Claas Lexion 430-410 (543) Combines Operator Manual EN

$50.00

- Model: Lexion 430-410 (543) Combines

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 325 MB

File List:

00 0018 552 1.pdf

00 0295 470 1.pdf

00 0298 425 0.pdf

00 0298 589 0.pdf

00 0298 852 1.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 1405 164 7.pdf

00 1405 184 7.pdf

00 1420 028 4.pdf

00 1420 056 2.pdf

00 0018 552 1.pdf:

TELEMATICS Website

Table of contents

1 About this Concise Operator’s Manual

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Notes regarding the Concise Operator’s Manual

1.1.3 Notes on warranty

2.1 Intended use

2.1.1 Proper use

3 Product description

3.1 Overview and method of operation

3.1.1 TELEMATICS product variants

3.1.2 TONI (TELEMATICS on implements)

3.1.3 Fleet View

3.1.4 TELEMATICS basic

3.1.5 TELEMATICS advanced

3.1.6 TELEMATICS professional

3.1.7 TELEMATICS app

4 Operating and control elements

4.1 TELEMATICS overview

4.1.1 Illustration conventions of buttons and navigation elements

4.1.2 Symbols and colours

4.2 Menu structure

4.2.1 Start screen

4.2.2 TELEMATICS website site map

4.2.3 Main menu overview

4.2.4

4.2.5

4.2.6

00 0295 470 1.pdf:

1 An-/Abkuppeln Anhänger

1.1 Hinweise zum An-/Abkuppeln von Anhängern

1.1.1 Allgemeine Hinweise

1.1.2 Allgemeine Sicherheitshinweise

1.1.3 Anhänger ankuppeln

1.1.4 Anhänger abkuppeln

1 Hitching/unhitching a trailer

1.1 Information about hitching/unhitching trailers

1.1.1 General information

1.1.2 General safety instructions

1.1.3 Hitching the trailer

1.1.4 Unhitching the trailer

1 Atteler / deteler a trailer

1.1 Conseils pour atteler / deteler the trailers

1.1.1 General councils

1.1.2 General safety advice

1.1.3 Workshop the trailer

1.1.4 Deteler the trailer

1 Hooking / unhooking the trailer

1.1 Instructions for hooking and unhooking the trailer

1.1.1 General warning

1.1.2 General safety rule

1.1.3 Hooking up the trailer

1.1.4 Sgo del rimorchio

1 Hook/unhook the trailer

1.1 Indications relating to hooking/unhooking trailers

1.1.1 General indications

1.1.2 General security measures

1.1.3 Hitch the trailer

1.1.4 Unhook the trailer

1 Coupling / uncoupling trailer

1.1 Indications relating to the coupling / uncoupling of trailers

1.1.1 General indications

1.1.2 General safety instructions

1.1.3 Attach trailer

1.1.4 Uncoupling or towing

1 Aan-/afkoppelen van tänders

1.1 Aanwijzingen bij het aan-/afkoppelen van tänders

1.1.1 General instructions

1.1.2 General safety instructions

1.1.3 Aanhanger aankoppelen

1.1.4 Aanhanger afkoppelen

1 Til-/frakoppling af anhænger

1.1 Anvisings til til-/frakoppling af anhængere

1.1.1 General notices

1.1.2 General safety instructions

1.1.3 Tilkoppling af anhänger

1.1.4 Frakoppling af anhänger

1 Till-/frånkällung av släpvagn

1.1 Anvisningar för till-/frånkolloppung av släpvagnar

1.1.1 General instructions

1.1.2 Generacautions

1.1.3 Tillkoppling av släpvagn

1.1.4 Disconnecting the trailer

1 Til-/frakoppling av tilhenger

1.1 Information on til-/frakoppling av tilhengere

1.1.1 General notices

1.1.2 General security information

1.1.3 Koble på tilhenger

1.1.4 Koble fra tilhengeren

1 Perävaunun täkkäminen/irrotatänä

1.1 Perävaunun küppä-/irrotusohjeet

1.1.1 Generality

1.1.3 Vehicle coupling

1.1.4 Perävaunun irrotus

1 Piekabes piekabinâ²ana/atkabinâ²ana

1.1 Norâdîjumi par piekabju piekabinâ²anu/atkabinâ²anu

1.1.1 Vispârîgie norâdîjumi

1.1.2 Vispârîgie dro²îbas norâdîjumi

1.1.3 Piekabes piekabinâ²ana

1.1.4 Piekabes atkabinâ²ana

1 Priekabø prikabinimas ir atkabinimas

1.1 Nurodymai priekaboms prikabinti ir atkabinti

1.1.1 Instructions

1.1.3 Priekabos prikabinimas

1.1.4 Connecting Priekabos

1.1.1 Üldised juhised

1.1.2 Üldised saifsjuhised

1.1.4 Haagise lahtiühendamine

1 Do-/od¸¶czanie przycepy

1.1 Wżczówki1 General instructions

1.1.2 General safety tips

1.1.3 Do¸¶czanie przycepy

1.1.4 Od¸¶czanie przycepy

1 Çàêà÷âàíå/îòêà÷âàíå íà ²åìà²êå

1.1 ÓêàçàíèØ çà çàêà÷âàíå/îòêà÷âàíå íà ²åìà²êåòà

1.1.1 Îáùè óêàçàíèØ

1.1.2 Îáùè èíñò²óêöèè çà áåçîïàñíîñò

1.1.3 Çåêà÷âàíå íà ²åìà²êå

1.1.4 Îòêà÷âàíå íà ²åìà²êåòî

1 Pøipojit/odpojit pøívìs

1.1 Pokyny pro pøipojování a odpojování pøívìsù

1.1.1 Vðobecná upozornìní

1.1.2 Vðobeconné bezpeènostní obsední

1.1.3 Personal connection

1.1.4 Personal disconnection

1 Cuplarea and decuplarea remorcii

1.1 Instruc iuni pentru cuplarea și decuplarea remorcilor

1.1.1 Indicate ii general

1.1.2 General safety instruction at work

1.1.3 Couplarea remorcii

1.1.4 Decuplaria remorcii

1 ÓÆíäåóç/Á²ïóÆíäåóç ñõìïõëêïÆìåíïõ

1.1 Õ²ïäåßîi Utasítás a pótkocsik fel- / leszállához

1.1.1 General instructions

1.1.2 General safety instructions

1.1.3 A pótkocsi (pótkocsi) felszóksi

1.1.4 A pótkocsi (pótkocsi) leszpóksi

1 Spajanje/odvajanje påres

1.1 Napomene uz spoženje/odvajanje prálakas

1.1.1 Opæenite napomene

1.1.2 Opæenite security napomene

1.1.3 Trailer coupling

1.1.4 Trailer removal

1 Pripojit’/odpojit’ ships

1.1 Pokyny na pripájanie a odpájanie návesov

1.1.1 I saw instructions

1.1.2 Vðobeconné bezpeènostné instructions

1.1.3 Návesu: Pripojenie

1.1.4 Odpojenie návesu

1 Priklop/odklop trailers

1.1 Instructions for priklop/odklop prikolic

1.1.1 Sploðna navoda

1.1.2 Exploding safety warning

1.1.3 Priklop trailers

1.1.4 Priklop trailers

1 Zakaèivanje/otkaèivanje tähälä

1.1 Instructions for the trailer

1.1.1 Opðte napomene

1.1.2 Choose safety instructions

1.1.3 Zakaèiti prikolicu

1.1.4 Otkaèiti prikolicu

1 Ïîäñîåäèíåí????????? /??????????? ???????

1.1.1 ????? ????????

1.1.2 ????? ???????? ?? ????????????

1.1.3 ϲ??????????? ??????

1.1.4 ??????????? ?????

1 R?mork ba?lama/??zme

1.1 R?mork ba?lama/??zme ile ilgidi bilgiler

1.1.1 General information

1.1.2 General security uyar?lar?

1.1.3 R?mork ba?lama

1.1.4 R?morkun d?zmelmesi

00 0298 425 0.pdf:

Introduction

Introduction

General information

Road traffic regulations

Identification plate / Serial number

Identification plate

Combine serial number

Engine serial number CATERPILLAR C9

Engine serial number CATERPILLAR 3126 B

Straw chopper identification plate

Cabin serial number

Safety rules

Safety rules

Safety lock

Fire extinguisher

Battery master switch

Wheel chocks

Positioning the wheel chocks

Safety decals with pictorials

Specifications

Conversion factors

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 410

CLAAS LEXION 410

CLAAS LEXION 410

Safety features

Front attachments – weights and dimensions

Prior to operation

Perform the following steps prior to operation

Cabin with Climatic

Operating and display elements

Putting the Climatic into operation

Setting the cabin temperature

Manually setting the evaporator blower speed

Fully automatic heating

Manually setting the heating

Floor heating

REHEAT operation (Dehumidify cab windows)

Displaying the outside temperature

Switching the temperature display to Fahrenheit

Display of malfunction: error in thermometer F0 (cabin, blue)

Display of malfunction: error in thermometer F1 (exhaust, yellow)

Display of malfunction: error in thermometer F2 (outside, red)

Cabin with air conditioner (Standard version)

Cabin with compressor-type air conditioning system

Cabin with heating

For heating

Demister System (Fogged windows)

Problem, possible cause and / or remedy – Compressor-_x0004_type air conditioner

Opening and closing the cabin roof

Windscreen washer system

Operator’s platform

Operator’s platform – Overview

Switch console

Monitor (Vehicle information display)

Monitor (Harvest display)

Rotary switch D

Steering column

Ignition switch (S)

Multi-function switch

Vehicle information unit

Multi-function handle

Adjusting the steering column

Swinging the steering column at the top

Steering wheel height adjustment

Central electrics

Swing grain tank unloading tube out and in

Safety feature

Switching grain tank unloading on and off

Switching threshing mechanism on and off

Operator’s seat

Operator’s seat, mechanical

Operator’s seat with air suspension (Optional equipment)

Front ladder

Hinged ladder

Access and ladder extension

Side position lights iexcess width

Side lights in case of excess width

Rear ladder

Other uses of the rear ladder

Driving the combine

Engine speed rotary switch

Manoeuvring

Starting the engine

Gear ranges

Servo gearshift (Optional equipment)

Adjusting the binds of the ground speed control lever

Driving behaviour

Foot brake

Parking brake

Stopping the engine

CLAAS Autopilot (Maize picker head)

CLAAS Autopilot (Grain cutterbar)

Adjusting the directional stability of the combine

Setting the laser sensor in the field

Putting the CLAAS Autopilot into operation

Use in rape with left-hand side cutter

Cutterbar hydraulic cylinders

Attaching cutterbar hydraulic cylinders

Third cutterbar cylinder

Rear wheel drive axle

Adjusting rear wheel drive axle from transport to working position

Wheel tread adjustment – Rear wheel drive axle

Adjustable rear axle

Rear axle wheels – steering angle limiter (Adjustable reale)

Side panels

Opening and closing the side panels and the rear door

Adjusting the side panel / rear door locks

Cabin and lighting

Headlights, worklights and mirrors

Towing / Crop inspection / Grain tank

Crop inspection

Grain tank

Closing the grain tank openings

Installing dual wheels

Operating the front ladder with dual tyres installed

Additional weights

Liquid filling for rear axle tyres

Installing the rear axle weights

Installing and removing the cutterbar

Installing the cutterbar

Tilting the cutterbar from transport position

Machines equipped with CLAAS Auto Contour

Adjusting the hydraulic cylinder for transverse cutter_x0004_bar control

Machines without CLAAS Auto Contour

Locking cutterbars and maize pickers (Cutterbars without Auto Contour)

Connecting the universal drive shafts

Fitting the stand

Removing the cutterbar

Removing the cutterbar

Laying down the cutterbar on the ground

Placing the cutterbar on the cutterbar trailer

Operation CEBIS

Operation – basic machine

Feeder housing

Cutterbar reverse drive

Cutterbar floatation springs

Checking the setting of the cutterbar floatation springs

Cutting height indicator

Cutterbar spring pressure indicator

Blocking the cutterbar floatation springs

Adjusting drop rate of the front attachment

Cutterbar clutch

Engaging and disengaging the cutterbar

Threshing mechanism

Stone trap

Engaging and disengaging the threshing mechanism

Threshing drum

Cleaning the threshing parts

Basic concave setting

Learning the limit stops

Threshing drum speed

Threshing drum drives

Threshing drum two-step variable speed drive

Installing and removing preconcave segments

Concave segment

Removing the concave segment

Installing the concave segment

Unslugging the threshing drum

Deflector curtain

Straw walkers

Straw walkers

Intensive separation system

Multiple finger paration system

Cleaning the straw walkers

Warning signal

Straw walker risers

Rice risers

Centre risers

Side risers

Parallel risers

CCM risers

Preparation floor

Frogmouth sieves

Electrical sieve adjustment

Removing the sieves

Installing the sieves

Tightening torques of axial mountings for _the upper and lower sieves

Sieves – Basic setting

Harvesting without finishing sieves

Cleaning fan

Electric fan speed adjustment

Wind-controlled cleaning step LEXION 460 – 420

Adjustment of primary wind duct LEXION 460 – 420

Wind board LEXION 460 – 420

Wind boards LEXION 410

Fan shutters for combining grass seed and other special crops (Extra equipment)

Dynamic sidehill levelling (3-D cleaning system)

Combine performance monitor

Grain delivery

Augers and auger troughs

Grain tank

Grain tank extension – electrical (9300 / 8500 litres grain tank)

Grain tank extechanical (8100 / 7800 / 7300 litres grain tank)

Unloading the grain tank

Grain tank unloading aid (Extra equipment)

Grain tank unloading tube

Swinging the unloading tube out and in

Inspection doors on the grain tank unloading tube

Shear bolt for grain tank unloading

Grain tank unloading – engaging and disengaging

Grain tank access

Automatic chain lubrication – grain tank unloading (Extra equipment)

Straw chopper

Straw chopper (hydraulic)

Before using the straw chopper, check

Adjusting spreading width

Spreader hopper height adjustment

Electric deflector adjustment

Adjusting the length of cut

Adjusting cross knife

Putting the straw chopper into operation

Putting the straw chopper out of operation

Chopper position for hitching the cutterbar trailer

Reducing the speed of the straw chopper

Moving the V-belt (12) on the pulley

Straw chopper

Straw chopper (rigid straw chopper)

Before u the straw chopper, check

Adjusting spreading width

Spreader hopper height adjustment

Electric deflector adjustment

Adjusting the length of cut

Adjusting cross knife

Putting the straw chopper into operation

Putting the straw chopper out of operation

Chopper position for cutterbar trailer hitching

Reducing the chopper speed

Chaff spreader / Straw spreader

Chaff spreader

Folding the chaff spreader open

Straw spreader

Adjusting the spread pattern

Sieve chart and suggested combine adjustments

Sieve chart

Suggested_x0004_ combine adjustments

Disawner plates

Threshing segment

Problem, cause and / or remedy – Basic machine

Maintenance – basic machine

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedules

Lubricants charts

Hydraulic system

Hydraulic accumulators

Checking thl level

Changing hydraulic oil

Changing the hydraulic oil filter

Cleaning the coarse filter

Refilling the system after a hydraulic oil change (Sauer 90 R 130 / 90 M 100)

Bleeding the hydraulic cylinders for cutterbar transverse control

Transmission / Brakes

Transmission gearbox

Checking the oil level

Oil change

Final drives (2-step) (20 t / 19 t / 20 t HD)

Checking the oil level

Oil change

Final drives (Planetary gear)

Checking the oil level

Oil change

Threshing drum two-step variable speed drive

Oil change

Checking the oil level

Transfer gearbox

Checking the oil level

Oil change

Grain tank unloading transmission

Checking the oil level

Oil change

Gear shift control adjustment

Foot brake and brake fluid

Parking brake

Feeder housing

Tension feeder chains

Cleaning the suction blower (extra equipment)

Elevator Chains

Tensioning the grain elevator chain (Combines without yield meter)

Tensioning the grain elevator chain (Combines with yield meter)

Tensioning the returns elevator chain

Drive belts / drive chains – basic machine

General notes

Drive system diagram, left-hand side

Drive belts and chains

Drive system diagram, right-hand side

Drive belts

Removing the cutterbar drive belt (1) (Cutterbar drive without variable-speed drive)

Installing and adjusting the cutterbar drive belt (1)

Removing the cutterbar drive belt (2) (Cutterbar drive with variable-speed drive)

Installing and tensioning the cutterbar drive belt (2)

Removing the cutterbar variable-speed drive belt (3)

Installing the cutterbar variable-speed drive belt (3)

Removing the impeller drive belt (4)

Installing and adjusting the impeller drive belt (4)

Removing the cutterbar intermediate drive belt (5)

Installing and adjusting the cutterbar inter_x0004_mediate drive belt (5)

Removing theydraulic pump drive belt (6) for straw spreader / chaff spreader

Installing and adjusting the hydraulic pump drive belt (6) for straw spreader / chaff spreader

Removing the main intermediate drive belt (7)

Installing and adjusting the main intermediate drive belt (7)

Removing the intermediate drive belt for grain tank unloading (8)

Installing and adjusting the intermediate drive belt for grain tank unloading (8)

Removing the straw chopper intermediate drive belt (9)

Installing and adjusting the straw chopper intermediate drive belt (9)

Straw chopper drive adjustment

Relieving the tension on V-belt (10) at spring-loaded_x0004_ cylinder (G) and removing the belt

Installing the V-belt (10) and tensioning the belt by means of spring-loaded cylinder (G)

Relieving the tension on drive belt (11) at spring-loaded cylinder (G) and removing the belt

Installing the drive belt (11) and tensioning it at spring-loaded cylinder (G)

Relieving the tension on straw chopper drive belt (12) and removing the belt (hydraulic straw cho…

Installing the straw chopper drive belt (12) and tensioning it at spring-loaded cylinder (F) (hyd…

Removing the sieve pan intermediate drive belt (13)

Installing and adjusting the sieve pan inter_x0004_mediate drive belt (13)

Removing the sieve pan intermediate drive belt (14)

Installing and adjusting the sieve pan inter_x0004_mediate drive belt (14)

Removing the sieve pan drive belt (15)

Folding the battery box / tool cabinet open:

Installing and adjusting the sieve pan drive belt (15)

Removing the fan intermediate drive belt (20)

Installing and adjusting the fan intermediate drive belt (20)

Removing the fan drive belt (21)

Installing the fan drive belt (21)

Removing the threshing mechanism variable speed drive belt (22)

Installing the threshing mechanism variable speed drive belt (22)

Removing the threshing drum drive belt (23)

Installing and adjusting the threshing drum drive belt (23)

Removing the accelerator drive belt (24)

Installing and adjusting the accelerator drive belt (24)

Removing the rotary radiator screen suction drive belt (28)

Installing and adjusting the rotary radiator screen suction drive belt (28)

Tensioning the rotary radiator screen drive belt (32)

Tensioning the suction blower drive belt (34)

Removing the grain tank unloading drive chain (17)

Installing and adjusting the grain tank unloading drive chain (17)

Cabin / Compressor-type air conditioner

Cleaning the filters

Cleaning the units located in the cabin roof

Compressor-type air conditioning system

Cleaning the condenser

Checking the refrigerant level

Replacing the filter receiver-drier

Required refrigerant charge – refrigerant R 134 a

Compressor oil

Maintenance work before the harvest

Fire extinguisher

Fire extinguisher

Compressed air system (Era equipment)

Compressed air connections

Draining the compressed air accumulator

Pressure controller

Straw chopper

Swinging down the straw guide plate

Replacing the free-swinging knives

Swinging back the straw guide plate

Replacing the knives (rigid straw chopper)

Removing the straw guide plate

Replacing the free-swinging knives

Installing the straw guide plate

Replacing the stationary knives

Spreading unit

Installing and adjusting the toothed belt

Speed monitoring

Setting the magnetic pick-ups (sensors)

Winter storage instructions for combines

Maintenance – engine

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedule

Lubricants chart

Maintenance – engine

Engine overview

Fuel system

Water separator / fuel pre-filter (Extra equipment – small version)

Fuel pre-filter, disassembled:

Waparator / Fuel pre-filter (Extra equipment, replaces fuel pre-filter Fig.8)

Water separator / fuel pre-filter disassembled:

Fuel filter

Replacing the filter cartridge

Bleeding the fuel system

Checking engine oil level

Engine oil change

Draining the old oil

Oil filter

Filling in engine oil

Cooling system

Water drain plugs on the engine block

Water cooler

Filling the cooling system with coolant

Overpressure

Antifreeze / corrosion protection

Warning notice

Cooling water temperature

Stopping the engine when overheated

Radiator rotary screen

Cleaning the radiator

Dry-type air cleaner

Warning device

Cleaning the air cleaner intake screen

Cleaning dry-type air cleaner

Cleaning the air cleaner

Safety filter cartridge

Electrical equipment

Alternator

Engine problems, cause and / or remedy

Engine winter storage

Engine preservation

Lubrication chart

Lubricants and lubrication instructions

0298_298_1_BA_EN_144.pdf

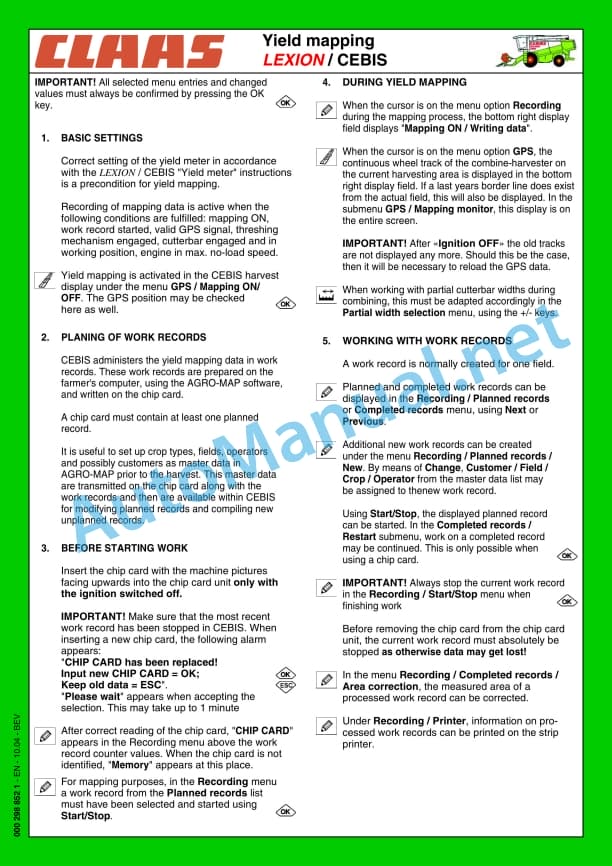

Operation CEBIS

CLAAS on-board information system (CEBIS)

CEBIS Monitor and rotary switch

Rotary switch D

Multifunctional handle M

Window sections E (Harvest display)

Rotary switch D

Prior-to-initial operation

Vehicle information display

Harvest display

Mapping ON/OFF

Mapping monitor

Presettings reel

Reel horizontal position

Reel speed

Reel height

Presettings front attachment

Clearance between snapping plates

Cutterbar table length

Cutting height settings (CAC)

Partial width selection

Yield meter

Componentes

Basic setting and calibration

Preparation for yield measurement

Moisture measurement ON/OFF, moisture correction_x0004_, storage moisture

Quick guide to accurate measuring data

Yield measurement

Calibration factor

Set zero yield

Test-weighing

Weight measured

Moisture correction

Moisture mesaurement ON/OFF

Set zero angle

Storage moisture

Display dry yield

Setting combine to type of crop

List of threshable crops

Load CLAAS adjustments

Load own adjustments

Save own adjustments

Print machine adjustments

Display of CLAAS adjustments

Display of own adjustments

Cleaning by blowing

Recording harvest work

Planned work records

Next planned work record

Previous planned work record

New planned work record

Change work record

Name / Field / Crop / Operator:

Start / Stop

Data recorded:

Completed work records

Next or previous completed work record

Restart a completed work record

Area correction

Daily recorder

Printing daily recorder

Clear daily recordings

Total recorder

Printing recorder summaries

Copy the chip card

Adjustments

Sensitivity CAC

Cutterbar upper and lower limits

Partial width proportions

Working position

Working width

Auto reel height

Reel end stops

Cutterbar automatics

Cutterbar table length stops

Fore & aft reel adjustment stops

Vario automatics ON/OFF

Snapping plate end stops

Learning speeds

Learning max. no-load speed

Belt slip limit indicator

Chaff spreader speed monitor (no function on rotor machines)

Returns RPM monitor

Tachometer

Calibration run

Impulses/100

Sensitivity Autopilot

Zero Autopilot front attachment

Zero steering

Separation

Sensor test

Upper and lower sieve end stops

Upper and lower sieve adjustment

Returns limit

Set zero returns

Display Positive/Negative

Measuring units

Time display:

Maintenance

XXh service list

Operator’s manual

Basic settings

Standard settings:

Specific standard settings:

Guide to adjustments

Problems/Remedies

Check list

Safety rules

Code protection

Switching off code protection:

Engine load

Engine diagsis

Problems / remedies – yield meter

Guide for impulses / 100 m

00 0298 589 0.pdf:

Introduction

Introduction

General information

Road traffic regulations

Identification plate / Serial number

Identification plate

Combine serial number

Engine serial number CATERPILLAR C9

Engine serial number CATERPILLAR 3126 B

Straw chopper identification plate

Cabin serial number

Safety rules

Safety rules

Safety lock

Fire extinguisher

Battery master switch

Wheel chocks

Positioning the wheel chocks

Safety decals with pictorials

Specifications

Conversion factors

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 410

CLAAS LEXION 410

CLAAS LEXION 410

Safety features

Front attachments – weights and dimensions

Prior to operation

Perform the following steps prior to operation

Cabin with Cmatic

Operating and display elements

Putting the Climatic into operation

Setting the cabin temperature

Manually setting the evaporator blower speed

Fully automatic heating

Manually setting the heating

Floor heating

REHEAT operation (Dehumidify cab windows)

Displaying the outside temperature

Switching the temperature display to Fahrenheit

Display of malfunction: error in thermometer F0 (cabin, blue)

Display of malfunction: error in thermometer F1 (exhaust, yellow)

Display of malfunction: error in thermometer F2 (outside, red)

Cabin with air conditioner (Standard version)

Cabin with compressor-type air conditioning system

Cabin with heating

Floor heating

Demister System (Fogged windows)

Problem, possible cause and / or remedy – Compressor-_x0004_type air conditioner

Opening and closing the cabin roof

Windscreen washer system

Operator’s platform

Operator’s platform – Overview

Switch conso Monitor area A

Rotary switch D

Monitor area B

Steering column

Ignition switch (S)

Multi-function switch

Vehicle information unit

Multi-function handle

Adjusting the steering column

Swinging the steering column at the top

Steering wheel height adjustment

Central electrics

Swing grain tank unloading tube out and in

Safety feature

Switching grain tank unloading on and off

Switching threshing mechanism on and off

Operator’s seat

Operator’s seat, mechanical

Operator’s seat with air suspension (Optional equipment)

Front ladder

Hinged ladder

Access and ladder extension

Side position lights in case of excess width

Side lights in case of excess width

Rear ladder

Other uses of the rear ladder

Driving the combine

Engine speed rotary switch

Manoeuvring

Starting the engine

Gear ranges

Servo gearshift (Optional equipment)

Adjusting the binds of the ground speed contrlever

Driving behaviour

Foot brake

Parking brake

Stopping the engine

CLAAS Autopilot (Maize picker head)

CLAAS Autopilot (Grain cutterbar)

Adjusting the directional stability of the combine

Setting the laser sensor in the field

Putting the CLAAS Autopilot into operation

Use in rape with left-hand side cutter

Cutterbar hydraulic cylinders

Attaching cutterbar hydraulic cylinders

Third cutterbar cylinder

Rear wheel drive axle

Adjusting rear wheel drive axle from transport to working position

Wheel tread adjustment – rear wheel drive axle

Adjustable rear axle

Rear axle wheels – steering angle limiter (Adjustable rear axle)

Side panels

Opening and closing the side panels and the rear door

Adjusting the side panel / rear door locks

Cabin and lighting

Headlights, worklights and mirrors

Towing / Crop inspection / Grain tank

Crop inspection

Grain tank

Closing the grain tank openings

Inling dual wheels

Operating the front ladder with dual tyres installed

Additional weights

Liquid filling for rear axle tyres

Installing the rear axle weights

Installing and removing the cutterbar

Installing the cutterbar

Tilting the cutterbar from transport position

Machines equipped with CLAAS Auto Contour

Adjusting the hydraulic cylinder for transverse cutter_x0004_bar control

Machines without CLAAS Auto Contour

Locking cutterbars and maize pickers (Cutterbars without Auto Contour)

Connecting the universal drive shafts

Fitting the stand

Removing the cutterbar

Removing the cutterbar

Laying down the cutterbar on the ground

Placing the cutterbar on the cutterbar trailer

Operation IMO

Operation – basic machine

Feeder housing

Cutterbar reverse drive

Cutterbar floatation sprin

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese