Claas Scorpion 6040 (K03) Telehandlers Operator Manual EN

$50.00

- Model: Scorpion 6040 (K03) Telehandlers

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 21.5 MB

File List:

00 0290 037 0.pdf

00 0293 934 2.pdf

00 0295 114 1.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 0293 934 2.pdf:

Operator’s Manual

Table of contents

1 Introduction

1.1 Important information on this Operator’s Manual

Abbreviations/symbols

1.2 Machine overview

1.3 Brief description

Hydrostatic drive

Work hydraulics and 4 wheel steering

Cooling system

1.4 Fields of application

1.5 Model designation – trade names

1.6 Use: implement

1.7 Regulations

Driving licences

Equipment

Machine inspections

Documents

Warning identification of the machine

1.8 EC declaration of conformity model 400-01

1.9 EC declaration of conformity model 401-01

1.10 EC declaration of conformity model 402-01

1.11 EC declaration of conformity model 403-01

1.12 Type labels and component numbers

Serial number

Cab number

Engine number

Hydraulic pump number

Variable displacement motor number

Variable displacement motor number (high speed option)

Front and rear axle numbers

1.13 Signs and symbols

Labels on the outside of the machine

Labels on the inside of the machine

2 Safety instructions

2.1 Identification of warnings and dangers

2.2 Warranty

2.3 Designated use and exemption from liability

2.4 General conduct and safety instructions

Organisational measures

Selection and qualification of staff, basic responsibilities

2.5 Safety instructions regarding operation

Normal operation

Applications with lifting gear

Trailers and implements

Transport

2.6 Safety instructions for maintenance

Service and maintenance work on ROPS/FOPS superstructures (ROPS bar)

2.7 Warning of special hazards

Electric energy

Gas, dust, steam, smoke

Hydraulic equipment

Oil, grease and other chemical substances

3 Operation

3.1 Overview of control elements

3.2 Cab overview

3.3 Instrument panel, multifunctional lever, switch consoles: overview

3.4 Telltales and warning lights: description

Telltale and warning light – instru ment panel

Telltale and warning light – instru ment panel

3.5 Taking the machine into service for the first time

Safety instructions

Important information

Running-in period

Check lists

Start-up checklist

Operation checklist

Parking checklist

Opening the door from the outside and inside

Side window

Rear window

3.7 Rear window emergency exit

3.8 Electric mirror adjustment (option)

3.9 Starting the engine

Before starting the engine

Starting the engine

3.10 Drive interlock with transponder key (option)

Disabling (releasing the drive interlock)

Enabling (locking the drive interlock)

3.11 Key-based drive interlock (option)

Disabling (releasing) the drive interlock

Enabling (locking) the drive interlock

Oil and fuel preheater (option)

3.12 Jump-starting the engine (external battery)

Safety instructions

Procedure

3.13 Before moving off

Special instructions for driving on public roads

Locking the control lever (joystick) and the 3rd control circuit (implements)

Steering column height and angle adjustment

Checking the steering system

Synchronous wheel position

Adjusting the height of the control lever base

Accelerator pedal

Brake/inching pedal

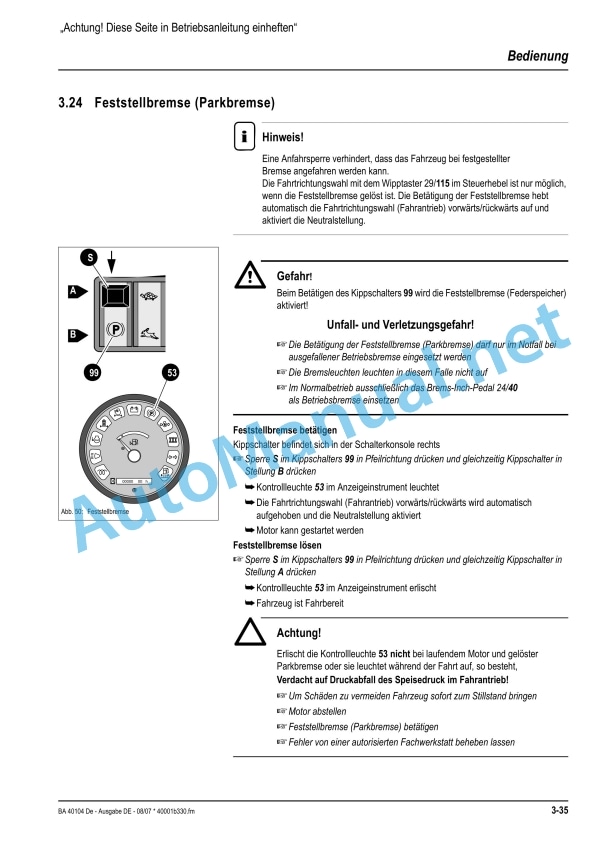

Parking brake

3.14 Moving off

Changing direction (forwards/reverse)

Selecting the speed range 0 – 20 kph

Selecting the drive range 0 – 30/40 kph (option)

Crawler gear potentiometer (option)

3.15 Load stabiliser

3.16 Backup warning system (option)

3.17 Differential lock

3.18 Synchronising the steering system

3.19 Changing steering mode

Front wheel steering

4 wheel steering

Changing over to diagonal steering (crab steering option)

3.20 Stopping/parking the machine

3.21 Light system

Headlights

Working light

Interior light

3.22 Signalling system

Turn indicator

Hazard warning system

Rotating beacon (option)

3.23 Cab heating and ventilation

3.24 Air conditioning (option)

3.25 Washer system

Tank for washer system

3.26 Seat

Seat adjustment

Weight adjustment

Backrest adjustment

Longitudinal adjustment with control lever base (option)

Horizontal adjustment without control lever base

3.27 Seat belt (lap belt)

Fastening the seat belt:

Unfastening the seat belt:

Longer/shorter lap belt adjustment:

3.28 Engine cover

3.29 Fire extinguisher (option)

3.30 Battery master switch (option)

3.31 Reversing cooling fan (option)

3.32 Towing and transporting the machine

Getting ready for towing

Towing the machine

3.33 Loading and transporting the telehandler

Safety instructions

Loading the machine

Strapping down the machine

3.34 Crane handling the machine

Safety instructions

Crane handling

3.35 Telescopic boom operation: overview

Operating the control lever for the lift, tilt and push-out rams

Operation of 3rd control circuit

3.36 Operating the telescopic boom

General safety instructions

Safe load indicator

Safe load indicator display

Functional check of the safe load indicator

Raising/extending the telescopic boom

Retracting/lowering the telescopic boom

3.37 Re-equipping implements

Picking up an implement with the hydraulic quickhitch facility

Re-equipping implements on the hydraulic quickhitch

Fitting an implement onto the mechanical quickhitch facility (option)

3.38 Safety feature “Hose burst valve”

3.39 Mounting/removing the pallet forks

Picking up the pallet forks

Removing the pallet forks from the quickhitaty

Driving on public roads with the pallet forks

3.40 Adjusting the fork arms

3.41 Working with the pallet forks

General safety instructions

Brief instructions for fork arms

Specific safety instructions

Load diagram for pallet forks (EN 1459/1998)

Bucket payloads

Approaching the material

Loading the material

Picking up material and setting it down in a high position

3.42 Working with the standard bucket

General instructions

Practical hints for digging

Tilt position of the bucket

Transport position of the bucket

Transporting with a full bucket

Loading loose material

Loading if the material is hard to penetrate

Removing material/digging in soft soil

Removing material/digging in hard soil

Loading vehicles

Freeing the machine

3.43 Mounting/removing the multipurpose bucket

Pressure relief on the quick couplers and the quickhitch facility

Hydraulic connections: telehandler – multipurpose bucket

Removing the multipurpose bucket from the quickhitch facility

3.44 Working with the multipurpose bucket

Driving on public roads with the multipurpose bucket

Grading and scraping

Stripping in thin layers (scraper)

Spreading material in layers

Pulling out material from slopes

Moving material with longer reach

Picking up residual material in grab operation

Grabbing bulky material

Grabbing large objects

Pulling out and setting posts

Precise unloading in grab operation

Backfilling round gravel into drainage ditches

Unloading from the bottom of the bucket for increased dump heights

3.45 Working with a crane jib (option)

3.46 Continuous operation of 3rd control circuit (option)

3.47 Changeover: 3rd control circuit to additional front control circuit (option)

3.48 Operation: front/rear additional hydraulic control circuit (option)

3.49 Tipping trailer operation (option)

3.50 Connection of electrically operated implements (option)

3.51 Operation of the Autohitch trailer coupling (option)

3.52 Trailer coupling operation (option)

3.53 Compressed-air brake system (option)

General safety instructions

Coupling and uncoupling com pressed-air hoses (dual-circuit brake system)

Compressed-air gauge

3.54 Hydraulic trailer brake connection (option)

4 Troubleshooting

4.1 Engine trouble

4.2 Malfunctions in the air conditioning system (option)

5 Maintenance

5.1 Introduction

5.2 Safety prop for telescopic boom

5.3 Fuel system

Specific safety instructions

Refuelling

Stationary fuel pumps

Diesel fuel specification

Checking/replacing the fuel prefilter (water separator)

Replacing the fuel filter

Bleeding the fuel system

5.4 Engine lubrication system

Checking the engine oil level

Filling up engine oil

Replacing the engine oil every 500 s/h (service hours)

Replacing the engine oil filter car tridge every 500 s/h (service hours)

5.5 Engine and hydraulics cooling system

Specific safety instructions

Checking the coolant level and quality

Filling up coolant

Draining coolant

Cleaning the radiator fins

Cleaning the radiator with the reversing fan (option)

5.6 Air filter

Checking air filter contamination

Replacing the filter cartridge at 500 s/ h (service hours)

5.7 V-belt

5.8 Hydraulic system

Specific safety instructions

Monitoring the hydraulic oil and the reflux filter

Checking the hydraulic oil level once a day

Filling up the hydraulic oil

Important information for the use of biodegradable oil

5.9 Checking hydraulic pressure lines

Specific safety instructions

5.10 Lubrication work

Central lubrication system (option)

General safety instructions

Lubricating the rear axle oscillation- type bearing

Lubricating the planetary drive bearing

Lubrication points on the telescopic boom: overview

Lubricating the telescopic boom

Checking and adjusting the wear plates

5.11 Maintenance of the brake system

Specific safety instructions

Checking/filling up the brake fluid level

5.12 Maintenance: compressed-air brake system (option)

Checking the compressed-air tank and lines

Checking compressor attachment and drive

5.13 Tyres

Daily tyre checks

Changing wheels

5.14 Heating – fresh air

Cleaning/replacing the fine-dust filter

Cleaning/replacing the recirculated-air filter

5.15 Air conditioning (option): maintenance

General safety instructions

Functional and visual check once a day

5.16 Maintenance of the electric system

Specific safety instructions

Service and maintenance work at regular intervals

Cables, bulbs and fuses

Alternator

Adjusting the headlights

Checking/replacing the battery

5.17 Maintenance: trailer coupling

Trailer coupling (option)

5.18 General maintenance work

Specific safety instructions

When using washing solvents

When using compressed air

When using a high-pressure cleaner or steam jet

When using volatile and easily flam mable anticorrosion agents and sprays

Cleaning inside the cab

Cleaning the seat belt

Cleaning the exterior of the machine

Cleaning the engine and the engine compartment

Screw connections

Pivots and hinges

5.19 Maintenance if the machine is used in a saline environment

Aggressive media (option)

5.20 Maintenance and service of the implements

5.21 Fluids and lubricants

5.22 Maintenance plan (overview)

5.23 Maintenance label

Explanation of symbols on mainte nance label

6 Specifications

6.1 Model and trade names: overview

6.2 Frame

6.3 Engine

6.4 Oil/water cooling fan

6.5 Power train

Variable displacement pump

Variable displacement motor

6.6 Axles

Front axle

Rear axle

6.7 Service and parking brake

6.8 Steering system

6.9 Work hydraulics

Hydraulic pump

Hydraulic ram protection

Lift, tilt and push-out rams: velocity

Hydraulic pilot control

Additional control circuit (option)

6.10 Electric system

Fuses: overview

Electric components

Main fuse box with relays

Relays: overview

6.11 Tyres for models 400-01/401-01

6.12 Tyres for models 402-01/403-01

6.13 Weights

6.14 Noise levels

6.15 Vibration

6.16 Coolant compound table

6.17 Tightening torques

General tightening torques

Specific tightening torques

6.18 Trailer couplings: trailer weight/drawbar load

6.19 Payload: load diagram up to serial no. 400 01 0033

6.20 Payload: load diagram starting serial no. 400 01 0034

6.21 Payload: load diagram up to serial no. 401 01 0046

6.22 Payload: load diagram starting serial no. 401 01 0047

6.23 Payload: load diagram starting serial no. 402 01 0001

6.24 Payload: load diagram up to serial no. 403 01 0015

6.25 Payload: load diagram starting serial no. 403 01 0016

6.26 Dimensions with bucket

6.27 Dimensions with pallet forks

00 0295 114 1.pdf:

Operator’s Manual

Table of contents

EC Declaration of Conformity

1 Introduction

1.1 Important information on this Operator’s Manual

1.2 Fields of application and work platform operation

1.3 Safety instructions regarding work platform operation

1.4 Driving on public roads with the work platform

1.5 Necessary machine equipment for work platform operation

1.6 Work platform type label

1.7 Warranty – work platform

2 Safety instructions

2.1 Identification of warnings and dangers

2.2 Designated use and exemption from liability

2.3 General conduct and safety instructions

2.4 Safety instructions regarding work platform operation

2.5 Lifting gear applications

2.6 Transporting the work platform

2.7 Safety instructions regarding work platfm mainnance

2.8 Warning of special hazards with the work platform

3 Installing and taking the work platform into service

3.1 Brief description of work platform

3.2 Work platform design

3.3 Picking up a work platform with the quickhitch

3.4 Preparing the work platform for operation

3.5 Radio control system (transmitter) operation

3.6 Overview of transmitter and receiver system control elements

3.7 “STOP switch” safety feature on the transmitter

3.8 Indications regarding the transmitter battery

3.9 Putting the transmitter into operation

3.10 Emergency lowering of the telescopic boom

3.11 Removing the work platform from the quickhitch

4 Maintenance and specifications

4.1 Maintenance work on the work platform

4.2 Maintenance work on the transmitter and receiver system

4.3 Charging the transmitter battery

4.4 Troubleshooting the transmitter and receiver system

4.5 Transmitter and receiver system specifications

4.6 List of frequencies for radio control system

4.7 Worktform spications

4.8 Inspection and maintenance work report

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF