Claas Disco 9100 C (F57) Mower Operator Manual EN

$50.00

- Model: Disco 9100 C (F57) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 52.3 MB

File List:

00 0290 715 1.pdf

00 0290 716 1.pdf

00 0292 531 1.pdf

00 0295 793 3.pdf

00 1329 399 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0292 531 1.pdf:

DISCO 9100 RC Contour

Table of contents

1 Introduction

1.1 General Information

1.1.1 Validity of manual

2 Machine description

2.1 Optional machine equipment

2.1.1 High-cut skids

2.1.2 Wear skids

2.1.3 Lucerne bar protection

3 Technical specifications

3.1 DISCO 9100 RC – Type F57

3.1.1 Operating utilities and filling quantities

4 Machine preparation

4.1 Adapting the machine

4.1.1 Installing the high-cut skids*

4.1.2 Installing wear skids*

5 Maintenance

5.1 Overview maintenance intervalls

5.1.1 before the harvest

5.1.2 Every 5 years

5.1.3 As needed

5.2 Mower unit

5.2.1 Mower head: Checking the oil level

5.2.2 Mower head: Changing the oil

5.2.3 Replacing the knives

5.2.4 Feed cylinder: Cleaning the drain opening

5.2.5 Feed cylinder: Checking the wear bars

5.2.6 Feed cylinder: Checking the lid

5.2.7 Feed drum: Installing the sealing washer

5.2.8 Replacing the cutting discs

5.2.9 Installing the pinion units

5.2.10 Replacing adapters

6 Spare parts list

6.1 Spare parts list

00 0295 793 3.pdf:

DISCO 9100 C / RC Contour

DISCO 9100 Contour

DISCO 8400 C / RC Contour

DISCO 8400 Contour

Table of contents

1 To this operator’s manual

1.1 Notes on the manual

1.1.1 General instructions

1.1.2 Using the manual

Directions

1.1.3 Validity of manual

1.1.4 Symbols and notes

1.1.5 Technical specifications

2 Safety

2.1 Safety rules

2.1.1 Particularly important

2.1.2 Qualification of drivers and maintenance personnel

2.1.3 Intended use

2.1.4 Reasonably foreseeable misuse

2.1.5 Safety and accident prevention regulations

2.1.6 First aid measures

2.1.7 Danger of injury from hydraulic liquid

2.2 Safety decals on the machine

2.2.1 Safety decals

2.2.2 Positioning on the machine

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of DISCO 9100 C / 9100 RC / 8400 C / 8400 RC

3.1.2 Overview of DISCO 9100 / 8400

3.1.3 Function of DISCO 9100 C / 8400 C

3.1.4 Function of DISCO 9100 RC / 8400 RC

3.1.5 Function of DISCO 9100 / 8400

3.2 Optional machine equipment

3.2.1 Optional machine equipment

3.2.2 High-cut skids

3.2.3 Bolted wear skids

3.2.4 Lucerne bar protection

3.2.5 Crop spreader

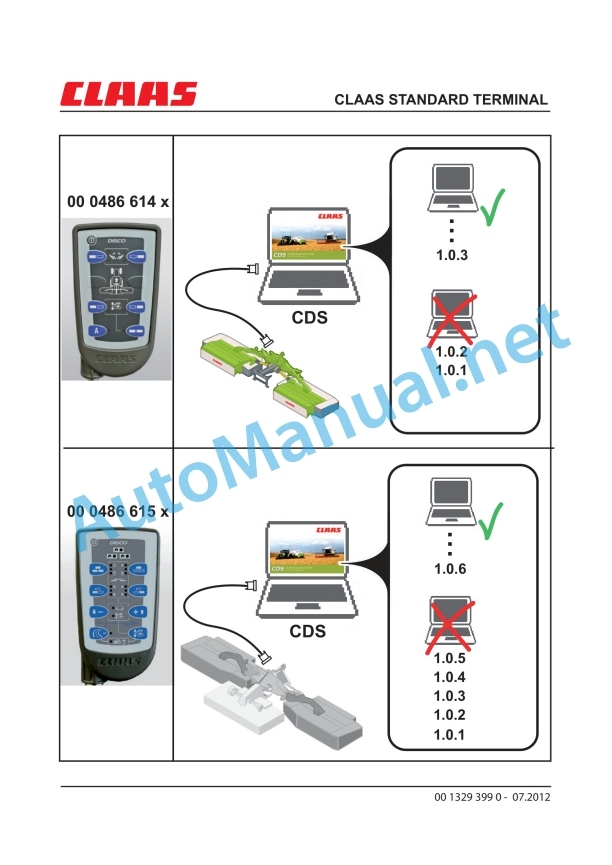

3.2.6 CLAAS Standard Terminal

3.2.7 CLAAS COMMUNICATOR

3.2.8 5 metre ISOBUS connecting cable

3.2.9 3 metre ISOBUS connecting cable

3.2.10 Hydraulically folding safety guards

3.2.11 Hydraulic system connectors, 3-fold

3.2.12 Slip-on yoke for 8-piece universal drive shaft

3.2.13 Legal equipment for France

3.2.14 Lighting adapter for USA

3.3 Identification plate and vehicle identification number

3.3.1 Spare parts and technical questions

3.3.2 Position of identification plate

3.3.3 Position of identification no.

3.3.4 Explanation of machine identification plate

3.3.5 ISOBUS program version

4 Operating and control elements

4.1 CLAAS STANDARD TERMINAL

4.1.1 Overview of keys

4.1.2 Overview of LEDs

4.2 ISOBUS terminal

4.2.1 ISOBUS monitor

4.2.2 ISOBUS title bar

4.2.3 ISOBUS menu bar

4.2.4 ISOBUS softkey

4.2.5 ISOBUS data field

4.2.6 ISOBUS status bar

4.3 CLAAS COMMUNICATOR

4.3.1 Overview

4.3.2 Monitor

4.3.3 Title bar

4.3.4 Menu bar

4.3.5 Data field

4.3.6 Softkey

5 Technical specifications

5.1 DISCO 9100 C – type F57

5.1.1 Dimensions

5.1.2 Weights

5.1.3 Requirements on the tractor

5.1.4 Version

5.1.5 Sound pressure level

5.1.6 Lubricants

5.2 DISCO 9100 RC – Type F57

5.2.1 Dimensions

5.2.2 Weights

5.2.3 Requirements on the tractor

5.2.4 Version

5.2.5 Noise level

5.2.6 Lubricants

5.3 DISCO 9100 – type F55

5.3.1 Dimensions

5.3.2 Weights

5.3.3 Requirements on the tractor

5.3.4 Version

5.3.5 Noise level

5.3.6 Lubricants

5.4 DISCO 8400 C – type F56

5.4.1 Dimensions

5.4.2 Weights

5.4.3 Requirements on the tractor

5.4.4 Version

5.4.5 Noise level

5.4.6 Lubricants

5.5 DISCO 8400 RC – Type F56

5.5.1 Dimensions

5.5.2 Weights

5.5.3 Requirements on the tractor

5.5.4 Version

5.5.5 Noise level

5.5.6 Lubricants

5.6 DISCO 8400 – type F54

5.6.1 Dimensions

5.6.2 Weights

5.6.3 Requirements on the tractor

5.6.4 Version

5.6.5 Noise level

5.6.6 Lubricants

6 Machine preparation

6.1 Tractor preparation

6.1.1 Axle loads, minimum ballast, total weight

6.1.2 Calculating the minimum front ballast

6.1.3 Calculating the minimum rear ballast

6.1.4 Calculating the actual front axle load

6.1.5 Calculating the actual total weight

6.1.6 Calculating the actual rear axle load

6.1.7 Calculation table

6.1.8 Converting the Walterscheid upper link

6.1.9 Installing the CLAAS COMMUNICATOR

6.1.10 Connecting the CLAAS COMMUNICATOR on tractors with ISOBUS socket

6.1.11 Connecting the CLAAS COMMUNICATOR on tractors without ISOBUS socket

6.2 Shutting down and securing the machine

6.2.1 Switching off and securing the machine

6.2.2 Securing the raised machine

6.3 Adapting the machine

6.3.1 Universal drive shaft – Checking the length

6.3.2 Universal drive shaft – Adapting the length

6.3.3 Cut off the universal drive shaft guard

6.3.4 Fitting the universal drive shaft to the machine

6.3.5 Adapting the lower link / upper link category

6.3.6 Fitting the rope

6.3.7 Adjusting the outer swathing disc

6.4 Hitching the machine

6.4.1 Hitching up the attachable frame

6.4.2 Installing the universal drive shaft

6.4.3 Connecting the hydraulic hoses

6.4.4 Connecting the electrics

6.4.5 Raising the stands

6.4.6 Laying the rope

6.5 Unhitching the machine

6.5.1 Parking the machine safely

6.5.2 Lowering the stands

6.5.3 Removing the rope

6.5.4 Disconnecting the electric system

6.5.5 Storing the control terminal

6.5.6 Disconnecting the hydraulic hoses

6.5.7 Removing the universal drive shaft

6.5.8 Unhitching the attachable frame

6.6 Loading the machine

6.6.1 Loading / unloading the machine

7 Operation

7.1 General safety precautions

7.1.1 Prior to operation

7.2 Driving on the road

7.2.1 Road travel

7.3 Fieldwork settings

7.3.1 Adjusting the attachable frame

7.3.2 Adjusting the load relief of the mower units

7.3.3 Adjusting the cutting height

7.3.4 Adjusting the tine conditioner

7.3.5 Adjusting the roller conditioner

7.3.6 Setting the swath width

7.3.7 Adjusting the crop spreader*

7.3.8 Mowing without conditioner effect

7.3.9 Engaging the bump safeguard

7.3.10 Retensioning the bump safeguard

7.4 Fieldwork

7.4.1 Fieldwork

7.4.2 Swinging to transport position

7.4.3 Folding to working position

7.4.4 Machine use

Optimum PTO speed

7.4.5 Mowing methods

7.4.6 Turning area position

7.4.7 Instructions for mowing

7.4.8 Difficult conditions of use

7.4.9 Recommendation for environmental protection

7.5 CLAAS STANDARD TERMINAL

7.5.1 General warnings

7.6 Switching the CLAAS STANDARD TERMINAL on/off

7.6.1 Switching on the terminal

7.6.2 Switching off the terminal

7.6.3 Terminal – automatic shutdown

7.7 CLAAS STANDARD TERMINAL load relief

7.7.1 Adjusting the load relief of the mower units

7.8 CLAAS Standard Terminal automatic function

7.8.1 Activating the automatic function

7.8.2 Deactivating the automatic function

7.9 CLAAS STANDARD TERMINAL transport position

7.9.1 Swinging the mower unit to transport position

7.10 CLAAS Standard Terminal working position

7.10.1 Moving the mower unit to working position

7.11 CLAAS Standard Terminal turning area position

7.11.1 Lifting the mower units to the turning area position

7.12 CLAAS Standard Terminal mower unit individual lifting function

7.12.1 Activating the mower unit individual lift

7.13 ISOBUS control unit

7.13.1 Description

7.13.2 Notes on this chapter

7.13.3 Explanations regarding the ISOBUS terms

7.14 Switching the ISOBUS terminal on/off

7.14.1 Switching on the ISOBUS terminal

7.14.2 Starting the ISOBUS control program

7.14.3 Switching off the ISOBUS terminal

7.14.4 Changing the menu

7.15 ISOBUS transport position

7.15.1 Moving the mower units to transport position

7.16 ISOBUS working position

7.16.1 Moving the mower units to working position

7.17 ISOBUS fieldwork

7.17.1 Automatic function

7.17.2 Lifting the mower units to the turning area position

7.17.3 Activating the mower unit individual lift

7.17.4 Adjusting the load relief of the mower units

7.18 ISOBUS Information menu

7.18.1 Calling up the Information“ menu

7.18.2 Resetting service meter

79 CLAAS COMMUNICATOR

7.19.1 Notes on this chapr

7.19.2 Recommendations to achieve best possible use

7.20 Switching the CLAAS Communicator on/off

7.20.1 Switching the CLAAS COMMUNICATOR on

7.20.2 Switching the CLAAS COMMUNICATOR off

7.21 Operating the CLAAS Communicator

7.21.1 Select menu“ / cancel key (ESC)

7.21.2 Function keys

7.21.3 Select wheel – data selection and data input

7.21.4 Navigation in the data field

7.21.5 Software maintenance

7.22 CLAAS Communicator service program

7.22.1 Scope of functions

7.22.2 Calling up the service program

7.23 CLAAS Communicator menu descriptions

7.23.1 Changing the menu

7.23.2 Information menu

7.23.3 Brightness / contrast menu

7.23.4 Time and date menu

7.23.5 Memory administration menu

7.23.6 Diagnosis sub-menu

7.23.7 Country settings menu

8 Faults and remedies

8.1 Causes and remedies

8.1.1 Observe for troubleshooting

8.1.2 General trouble and remedy

8.1.3 Removing an ISOBUsensor fault

9 Maintenance

9.1 Maintenance Informaon

9.1.1 General warnings

9.1.2 Electrical system

9.1.3 Protective guards

9.1.4 Spare parts

9.1.5 Unbalance

9.1.6 Compressed air and water

9.1.7 Burn prevention

9.1.8 Oils

9.1.9 Fire prevention and explosion prevention

9.1.10 Lines, tubes and hoses

9.2 Overview maintenance intervalls

9.2.1 Handling of maintenance intervals

9.2.2 Before the harvest

9.2.3 After the first 10 operating hours

9.2.4 After the first 50 operating hours

9.2.5 Every 8 operating hours

9.2.6 Every 20 operating hours

9.2.7 Every 50 operating hours

9.2.8 Every 100 operating hours

9.2.9 Every 250 operating hours

9.2.10 Every 500 operating hours or annually

9.2.11 As needed

9.2.12 After the harvest

9.3 Maintenance operations in general

9.3.1 Clean machine

9.3.2 Preserve the machine

9.3.3 Fastening material

9.4 Maintenance operations gearbox

9.4.1 Check gearbox tightness

9.4.2 Check the main gearbox oil level

9.4.3 Changing the main gearbox oil

9.4.4 Cleaning the main transmission breather valve

9.4.5 Checking the angle drive oil level

9.4.6 Checking the angle drive oil level

9.4.7 Changing the angle drive oil

9.4.8 Changing the angle drive oil

9.4.9 Cleaning the angle drive breather valve

9.5 Maintenance operations clutch

9.5.1 Adjusting the friction clutch

9.5.2 Removing and installing the friction clutch

9.5.3 Venting the friction clutch

9.5.4 Replacing the friction discs

9.6 Maintenance operations drive shaft

9.6.1 Maintaining drive shafts

9.6.2 Pulling off the universal drive shaft angle drive

9.7 Maintenance operations hydraulic

9.7.1 Hydraulic system maintenance

9.7.2 Maintaining hydraulic hoses

9.7.3 Accumulator

9.7.4 Removing hydraulic cylinders

9.7.5 Fitting the load relief cylinders

9.8 Mower unit maintenance work

9.8.1 Checking the mower head oil level

9.8.2 Checking the mower head oil level

9.8.3 Changing the mower head oil

Topping up oil

9.8.4 Changing the mower head oil

Topping up oil

9.8.5 Removing the mower knife box

9.8.6 Observing the direction of rotation of cutting discs

9.8.7 Removing the fixing lever

9.8.8 Checking the knives

9.8.9 Replacing the knives

9.8.10 Checking the mower knife holder

9.8.11 Checking the cutting discs

9.8.12 Replacing the cutting discs

9.8.13 Installing the pinion units

9.8.14 Adjusting the anti-wrap guard

9.8.15 Adjusting the safety device

Rear safety guard holder

Front safety guard holder

Outer safety guard holder (DISCO 9100 C / 9100 RC / 9100)

9.9 Tine conditioner maintenance work

9.9.1 Tensioning the drive belt

9.9.2 Changing the drive belts

9.9.3 Attaching/removing the tines

9.10 Roller conditioner maintenance work

9.10.1 Tensioning the drive belt

9.10.2 Changing the drive belts

9.10.3 Adjusting the roller conditioner

Adjusting the tension spring

Adjusting synchronous running

Adjusting the roller clearance

9.11 Various components / Machine body

9.11.1 Marking of pressure gauge, setting aid, machine frame and arm

9.11.2 Installing the arm

9.11.3 Greasing the arm pins

9.11.4 Fitting the shock absorbers

9.11.5 Installing the adjusting aid

9.12 Lubrication chart

9.12.1 Greasing points to be greased every 8 operating hours

9.12.2 Greasing points to be greased every 20 operating hours

9.12.3 Greasing points to be greased every 100 operating hours

9.12.4 Greasing points to be greased every 250 operating hours

9.12.5 Greasing points to be greased every 500 operating hours or once a year

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 EC-declaration of conformity

11.1 DISCO 9100 C / 9100 RC / 9100 / 8400 C / 8400 RC / 8400

11.1.1 EC Declaration of Conformity

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Technical terms

12.1.2 Abbreviations

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish