Claas Gps Pilot – Hydraulic (B85) Digital Solutions Operator Manual ES

$50.00

- Model: Gps Pilot – Hydraulic (B85) Digital Solutions

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 310 MB

File List:

00 1400 639 3.pdf

00 1402 656 2.pdf

00 1402 657 1.pdf

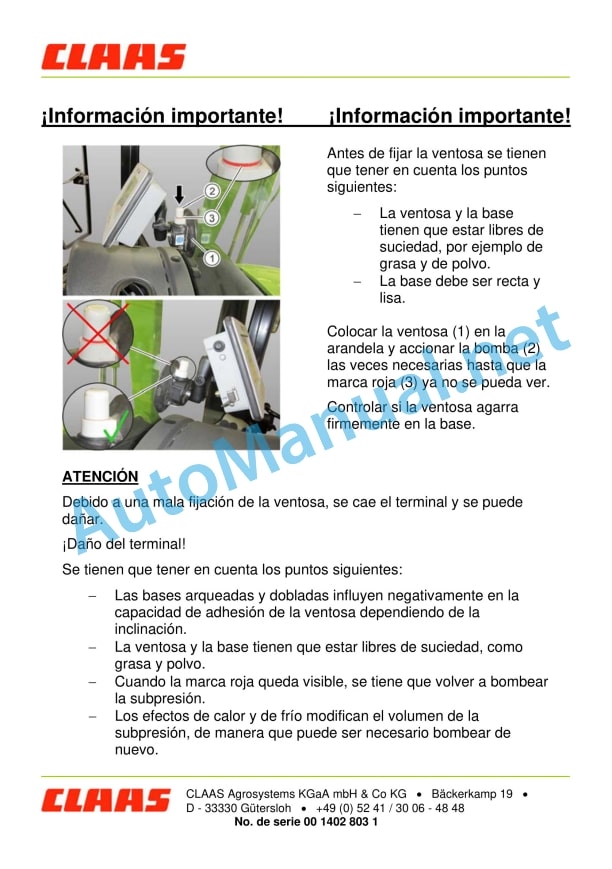

00 1402 803 1.pdf

00 1405 165 7.pdf

00 1405 185 7.pdf

00 1420 029 4.pdf

00 1420 057 2.pdf

00 1400 639 3.pdf:

COPILOT S7 GPS

1. Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this instruction manual

1.1.3 Symbols and indications

1.1.4 Optional equipment

1.1.5 Qualified specialized workshop

1.1.6 Maintenance instructions

1.1.7 Information regarding warranty

1.1.8 Spare parts and technical questions

1.2 Proper application of the machine

1.2.1 Suitable GPS COPILOT application

1.2.2 Logically foreseeable erroneous application GPS COPILOT

2 Security

2.1 Recognize warning signs

2.1.1 Danger symbols

2.1.2 Keyword

2.2 Safety instructions

2.2.1 Importance of the instruction manual

2.2.2 Terminal software update

2.2.3 Observe graphic danger symbols and warning instructions

2.2.4 Requirements for all people who work with the product

2.2.5 Construction modifications

2.2.6 Optional equipment and spare parts

2.2.7 Using USB devices

2.2.8 Operation only in accordance with statutory commissioning

2.2.9 Technical status

2.2.10 Dangers when driving on the road and on terrain

Road traffic

Field trip

2.2.11 Electrical shock from electrical equipment

2.2.12 Maintenance work and repair work

3 Product Description

3.1 Summary and operation

3.1.1 COPILOT GPS Summary

3.1.2 S7 terminal overview

3.1.3 Summary corrective signals

EGNOS / WAAS / MSAS

3.1.4 Antenna summary

GNSS antenna

3.2 Optional equipment

3.2.1 GLONASS*

3.3 Identification plates and identification numbers

3.3.1 COPILOT S7 GPS identification plate

3.3.2 Terminal identification plate

4 Control and display instruments

4.1 S7 terminal overview

4.1.1 Button and prompt representation conventions

4.2 GPS COPILOT menu structure

4.2.1 Initial menu

4.2.2 Main menu, summary

4.2.3 Summary of DGPS visualizations

4.2.4 Menu

4.2.5 Menu

4.2.6 Menu

4.2.7 Menu

4.2.8 Menu

4.2.9 Menu

4.2.10 Menu

4.2.11 Menu

4.2.12 Menu

4.2.13

4.2.14 Menu

4.2.15 Menu

4.2.16 Menu

4.2.17 Menu

4.2.18 Menu

4.2.19 Menu

Menu

Menu

5 Technical data

5.1 GPS COPILOT

5.1.1 Corrective signal accuracy

5.1.2 COPILOT GPS Specification

5.2 S7 Terminal

5.2.1 Specification

6 Prepare the product

6.1 Turn off the machine and secure it

6.1.1 Turn off the machine and secure it

6.2 Perform before commissioning

6.2.1 Perform before the first commissioning of GPS COPILOT

6.2.2 Perform GPS COPILOT before each start-up

6.3 First start-up of the machine

6.3.1 Create vehicle profile

6.4 First start-up of the working device

6.4.1 Create device profile checklist

6.4.2 Create device profile

6.4.3 Select the type of coupling

6.4.4 Enter the measurements of the devices

Adjust the width of the device

Particularity in LEXION and TUCANO in MONTANA version

Adjust the overlap or gap

Working width

Adjust the movement of the device in the longitudinal direction

Adjust the movement of the device in the transverse direction

6.5 First start-up of the correction signal

6.5.1 First commissioning of the GNSS signal

6.5.2 Select the E-DIF correction type

6.5.3 Select the type of SBAS correction

6.6 Adjust subscriptions

6.6.1 Enter codes

7 Management

7.1 Checklists

7.1.1 Prepare field work

7.1.2 Carry out field work

7.2 GPS COPILOT

7.2.1 Turn on the terminal

Starting screen

7.2.2 Turn off the terminal

7.2.3 Manage control elements

Manage the keyboard

Operate the numeric keypad

Handle buttons with attached list

7.2.4 Direction direction indicator

7.2.5 GPS status

7.2.6 Connect USB data memory

7.3 GPS settings

7.3.1 Adjust BEIDOU

7.3.2 Adjust GNSS

7.3.3 Adjust NMEA broadcast

Limit NMEA broadcast to GPS signal

Record entries

Continue using the GNSS signal

7.3.4 Adjust E-DIF

Set reference point

Update reference point

7.3.5 Adjust SBAS

7.4 System settings

7.4.1 Adjust vision

Zoom in and out

Adjust the display mode

Adjust perspective

Hide buttons

View the buttons

7.4.2 Setting the language

7.4.3 Set units

7.4.4 Set the time

GMT Offset

7.4.5 Exchange control elements

7.4.6 Connect or disconnect the worked surface signal

7.4.7 Adjust day and night mode

7.4.8 Adjust screen brightness

7.4.9 Adjust the direction indicator

Sensitivity

7.4.10 Adjust the matrix

7.5 Vehicle settings

7.5.1 Load vehicle profile

7.5.2 Process vehicle profile

7.5.3 Export vehicle profiles

7.5.4 Import vehicle profiles

7.5.5 Delete vehicle profiles

7.6 Device settings

7.6.1 Load vehicle profile

7.6.2 Process device profile

7.6.3 Export device profiles

7.6.4 Import the device profile

7.6.5 Delete device profiles

7.7 Order processing

7.7.1 Create job

Create a new job from the initial menu

Create a new job from job management

7.7.2 Process notes

7.7.3 Load job

7.7.4 End the job

7.7.5 Continue the last used job

7.7.6 Export job

7.7.7 Import job

7.7.8 Delete job

7.7.9 Create template

7.7.10 Use model

7.7.11 Delete templates

7.8 Field trip with COPILOT GPS

7.8.1 Summary of types of field trips

7.9 Boundaries and markers

7.9.1 Use a surface counter

Record the parcel boundary

Interrupt recording

Plot boundary as a reference footprint

7.9.2 Set marker

User-defined bookmarks

Set user-defined bookmarks

7.9.3 Drive to markers

Select bookmark

Drive to bookmarks

7.10 Straight line guide

7.10.1 Straight line guide

7.10.2 Create reference fingerprint

7.10.3 Fix point B again

7.10.4 Straight line guide with angle (angle A=B)

7.10.5 Work the plot

Commutation

7.10.6 Load lines A=B

7.10.7 Process the naming of a line A=B

7.10.8 Move line A=B

7.11 Guide by circular lines

7.11.1 Guide service through circular lines

7.11.2 Create reference footprint

7.11.3 Work the plot

7.11.4 Load the circular footprint

7.11.5 Move the circular footprint

7.12 Guidance by contour lines

7.12.1 Using contour line guidance

7.12.2 Record reference fingerprint

Record new reference fingerprint

7.12.3 Work the plot

Commutation

Padlock function

7.13 Display of partial widths

7.13.1 Activate and deactivate the display of partial widths

7.13.2 Adjust the display of partial widths

Enter the number of partial widths of the attached device

Adjust the width of the individual sections of the attached device

Adjust the allowed overlap

Set the connection time

Set the shutdown time

7.13.3 Using the display of partial widths

8 Incident and solution

8.1 Errors and measures to take

8.1.1 Starting the COPILOT GPS system

8.1.2 Defective GNSS signal

8.1.3 EGNOS/WAAS/MSAS corrective signal

8.1.4 Error in footprint guidance

8.2 S7 Terminal

8.2.1 Take screenshots

8.3 Diagnosis

8.3.1 GPS-Setup

8.3.2 GPS Status

8.3.3 E-DIF Status

9 Maintenance

9.1 Summary of maintenance intervals

9.1.1 Every 100 hours of service or monthly

10 Decommissioning and waste disposal

10.1 General information

10.1.1 Decommissioning and waste disposal

11 EC declaration of conformity

11.1 GPS COPILOT

11.1.1 EC declaration of conformity

12 Technical dictionary and abbreviations

12.1 GPS COPILOT

12.1.1 Abbreviations

12.1.2 Units

00 1402 657 1.pdf:

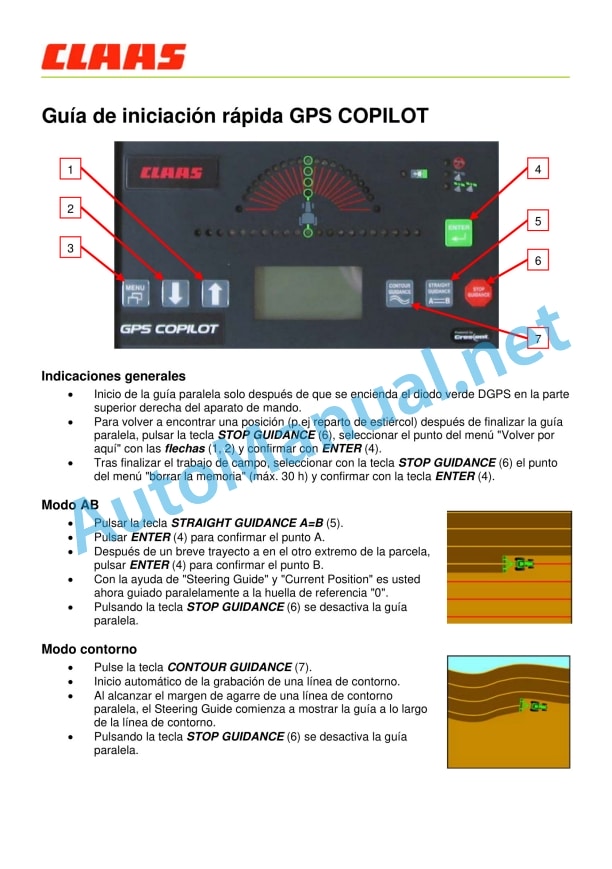

COPILOT GPS Quick Start Guide

General indications

Contour mode

Changing the working width

Change of signal type

Surface measurement

Automatic movement of lines A-B

00 1405 165 7.pdf:

GPS PILOT

1. Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this instruction manual

1.1.3 Symbols and indications

1.1.4 Optional equipment

1.1.5 Qualified specialized workshop

1.1.6 Maintenance instructions

1.1.7 Information regarding warranty

1.1.8 Spare parts and technical questions

1.1.9 Road traffic permit

Model report

No objection certificate

General circulation permit

1.2 Proper application of the machine

1.2.1 Compliant use

1.2.2 Logically foreseeable non-conforming uses

2 Security

2.1 Recognize warning signs

2.1.1 Danger symbols

2.1.2 Keyword

2.2 Safety instructions

2.2.1 Meaning of the instruction manual

2.2.2 Terminal software update

2.2.3 Requirements for all people who work with the product

2.2.4 Danger zones

Danger zones

2.2.5 Interaction between the terminal and the machine or tractor

2.2.6 Construction modifications

2.2.7 Optional equipment and spare parts

2.2.8 Using USB devices

2.2.9 Operation only in accordance with statutory commissioning

2.2.10 Technical status

2.2.11 Danger from damage to the product

2.2.12 Comply with technical limit values

Comply with technical limit values

2.2.13 Prepare a product for road circulation

2.2.14 Dangers when traveling on the road with an ISOBUS coupled device

Turn on the terminal while driving on the road

2.2.15 Dangers when driving on the road and in the countryside

2.2.16 Electrical shock from electrical equipment

2.2.17 Fatal electric shock due to overhead lines

2.2.18 Liquids under pressure

2.2.19 Maintenance work and repair work

2.2.20 Driving with GPS PILOT

Road traffic

Field trip

2.2.21 Working with Task Control* and Section Control*

3 Product Description

3.1 Summary and operation

3.1.1 Summary GPS PILOT – Hydraulic

3.1.2 Summary GPS PILOT – Steer ready

3.1.3 GPS PILOT FLEX Summary

3.1.4 Factory GPS PILOT Summary

3.1.5 S10 terminal summary

3.1.6 Navigation computer summary (ECU)

3.1.7 Electric steering wheel

3.1.8 Summary corrective signals

EGNOS / WAAS / MSAS

Omnistar HP/XP/G2

RTK FIELD BASE and BASELINE HD

RTK FARM BASE

3.1.9 Module summary

BASELINE HD

RTK FIELD BASE

RTK (Motorola)

RTK FARM BASE

3.2 Safety devices

3.2.1 Automatic disconnection when exceeding the maximum speed

3.2.2 Automatic disconnection when the minimum speed is not reached

3.2.3 Seat contact switch

3.2.4 Manual overexcitation

electric steering wheel

3.3 Optional equipment

3.3.1 GPS L2*

3.3.2 GLONASS*

3.3.3 TURN IN*

3.3.4 AUTO TURN*

3.3.5 Task Control*

Task Control Basic*

Task Control Geo*

3.3.6 Section Control*

3.4 Identification plates and identification numbers

3.4.1 GPS PILOT identification plate

3.4.2 Terminal identification plate

3.4.3 Navigation computer identification plate

4 Control and display instruments

4.1 GPS PILOT

4.1.1 Main switch and start switch

Main switch

Main switch

4.2 S10 terminal summary

4.2.1 Button and prompt representation conventions

4.3 GPS PILOT menu structure

4.3.1 Initial menu

Initial menu without Task Control*

Initial menu with Task Control*

4.3.2 Summary menu

4.3.3 Indicator cell summary

Loss of corrective signal

4.3.4

4.3.5 Menu

4.3.6 Menu

4.3.7 Menu

Menu

Menu

Menu

4.3.8 Menu

4.3.9 Menu

4.3.10 Menu

Menu

4.3.11

4.3.12 Menu

4.3.13 Menu

4.3.14 Menu

4.3.15 Menu

4.3.16 Menu

4.3.17 Menu

4.3.18 Menu

4.3.19

4.3.20

4.3.21 Menu

4.3.22 Menu

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)