Claas Rollant 250 255 Uniwrap (726) Baler Technical System ES

$300.00

- Model: Rollant 250 255 Uniwrap (726) Baler

- Type Of Manual: Technical System

- Language: ES

- Format: PDF(s)

- Size: 8.3 MB

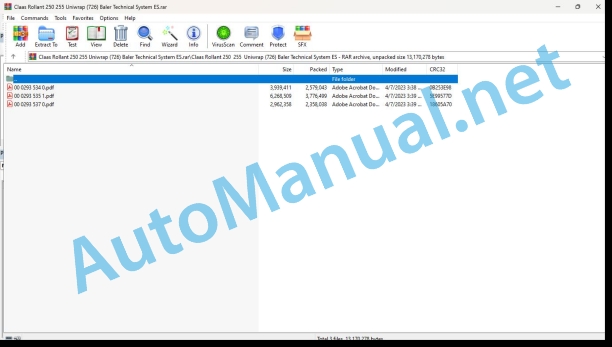

File List:

00 0293 534 0.pdf

00 0293 535 1.pdf

00 0293 537 0.pdf

00 0293 534 0.pdf:

Electrical installation Rollant 240 – 250

Assembly of connection diagrams

central electrical system

Rollant 240/250 Standard central electrical system

Rollant 250 Comfort central electrical system

UNIWRAP central electrical system

Module pin assignment

Module A23 Rollant 240/250 Standard

Module A23 – 1 Rollant 250 Comfort and Rollant 250 Comfort for Uniwrap

Module A23 – 2 Rollant 250 Comfort and Rollant 250 Comfort for Uniwrap

Module A22 – Uniwrap wrapper (Pin assignment in the X100 socket)

Fixing fuses and relays in the connection diagrams

01a – 40c

01a – Supply of the main tension system Rollant 240/250 Standard

01b – Main tension system supply Rollant 250 Comfort

01c – Supply of the main tension system Rollant 250 Comfort for UNIWRAP

01d – Power supply to the main UNIWRAP voltage system

04a – Circulation blocking valve (with central electrical system) Rollant 250 Comfort

04b – Rollant 250 Comfort circulation blocking valve for UNIWRAP

04c – UNIWRAP circulation blocking valve

05a – Terminal Rollant 250 Comfort

05b – UNIWRAP terminal up to machine number 726 00 130

06a – CAN-Bus, voltage supply for Rollant 240/250 Standard modules

06b – CAN-Bus, voltage supply of Rollant 250 Comfort modules

06c – CAN-Bus, power supply of Rollant 250 Comfort modules for UNIWRAP

06d – CAN-Bus, power supply from the UNIWRAP modules to machine no. 72900130

06e – CAN-Bus, power supply of the UNIWRAP modules from machine no. 72900131

07a – Rotocut Rollant 240/250 Standard

07b – Rotocut Rollant 250 Comfort / Comfort for UNIWRAP

11a – Activation of the Rollant 240/250 Standard tying

11b – Activation of the Rollant 250 Comfort / Comfort tying for UNIWRAP

12a – Open / close tailgate – Rollant 250 Comfort / Comfort for UNIWRAP

19a – Load/unload UNIWRAP bales

20a – Raise / lower the Pickup – Rollant 250 Comfort / Comfort for UNIWRAP

21a – Rotation of the avvolgitore arm – UNIWRAP

22a – Open / close the plastic tape knives, control plastic tape breakage – UNIWRAP

32a – Rear light, position light (with central electrical system)

40a – Additional sockets

40b – Additional sockets

40c – Additional female sockets

cable trunk

Cable trunk A – 1 part (Rollant 250 Standard)

Cable trunk A – 2 part (Rollant 250 Standard)

Cable trunk B – 1 part (Rollant 250 Comfort / Rollant 250 Comfort for UNIWRAP)

Cable trunk B – 2 part (Rollant 250 Comfort / Rollant 250 Comfort for UNIWRAP)

Cable trunk B – 3 part (Rollant 250 Comfort / Rollant 250 Comfort for UNIWRAP)

Cable trunk C (Rollant 250 Comfort / Rollant 250 Comfort for UNIWRAP)

Cable trunk D (Rollant 250 Comfort for UNIWRAP)

Cable trunk K (UNIWRAP)

Cable trunk L (UNIWRAP)

Cable trunk M (UNIWRAP)

Alphabetical index

0293 534.0

00 0293 535 1.pdf:

Technical systems – Electrical installation ROLLANT 254/255 UNIWRAP

Assembly of connection diagrams

central electrical system

ROLLANT 254/255 Standard

ROLLANT 254/255 Comfort – equipped with CCT

ROLLANT 254/255 Comfort – equipped with COMMUNICATOR

Module pin assignment

Module A23 Rollant 254/255 Standard

Module A23 -1 Rollant 254/255 Comfort – equipped with CCT

ROLLANT 254/255 Comfort – equipped with CCT

Module A23 -2 Rollant 254/255 Comfort – equipped with CCT

ROLLANT 254/255 Comfort – equipped with COMMUNICATOR

A20 CCU module – ROLLANT 254/255 Comfort – equipped with COMMUNICATOR

Module A22 – Uniwrap wrapper (Pin assignment in the X100 socket)

Fixing in the connection diagrams of the fu

Connection diagrams 01a – 40a

01a – Supply of the main tension system ROLLANT 254/255 Standard

01b – Supply of the main voltage system ROLLANT 254/255 Comfort – with CCT equipment

01c – Supply of the main tensioning system ROLLANT 255 Comfort for UNIWRAP – with CCT equipment

01d – Power supply to the main voltage system ROLLANT 254/255 Comfort – equipped with Communicator

01e – Supply of the main tensioning system ROLLANT 255 Comfort for UNIWRAP – equipped with Communicator

01f – UNIWRAP main voltage system power supply

04a – ROLLANT 254/255 Comfort circulation blocking valve – with CCT equipment

04b – ROLLANT 254/255 Comfort circulation blocking valve for UNIWRAP – with CCT equipment

04c – ROLLANT 254/255 Comfort circulation blocking valve – equipped with Communicator

04d – ROLLANT 254/255 Comfort circulation blocking valve for UNIWRAP – equipped with Communicator

04e – UNIWRAP circulation blocking valve

05a – ROLLANT 254/255 Standard Terminal

05b – ROLLANT 254/255 Comfort Terminal – equipped with CCT

05c – ROLLANT 254/255 Comfort Terminal for UNIWRAP – equipped with CCT

06a – CAN-Bus, power supply for ROLLANT 254/255 Standard modules

06b – CAN-Bus, power supply of the ROLLANT 254/255 Comfort modules – with CCT equipment

06c – CAN-Bus, power supply of ROLLANT 255 Comfort modules for UNIWRAP – with CCT equipment

06d – CAN-Bus, power supply of the ROLLANT 254/255 Comfort modules – with Communicator equipment

06e – CAN-Bus, power supply of the ROLLANT 255 Comfort modules for UNIWRAP – with Communicator equipment

06f – CAN-Bus, power supply from the UNIWRAP modules to machine no. 130

06g – CAN-Bus, power supply of UNIWRAP modules from machine no. 131

07a – Rotocut ROLLANT 254/255 Standard

07b – Rotocut ROLLANT 254/255 Comfort / Comfort for UNIWRAP – with CCT equipment

07c – Rotocut ROLLANT 254/255 Comfort / Comfort for UNIWRAP – equipped with Communicator and reversing switch (Z48) – compare with diagram 7d

07d – Rotocut ROLLANT 254/255 Comfort / Comfort for UNIWRAP – equipped with Communicator and reversing sensor (B131) – compare with diagram 7c

11a – Activation of the ROLLANT 254/255 Standard tying

11b – Activation of ROLLANT 254/255 Comfort / Comfort tying for UNIWRAP – with CCT equipment

11c – Activation of the ROLLANT 254/255 Comfort / Comfort tying for UNIWRAP – equipped with Communicator and tailgate closed switch (Z16) – compare with diagram 11d

11d – Activation of the ROLLANT 254/255 Comfort / Comfort tying for UNIWRAP – equipped with Communicator and tailgate closed sensor (B135) – compare with diagram 11c

12a – Open / close the rear hatch sera ROLLANT 254/255 Comfort / Comfort for UNIWRAP – with CCT equipment

12b – Open / close the tailgate ROLLANT 254/255 Comfort / Comfort for UNIWRAP – with Communicator equipment

19a – Load/unload UNIWRAP bales

20a – Raise / lower the ROLLANT 254/255 Comfort / Comfort Pickup for UNIWRAP – with CCT equipment

20b – Raise / lower the ROLLANT 254/255 Comfort / Comfort Pickup for UNIWRAP – equipped with Communicator

21a – Rotate the UNIWRAP wrapping arm

22a – Open/close the plastic tape blades Check for breakage of the plastic tape

32a – Rear light, position light (with central electrical system)

40a – Additional ROLLANT 254/255 Comfort / Comfort sockets for UNIWRAP – equipped with Communicator

Cable trunks A – M

Cable trunk A – 1 part (ROLLANT 254/255 Standard)

Cable trunk A – 2 part (ROLLANT 254/255 Standard)

Cable trunk B – 1 part (ROLLANT 254/255 Comfort)

Cable trunk B – 2 part (ROLLANT 254/255 Comfort)

Cable trunk B – 3 part (ROLLANT 254/255 Comfort)

Cable trunk C (ROLLANT 254/255 Comfort)

Cable trunk D – 1 part (ROLLANT 255 Comfort for Uniwrap)

Cable trunk D – 2 part (ROLLANT 255 Comfort for Uniwrap)

Cable trunk D – 3 part (ROLLANT 255 Comfort for Uniwrap)

Cable trunk E (ROLLANT 255 Comfort for Uniwrap)

Cable trunk K (UNIWRAP)

Cable trunk L (UNIWRAP)

Cable trunk M (UNIWRAP)

Alphabetical index

0293 535.1

00 0293 537 0.pdf:

Technical Systems UNIWRAP hydraulic installation

1 Hydraulic connection diagram

1.1 Hydraulic connection diagram up to machine number 72600130

1.2 Hydraulic connection diagram from machine number: 72600131 with tilting platform shut-off valve (631)

1.3 Hydraulic connection diagram from machine number: 72600531, with clamping shear distributor (769)

1.4 Hydraulic connection diagram from machine no.: 72601047, with valve combination (630, 706, 769), without 3-stage restrictor (645)

1.5 Hydraulic connection diagram from machine number: 72601047, with valve combination (630, 706, 769), with 3-level restrictor (645)

2 Prerequisites for use

2.1 Close the circulation blocking valve (Y77)

2.2 Connection to the tractor hydraulic system

3 Valve block

3.1 Valve block, up to machine no. 130

3.2 Valve block, from machine no. 131, with shut-off valve for service work on the tilting platform (631)

4 Individual components

4.1 Initial pressure regulator (763)

4.2 Circulation blocking valve (Y77-2)

4.3 Taping arm control unit (Y133)

4.4 Tilting platform control unit (Y135/Y136)

4.4.1 Up to machine no.: with block valve block

4.4.2 From machine no.: without block valve block

4.5 Taping table control unit (Y137 / Y138)

4.6 Control unit for clamping shears (Y139 / Y140)

4.7 Flow regulator (630)

4.8 Pressure limiting valve (706)

4.9 Taping arm motor (234)

4.10 Taping table motor (235)

4.11 Tilting platform shut-off valve (631)

4.12 Hydraulic cylinder clamping shears (374)

4.13 Flow divider for clamping shears (769)

4.14 Taping arm motor valve block (4)

4.15 3 level restrictor

4.16 Valve combination (7)

4.17 Distributor (8)

0293 537.0

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF