- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SK1026-5N Skid Steer Loader Operation and Maintenance Manual CEAM014301

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM014301

- Format: PDF

- Size: 26.0MB

- Number of Pages: 236

-

Model List:

- SK1026-5N Skid Steer Loader

- 1. CEAM014301 SK10265N

- 2. INTRODUCTION

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. APPROVED AND NONAPPROVED USES

- 2.3.1. Approved

- 2.3.2. NonApproved

- 2.4. PRODUCT INFORMATION

- 2.4.1. Main Features

- 2.4.2. BreakIn Period

- 2.4.3. Synthetic Biodegradable Oil Type HEES

- 2.5. PRODUCT IDENTIFICATION

- 2.5.1. Machine Serial Number

- 2.5.2. Machine Identification Plate

- 2.5.3. Engine Serial Number and Emission Label

- 2.5.4. Travel Reduction Gear Serial Number

- 2.5.5. Cab Serial Number

- 2.5.6. Backhoe Identification Plate (If Installed)

- 2.6. SERIAL NUMBERS AND DEALER INFORMATION

- 2.7. TABLE OF CONTENTS

- 3. SAFETY

- 3.1. GENERAL SAFETY RULES AND PRECAUTIONS

- 3.1.1. General Safety Rules

- 3.1.2. Safety Features

- 3.1.3. Personal Protective Equipment

- 3.1.4. Unauthorized Modifications

- 3.1.5. Leaving Operators Compartment

- 3.1.6. Mounting and Dismounting

- 3.1.7. RearView Mirrors

- 3.1.8. Fire Prevention for Fuel and Oil

- 3.1.9. Dust Hazard Precautions

- 3.1.10. Crush or Pinch Point Dangers

- 3.1.11. Fire Extinguisher and First Aid Kit

- 3.1.12. Inside Operators Compartment

- 3.1.13. Precautions when using ROPS

- 3.1.14. Precautions for all Attachments

- 3.2. PRECAUTIONS BEFORE STARTING WORK OPERATIONS

- 3.2.1. General PreOperational Checks

- 3.2.2. Starting Work Operations

- 3.2.3. Work Site Hazards

- 3.2.4. Working Clearances

- 3.2.5. Rules for Road Travel

- 3.2.6. Rules for Traveling in Reverse

- 3.2.7. Traveling on Icy or Snow Covered Surfaces

- 3.2.8. Working on Loose or Unstable Ground

- 3.3. PRECAUTIONS DURING MAINTENANCE OPERATIONS

- 3.3.1. Warning Tags

- 3.3.2. Equipment Storage

- 3.3.3. Working Under the Machine

- 3.3.4. Using Drop Lamps

- 3.3.5. Keeping the Machine Clean

- 3.3.6. Rules for Refueling the Machine

- 3.3.7. Cooling System Precautions

- 3.3.8. Battery Precautions

- 3.3.9. Starting the Machine

- 3.3.10. High Pressure Hoses

- 3.3.11. High Temperatures Areas

- 3.3.12. Rotating Parts

- 3.3.13. Disposal of Waste Materials

- 3.3.14. Inflating Tires

- 3.3.15. Critical Parts

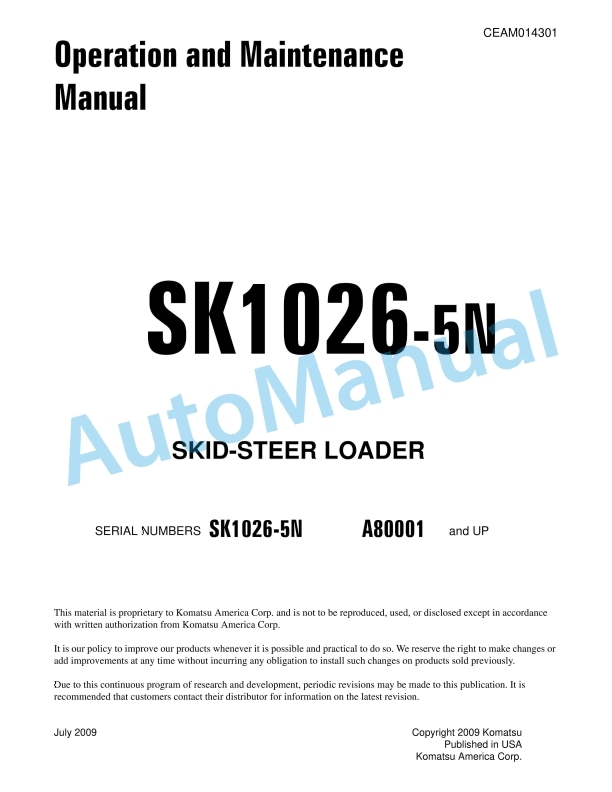

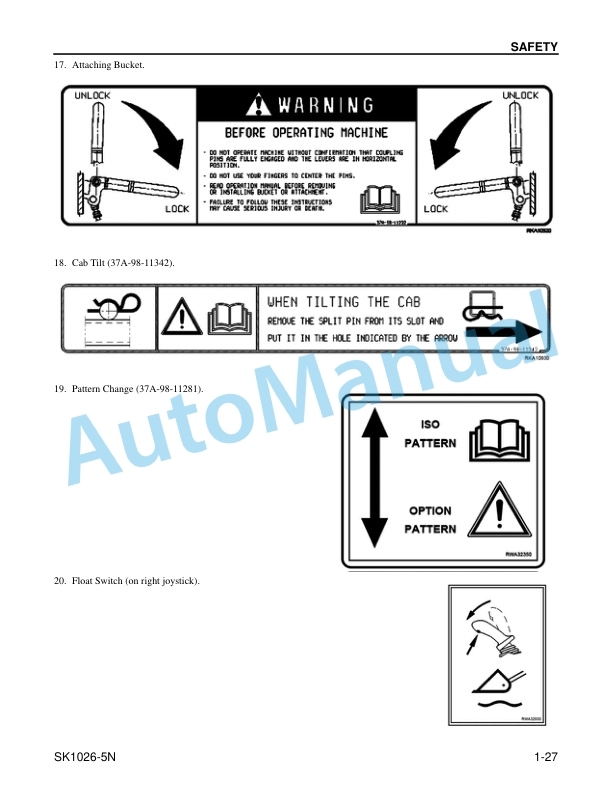

- 3.4. SAFETY AND WARNING DECALS

- 3.4.1. Location of Safety Decals

- 3.4.2. Location of Pictogram Decals

- 4. OPERATION

- 4.1. GENERAL VIEW OF MACHINE

- 4.1.1. Location of Pictogram Decals and Front View

- 4.1.2. Rear View of Machine

- 4.1.3. Additional Pictograms

- 4.2. LOCATION AND FUNCTION OF IN CAB MACHINE CONTROLS

- 4.2.1. Cab View From Operators Position

- 4.3. INSTRUMENT PANEL AND SWITCHES

- 4.3.1. Instrument Panel

- 4.3.2. Indicator Lights

- 4.3.3. Switches and Push Buttons

- 4.4. LOCATION AND FUNCTIONS OF OUTSIDE MACHINE

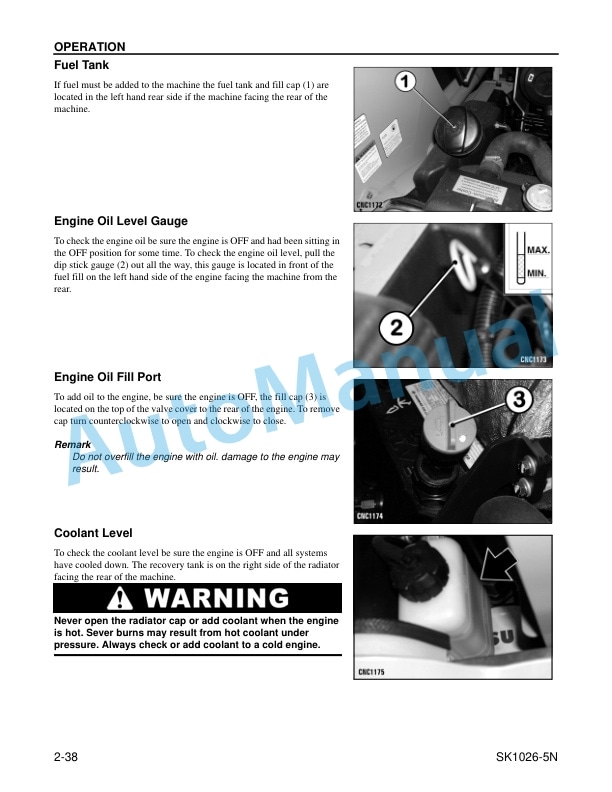

- 4.4.1. Fluid Fill and Check Locations

- 4.5. SAFETY LOCKS AND SECURITY

- 4.5.1. Ignition Switch

- 4.5.2. Hood Lock

- 4.5.3. Loader Arm Support

- 4.5.4. Master Electrical Disconnect

- 4.6. PATTERN CONTROL SYSTEM

- 4.6.1. Changing Pattern Control

- 4.6.2. ISO Pattern Control

- 4.6.3. Optional Pattern Control

- 4.7. FUSES AND RELAYS

- 4.7.1. System Fuses

- 4.7.2. Main Fuse

- 4.7.3. Relays

- 4.8. STARTING THE MACHINE

- 4.8.1. StartUp Preparations

- 4.8.2. Starting the Engine

- 4.9. GENERAL TRAVEL WITH THE MACHINE

- 4.9.1. Travel Route

- 4.9.2. Travel on Hills or Slopes

- 4.9.3. Traveling with a Load

- 4.9.4. Traveling in Water

- 4.10. TRAVELING IN ISO OR OPTIONAL PATTERN

- 4.10.1. Operating in ISO Pattern

- 4.10.2. Operating in Optional Pattern

- 4.11. PARKING THE MACHINE

- 4.11.1. Parking on Level Ground

- 4.11.2. Parking on Slopes

- 4.12. USING THE WORK EQUIPMENT

- 4.12.1. Situations to Avoid

- 4.12.2. Cutting a Grade and Leveling

- 4.12.3. Loading Material

- 4.13. CHANGING BUCKET OR ATTACHMENT

- 4.13.1. Locking the Bucket or Attachment

- 4.13.2. Unlocking the Bucket or Attachment

- 4.13.3. Removing the Bucket or Attachment

- 4.13.4. Attaching the Bucket

- 4.13.5. Checking Position of the Locking Pins

- 4.13.6. Adjusting the Locking Pins

- 4.14. TRANSPORTING THE MACHINE

- 4.14.1. Loading and Unloading the Machine

- 4.14.2. Transport

- 4.14.3. Emergency Recovery

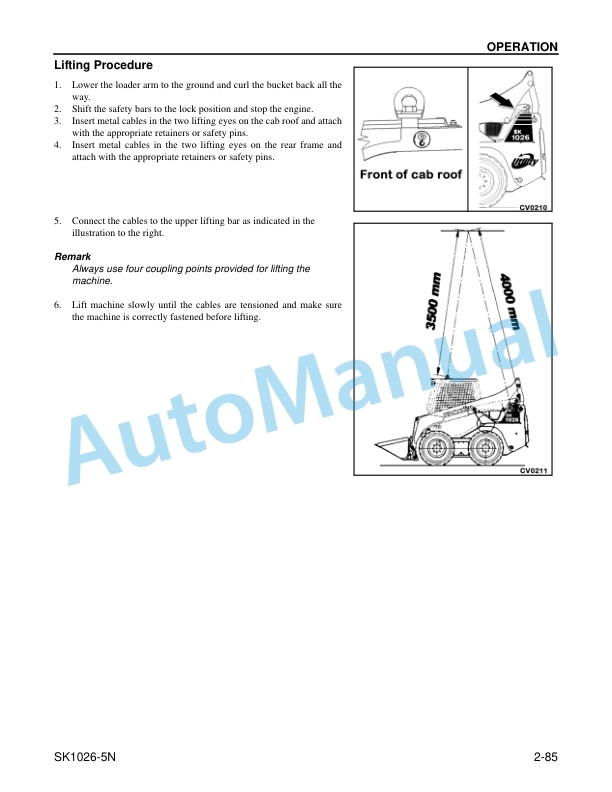

- 4.14.4. Lifting the Machine

- 4.15. PRECAUTIONS DURING SEASONAL CHANGES

- 4.15.1. Cold Seasons

- 4.15.2. Warm Seasons

- 4.16. LONG PERIODS OF INACTIVITY

- 4.16.1. Before Inactivity

- 4.16.2. After Inactivity

- 4.17. BASIC TROUBLESHOOTING

- 4.17.1. The Battery

- 4.17.2. Electrical Circuits

- 4.17.3. Hydraulic System

- 4.17.4. Engine

- 4.17.5. Hydrostatic Transmission

- 4.18. ADDTIONAL PRECAUTIONS TO BE TAKEN

- 4.18.1. Using Synthetic Biodegradable Oil Type HEES

- 4.18.2. Critical Parts

- 5. MAINTENANCE

- 5.1. GUIDE TO MAINTENANCE

- 5.2. MAINTENANCE NOTES

- 5.2.1. Notes Regarding The Engine

- 5.2.2. Notes Regarding the Hydraulic System

- 5.2.3. Notes Regarding The Electrical System

- 5.2.4. Notes Regarding Lubrication

- 5.3. FUEL, COOLANT AND LUBRICANTS

- 5.3.1. Proper Selection Of Fuel, Coolant And Lubricants

- 5.3.2. Lubrication with Grease

- 5.4. HOMOLOGATED (HEES) SYNTHETIC BIODEGRADABLE LUBRICANTS

- 5.5. DRIVING TORQUES FOR SCREWS AND NUTS

- 5.5.1. Standard Driving Torques

- 5.5.2. Specific Driving Torques

- 5.6. LUBRICATION

- 5.6.1. Lubrication Diagram

- 5.7. PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY

- 5.7.1. Critical Parts For Safety

- 5.8. MAINTENANCE SCHEDULE CHART

- 5.9. MAINTENANCE PROCEDURES

- 5.9.1. Servicing When Required

- 5.9.2. Checks Before Starting

- 5.9.3. Initial 50 Hours Service

- 5.9.4. Every 50 Hours Service

- 5.9.5. Initial 250 Hours Service

- 5.9.6. Every 250 Hours Service

- 5.9.7. Initial 500 Hours Service

- 5.9.8. Every 500 Hours Service

- 5.9.9. Every 1000 Hours Service

- 5.9.10. Every 2000 Hours Service

- 6. SPECIFICATIONS

- 6.1. TECHNICAL DATA

- 6.1.1. Standard Machine Overall Dimensions

- 6.1.2. Machine Overall Dimensions With Optional Equipment

- 6.1.3. Technical Characteristics

- 7. OPTIONS, ATTACHMENTS

- 7.1. AUTHORIZED OPTIONAL EQUIPMENT

- 7.1.1. Basic Precautions

- 7.1.2. Optional Equipment Measurements

- 7.2. CHANGING AUTHORIZED EQUIPMENT

- 7.2.1. Connecting the Backhoe

- 7.2.2. Connecting The Hydraulic Circuit

- 7.2.3. Connecting Direct Drain Circuit

- 7.3. PREPARING THE MACHINE FOR THE BACKHOE

- 7.3.1. Using the Machine with the Backhoe

- 7.3.2. Backhoe Locks (If Installed)

- 7.4. PALLET FORKS

- 7.5. COLD PLANER LOCKS (IF INSTALLED)

- 7.6. HAND AND FOOT CONTROL SYSTEM

- 7.6.1. Machine Controls

- 7.6.2. Travel and Steering Control Levers

- 7.6.3. Work Equipment Control Pedals

- 7.6.4. Auxiliary Hydraulic Control Lever

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF