Claas Dominator 130 68 S (156) Combines Technical System ES

$300.00

- Model: Dominator 130 68 S (156) Combines

- Type Of Manual: Technical System

- Language: ES

- Format: PDF(s)

- Size: 11.0 MB

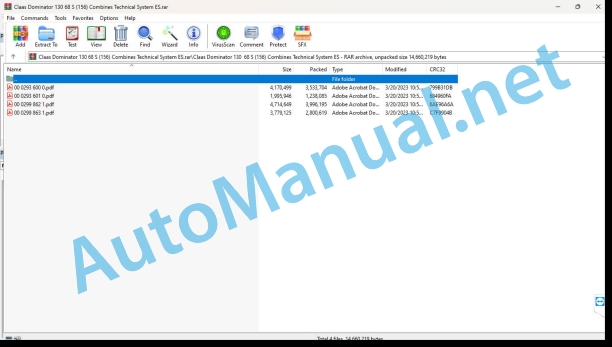

File List:

00 0293 600 0.pdf

00 0293 601 0.pdf

00 0299 862 1.pdf

00 0299 863 1.pdf

00 0293 600 0.pdf:

Technical systems DOMINATOR 130 hydraulic installation

1_x000B__x000B_Global hydraulic installation

1.1_x000B__x000B_Hydraulic installation in general

1.1.1 Hydraulic pumps

1.1.2 Oil filter head

1.2 Connection diagram of the global hydraulic system

1.2.1 Connection diagram of the overall hydraulic system – machine with grain tank

1.2.2 Connection diagram of the global hydraulic system – machine with bagging platform

2 Hydraulic steering installation / 3D control

2.1 Connection diagram of the hydraulic steering installation without AUTOPILOT

2.2 Connection diagram of the hydraulic steering system with AUTOPILOT

2.3 Steering valve unit

2.4 Steering function

2.5 Address Check

2.6 SELF-PILOT electromagnetic valve

2.7 Checking the AUTOPILOT system

2.8 3D controller

3_x000B__x000B_Operations hydraulic system

3.1 Connection diagram of the operating hydraulic system – machine with grain tank

3.2 Pressure limiting valve

3.2.1 Pressure limiting valve (703) – machine with grain tank

3.2.2 Pressure limiting valve – machine with bagging platform

3.3 Rotate the grain tank discharge tube

4/3 way valve

Hydraulic cylinder

3.4 Block valve block

3.5 Flow divider (optional) – with horizontal regulation of the reel

3.6 Reverse the direction of travel of the head

3/2 way valve (Y86)

Hydraulic cylinder

3.7 Horizontal adjustment of the reel

4/3 way valve

Hydraulic cylinder

3.8 Raise/lower the header, speed variator, vertical adjustment of the reel, variator of the shelling cylinder

6/9-way multifunctional valve

Hydraulic cylinder, vertical adjustment of the reel

Hydraulic cylinder, speed variator, sheller cylinder variator

Rotary connection and throttle check valve

3.9 Foot valve, speed variator

4_x000B__x000B_Location of components

Component Grid

Alphabetical index

0293 600.0

00 0293 601 0.pdf:

Technical systems Electrical installation DOMINATOR 130

Connection diagram configuration

central electrical system

Module occupancy

Module A12-1 – Speed Controller (DZW)

Module A12-2 – Speed Controller (DZW)

Module A12-3 – Speed Controller (DZW)

Module A15 – CATERPILLAR electronic engine regulation (CAT)

Connection diagrams 01a – 40a

01a Main voltage supply, diesel engine starter motor

02a Start the diesel engine and check the engine

03a Operational control of the diesel engine

12a Control of grain passage

13a Reverse whistle

17a Drive of the head, reversing the direction of travel

25a Speed control

26a Functional control of the machine

28a AUTOPILOT – (connection possibilities)

30a Omnidirectional flashing light – (connection options)

31a Flashing lights, alarm flashing lights

32a Main lighting switching, parking lights

34a Work lights, instrument lighting

35a Brake lights

37a Windshield wconditioning equipment

40a Additional sockets (cs)

Component Grid

Alphabetical index

0293 601.0

00 0299 862 1.pdf:

Technical systems – Hydraulic installation, Dominator 48 – 68, DO 48 from no. 15403117, DO 68 from no. 15608462

1 Global hydraulic installation

1.1 Hydraulic installation in general

Hydraulic bombs

Oil pressure

Type of oil

Oil change

Filling quantity

oil filter head

Oil filter

1.2 Connection diagram of the global hydraulic system

1.2.2 Connection diagram of the global hydraulic system – with straw gatherer

pressure measurement

1.2.1 Connection diagram of the overall hydraulic system – without straw gatherer

pressure measurement

2 Hydraulic steering installation / 3D control

2.1 Connection diagram of the hydraulic steering installation without AUTOPILOT

2.2 Connection diagram of the hydraulic steering system with AUTOPILOT

2.3 Steering valnit

2.4 Neutral steering function

Use of address

2.5 ess Check

2.6 SELF-PILOT electromagnetic valve

2.7 Checking the AUTOPILOT system

2.8 3D controller

3 Hydraulic operating system

3.1 Connection diagram of the hydraulic system for operations without straw gatherer

3.2 Pressure limiting valve

3.2.1 Pressure limiting valve (703) – with hydraulic swing grain tank discharge pipe

3.2.2 Pressure limiting valve – without hydraulic swing grain tank discharge pipe

3.3 Rotate the grain tank discharge tube

4/3 way valve

Hydraulic cylinder

3.4 Block valve block

3.5 Flow divider (optional) – with horizontal regulation of the reel or, where appropriate, straw gatherer

3.6 Cutting height automation (optional)

3/3 way electromagnetic valve

3.7 Horizontal adjustment of the reel

4/3 way valve

Hydraulic cylinder

3.8 Raise/lower the header, speed variator, vertical adjustment of the reel, variator of the shelling cylinder

6/9-way multifunctional valve

Hydraulic cylinder, vertical adjustment of the reel

Hydraulic cylinder, speed variator, sheller cylinder variator

Rotary connection and throttle check valve

3.9 Foot valve, speed variator

3.10 Straw gatherer

3/3 way valve

Location of components

Alphabetical index

0299 862.1

00 0299 863 1.pdf:

Technical systems – Electrical installation – Dominator 48 – 68, DO 48 from n° 15403117, DO 68 from n° 15608462

Electric system

Module occupancy

Module A12-1 – Speed Controller (DZW)

Module A12-2 – Speed Controller (DZW)

Module A12-3 – Speed controller (DZW)

Module A15 – CATERPILLAR electronic engine regulation (CAT)

01a Main power supply, diesel engine starter motor – with mechanical engine regulation

01b Main power supply, diesel engine starter – with electronic engine regulation (CAT)

02a Starting the diesel engine and engine control – with mechanical engine rarting the diesel engine and engine control – with electronic engine rega Diesel engine operational control – with mechanical engine control

03b Diesel engine operational control – with electronic engine control (CAT)

12a Control of grain passage

13a Straw collector – with mechanical motor regulation

13b Straw collector – with electronic motor regulation (CAT)

17a Drive of the head, reversing the direction of travel

25a Speed control

26a Functional control of the machine

28a AUTOPILOT – (connection possibilities)

30a Omnidirectional flashing light – (connection options)

31a Flashing lights, alarm flashing lights

32a Main lighting switching, parking lights

34a Work lights, instrument lighting

35a Brake lights

37a Windshield wipers

38a Air conditioning unit – with mechanical engine regulation

38b Air conditioning system – with electronic engine regulation (CAT)

40a Additional sockets (connection possible)

Component Grid

Alphabetical index

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF