Claas Lexion 470 (545) Combines Operator Manual EN

$50.00

- Model: Lexion 470 (545) Combines

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 303 MB

File List:

00 0295 470 1.pdf

00 0298 247 1.pdf

00 0298 852 1.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 1405 164 7.pdf

00 1405 184 7.pdf

00 1420 028 4.pdf

00 1420 056 2.pdf

00 0295 470 1.pdf:

1 An-/Abkuppeln Anhänger

1.1 Hinweise zum An-/Abkuppeln von Anhängern

1.1.1 Allgemeine Hinweise

1.1.2 Allgemeine Sicherheitshinweise

1.1.3 Anhänger ankuppeln

1.1.4 Anhänger abkuppeln

1 Hitching/unhitching a trailer

1.1 Information about hitching/unhitching trailers

1.1.1 General information

1.1.2 General safety instructions

1.1.3 Hitching the trailer

1.1.4 Unhitching the trailer

1 Atteler / deteler a trailer

1.1 Conseils pour atteler / deteler the trailers

1.1.1 General councils

1.1.2 General safety advice

1.1.3 Workshop the trailer

1.1.4 Deteler the trailer

1 Hooking / unhooking the trailer

1.1 Instructions for hooking and unhooking the trailer

1.1.1 General warning

1.1.2 General safety rule

1.1.3 ing up the trailer

1.1.4 Sgancio del rimorchio

1 Hook/unhook the trailer

1.1 Indications relating to hooking/unhooking trailers

1.1.1 General indications

1.1.2 General security measures

1.1.3 Hitch the trailer

1.1.4 Unhook the trailer

1 Coupling / uncoupling trailer

1.1 Indications relating to the coupling / uncoupling of trailers

1.1.1 General indications

1.1.2 General safety instructions

1.1.3 Attach trailer

1.1.4 Uncoupling or towing

1 Aan-/afkoppelen van tänders

1.1 Aanwijzingen bij het aan-/afkoppelen van tänders

1.1.1 General instructions

1.1.2 General safety instructions

1.1.3 Aanhanger aankoppelen

1.1.4 Aanhanger afkoppelen

1 Til-/frakoppling af anhænger

1.1 Anvisings til til-/frakoppling af anhængere

1.1.1 General notices

1.1.2 General safety instructions

1.1.3 Tilkoppling af anhänger

1.1.4 Frakoppling af anhänger

1 Till-/frånkällung av släpvagn

1.1 Anvisningar för till-/frånkolloppung av släpvagnar

1.1.1 Gections

1.1.2 General safety precautions

1.1.3 Tillkoppling av släpvagn

1.1.4 Disconnecting the trailer

1 Til-/frakoppling av tilhenger

1.1 Information on til-/frakoppling av tilhengere

1.1.1 General notices

1.1.2 General security information

1.1.3 Koble på tilhenger

1.1.4 Koble fra tilhengeren

1 Perävaunun täkkäminen/irrotatänä

1.1 Perävaunun küppä-/irrotusohjeet

1.1.1 Generality

1.1.3 Vehicle coupling

1.1.4 Perävaunun irrotus

1 Piekabes piekabinâ²ana/atkabinâ²ana

1.1 Norâdîjumi par piekabju piekabinâ²anu/atkabinâ²anu

1.1.1 Vispârîgie norâdîjumi

1.1.2 Vispârîgie dro²îbas norâdîjumi

1.1.3 Piekabes piekabinâ²ana

1.1.4 Piekabes atkabinâ²ana

1 Priekabø prikabinimas ir atkabinimas

1.1 Nurodymai priekaboms prikabinti ir atkabinti

1.1.1 Instructions

1.1.3 Priekabos prikabinimas

1.1.4 Connecting Priekabos

1.1.1 Üldised juhised

1.1.2 Üldised saifsjuhised

1.1.4 Haagise lahtiühendamine

1 Do-/odece do-/od¸¶czania przyczep

1.1.1 General instructions

1.1.2 General safety tips

1.1.3 Do¸¶czanie przycepy

1.1.4 Od¸¶czanie przycepy

1 Çàêà÷âàíå/îòêà÷âàíå íà ²åìà²êå

1.1 ÓêàçàíèØ çà çàêà÷âàíå/îòêà÷âàíå íà ²åìà²êåòà

1.1.1 Îáùè óêàçàíèØ

1.1.2 Îáùè èíñò²óêöèè çà áåçîïàñíîñò

1.1.3 Çåêà÷âàíå íà ²åìà²êå

1.1.4 Îòêà÷âàíå íà ²åìà²êåòî

1 Pøipojit/odpojit pøívìs

1.1 Pokyny pro pøipojování a odpojování pøívìsù

1.1.1 Vðobecná upozornìní

1.1.2 Vðobeconné bezpeènostní obsední

1.1.3 Personal connection

1.1.4 Personal disconnection

1 Cuplarea and decuplarea remorcii

1.1 Instruc iuni pentru cuplarea și decuplarea remorcilor

1.1.1 Indicate ii general

1.1.2 General safety instruction at work

1.1.3 Couplarea remorcii

1.1.4 Decuplaria remorcii

1 ÓÆíäåóç/Á²ïóÆíäåóç ñõìïõëe?

1 A p?tkocsi fel- / lesk?pa

1.1 Utas?t?s a p?tkocsik fel- / lesz?ll?hoz

1.1.1 General instructions

1.1.2 General safety instructions

1.1.3 A p?tkocsi (p?tkocsi) felsz?ksi

1.1.4 A p?tkocsi (p?tkocsi) leszp?ksi

1 Spajanje/odvajanje p?res

1.1 Napomene uz spo~enje/odvajanje pr?lakas

1.1.1 Op?enite napomene

1.1.2 Op?enite security napomene

1.1.3 Trailer coupling

1.1.4 Trailer removal

1 Pripojit’/odpojit’ ships

1.1 Pokyny na prip?janie a odp?janie n?vesov

1.1.1 I saw instructions

1.1.2 V?obeconn? bezpe?nostn? instructions

1.1.3 N?vesu: Pripojenie

1.1.4 Odpojenie n?vesu

1 Priklop/odklop trailers

1.1 Instructions for priklop/odklop prikolic

1.1.1 Splo?na navoda

1.1.2 Exploding safety warning

1.1.3 Priklop trailers

1.1.4 Priklop trailers

1 Zaka?ivanje/otka?ivanje t?h?l?

1.1 Instructions for the trailer

1.1.1 Op?te napomene

1.1.2 Choose safety instructions

1.1.3 Zaka?iti prikolicu

1.1.4 Otka?iti prikolicu

1 ?????????????/???????????? ??????

1.1 ???????? ?? ???????????? /??????????? ???????

1.1.1 ????? ????????

1.1.2 ????? ???????? ?? ????????????

1.1.3 ϲ??????????? ??????

1.1.4 ??????????? ?????

1 R?mork ba?lama/??zme

1.1 R?mork ba?lama/??zme ile ilgidi bilgiler

1.1.1 General information

1.1.2 General security uyar?lar?

1.1.3 R?mork ba?lama

1.1.4 R?morkun d?zmelmesi

00 0298 247 1.pdf:

Introduction

Introduction

General information

Road traffic regulations

Identification plate / Serial number

Identification plate

Combine serial number

Engine serial number CATERPILLAR C12

Engine serial number CATERPILLAR C9

Straw chopper identification plate

Cabin serial number

Safety rules

Safety rules

Safety lock

Fire extinguisher

Battery master switch

Wheel chocks

Positioning the wheel chocks

Safety decals with pictorials

Specifications

Conversion factors

CLAAS LEXION 480

CLAAS LEXION 480

CLAAS LEXION 480

CLAAS LEXION 470

CLAAS LEXION 470

CLAAS LEXION 470

Safety features

Front attachments – weights and dimensions

Prior to operation

Perform the following steps prior to operation

Cabin with Climatic

Operating and display elements

Putting the Climatic into operation

Setting the cabin temperature

Manually setting the evaporator blower speed

Fully automatic heating

Manually setting the heating

Floor heating

REHEAT operation (Dehumidify cab windows)

Displaying the outside temperature

Switching the temperature display to Fahrenheit

Display of malfunction: error in thermometer F0 (cabin, blue)

Display of malfunction: error in thermometer F1 (exhaust, yellow)

Display of malfunction: error in thermometer F2 (outside, red)

Cabin with air conditioner (Standard version)

Cabin with compressor-type air conditioning system

Cabin with heating

Floor heating

Demister System (Fogged windows)

Problem, cause and / or remedy – Compressor-type air conditioner

Opening and closing the cabin roof

Windscreen washer system

Operator’s platform

Operator’s platform – Overview

Switch console

Monitor (Vehicle information display)

Monitor (Harvest display)

Rotary switch D

Steering column

Ignition switch (S)

Multi-function switch

Vehicle information unit

Multi-function handle

Adjusting the steering column

Swinging the steering column at the top

Steering wheel height adjustment

Central electrics

Swing grain tank unloading tube out and in

Safety feature

Switching grain tank unloading on and off

Switching threshing mechanism on and off

Operator’s seat

Operator’s seat, mechanical

Operator’s seat with air suspension (Optional equipment)

Front ladder

Hinged ladder

Access and ladder extension

Side position lights in case of excess width

Side lights in case of excess width

Rear ladder

Other uses of the reder

Driving the combine

Engine speed rotary switch

Manoeuvring

Starting the engine

Gear ranges

Servo gearshift (Optional equipment)

Adjusting the binds of the ground speed control lever

Driving behaviour

Foot brake

Parking brake

Stopping the engine

CLAAS Autopilot (Maize picker head)

CLAAS Autopilot (Grain cutterbar)

Adjusting the directional stability of the combine

Setting the laser sensor in the field

Putting the CLAAS Autopilot into operation

Use in rape with left-hand side cutter

Cutterbar hydraulic cylinders

Attaching cutterbar hydraulic cylinders

Third cutterbar cylinder

Rear wheel drive axle

Adjusting rear wheel drive axle from transport to working position

Wheel tread adjustment – Rear wheel drive axle

Adjustable rear axle LEXION 470

Rear axle wheels – steering angle limiter (Adjustable rear axle)

8 t rear axle LEXION 480

Side panels

Opening and closing the side panels and the rear door

Adjusting the side panel / rear door locks

Cabin and lighting

Headlights, worklights and mirrors

Towing / Crop inspection / Grain tank

Crop inspection

Grain tank

Closing the grain tank openings

Installing dual wheels LEXION 480

Operating the front ladder with dual tyres installed

Additional weights LEXION 470

Installing the rear axle weights

Installing and removing the cutterbar

Installing the cutterbar

Tilting the cutterbar from transport position

Machines equipped with CLAAS Auto Contour

Adjusting the hydraulic cylinder for transverse cutterbar control

Machines without CLAAS Auto Contour

Locking cutterbars and maize pickers (Cutterbars without Auto Contour)

Connecting the universal drive shaft

Connecting the reel drive hydraulic hoses (Cutterbar with hydraulic reel drive)

Mounting the stands

Removing the cutterbar

Disconnecting the reel drive hydraulic hoses (Cutterbar with hydraulic reel drive)

Removing the universal drive shaft

Removing the universal coupling

Opening the cutterbar locking

Laying down the cutterbar on the ground

Placing the cutterbar on the cutterbar trailer

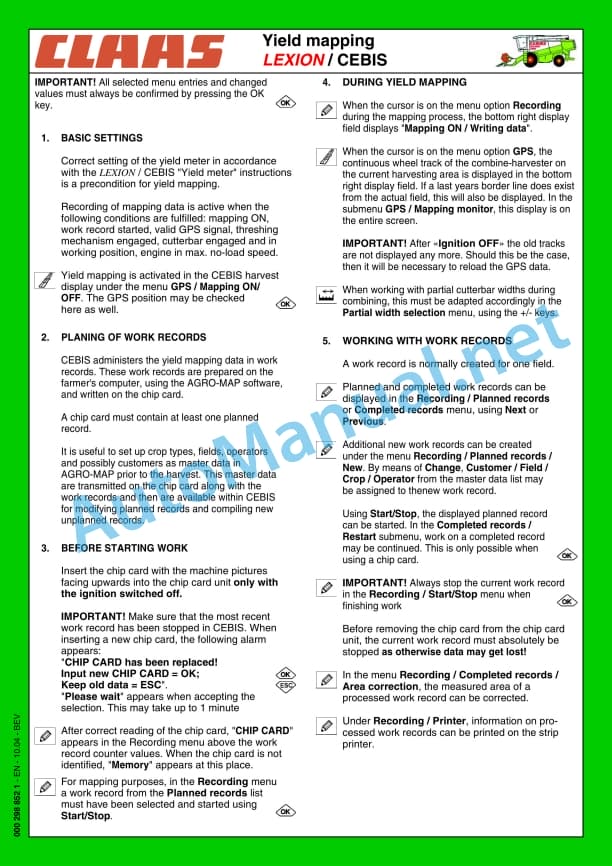

Operation CEBIS

Operation – basic machine

Feeder housing

Cutterbar reverse drive

Cutterbar floatation springs

Checking the setting of the cutterbar floatation springs

Cutting height indicator

Cutterbar spring pressure indicator

Blocking the cutterbar springs

Adjusting drop rate of the front attachment

Cutterbar clutch

Engaging and disengaging the cutterbar

Threshing mechanism

Stone trap

Engaging and disengaging the threshing mechanism

Threshing drum

Cleaning the threshing parts

Basic concave setting

Learning the limit stops

Threshing drum speed

Threshing drum drives

Threshing drum two-step variable speed drive

Installing and removing preconcave segments

Concave segment

Removing the concave segment

Installing the concave segment

Unslugging the threshing drum

Separation rotors LEXION 480

Separation rotors

Step drive

Variable-speed rotor drive (Optional equipment)

Removing the separation grates

Installing the separation grates

Warning signal

Covering the rotor separating jackets

Separation rotors LEXION 470

Separation rotors

Step drive

Variable-speed rotor drive (Optional equipment)

Dummy concaves

Installing and removing dummy concaves

Installing the dummy concaves

Warning signal

Preparation floor

Frogmouth sieves

Electrical sieve adjustment

Removing the sieves (Electric sieve adjustment system)

Installing the sieves

Tightening torques of axial mountings for the upper and lower sieves

Sieves – Basic setting

Harvesting without finishing sieves

Cleaning fan

Electric fan speed adjustment

Wind-controlled cleaning step

Adjustment of primary wind duct

Wind board

Fan shutters for combining grass seed and other special crops (Extra equipment)

Dynamic sidehill levelling (3-D cleaning system)

Combine performance monitor

Rotary separation system

Grain delivery

Augers and auger troughs

Grain tank

Grain tank extension

Unloading the grain tank

Grain tank unloading aid (Extra equipment)

Grain tank unloading tube

Swinging the unloading tube out and in

Inspection doors on the grain tank unloading tube

Shear bolt for grain tank unloading

Grain tank unloading – engaging and disengaging

Grain tank access

Automatic chain lubrication – grain tank unloading (Extra equipment)

Straw chopper / Uni-Spreader LEXION 480

Straw chopper

Before using the straw chopper for the first time, check

Adjusting length of cut

Adjusting the cross blade

Putting the straw chopper into operation

Uni-spreader fans

Adjusting the spreading width

Setting of the range of spreader spout swing

Putting the chopper out of operation and converting the machine for laying swaths

Removing the chopper feed pan

Reducing the chopper speed

Straw chopper / Chaff spreader LEXION 470

Straw chopper

Before using the straw chopper, check

Adjusting spreading width

Spreader hopper height adjustment

Electric deflector adjustment

Adjusting the length of cut

Adjusting cross knife

Putting the straw chopper into operation

Putting the straw chopper out of operation

Chopper position for cutterbar trailer hitching

Reducing the chopper speed

Chaff spreader

Folding the chaff spreader open

Straw spreader

Adjusting the spread pattern

Sieve chart and suggested combine adjustments

Sieve chart

Suggested combine adjustments

Disawner plates

Threshing segment

Problem, cause and / or remedy – Basic machine

Maintenance – basic machine

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedules

Lubricants charts

Hydraulic system

Hydraulic accumulators

Checking the oil level

Changing hydraulic oil

Changing the hydraulic oil filter

Cleaning the coarse filters

Refilling the system after a hydraulic oil change (Sauer 90 R 130 / 90 M 100)

Bleeding the hydraulic cylinders for cutterbar transverse control

Transmission / Brakes

Transmission gearbox

Checking the oil level

Oil change

Final drives (2-step) (20 t / 19 t / 20 t HD)

Checking the oil level

Oil change

Final drives (Planetary gear)

Checking the oil level

Oil change

Threshing drum two-step variable speed drive

Oil change

Checking the oil level

Transfer gearbox (Engine)

Checking the oil level

Oil change

Rotor drive gearboxes

Checking the oil level

Oil change

Grain tank unloading transmission

Checking the oil level

Oil change

Uni-spreader gearbox (straw chopper)

Checking the oil level

Changing the oil

Gear shift control adjustment

Foot brake and brake fluid

Parking brake

Feeder housing

Tension feeder chains

Cleaning the suction blower (extra equipment)

Elevator chains

Tensioning the grain elevator chain (Combines without yield meter)

Tensioning the grain elevator chain (Combines with yield meter)

Tensioning the returns elevator chain

Drive belts / drive chains – basic machine

General notes

Drive system diagram, left-hand side

Drive belts and chains

Drive system diagram, right-hand side

Drive belts

Removing the cutterbar drive belt (1) (Cutterbar drive without variable-speed drive)

Installing and tensioning the cutterbar drive belt (1)

Removing the cutterbar drive belt (2) (Cutterbar drive with variable-speed drive)

Installing and tensioning the cutterbar drive belt (2)

Removing the cutterbar variable-speed drive belt (3)

Installing the cutterbar variable-speed drive belt (3)

Removing the impeller drive belt (4)

Installing and tensioning the impeller drive belt (4)

Removing the cutterbar intermediate drive belt (5)

Installing and tensioning the cutterbar intermediate drive belt (5)

Removing the hydraulic pump drive belt (6) for straw spreader / chaff spreader

Installing and tensioning the hydraulic pump drive belt (6) for straw spreader / chaff spreader

Removing the main intermediate drive belt (7)

Installing and tensioning the main intermediate drive belt (7)

Removing the intermediate drive belt for grain tank unloading (8)

Installing and tensioning the intermediate drive belt for grain tank unloading (8)

Removing the straw chopper intermediate drive belt (9)

Installing and tensioning the straw chopper intermediate drive belt (9)

Removing the straw chopper drive belt (10 and 11)

Installing and tensioning the straw chopper drive belt (10 and 11)

Adjusting the uni-spreader intermediate drive LEXION 480

Removing the uni-spreader drive belt (12)

Installing and tensioning the uni-spreader drive belt (12)

Adjusting the uni-spreader drive

Installing and tensioning the uni-spreader drive belt (16)

Removing the sieve pan intermediate drive belt (13)

Installing and tensioning the sieve pan intermediate drive belt (13)

Removing the sieve pan intermediate drive belt (14)

Installing and tensioning the sieve pan intermediate drive belt (14)

Removing the sieve pan drive belt (15)

Installing and tensioning the sieve pan drive belt (15)

Adjusting the axial rotor step drive (18)

Adjusting the axial rotor intermediate drive

Removing and installing drive belt (19)

Removing the fan intermediate drive belt (20)

Installing and tensioning the fan intermediate drive belt (20)

Removing the fan drive belt (21)

Installing the fan drive belt (21)

Removing the threshing mechanism variable speed drive belt (22)

Installing the threshing mechanism variable speed drive belt (22)

Removing the threshing drum drive belt (23)

Installing and tensioning the threshing drum drive belt (23)

Removing the accelerator drive belt (24)

Installing and tensioning the accelerator drive belt (24)

Removing the rotary radiator screen suction drive belt (28)

Installing and tensioning the rotary radiator screen suction drive belt (28)

Tensioning the rotary radiator screen drive belt (32)

Tensioning the suction blower drive belt (34)

Removing the grain tank unloading drive chain (17)

Installing and tensioning the grain tank unloading drive chain (17)

Cabin / Compressor-type air conditioner

Cleaning the filters

Cleaning the units located in the cabin roof

Compressor-type air conditioning system

Cleaning the condenser

Checking the refrigerant level

Replacing the filter receiver-drier

Required refrigerant charge – refrigerant R 134 a

Compressor oil

Maintenance work before the harvest

Combine performance monitor / Fire extinguisher

Combine performance monitor

Fire extinguisher

Compressed air system (Extra equipment)

Compressed air connections

Draining the compressed air accumulator

Pressure controller

Straw chopper

Removing the knives

Removing the straw guide plate (LEXION 470)

Installing the straw guide plate (LEXION 470)

Removing the straw guide plate (LEXION 480)

Installing the straw guide plate (LEXION 480)

Changing the knives

Replacing the stationary knives

Spreading unit

Installing and adjusting the toothed belt

Speed monitoring

Setting the magnetic pick-ups (sensors)

Winter storage instructions for combines

Maintenance – engine

Important maintenance instructions

Important maintenance instructions and safety rules

Maintenance schedules and lubricants charts

Maintenance schedule

Lubricants chart

Maintenance – engine

Engine overview

Fuel system

Additional fuel tank (Extra equipment)

Replaceable filter of additional fuel tank

Water separator / fuel pre-filter (Extra equipment – small version)

Fuel pre-filter, disassembled:

Water separator / Fuel pre-filter (Extra equipment, replaces fuel pre-filter Fig. 11)

Water separator / fuel pre-filter disassembled:

Fuel filter

Replacing the filter cartridge

Bleeding the fuel system

Checking engine oil level

Engine oil change

Draining the old oil

Oil filter

Filling in engine oil

Cooling system

Water drain plugs on the engine block

Water cooler

Filling the cooling system with coolant

Overpressure

Antifreeze / corrosion protection

Warning notice

Cooling water temperature

Stopping the engine when overheated

Radiator rotary screen

Cleaning the radiator

Dry-type air cleaner

Warning device

Cleaning the air cleaner intake screen

Cleaning dry-type air cleaner

Cleaning the air cleaner

Safety filter cartridge

Electrical equipment

Alternator

Engine problems, cause and / or remedy

Engine winter storage

Engine preservation

Lubrication chart

Lubricants and lubrication instructions

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 1405 164 7.pdf:

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of Manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.1.9 Licensing for road traffic

Sample report

Clearance certificate

General operating permit

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Update of terminal software

2.2.3 Requirements made on all persons working with the product

2.2.4 Hazard areas

Hazard areas

2.2.5 Interaction between the control terminal and the machine or tractor

2.2.6 Structural changes

2.2.7 Optional equipment and spare parts

2.2.8 Use of USB devices

2.2.9 Operation only following proper putting into operation

2.2.10 Technical status

2.2.11 Hazard from damage on the product

2.2.12 Respecting technical limit values

Respecting technical limit values

2.2.13 Preparing the product for road travel

2.2.14 Hazards when driving on the road with an ISOBUS implement

Switching on the terminal during road travel.

2.2.15 Hazards when driving on the road and on the field

2.2.16 Electrocution by electrical system

2.2.17 Potentially fatal electric shock from overhead lines

2.2.18 Liquids under pressure

2.2.19 Maintenance operations and repair work

2.2.20 Driving with the GPS PILOT

Road travel

2.2.21 Working with Task Control* and Section Control*

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of GPS PILOT – Hydraulic system

3.1.2 Overview of GPS PILOT – Steer ready

3.1.3 Overview of GPS PILOT FLEX

3.1.4 Overview of GPS PILOT ex works

3.1.5 Overview of the S10 terminal

3.1.6 Overview of navigation computer (ECU)

3.1.7 Electric steering wheel

3.1.8 Overview of correction signals

EGNOS/WAAS/MSAS

Omnistar HP / XP / G2

RTK FIELD BASE and BASELINE HD

RTK FARM BASE

3.1.9 Module overview

BASELINE HD

RTK FIELD BASE

RTK (Motorola)

RTK FARM BASE

3.2 Safety devices

3.2.1 Automatic cut-out when the maximum speed is exceeded

3.2.2 Automatic cut-out when the speed falls below the minimum

3.2.3 Seat contact switch

3.2.4 Manual override

Electric steering wheel

3.3 Optional equipment

3.3.1 GPS L2*

3.3.2 GLONASS*

3.3.3 TURN IN*

3.3.4 AUTO TURN*

3.3.5 Task Control*

Task Control Basic*

Task Control Geo*

3.3.6 Section Control*

3.4 Identification plates and identification numbers

3.4.1 GPS PILOT identification plate

3.4.2 Identification plate of terminal

3.4.3 Identification plate of navigation controller

4 Operating and display elements

4.1 GPS PILOT

4.1.1 Master switch and drive switch

4.2 Overview of the S10 terminal

4.2.1 Layout conventions of buttons and displays

4.3 GPS PILOT menu structure

4.3.1 Start menu

Start menu without Task Control*

Start menu with Task Control*

4.3.2 Menu overview

4.3.3 Overview of display field

4.3.4

4.3.5

4.3.6

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07