Claas Xerion 5000-4200 (784) Tractors Repair Manual EN

$300.00

- Model: Xerion 5000-4200 (784) Tractors

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 205 MB

File List:

00 0288 549 3.pdf

00 0288 638 1.pdf

00 0300 667 6.pdf

00 0303 522 2.pdf

1 183 409_e.pdf

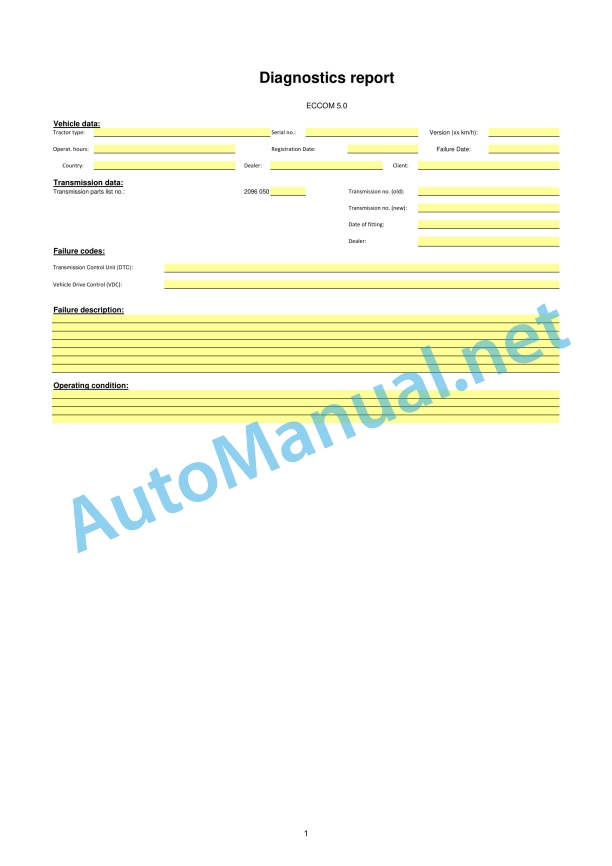

Diagnostics report ECCOM 5.0.pdf

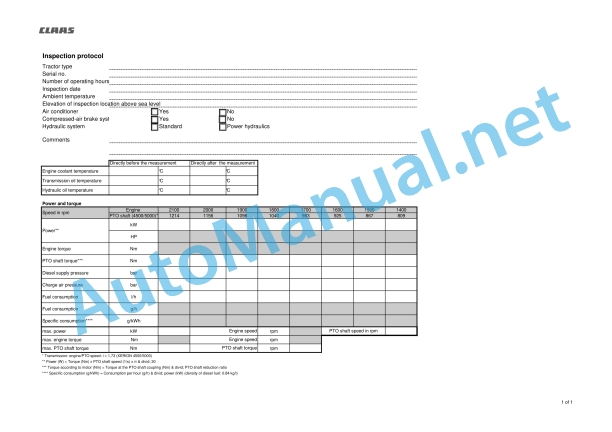

Inspection protocol XERION 5000 – 4500.pdf

00 0288 549 3.pdf:

ZF ECCOM 5.0

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Chain connector type E with spring

Chain connector type G with wire

Chain connector type S with cotter pins

Taper ring fasteners

Dismounting

Installation

Gib head key connections

Dismounting

Installation

Lock collar bearing

Dismounting

Installing

Adapter sleeve bearing

Dismounting

Installation

Chuck bushing

Removing

Dismounting of version A

Dismounting of version B

Installing

Chuck bushing version A

Chuck bushing version B

Circlips

Ferrule fittings

Screwing in

Leaky ferrule fittings

Sealing cone fittings

Hydraulic hoses

Hose placement

Radial shaft seals

Treatment of sealing faces

Drive belts / drive chains

Diesel engine

Alternator

Spare parts

Reason of damage

Tightening torques

Tightening torques for metric ISO screw thread

Tightening torques for metric fine thread

Tightening torques for hydraulic fittings with ferrule

Tightening torques for screwed pipe connections with sealing cone joint and hydraulic threaded joints with soft core seal

Tightening torques for hydraulic male connectors SDS shape B and E

Tightening torques for hydraulic male connectors SDE shape H, with adjustable direction

Tightening torques for hydraulic swivel screw fittings

Tightening torque for hollow screws (with copper sealing ring)

Tightening torques for brake line screw fittings

Tightening torque for tubes with O-ring and union nuts

Tightening torques for worm drive hose clamps

Tightening torques for hose clamps with round pins

Technical specifications

Operating materials

CCN explanation

CCN (CLAAS Component Number)

Electric system standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

General information

Important

Hazard signs

Signal word

General safety and accident prevention regulations

Combine-harvester safety and accident prevention regulations

First aid measures

Leaving the machine

Adjusting and maintenance work

Danger of injury from hydraulic liquid

Hydraulic accumulators

Battery isolating switch

Jacking up the machine

Putting the machine out of operation

Welding work

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Diagnostic protocol

Removing / installing the gearbox

Separating / joining the gearbox housing

Technical specifications

Work preparation

Special tool

Special tool

Separating

0220 Mechanical reverser

Clutch KR

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutch KV

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

0230 Mechanical gearbox

Engine input shaft

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Installing

Central shaft

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Brake BG

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Shifter roller

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutches K3/K4 and planetary gear P4

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Planetary gears P1/P2/P3

Technical specifications

Work preparation

Special tool

Removing planetary gear P1

Disassembling planetary gear P1

Removing planetary gear P2

Disassembling planetary gear P2

Removing planetary gear P3

Disassembling planetary gear P3

Assembling planetary gear P3

Assembling planetary gear P2

Assembling planetary gear P1

Assembling the profile tube

Installing P3

Installing P2

Installing P1

Clutch K1/K2

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Front axle output shaft

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Rear axle output shaft

Technical specifications

Work preparation

Special tool

Removing

Installing

PTO shaft

Technical specifications

Work preparation

Special tool

Removing the output flange

Removing the PTO shaft

Disassembling the PTO shaft

Assembling the PTO shaft

Installing the PTO shaft

Installing the output flange

PTO shaft clutch

Technical specifications

Work preparation

Special tool

Removing the PTO shaft housing

Removing the PTO shaft clutch

Disassembling the PTO clutch

Assembling the PTO shaft clutch

Disassembling the housing

Assembling the housing

Installing the PTO shaft clutch

Adjusting the PTO shaft axial play

Calculating the axial play:

Spur gear Z6

Technical specifications

Work preparation

Special tool

Removing

Installing

Spur gear Z23

Technical specifications

Special tool

Removing

Installing

Assembling

Spur gear Z2, Z3 and pump drive

Technical specifications

Work preparation

Special tool

Removing

Oil tubes

Spur gear Z2, Z3 and pump drive

Installing

Spur gear Z3

Spur gear Z2 and pump drive

Oil tubes

Spur gear Z33

Technical specifications

Work preparation

Special tool

Removing

Installing

Intermediate gear wheel Z24

Technical specifications

Work preparation

Special tool

Removing

Installing

0232 Hydraulical gearbox

Hydrostatic drive

Technical specifications

Work preparation

Special tool

Removing

Installing

0238 Gearbox control

System pressure control block

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutch control block

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Sensors / valves / filters

Technical specifications

Work preparation

Removing

Installing

0255 Gearbox cooling system

Gearbox pump (ECCOM 5.0)

Technical specifications

Work preparation

Removing

Installing

00 0288 638 1.pdf:

ZF ECCOM 3.5 / 4.5

Table of contents

Introduction

General information

Validity of manual

Handling of this manual

Texts and figures

Document structure based on subassemblies

Search and find

Directions

Abbreviations

Technical terms

Converting metric units to US units

Pressure

Ground speed

Acceleration (vibration intensity)

Viscosity

Temperature

Electric system

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Taper ring fasteners

Dismounting

Installing

Gib head key joints

Dismounting

Installation

Lock collar bearing

Dismounting

Installing

Adapter sleeve bearings

Dismounting

Installation

Chuck bushing

Removing version A

Removing version B

Installation

Version A chuck bushing

Version B chuck bushing

Circlips

Ferrule joints

Screwing in

Leaky ferrule joints

Sealing cone joints

Hydraulic hoses

Hose placement

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torque for metric fine threads

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with sealing cone and O-ring according to DIN 3865

Tightening torques for SDS hydraulic male connectors

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for hydraulic swivel fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for brake line screw fittings

Tightening torques for worm-type threaded clips

Tightening torques for hose clamps with round pins

Tightening torques for tyres

General information

Important

Identification of warning and danger signs

General safety and accident prevention regulations

First aid measures

Danger of injury from hydraulic liquid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjustment and maintenance work

Welding work

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Diagnostic protocol

Removing / installing the gearbox

Transmission housing

Technical specifications

Work preparation

Special tool

Separating the halves of the housing

Joining the halves of the housing

0220 Mechanical reverser

Clutch KR

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutch KV

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Adjusting the axial play

Special tool

Adjusting the axial play of the clutches and spur gears

0230 Mechanical gearbox

Engine input shaft

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Installing

Central shaft

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Multi-disc brake BG

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Shifter roller

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutches K3/K4 and planetary gear P4

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Planetary gears P1/P2/P3

Technical specifications

Work preparation

Special tool

Removing

Removing P1

Disassembling planetary gear P1

Removing planetary gear P2

Disassembling planetary gear P2

Removing planetary gear P3

Disassembling planetary gear P3

Assembling planetary gear P3

Assembling planetary gear P2

Assembling planetary gear P1

Assembling the profile tube

Clutch K1/K2

Technical specifications

Special tool

Removing

Disassembling

Assembling

Front axle output shaft (ECCOM 3.5 / 4.5)

Technical specifications

Work preparation

Special tool

Removing

Installing

Rear axle output shaft

Technical specifications

Work preparation

Special tool

Removing the output flange

Removing the output shaft

Disassembling the output shaft

Assembling the output shaft

Installing the output shaft

Installing the output flange

PTO (ECCOM 3.5 / 4.5)

Technical specifications

Work preparation

Special tool

Disconnecting the PTO from the intermediate housing

Disassembling

Disassembling the PTO clutch

Assembling

Installing

Spur gear Z4

Technical specifications

Removing the spur gear (Z4)

Installing the spur gear (Z4)

Spur gear Z5

Special tool

Removing

Removing the spur gear (Z5)

Installing the spur gear (Z5)

Spur gear Z6

Technical specifications

Work preparation

Special tool

Removing

Removing gear (Z6)

Installing gear (Z6)

Spur gear Z23

Technical specifications

Special tool

Removing

Installing

Spur gears Z2 / Z3

Technical specifications

Work preparation

Special tool

Removing

Removing gear (Z2)

Disassembling the gear (Z2)

Assembling the gear (Z2)

Installing gear (Z2)

Removing gear (Z3)

Disassembling the gear (Z3)

Installing gear (Z3)

Spur gear Z33

Technical specifications

Work preparation

Special tool

Removing

Removing gear (Z33)

Installing gear (Z33)

Intermediate gear Z24 / Z25

Technical specifications

Work preparation

Special tool

Removing (Z24) and (Z25)

Fitting Z24

Fitting Z25

Auxiliary PTO power hydraulics (ECCOM 4.5)

Technical specifications

Work preparation

Removing

Installing

0232 Hydraulical gearbox

Hydrostatic drive

Technical specifications

Work preparation

Special tool

Removing

Removing gear (Z4)

Installing gear (Z4)

Installing

0238 Gearbox control

System pressure control block

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Clutch control block

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

0242 Differential

Longitudinal differential lock clutch (ECCOM 3.5 / 4.5)

Technical specifications

Work preparation

Special tool

Removing

Installing

Differential (ECCOM 3.5 / 4.5)

Technical specifications

Work preparation

Special tool

Removing

Assembling

0255 Gearbox cooling system

Gear pump (ECCOM 3.5 / 4.5)

Technical specifications

Work preparation

Special tool

Removing

Installing

CCN (CLAAS Component Number)

00 0300 667 6.pdf:

Mercedes-Benz OM470LAMercedes-Benz OM471LAMercedes-Benz OM473LA

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Chain connector type E with spring

Chain connector type G with wire

Chain connector type S with cotter pins

Taper ring fasteners

Dismounting

Installation

Gib head key connections

Dismounting

Installation

Lock collar bearing

Dismounting

Installing

Adapter sleeve bearing

Dismounting

Installation

Chuck bushing

Removing

Dismounting of version A

Dismounting of version B

Installing

Chuck bushing version A

Chuck bushing version B

Circlips

Ferrule fittings

Screwing in

Leaky ferrule fittings

Sealing cone fittings

Hydraulic hoses

Hose placement

Treatment of sealing faces

Spare parts

Tightening torques

Tightening torques for metric ISO screw thread

Tightening torques for metric fine thread

Tightening torques for screwed pipe connections with sealing cone joint and hydraulic threaded joints with soft core seal

Tightening torques for hydraulic fittings with ferrule

Tightening torques for hydraulic male connectors SDS shape B and E

Tightening torques for hydraulic swivel screw fittings

Tightening torque for hollow screws (with copper sealing ring)

Tightening torques for hydraulic male connectors SDE shape H, with adjustable direction

Tightening torques for brake line screw fittings

Tightening torques for worm drive hose clamps

Tightening torques for hose clamps with round pins

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Hydraulic system standard

CCN (CLAAS Component Number)

General information

Important

Hazard signs

Signal word

Regulations for avoiding accidents with personal injuries

Testing, adjusting and repair work

Engine operation

Suspended loads

Working on piping and hoses

Work on the Common Rail System

Working on the electric system

Working on the hydraulic system

Electric welding

Painting work

Working with urea solution

Information on how to avoid damage and premature wear

Liability limitation

Shutting down and storage

Regulations for avoiding health and environmental damage

Precautionary measures for protection against health and environmental damage

Disposal of operating utilities and auxiliary operating utilities

Information for working on the diesel engine

Accident protection

Cleanliness

Installation instructions

Engine overhaul

Putting into operation after an engine overhaul

First aid measures

01 Engine

0102 Complete component

Type design

Engine data

OM 470 LA

OM 471 LA

OM 473 LA

Engine description

Engine components

Actuators

Ignition order

Cranking the engine

Special tool

Special tool for built-in engine

Cranking the engine in built-in condition

Cranking the engine in removed condition

Setting the engine to ignition TDC

Setting the engine to ignition TDC: Removing

0105 Engine suspension

Lifting eyes

Technical specifications

Lifting eyes

Technical specifications

0110 Engine housing

Technical specifications

Special tool

Installation

Crankshaft front seal

Technical specifications

Special tool

Installing the cassette seal ring

Crankshaft rear seal

Technical specifications

Special tool

Installation

Housing cover

Technical specifications

Installation

Timing housing

Technical specifications

Installation

Oil separator

Technical specifications

Disassembly

Assembly

Installation

Oil separator

Technical specifications

Disassembly

Assembly

Installation

Oil separator

Technical specifications

Disassembly

Assembly

Installation

0115 Engine unit

Technical specifications

Special tool

Disassembly

Checking

Assembly

Installation

Measuring the excess dimension

Checking the combustion pressure

Connecting rod

Technical specifications

Special tool

Checking

Installation

Cylinder liner

Technical specifications

Special tool

Checking

Installation

Measuring the excess dimension

Measuring the cylinder bore

Crankshaft

Technical specifications

Special tool

Removing the crankshaft

Checking the crankshaft

Installing the crankshaft

Crankshaft main bearings

Technical specifications

Special tool

Installation

Oscillation damper

Technical specifications

Special tool

Installation

Flywheel

Technical specifications

Special tool

Checking

Installation

0120 Cylinder head / Valves / Idler gear

Valve cover

Technical specifications

Installation

Reinforcing frame

Technical specifications

Installation

Camshaft housing

Technical specifications

Special tool

Applies to: OM 470 LA

Applies to: OM 470 LA

Installation

Applies to: OM 470 LA

Applies to: OM 470 LA

Camshaft

Technical specifications

Special tool

Installation

Checking

Cylinder head

Technical specifications

Special tool

Installation

Cleaning

Checking

Cylinder head

Technical specifications

Work preparation

Special tool

Installation

Cleaning

Checking

Cylinder head

Technical specifications

Work preparation

Special tool

Installation

Cleaning

Checking

Inlet rocker arm mechanism

Technical specifications

Disassembly

Assembly

Installation

Outlet rocker arm mechanism

Technical specifications

Special tool

Disassembly

Assembly

Installation

Technical specifications

Special tool

Installation

Checking the valves

Adjusting the valve lash

Valve springs and valve stem seals

Technical specifications

Special tool

Installation

Gear drive

Technical specifications

Special tool

Installation

Checking

Adjustment

Gear drive

Technical specifications

Special tool

Installation

Checking

Adjustment

Gear drive

Technical specifications

Special tool

Installation

Checking

Adjustment

0125 Injection – / Fuel system

High-pressure lines and rail

Technical specifications

Special tool

Installation

Rail pressure relief valve

Technical specifications

Installation

Injectors

Technical specifications

Work preparation

Special tool

Installation

Injectors line kit

Technical specifications

Work preparation

Installation

Protective sleeve

Technical specifications

Special tool

Installation

Fuel high-pressure pump

Technical specifications

Work preparation

Special tool

Removing the drive gearwheel

Installing the drive gearwheel

Installation

2-step valve

Technical specifications

Installation instructions

Fuel pump

Technical specifications

Work preparation

Special tool

Applies to: OM 470/471 LA

Installation

Applies to: OM 470/471 LA

Pressure relief valve

Technical specifications

Installation instructions

Fuel controller valve

Technical specifications

Work preparation

Installation

Fuel controller valve

Technical specifications

Work preparation

Installation

Fuel controller valve

Technical specifications

Work preparation

Installation

Fuel filter module

Technical specifications

Work preparation

Special tool

Installation

0130 Lubricating oil system

Lubricating oil system

Technical specifications

Special tool

Pre-filling

Oil spray nozzle

Technical specifications

Installation

Oil/coolant module

Technical specifications

Work preparation

Installation

Oil cooler

Technical specifications

Installation instructions

Oil cooler

Technical specifications

Installation instructions

Oil pump

Technical specifications

Disassembly

Assembly

Installation

Oil pump

Technical specifications

Disassembly

Assembly

Installation

Oil pump

Technical specifications

Disassembly

Assembly

Installation

Oil thermostat

Technical specifications

Special tool

Installation

0135 Cooling system

Technical specifications

Special tool

Draining

Filling up

Cleaning the coolant circuit

Coolant pump

Technical specifications

Work preparation

Installation

Coolant thermostat

Technical specifications

Installation

0140 Exhaust system

Exhaust recirculation cooler

Technical specifications

Special tool

Installation

Checking

Exhaust recirculation cooler

Technical specifications

Special tool

Installation

Checking

Exhaust recirculation cooler

Technical specifications

Special tool

Installation

Checking

Exhaust gas recirculation cooler bracket

Technical specifications

Work preparation

Removing the exhaust gas recirculation cooler bracket

Installing the exhaust gas recirculation cooler bracket

Exhaust recirculation actuator

Technical specifications

Installation

Exhaust recirculation actuator

Technical specifications

Special tool

Installation

Exhaust recirculation valve

Technical specifications

Installation

Differential pressure sensor

Technical specifications

Exhaust manifold

Technical specifications

Work preparation

Installation

Exhaust manifold

Technical specifications

Work preparation

Installation

Exhaust manifold

Technical specifications

Work preparation

Installation

Turbocharger

Technical specifications

Work preparation

Installation

Turbocharger

Technical specifications

Work preparation

Installation

Turbocharger

Technical specifications

Work preparation

Installation

TURBO-COMPOUND turbine

Technical specifications

Work preparation

Installation

TURBO-COMPOUND transmission

Technical specifications

Work preparation

Installation

0145 Air intake

Charge air housing

Technical specifications

Installation

Charge air housing

Technical specifications

Installation

0150 Engine attachment parts

Electric starting motor

Technical specifications

Installation

Alternator

Technical specifications

Special tool

Removing the alternator

Installing the alternator

Resonance vessel

Technical specifications

Installation instructions

Resonance vessel

Technical specifications

Installation instructions

Air compressor

Technical specifications

Work preparation

Special tool

Installation

Removing the drive gearwheel

Installing the drive gearwheel

Air compressor

Technical specifications

Work preparation

Special tool

Installation

Removing the drive gearwheel

Installing the drive gearwheel

0155 Engine control

Control unit

Technical specifications

Installation

0165 Exhaust gas aftertreatment

Exhaust gas aftertreatment system

Technical specifications

Work preparation

Special tool

Checking the urea solution (purity)

Checking the urea solution (density)

Urea heater valve

Technical specifications

Work preparation

Special tool

Installation

Urea pump

Technical specifications

Work preparation

Special tool

Removing the urea pump

Installing the urea pump

Removing the inlet nozzle filter

Installing the inlet nozzle filter

Removing the pressure relief valve

Installing the pressure relief valve

Removing the frost protection element

Installing the frost protection element

Urea dosing unit (A089 / A67-MB)

Technical specifications

Work preparation

Special tool

Removing the dosing unit

Installing the dosing unit

Removing the filter

Installing the filter

0190 Accessories

Engine insulation

Technical specifications

Work preparation

Installing

00 0303 522 2.pdf:

XERION 5000-4200

Table of contents

Introduction

Notes on the manual

Validity of manual

Information about this Repair Manual

Using the manual

Document structure based on subassemblies

Search and find

Directions

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Chain connector type E with spring

Chain connector type G with wire

Chain connector type S with cotter pins

Taper ring fasteners

Dismounting

Installing

Gib head key connections

Dismounting

Installing

Lock collar bearing

Dismounting

Installing

Adapter sleeve bearing

Dismounting

Installation

Chuck bushing

Removing

Dismounting of version A

Dismounting of version B

Installing

Chuck bushing version A

Chuck bushing version B

Circlips

Radial shaft seals

Hose clamps

Tightening torques

Alignment of clamps

Installation aids

Assembly tools

Ferrule fittings

Screwing in

Leaky ferrule fittings

Sealing cone fittings

Hydraulic hoses

Hose placement

Diaphragm accumulator (pressure accumulator) according to CLAAS works standard CN 24 0403

Operating utilities

Service and assembly

Change of gas filling

Special tool

Treatment of sealing faces

Spare parts

Operating materials

Welding work

ESD protection measures

Special tool

ESD protection measures

Notes on inspection and repair

Tightening torques

Threaded assemblies according to CLAAS works standard CN 02 5000

Description of threaded assembly

Tolerance class

Tightening specifications

Tightening torques for metric ISO screw threads

Tightening torques for metric fine thread screws

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF