female)

- 1.3.1.1.1.2. Defective crimping or soldering of connectors

- 1.3.1.1.1.3. Disconnections in wiring

- 1.3.1.1.1.4. Highpressure water entering connector

- 1.3.1.1.1.5. Oil or dirt stuck to connector

- 1.3.1.1.2. Removing, installing, and drying connectors and wiring harnesses

- 1.3.1.1.2.1. Hold the connectors when disconnecting.

- 1.3.1.1.2.2. When removing from clips

- 1.3.1.1.2.3. Action to take after removing connectors

- 1.3.1.1.2.4. Check the connector visually.

- 1.3.1.1.2.4.1. Check that there is no oil, dirt, or water stuck to the connector pins (mating portion).

- 1.3.1.1.2.4.2. Check that there is no deformation, defective contact, corrosion, or damage to the connector p…

- 1.3.1.1.2.4.3. Check that there is no damage or breakage to the outside of the connector.

- 1.3.1.1.2.5. Fix the connector securely.

- 1.3.1.1.2.6. Correct any protrusion of the boot and any misalignment of the wiring harness

- 1.3.1.1.2.7. If the connector clamp has been removed, be sure to return it to its original position. Check …

- 1.3.1.1.2.8. Disconnect the connector and wipe off the water with a dry cloth.

- 1.3.1.1.2.9. Dry the inside of the connector with a dryer.

- 1.3.1.1.2.10. Carry out a continuity test on the connector.

- 1.3.1.1.3. Handling control box

- 1.3.1.1.3.1. The control box contains a microcomputer and electronic control circuits. These control all of…

- 1.3.1.1.3.2. Do not open the cover of the control box unless necessary.

- 1.3.1.1.3.3. Do not place objects on top of the control box.

- 1.3.1.1.3.4. Cover the control connectors with tape or a vinyl bag.

- 1.3.1.1.3.5. During rainy weather, do not leave the control box in a place where it is exposed to rain.

- 1.3.1.1.3.6. Do not place the control box on oil, water, or soil, or in any hot place, even for a short time.

- 1.3.1.1.3.7. Precautions when carrying out arc welding

- 1.3.1.2. Points to remember when troubleshooting electric circuits

- 1.3.1.2.1. Always turn the power OFF before disconnecting or connect connectors.

- 1.3.1.2.2. Before carrying out troubleshooting, check that all the related connectors are properly inserted.

- 1.3.1.2.3. Always connect any disconnected connectors before going on to the next step.

- 1.3.1.2.4. When carrying out troubleshooting of circuits (measuring the voltage, resistance, continuity, …

- 1.3.1.3. Points to remember when handling hydraulic equipment

- 1.3.2. With the increase in pressure and precision of hydraulic equipment, the most common cause of fail…

- 1.3.2.1. Be careful of the operating environment.

- 1.3.2.2. Disassembly and maintenance work in the field

- 1.3.2.3. Sealing openings

- 1.3.2.4. Do not let any dirt or dust get in during refilling operations.

- 1.3.2.5. Change hydraulic oil when the temperature is high.

- 1.3.2.6. Flushing operations

- 1.3.2.7. Cleaning operations

- 1.4. Inspection before troubleshooting

- 1.5. Classification of and procedures for troubleshooting

- 1.5.1. If a phenomenon looking like a trouble occurs in the machine, select a proper troubleshooting No….

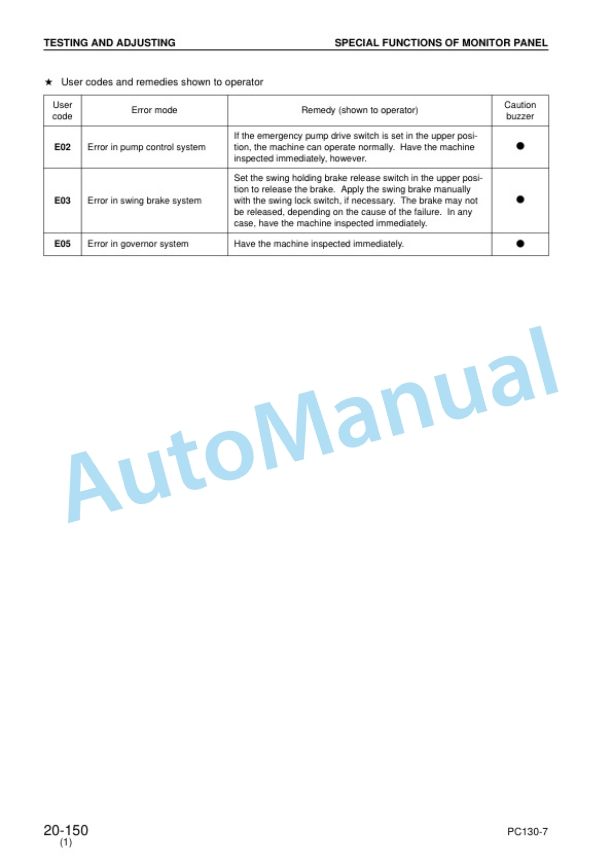

- 1.5.1.1. Procedure for troubleshooting to be taken when user code is displayed on monitor panel

- 1.5.1.2. Procedure for troubleshooting when electrical system error code or mechanical system error cod…

- 1.5.1.3. Procedure for troubleshooting to be taken when user code is not displayed and error history is…

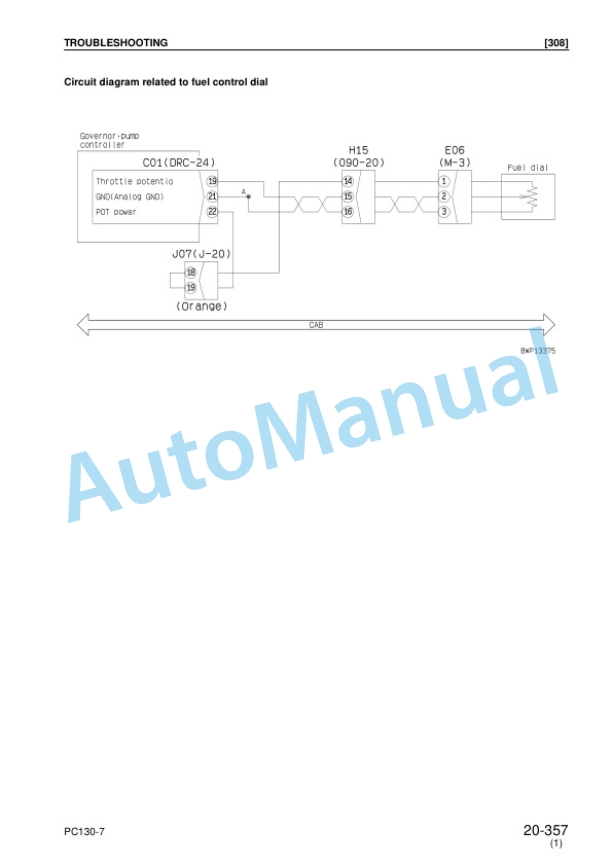

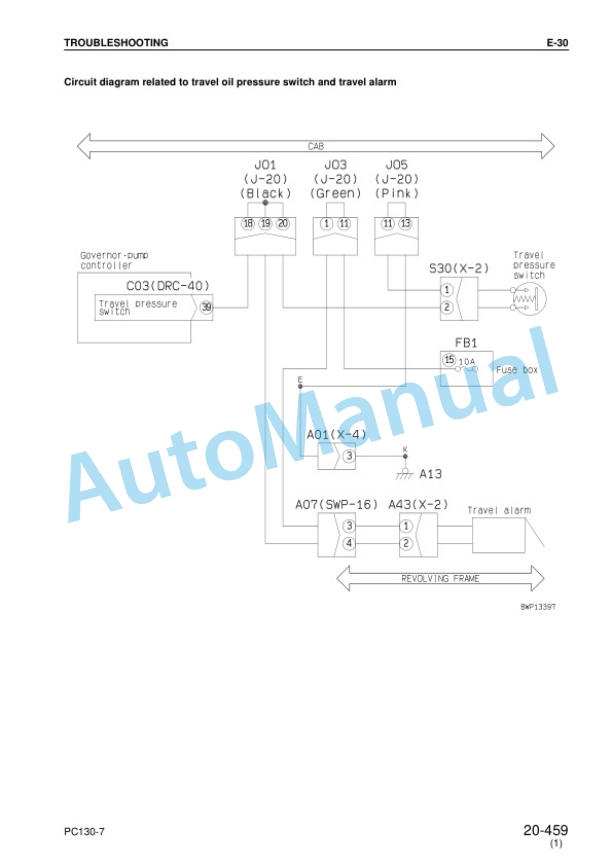

- 1.6. Connector arrangement drawing and electric circuit diagram of each system

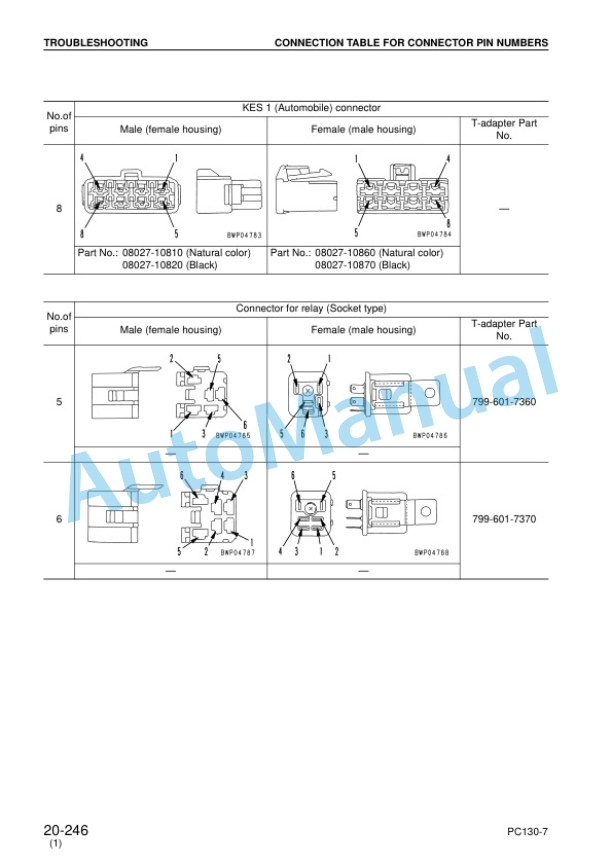

- 1.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 1.7.1. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.2. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.3. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.4. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.5. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.6. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.7. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.8. R 7996019060

- 1.7.9. 7996019070

- 1.7.10. 7996019080

- 1.7.11. R 7996019090

- 1.7.12. R 7996019110

- 1.7.13. 7996019120

- 1.7.14. 7996019130

- 1.7.15. R 7996019140

- 1.7.16. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.17. The pin No. is also marked on the connector (electric wire insertion end)

- 1.7.18. The pin No. is also marked on the connector (electric wire insertion end)

- 1.8. TBRANCH BOX AND TBRANCH TABLE

- 1.8.1. TROUBLESHOOTING

Rate this product

You may also like