Komatsu PC450-6, PC450LC-6 Hydraulic Excavator Shop Manual UEBM000100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM000100

- Format: PDF

- Size: 52.6MB

- Number of Pages: 824

Category: Komatsu Shop Manual PDF

-

Model List:

- PC450-6 Hydraulic Excavator

- PC450LC-6 Hydraulic Excavator

- 1. General

- 1.1. Specification drawings

- 1.2. Specifications

- 1.3. Weight table

- 1.4. Fuel, coolant and lubricants

- 2. Structure and Function

- 2.1. Parts related to engine

- 2.2. Radiator, oil cooler

- 2.3. Power train

- 2.4. Final drive

- 2.5. Swing circle

- 2.6. Swing machinery

- 2.7. Track frame, recoil spring

- 2.8. Track shoe

- 2.9. Hydraulic piping drawing

- 2.10. Hydraulic circuit diagram

- 2.11. Hydraulic tank, hydraulic filter

- 2.12. Hydraulic pump

- 2.13. Control valve

- 2.14. Selfreducing pressure valve

- 2.15. Suction safety valve

- 2.16. CLSS

- 2.17. Swing motor

- 2.18. Center swivel joint

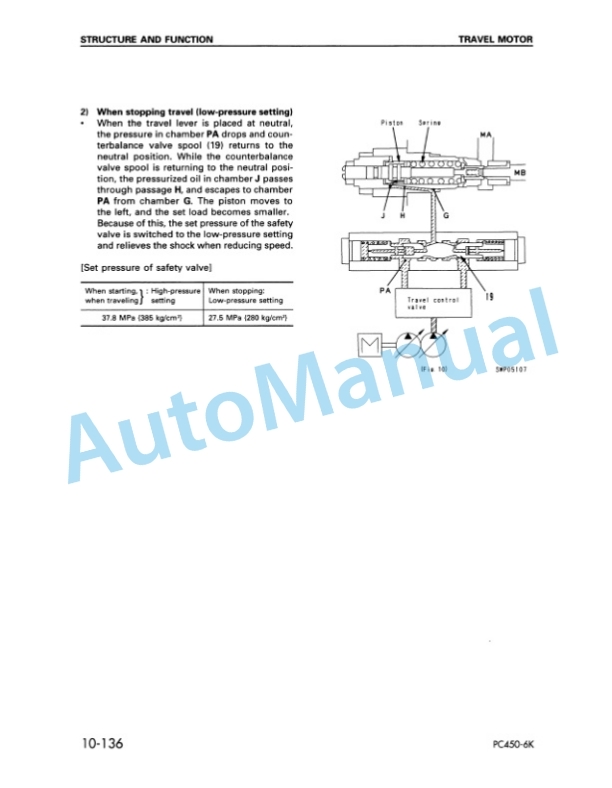

- 2.19. Travel motor

- 2.20. Valve control

- 2.21. Work equipment swing PPC valve

- 2.22. Travel PPC valve

- 2.23. Service PPC valve

- 2.24. PPC safety lock valve

- 2.25. PPC accumulator

- 2.26. PPC shuttle valve, travel junction valve

- 2.27. LSEPC valve

- 2.28. Solenoid valve

- 2.29. Boom safety valve

- 2.30. Overload warning device

- 2.31. Work equipment

- 2.32. Air conditioner

- 2.33. Actual electric wiring diagram

- 2.34. Electric circuit diagram

- 2.35. Engine control

- 2.36. Electronic control system

- 2.37. Machine monitor system

- 2.38. Breaker mode hydraulic performance

- 3. Testing and Adjusting

- 3.1. Standard value table

- 3.1.1. Standard value table for engine related parts

- 3.1.2. Standard value table for chassis related parts

- 3.1.3. Standard value table for electrical parts

- 3.2. Testing and adjusting

- 3.2.1. Tools for testing, adjusting, and troubleshooting

- 3.2.2. Measuring engine speed

- 3.2.3. Measuring exhaust color

- 3.2.4. Adjusting valve clearance

- 3.2.5. Measuring compression pressure

- 3.2.6. Measuring blowby pressure

- 3.2.7. Testing and adjusting fuel injection timing

- 3.2.8. Measuring engine oil pressure

- 3.2.9. Testing and adjusting fan belt tension

- 3.2.10. Testing and adjusting belt tension for air conditioner compressor

- 3.2.11. Adjusting engine speed sensor

- 3.2.12. Measuring air supply pressure (boost pressure)

- 3.2.13. Testing and adjusting governor motor lever stroke

- 3.2.14. Testing and adjusting hydraulic pressure in work equipment, swing, travel circuit

- 3.2.15. Testing and adjusting TVC valve output pressure (servo piston input pressure)

- 3.2.16. Testing and adjusting LS valve output pressure (servo piston input pressure) and LS differential pressure

- 3.2.17. Testing control circuit oil pressure (oil pressure when selfpressure is reduced)

- 3.2.18. Testing solenoid valve output pressure

- 3.2.19. Measuring PPC valve output pressure and testing PPC shuttle valve

- 3.2.20. Adjusting work equipment, swing PPC valve

- 3.2.21. Testing travel deviation

- 3.2.22. Testing locations causing hydraulic drift of work equipment

- 3.2.23. Measuring oil leakage

- 3.2.24. Releasing remaining pressure in hydraulic circuit

- 3.2.25. Testing clearance of swing circle bearing

- 3.2.26. Testing wear of sprocket

- 3.2.27. Testing and adjusting track shoe tension

- 3.2.28. Bleeding air

- 3.3. Troubleshooting

- 3.3.1. Points to remember when troubleshooting

- 3.3.2. Sequence of events in troubleshooting

- 3.3.3. Points to remember when carrying out maintenance

- 3.3.4. Checks before troubleshooting

- 3.3.5. Connector types and mounting locations

- 3.3.6. Connector arrangement diagram

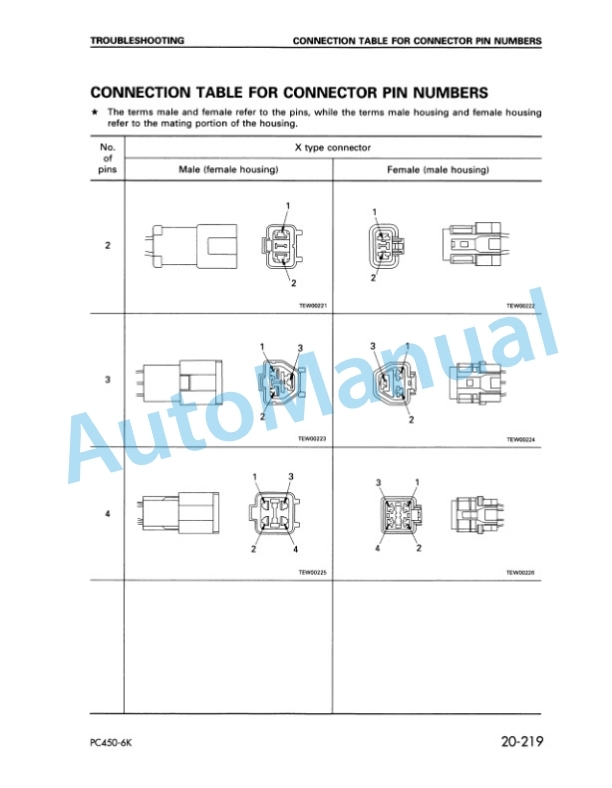

- 3.3.7. Connection table for connector pin numbers

- 3.3.8. Explanation of control mechanism of electrical system

- 3.3.9. Display method of special functions of monitor panel

- 3.3.10. Method of using judgement table

- 3.3.11. Method of using troubleshooting charts

- 3.3.12. Details of troubleshooting and troubleshooting procedure

- 3.3.13. Service code table

- 3.3.14. Troubleshooting of communication abnormality system (N mode)

- 3.3.15. Troubleshooting of governor, pump controller (governor control system) (E mode)

- 3.3.16. Troubleshooting of engine system (S mode)

- 3.3.17. Troubleshooting of governor, pump controller (pump control system) (C mode)

- 3.3.18. Troubleshooting of governor, pump controller (input signal system) (F mode)

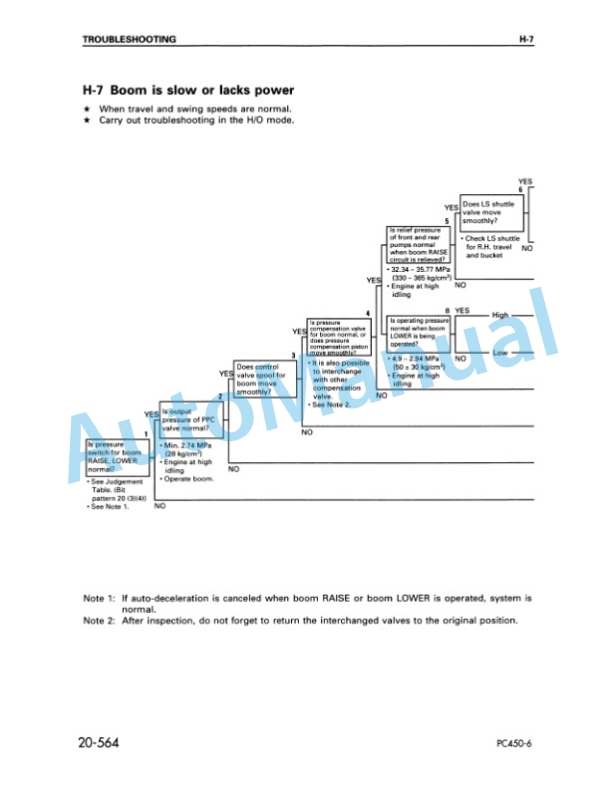

- 3.3.19. Troubleshooting of hydraulic, mechanical system (H mode)

- 3.3.20. Troubleshooting of machine monitor system (M mode)

- 4. Disassembly and Assembly

- 4.1. Method of using manual

- 4.2. Precautions when carrying out operation

- 4.3. Special tool list

- 5. Maintenance Standard

- 6. Others

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00