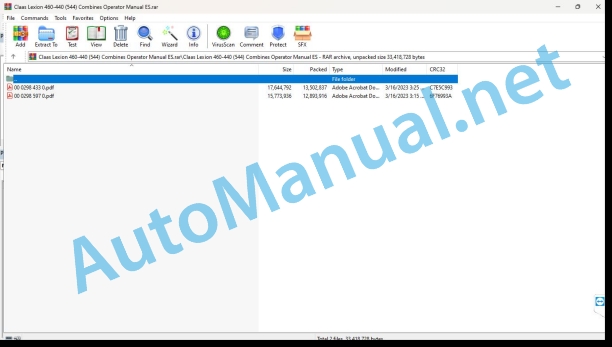

Claas Lexion 460-440 (544) Combines Operator Manual ES

$50.00

- Model: Lexion 460-440 (544) Combines

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 25.2 MB

File List:

00 0298 433 0.pdf

00 0298 597 0.pdf

00 0298 433 0.pdf:

Introduction

Introduction

General indications

Circulation on public roads

Important note

Nameplate / Serial_x0011_number

Machine factory plate

Chassis number

CATERPILLAR C9 engine number

Engine number CATERPILLAR 3126 B

Factory plate – straw chopper

Cabin serial number

Security measures

Security measures

Security support

Extinguisher

Battery disconnect switch

Place the shims

Safety stickers with graphic danger symbols

Technical data

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 410

CLAAS LEXION 410

CLAAS LEXION 410

Safety devices

Front implements – weights, measurements

Before starting_x0011_start

Tasks to be performed before the first_x0004_ start-up

Cabin with Climatic

Climatic

Control and display elements

Put Climatic into operation

Set the cabin temperature

Manually adjust the fan speed_x0004_

Fully automatic heating

Manual heating programming

Foot heating

REHEAT operation (removing moisture from the cabin windshields)

Show outside temperature

Change the temperature to Fahrenheit

Fault/error indication on temperature meter F0 (compartment, blue)

Fault/error indication on temperature meter F1 (blown, yellow)

Fault/error indication on temperature meter F2 (out, red)

Cabin with air conditioning equipment (base equipment)

Cabin with air conditioning equipment

Heated cabin

Foot heating

REHEAT system (fogged windows)

Incident, possible causes and solutions – air conditioning equipment

Open and close the cabin roof

Window washing equipment

Driver’s platform

Driver Platform Presentation

Scorecard

Monitor (picture running)

Monitor (crop image)

Area C keys

Rotary switch D

steering bar

Ignition lock (S)

Multifunctional switch

Gait monitor

Multifunctional controller

Adjust the steering bar

Swing the top of the steering rod_x0004_

Steering wheel height adjustment

central electrical system

Extend and retract discharge tube

Safety device

Connect and disconnect the discharge of the grain tank_x0004_

Connecting and disconnecting the threshing unit

Driver’s seat

Mechanical driver’s seat

Driver’s seat with air suspension_x0004_ (optional equipment)

Front staircase

pivoting ladder

Ascent and widening of the staircase

Position lights for excessive width

Install position lights for excessive width

Back staircase

Other uses of the back staircase

Drive the combine

Rotary switch for engine speed_x0004_

Maneuver

Engine start

Servo-assisted gear shifting (optional equipment)

Adjustment of the hardness of the gear shift lever movement

Driving characteristics

Footbrake

Parking break

stop the engine

CLAAS autopilot (corn milking head)

CLAAS autopilot (cereal cutting tables)

Adjusting the straight line running of the combine

Orient the laser sensor relative to the field

Putting CLAAS Autopilot into service

Use in rapeseed with left side blade

Cutting table hydraulic cylinders

Engage the hydraulic cylinders

Third cylinder for the cutting table

Drive steering axle

Changing the drive steering axle from transport position to work position

Adjust the track width of the drive steering axle

Variable steering axle

Steering wheels – impact limitations (variable steering axle)

Side gates

Open and close the side doors and tailgate

Adjustment of the gate closures

Cabin and lighting

Running lights, work lights and mirrors

Trailer / harvest control / grain tank

Tow the combine

Backward

Harvest control

grain warehouse

Close the holes in the grain tank

Install the twin wheels

Front ladder handling with twin tires_x0004_

Additional weights

Fluid refill for steering axle wheels

Install additional weights on the steering axle

Volume of parts – steering axle weights (variable and fixed axle)

Parts volume – steering axle (steering drive axle) weights

Assemble and disassemble the_x0011_cutting table

Assemble the cutting table

Tip the cutting table out of the transport position

Machines with CLAAS-Auto-Contour

Adjustment of the hydraulic cylinders for transversal regulation of the cutting table

Machines without CLAAS-Auto-Contour

Fix corn cutting tables and milking heads (cutting tables without Auto-Contour)

Connect the cardan shafts

Install the support leg

Disassemble the cutting table

Disassemble the cutting table

Place the cutting table on the ground

Place the cutting table on the cutting table trailer

CEBIS Operation

Operation – base machine

Carrier feed channel_x0004_

Carrier Chains

Gear reversal equipment for cutting table

Cutting table discharge springs

Check the adjustment of the discharge springs

Cutting height indicator

Discharge indication

Lock the cutting table discharge springs

Adjust the lowering speed of the front implement_x0004_

Cutting table clutch

Connect and disconnect the cutting table

Threshing organs

Stone collecting device

Connecting and disconnecting the threshing mechanism

Sheller cylinder

Clean the threshing units

Basic concave adjustment

Learn final positions

Speed of revolutions of the sheller cylinder_x0004_

Cylinder drives

Two scale variator

Assemble and disassemble the preconcave segments_x0004_

Threshing segments

Remove the threshing segment

Assemble the threshing segment

Shelling

Unclog the sheller cylinder

splash cloth

Shak Intensive shakers

Multi-finger separation system

Clean the shakers

Emergency Signal

Shaker steps

Rice steps

Middle shaker steps

Side steps

Parallel steps

CCM steps

Cleaning

sieve box

Preparation Fund

Lamellar sieves

Electrical regulation of the sieves

Dismantle the sieves

Assemble the screens

Tightening torque of axial screws for upper and lower screens

Basic adjustment of the screens

Harvest without the lower sieves

Cleaning fan

Regulation of fan revolutions_x0004_

LEXION 460 – 420 ventilated shaker

Adjusting the air nozzle for pre-separation LEXION 460 – 420

LEXION 460 – 420 air guide plate

LEXION 410 air guide plates

Choke caps for grass seeds and similar (additional equipment)

Dynamic slope compensation (clean 3-D)

Grain passage control unit

Augers and trays

Elevators

grain warehouse

Supplement for the grain tank – electric (9300 / 8500 liter grain tank)

Grain tank cover – mechanical (8100 / 7800 / 7300 liter grain tank)

Download grain bin

Help for downloading the_x0011_grain tank (additional equipment)

Grain tank discharge pipe

Retract and extend the grain tank_x0011_discharge tube

Discharge tube cleaning flaps

Safety screw for unloading the grain tank_x0011_

Connecting and disconnecting the grain tank discharge

Entrance to the grain warehouse

Automatic chain lubrication – grain tank discharge (additional equipment)

Straw chopper

Straw chopper (hydraulic)

Check before starting the chopper

Spreading width variation

Distribution funnel – height adjustment

Electrical variation of the spreader plates

Adjust chopping length

Cross knife adjustment

Start the chopper

Disconnect the chopper

Cutter position to hang the trailer from the cutting table

Reduce chopper revolutions

Change the position of the V-belts_x0011_(12)

Straw chopper

Straw chopper (Fixed straw chopper)

Check before starting the chopper

Spreading width variation

Distribution funnel – height adjustment

Electrical variation of the spreader plates

Adjust chopping length

Cross knife adjustment

Connect the chopper

Disconnect the chopper

Cutter position for towing the cutting table trailer

Lower the chopper revolutions

Chaff spreader/straw spreader

chaff spreader

Fold down the chaff spreader

straw spreader

Adjust spreading width

Screening and threshing frames

Sieve box

Threshing table

Sheller plates

Threshing segment

Incident, causes and solutions – base machine

Entertainment by_x0011_la_x0011_harvester

Important information for entertainment

Important information for entertainment and safety

Entertainment and lubricant tables

Entertainment tables

Lubricant charts

Hydraulic system

pressure accumulator

Check the oil level

Change hydraulic oil

Changing the hydraulic oil filter

Clean coarse filters

Filling instructions for oil change (Sauer 90 R 130 / 90 M 100)

Vent the hydraulic cylinders for transversal operation of the cutting table

Gears/brakes

Check the oil level

Change the oil

Two-step side reducers (20 t / 19 t / 20 t HD)

Check the oil level

Change the oil

Lateral reducers (planetary reducers)

Check the oil level

Oil change

Sheller cylinder reducer

Change the oil

Check the oil level

timing gear

Check the oil level

Change the oil

Grain tank discharge gear_x0011_grains_x0004_

Check the oil level

Change the oil

Adjust the gear shift

Foot brake and brake fluid

Parking break

conveyor channel

Tension the feed chains

Cleaning the vacuum cleaner (additional equipment)

elevator chains

Tension the grain tank elevator chain (machine without performance meter)

Tension the chain of the grain tank elevator (machine with yield meter)

Tension the return elevator chain

Drive belts / drive chains – base machine

General indications

General table of left drives

Drive Belts and Chains

General table of right drives_x0004_

Drive belts

Remove the cutting table drive belt (1) (cutting table drive without…

Install and adjust the cutting table drive belt (1)

Remove the cutting table drive belt (2) (cutting table drive with…

Put on and adjust the driving belt of the cutting table (2)

Remove the cutting table variator belt (3)

Assemble the belt of the variator of the_x0011_cutting table (3)

Remove the drive belt from the straw thrower_x0004_ (4)

Assemble and adjust the straw thrower drive belt (4)

Remove the drive belt from the cutting table gear train (5)

Assemble and adjust the cutting table gear train drive belt_x0011_(5)

Remove the drive belt from the hydraulic pump for the straw spreader (6)

Assemble and adjust the drive belt of the hydraulic pump for the de_x0011_straw spreader / …

Remove the main gear train drive belt (7)

Install and adjust the main gear train drive belt (7)

Remove the drive belt from the grain tank discharge gear train_x0011_(8)

Assemble and adjust the drive belt of the tank discharge gear train_x0011_de…

Remove the drive belt from the straw chopper gear train (9)

Assemble and adjust the drive belt of the straw chopper gear train (9)

Adjust the drive of the straw chopper

Release and remove the V-belt (10) from the cylindrical spring (G)

Install the V-belt (10) and tension it on the cylindrical spring (G)

Release and remove the V-belt (11) from the cylindrical spring (G)

Install the V-belt (11) and tension it on the cylindrical spring (G)

Loosen and remove the straw chopper drive belt (12) (hydraulic straw chopper)

Assemble the driving belt of the straw chopper_x0004_ (12) and tension it on the cylindrical spring (…

Remove the drive belt from the sieve box gear train (13)

Assemble and adjust the screen box gear train drive belt (13)

Remove the screen box gear train drive belt (14)

Assemble and adjust the screen box gear train drive belt (14)

Remove the sieve box drive belt (15)

Open the battery/tool drawer:

Assemble and adjust the sieve box drive belt (15)

Remove the fan gear train drive belt (20)

Install and adjust the fan gear train drive belt (20)

Remove the fan drive belt_x0011_(21)

Install the fan drive belt_x0011_(21)

Remove the drive belt from the threshing organs variator (22)

Assemble the drive belt of the threshing organs variator_x0004_ (22)

Remove the drive belt from the shelling cylinder (23)

Assemble and adjust the sheller cylinder drive belt (23)

Remove the throttle drive belt_x0011_previous (24)

Install and adjust the pre-throttle drive belt (24)

Remove the vacuum cleaner drive belt_x0011_(28)

Assemble and adjust the vacuum cleaner drive belt (28)

hten the radiator screen drive belt (32)

Tension the vacuum cleaner drive belt_x0011_(34)

Remove the drive chain for the grain tank discharge_x0004_ (17)

Assemble and adjust the grain tank discharge drive chain (17)

Cab air conditioning equipment

Clean the filters

Clean the equipment installed on the cabin roof

Air conditioning equipment

Clean the condenser

Check the refrigerant level

Replace the dehumidifier filter

Necessary amount of refrigerant agent – refrigerant_agent_x0011_R_x0011_134_x0011_a

compressor oil

Entertainment work before beginning_x0004_ the harvest

Extinguisher

Extinguisher

Compressed air equipment (additional equipment)

Connections for compressed air intake

Drain the air tank

pressure regulator

Straw chopper

Change the blades (hydraulic straw chopper)

Move the deburring blade down

Change the chopper blade

Return the deburring blade to its position_x0004_

Chathe blades (fixed straw chopper)

Remove the straw guide plate

Change the chopper blade

Assemble the straw guide plate

Change the counterblades

straw spreader

Install and adjust the timing belt

Speed control_x0004_

Adjustment of emi induction

Instructions for preserving the combine during winter

Entertainment – motor

Important information for entertainment

Important information for entertainment_x0004_ and safety_x0011_

Entertainment and lubricant tables

Entertainment table

Lubricants table

Entertainment – motor

Engine overview

fuel circuit

Fuel tank

fuel cock

Water separator / fuel prefilter (standard equipment – small version)

Disassembled fuel prefilter:

Water separator / fuel prefilter (additional equipment, instead of the fuel prefilter…

Fuel filter

Change the filter cartridge

Bleed the fuel system

Engine oil level check

Engine oil change

Emptyin Oil filter

Top up engine oil

Refrigeration system

Cooling liquid

Engine block water drain plugs

Water radiator

Fill the coolant

Overpressure

Antifreeze/anticorrosive

notice plate

Coolant temperature

Stop the overheated engine

Radiator Clean the water radiator

Air filter

alarm device

Clean the air filter screen

Clean the dry air filter

Clean the air filter

Safety cartridge

Electric system

Three-phase current generator

Engine incidents, causes and solutions

Engine conservation during_x0011_winter

Engine conservation

Greasing scheme

Lubricants and indications

Alphabetical index

Alphabetical index

0298_303_1_BA_ES_144.pdf

CEBIS Operation

CLAAS CEBIS on-board information system

CEBIS monitor and rotary switch_x0004_

C key area

Rotary switch D

Multifunctional handle M

Screen area E (crop box)

Rotary switch D

Before first use

Gear chart

harvest box

Cartography ON/OFF

Cartographic indication

Reel Presets

Horizontal reel position

Proportional reel speed

Reel height

Presets for the head

Distance between starter plates

Mowing mechanism table length

Cutting height adjustment (CAC)

Partial width switching

Harvest Measuring Equipment

Components

Basic and calibrated adjustment

Preparation for performance measurement

Humidity measurement ON/OFF, humidity correction, humidity to store

Fast track to achieving reasonable measurement data

Performance measurement

Calibration factor

Zero point performance

Checked weight

Humidity correction

Humidity measurement ON/OFF

Zero angle

Humidity to store

Dry product indication

Adjustment according to the type of fruit

List of types of fruit to thresh

Load CLAAS values

Load own values

Memorize own values

Print values

Enter CLAAS values

Indicate own values

Clean by blowing

to register

Planned jobs

Next planned work

Previous planned work

New work planned

Modify a planned job

Name / Plot / Fruit / Operator:

Start/Stop

Memorization data:

Dispatched jobs

Next or Previous job dispatched

New batch of a dispatched job

Correct the surface

daily counter

Print the daily counter

Cancel daily counter

Total counter

Print the total counter

Copy the chip card

Mowing mechanism

CAC Sensitivity

Cutting height stops

Graduation of partial heights

Work position

Working width

Automatic reel height

Reel Height Stops

Automatic mowing mechanism

Mech table length limits. mowing

Limits of horizontal adjustment of the reel

Varioautomatic ON/OFF

Starter plate stops

Revolution regime

Learn revolutions

R.P.M. max empty

Chaff spreader (without function for rotor machines)

Return lift revolution control

Tachometer

Calibration path

Pulses/100

Autopilot Sensitivity (ATP)

Head zero point with Autopilot

zero point direction

Separation

Test sensors

Final positions of the upper and lower sieves

Adjustment of the upper and lower sieves

Return limit indication

Return zero point

Language

Date hour

Measurement units

Time indication:

Maintenance

Jobs every XXh

Instructions for use

Basic adjustment

General standard settings:

Specific standard settings:

Adjustment guide

Incident/solution

Check list

Security measures

Security code

Disconnect security code:

engine load

Engine diagnosis

Incident/Solution – Harvest Measuring Equipment

Guideline values for pulses/100 m

Alphabetical index

00 0298 597 0.pdf:

Introduction

Introduction

General indications

Circulation on public roads

Important note

Nameplate / Serial_x0011_number

Machine factory plate

Chassis number

CATERPILLAR C9 engine number

Engine number CATERPILLAR 3126 B

Factory plate – straw chopper

Cabin serial number

Security measures

Security measures

Security support

Extinguisher

Battery disconnect switch

Place the shims

Safety stickers with graphic danger symbols

Technical data

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LEXION 460 / 450 / 440

CLAAS LE 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 430 / 420

CLAAS LEXION 410

CLAAS LEXION 410

CLAAS LEXION 410

Safety devices

Front implements – weights, measurements

Before starting_x0011_start

Tasks to be performed before the first_x0004_ start-up

Cabin with Climatic

Climatic

Control and display elements

Put Climatic into operation

Set the cabin temperature

Manually set the fan speed

Fully automatic heating

Manual heating programming

Foot heating

REHEAT operation (removing moisture from the cabin windshields)

Show outside temperature

Change the temperature to Fahrenheit

Fault/error indication on temperature meter F0 (compartment, blue)

Fault/error indication on temperature meter F1 (blown, yellow)

Fault/error indication on temperature meter F2 (out, red)

Cabin with air conditioning equipment (base equipment)

Cabin with air conditioning equipment

Heated cabin

Foot heating

REHEAT system (fogged windows)

Incident, possible causes and solutions – air conditioning equipment

Open and close the cabin roof

Window washing equipment

Driver’s platform

Driver Platform Presentation

Scorecard

Monitor Zone A

Rotary switch D

Monitor Zone B

steering bar

Ignition lock (S)

Multifunctional switch

Gait monitor

Multifunctional controller

Adjust the steering bar

Swing the top of the steering rod_x0004_

Steering wheel height adjustment

central electrical system

Extend and retract discharge tube

Safety device

Connect and disconnect the discharge of the grain tank_x0004_

Connecting and disconnecting the threshing unit

Driver’s seat

Mechanical driver’s seat

Driver’s seat with air suspension_x0004_ (optional equipment)

Front staircase

pivoting ladder

Ascent and widening of the staircase

Position lights for excessive width

Install position lights for excessive width

Back staircase

Other uses of the back staircase

Drive the combine

Rotary switch for engine speed_x0004_

Maneuver

Engine start

Servo-assisted gear shifting (optional equipment)

Adjustment of the hardness of the gear shift lever movement

Driving characteristics

Footbrake

Parking break

stop the engine

CLAAS autopilot (corn milking head)

CLAAS autopilot (cereal cutting tables)

Adjusting the straight line running of the combine

Orient the laser sensor relative to the field

Putting CLAAS Autopilot into service

Use in rapeseed with left side blade

Cutting table hydraulic cylinders

Engage the hydraulic cylinders

Third cylinder for the cutting table

Drive steering axle

Changing the drive steering axle from transport position to work position

Adjust the track width of the drive steering axle

Variable steering axle

Steering wheels – impact limitations (variable steering axle)

Side gates

Open and close the side doors and tailgate

Adjustment of the gate closures

Cabin and lighting

Running lights, work lights and mirrors

Trailer / harvest control / grain tank

Tow the combine

Backward

Harvest control

grain warehouse

Close the holes in the grain tank

Install the twin wheels

Front ladder handling with twin tires_x0004_

Additional weights

Fluid refill for steering axle wheels

Install additional weights on the steering axle

Volume of parts – steering axle weights (variable and fixed axle)

Parts volume – steering axle (steering drive axle) weights

Assemble and disassemble the_x0011_cutting table

Assemble the cutting table

Tip the cutting table out of the transport position

Machines with CLAAS-Auto-Contour

Adjustment of the hydraulic cylinders for transversal regulation of the cutting table

Machines without CLAAS-Auto-Contour

Fix corn cutting tables and milking heads (cutting tables without Auto-Contour)

Connect the cardan shafts

Install the support leg

Disassemble the cutting table

Disassemble the cutting table

Place the cutting table on the ground

Place the cutting table on the cutting table trailer

IMO Operation

Operation – base machine

Carrier feed channel_x0004_

Carrier Chains

Gear reversal equipment for cutting table

Cutting table discharge springs

Check the adjustment of the discharge springs

Cutting height indicator

Discharge indication

Lock the cutting table discharge springs

Adjust the lowering speed of the front implement_x0004_

Cutting table clutch

Connect and disconnect the cutting table

Threshing organs

Stone collecting device

Connecting and disconnecting the threshing mechanism

Sheller cylinder

Clean the threshing units

Basic concave adjustment

Learn final positions

Speed of revolutions of the sheller cylinder_x0004_

Cylinder drives

Two scale vaor

Assemble and disassemble the preconcave segments_x0004_

Threshing segments

Remove the threshing segment

Assemble the threshing segment

Shelling

Unclog the sheller cylinder

splash cloth

Intensive shakers

Multi-finger separation system

Clean the shakers

Emergency Signal

Shaker steps

Rice steps

Middle shakeeps

Side steps

Parallel steps

CCM steps

Cleaning

sieve box

Preparation Fund

Lamellar sieves

Electrical regulation of the sieves

Dismantle the sieves

Assemble the screens

Tightening torque of the axial screws for upper and lower sieves_x0004_

Basic adjustment of the screens

Harvest without the lower sieves

Cleaning fan

Regulation of fan revolutions_x0004_

LEXION 460 – 420 ventilated shaker

Adjusting the air nozzle for pre-separation LEXION 460 – 420

LEXION 460 – 420 air guide plate

LEXION 410 air guide plates

Choke caps for grass seeds and similar (additional equipment)

Dynamic slope compensation (clean 3-D)

Grain passage control unit

Augers and trays

Elevators

grain warehouse

Supplement for the grain tank – electric (9300 / 8500 liter grain tank)

Grain tank cover – mechanical (8100 / 7800 / 7300 liter grain tank)

Download grain bin

Help for downloading the_x0011_grain tank (additional equipment)

Grain tank discharge pipe

Retract and extend the grain tank_x0011_discharge tube

Discharge tube cleaning flaps

Safety screw for unloading the grain tank_x0011_

Connect and disconnect the grain tank discharge

Entrance to the grain warehouse

Automatic chain lubrication – grain tank discharge (additional equipment)

Straw chopper

Straw chopper (hydraulic)

Check before starting the chopper

Spreading width variation

Distribution funnel – height adjustment

Electrical variation of the spreader plates

Adjust chopping length

Cross knife adjustment

Start the chopper

Disconnect the chopper

Cutter position to hang the trailer from the cutting table

Reduce chopper revolutions

Change the position of the V-belts_x0011_(12)

Straw chopper

Straw chopper (Fixed straw chopper)

Check before starting the chopper

Spreading width variation

Distribution funnel – height adjustment

Electrical variation of the spreader plates

Adjust chopping length

Cross knife adjustment

Connect the chopper

Disconnect the chopper

Cutter position for towing the cutting table trailer

Lower the chopper revolutions

Chaff spreader/straw spreader

chaff spreader

Fold down the chaff spreader

straw spreader

Adjust spreading width

CLAAS-Auto-Contour

Automatic regulation of cutting height and transversal adaptation of the cutting table

Putting CLAAS Auto-Contour into operation

Second cutting height

Raise the cutting table

Putting CLAAS Auto-Contour back into operation

Pre-selection of cutting height with automatic_x0011_regulation (machines with CLAAS Auto-Contour)

Activate cutting height preselection

Program an additional cutting height

Adjustment table for automatic cutting height regulation

CLAAS-Contour (support pressure regulation)

Putting CLAAS-Contour into operation

Raise the cutting table

Screening and threshing frames

Sieve box

Threshing table

Sheller plates

Threshing segment

Incident, causes and solutions – base machine

Entertainment by_x0011_la_x0011_harvester

Important information for entertainment

Important information for entertainment and safety

Entertainment and lubricant tables

Entertainment tables

Lubricant charts

Hydraulic system

pressure accumulator

Check the oil level

Change hydraulic oil

Changing the hydraulic oil filter

Clean coarse filters

Filling instructions for oil change (Sauer 90 R 130 / 90 M 100)

Vent the hydraulic cylinders for transversal operation of the cutting table

Gears/brakes

Check the oil level

Change the oil

Two-step side reducers (20 t / 19 t / 20 t HD)

Check the oil level

Change the oil

Lateral reducers (planetary reducers)

Check the oil level

Change the oil

Sheller cylinder reducer

Change the oil

Check the oil level

timing gear

Check the oil level

Change the oil

Grain tank discharge gear_x0011_grains_x0004_

Check the oil level

Change the oil

Adjust the gear shift

Foot brake and brake fluid

Parking break

conveyor channel

Tension the feed chains

Cleaning the vacuum cleaner (additional equipment)

elevator chains

Tension the grain tank elevator chain (machine without performance meter)

Tension the chain of the grain tank elevator (machine with yield meter)

Tension the return elevator chain

Drive belts / drive chains – base machine

General indications

General table of left drives

Drive Belts and Chains

General table of the right drives_x0004_

Drive belts

Remove the cutting table drive belt (1) (cutting table drive without…

Install and adjust the cutting table drive belt (1)

Remove the cutting table drive belt (2) (cutting table drive with…

Put on and adjust the driving belt of the cutting table (2)

Remove the cutting table variator belt (3)

Assemble the belt of the variator of the_x0011_cutting table (3)

Remove the drive belt from the straw thrower_x0004_ (4)

Assemble and adjust the straw thrower drive belt (4)

Remove the drive belt from the cutting table gear train (5)

Assemble and adjust the cutting table gear train drive belt_x0011_(5)

Remove the drive belt from the hydraulic pump for the straw spreader (6)

Assemble and adjust the drive belt of the hydraulic pump for the de_x0011_straw spreader / …

Remove the main gear train drive belt (7)

Install and adjust the main gear train drive belt (7)

Remove the drive belt from the grain tank discharge gear train_x0011_(8)

Assemble and adjust the drive belt of the tank discharge gear train_x0011_de…

Remove the drive belt from the straw chopper gear train (9)

Assemble and adjust the drive belt of the straw chopper gear train (9)

Adjust the drive of the straw chopper

Release and remove the V-belt (10) from the cylindrical spring (G)

Install the V-belt (10) and tension it on the cylindrical spring (G)

Release and remove the V-belt (11) from the cylindrical spring (G)

Install the V-belt (11) and tension it on the cylindrical spring (G)

Loosen and remove the straw chopper drive belt (12) (hydraulic straw chopper)

Assemble the driving belt of the straw chopper_x0004_ (12) and tension it on the cylindrical spring (…

Remove the drive belt from the sieve box gear train (13)

Assemble and adjust the screen box gear train d

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20