Claas Gps Pilot S3 Terminal (B82) Digital Solutions Operator Manual ES

$50.00

- Model: Gps Pilot S3 Terminal (B82) Digital Solutions

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 41.9 MB

File List:

00 1400 639 3.pdf

00 1401 055 2.pdf

00 1402 656 2.pdf

00 1402 657 1.pdf

00 1402 803 1.pdf

00 1400 639 3.pdf:

COPILOT S7 GPS

1. Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this instruction manual

1.1.3 Symbols and indications

1.1.4 Optional equipment

1.1.5 Qualified specialized workshop

1.1.6 Maintenance instructions

1.1.7 Information regarding warranty

1.1.8 Spare parts and technical questions

1.2 Proper application of the machine

1.2.1 Suitable GPS COPILOT application

1.2.2 Logically foreseeable erroneous application GPS COPILOT

2 Security

2.1 Recognize warning signs

2.1.1 Danger symbols

2.1.2 Keyword

2.2 Safety instructions

2.2.1 Importance of the instruction manual

2.2.2 Terminal software update

2.2.3 Observe graphic danger symbols and warning instructions

2.2.4 Requirements for all people who work with the product

2.2.5 Construction modifications

2.2.6 Optional equipment and spare parts

2.2.7 Using USB devices

2.2.8 Operation only in accordance with statutory commissioning

2.2.9 Technical status

2.2.10 Dangers when driving on the road and on terrain

Road traffic

Field trip

2.2.11 Electrical shock from electrical equipment

2.2.12 Maintenance work and repair work

3 Product Description

3.1 Summary and operation

3.1.1 COPILOT GPS Summary

3.1.2 S7 terminal overview

3.1.3 Summary corrective signals

EGNOS / WAAS / MSAS

3.1.4 Antenna summary

GNSS antenna

3.2 Optional equipment

3.2.1 GLONASS*

3.3 Identification plates and identification numbers

3.3.1 COPILOT S7 GPS identification plate

3.3.2 Terminal identification plate

4 Control and display instruments

4.1 S7 terminal overview

4.1.1 Button and prompt representation conventions

4.2 GPS COPILOT menu structure

4.2.1 Initial menu

4.2.2 Main menu, summary

4.2.3 Summary of DGPS visualizations

4.2.4 Menu

4.2.5 Menu

4.2.6 Menu

4.2.7 Menu

4.2.8 Menu

4.2.9 Menu

4.2.10 Menu

4.2.11 Menu

4.2.12 Menu

4.2.13

4.2.14 Menu

4.2.15 Menu

4.2.16 Menu

4.2.17 Menu

4.2.18 Menu

4.2.19 Menu

Menu

Menu

5 Technical data

5.1 GPS COPILOT

5.1.1 Corrective signal accuracy

5.1.2 COPILOT GPS Specification

5.2 S7 Terminal

5.2.1 Specification

6 Prepare the product

6.1 Turn off the machine and secure it

6.1.1 Turn off the machine and secure it

6.2 Perform before commissioning

6.2.1 Perform before the first commissioning of GPS COPILOT

6.2.2 Perform GPS COPILOT before each start-up

6.3 First start-up of the machine

6.3.1 Create vehicle profile

6.4 First start-up of the working device

6.4.1 Create device profile checklist

6.4.2 Create device profile

6.4.3 Select the type of coupling

6.4.4 Enter the measurements of the devices

Adjust the width of the device

Particularity in LEXION and TUCANO in MONTANA version

Adjust the overlap or gap

Working width

Adjust the movement of the device in the longitudinal direction

Adjust the movement of the device in the transverse direction

6.5 First start-up of the correction signal

6.5.1 First commissioning of the GNSS signal

6.5.2 Select the E-DIF correction type

6.5.3 Select the type of SBAS correction

6.6 Adjust subscriptions

6.6.1 Enter codes

7 Management

7.1 Checklists

7.1.1 Prepare field work

7.1.2 Carry out field work

7.2 GPS COPILOT

7.2.1 Turn on the terminal

Starting screen

7.2.2 Turn off the terminal

7.2.3 Manage control elements

Manage the keyboard

Operate the numeric keypad

Handle buttons with attached list

7.2.4 Direction direction indicator

7.2.5 GPS status

7.2.6 Connect USB data memory

7.3 GPS settings

7.3.1 Adjust BEIDOU

7.3.2 Adjust GNSS

7.3.3 Adjust NMEA broadcast

Limit NMEA broadcast to GPS signal

Record entries

Continue using the GNSS signal

7.3.4 Adjust E-DIF

Set reference point

Update reference point

7.3.5 Adjust SBAS

7.4 System settings

7.4.1 Adjust vision

Zoom in and out

Adjust the display mode

Adjust perspective

Hide buttons

View the buttons

7.4.2 Setting the language

7.4.3 Set units

7.4.4 Set the time

GMT Offset

7.4.5 Exchange control elements

7.4.6 Connect or disconnect the worked surface signal

7.4.7 Adjust day and night mode

7.4.8 Adjust screen brightness

7.4.9 Adjust the direction indicator

Sensitivity

7.4.10 Adjust the matrix

7.5 Vehicle settings

7.5.1 Load vehicle profile

7.5.2 Process vehicle profile

7.5.3 Export vehicle profiles

7.5.4 Import vehicle profiles

7.5.5 Delete vehicle profiles

7.6 Device settings

7.6.1 Load vehicle profile

7.6.2 Process device profile

7.6.3 Export device profiles

7.6.4 Import the device profile

7.6.5 Delete device profiles

7.7 Order processing

7.7.1 Create job

Create a new job from the initial menu

Create a new job from job management

7.7.2 Process notes

7.7.3 Load job

7.7.4 End the job

7.7.5 Continue the last used job

7.7.6 Export job

7.7.7 Import job

7.7.8 Delete job

7.7.9 Create template

7.7.10 Use model

7.7.11 Delete templates

7.8 Field trip with COPILOT GPS

7.8.1 Summary of types of field trips

7.9 Boundaries and markers

7.9.1 Use a surface counter

Record the parcel boundary

Interrupt recording

Plot boundary as a reference footprint

7.9.2 Set marker

User-defined bookmarks

Set user-defined bookmarks

7.9.3 Drive to markers

Select bookmark

Drive to bookmarks

7.10 Straight line guide

7.10.1 Straight line guide

7.10.2 Create reference fingerprint

7.10.3 Fix point B again

7.10.4 Straight line guide with angle (angle A=B)

7.10.5 Work the plot

Commutation

7.10.6 Load lines A=B

7.10.7 Process the naming of a line A=B

7.10.8 Move line A=B

7.11 Guide by circular lines

7.11.1 Guide service through circular lines

7.11.2 Create reference footprint

7.11.3 Work the plot

7.11.4 Load the circular footprint

7.11.5 Move the circular footprint

7.12 Guidance by contour lines

7.12.1 Using contour line guidance

7.12.2 Record reference fingerprint

Record new reference fingerprint

7.12.3 Work the plot

Commutation

Padlock function

7.13 Display of partial widths

7.13.1 Activate and deactivate the display of partial widths

7.13.2 Adjust the display of partial widths

Enter the number of partial widths of the attached device

Adjust the width of the individual sections of the attached device

Adjust the allowed overlap

Set the connection time

Set the shutdown time

7.13.3 Using the display of partial widths

8 Incident and solution

8.1 Errors and measures to take

8.1.1 Starting the COPILOT GPS system

8.1.2 Defective GNSS signal

8.1.3 EGNOS/WAAS/MSAS corrective signal

8.1.4 Error in footprint guidance

8.2 S7 Terminal

8.2.1 Take screenshots

8.3 Diagnosis

8.3.1 GPS-Setup

8.3.2 GPS Status

8.3.3 E-DIF Status

9 Maintenance

9.1 Summary of maintenance intervals

9.1.1 Every 100 hours of service or monthly

10 Decommissioning and waste disposal

10.1 General information

10.1.1 Decommissioning and waste disposal

11 EC declaration of conformity

11.1 GPS COPILOT

11.1.1 EC declaration of conformity

12 Technical dictionary and abbreviations

12.1 GPS COPILOT

12.1.1 Abbreviations

12.1.2 Units

00 1401 055 2.pdf:

GPS PILOT

1 Regarding this instruction manual

1.1 General data

1.1.1 Manual handling

1.1.2 Validity of instructions

1.1.3 Technical data

1.1.4 Road traffic permit

2 Security

2.1 General data

2.1.1 Read and observe the safety measures

2.1.2 To take special account

2.1.3 Proper machine application

2.2 Safety measures in this manual

2.2.1 Identification of warning and danger statements

3 Machine Description

3.1 Summary of correction signals

3.1.1 GPS PILOT EGNOS

3.1.2 GPS PILOT e-Dif

3.1.3 GPS PILOT OMNISTAR HP / XP

3.1.4 GPS PILOT BASELINE HD

3.1.5 GPS PILOT RTK

3.1.6 GPS PILOT RTK NET

3.2 Antenna summary

3.2.1 Antenna (EGNOS, e-Dif, BASELINE)

3.2.2 Antenna (BASELINE HD)

3.2.3 GPS antenna (OMNISTAR HP / XP, RTK ready, RTK, RTK NET)

3.2.4 Antenna (RTK)

3.2.5 Antenna (RTK NET)

CLAAS communication module (CCM) – connections

CLAAS Communication Module (CCM) – LED description

3.3 Terminal S3

3.3.1 Rear connections on terminal S3

3.3.2 Connections to the left of the S3 terminal

3.4 Navigation calculator (ECU)

3.4.1 Front side navigation calculator

3.4.2 Rear side navigation calculator

3.5 Valve unit

3.5.1 Valve control unit

3.5.2 Valve block

3.5.3 Locking block

3.5.4 Priority valve

3.5.5 Interchangeable shut-off valve

3.5.6 Wheel angle sensor

3.6 Steering wheel

3.6.1 Electric steering wheel

3.6.2 Control unit, steering wheel

3.7 Safety devices

3.7.1 Seat contact switch

3.7.2 Manual overexcitation

Hydraulic steering

electric steering wheel

3.7.3 Automatic shutdown / speed

3.8 Run switch

3.8.1 Standard main switch

3.8.2 Main switch in Challenger Auto-Guide

3.8.3 Main switch in FENDT Auto-Guide

3.8.4 Flywheel main switch

3.9 BASELINE HD base station

3.9.1 Base station

3.9.2 Charging device

3.9.3 Cable for external power supply

3.9.4 Cable for connection to PC

3.10 RTK fixed station

3.10.1 RTK Base Station

3.10.2 RTK broadcast antenna

4 Control and display instruments

4.1 General data

4.1.1 General warnings

4.1.2 Validity

4.2 S3 terminal summary

4.2.1 Button and prompt representation conventions

4.2.2 Connect the terminal

4.2.3 Turn off the terminal

4.2.4 Initial image

4.2.5 Summary menu

4.3 Main menu summary

4.3.1 Basic settings

4.3.2 GPS / settings

4.3.3 NMEA

4.3.4 GPS/radio-transmission

4.3.5 e-Diff

4.3.6 GPS / GPS details

4.3.7 Steering / Auto Settings

4.3.8 Address settings / details

4.3.9 Steering settings / settings

4.3.10 Steering settings / calibrate

Electric steering wheel variant

4.3.11 Address/status settings

4.3.12 Machine settings

4.3.13 Display of partial widths

4.3.14 Order processing

4.3.15 Field view

4.4 Address menu overview

4.4.1 Function buttons in the steering menu

5 Technical data

5.1 GPS PILOT

5.1.1 Correction signal accuracy

5.1.2 Power supply

5.1.3 Terminal S3

5.1.4 BASELINE

6 Preparation of the machine

6.1 General data

6.1.1 General warnings

6.2 Turn off the machine and secure it

6.2.1 Turn off the machine and secure it

6.3 Perform before commissioning

6.3.1 Perform before first start-up

6.3.2 Perform before each start-up

6.4 First start-up of the machine

6.4.1 General warnings

6.4.2 Open the calibration menu

6.4.3 Vehicle type and valve type calibration

Vehicle type

Valve type

Calibration set

6.4.4 Calibration of measurements

Longitudinal displacement of the antenna

Antenna height

Left/Right Antenna Shift

Distance between axis

6.4.5 ECU position calibration

6.4.6 Wheel angle sensor calibration

Left wheelbase

Right wheelbase

center wheelbase

6.4.7 Turn radius calibration

Left turning radius

Right turning radius

Maximum cornering speed

6.4.8 Valve current calibration

6.4.9 Calibration of the fine adjustment of the wheel angle sensor

Create line A=B

Follow the line A=B

6.4.10 Calibration of the electric steering wheel

Transmission of address

6.4.11 Lateral tilt calibration

Create line A=B

6.5 First start-up of the correction signal

6.5.1 EGNOS

6.5.2 OMNISTAR HP/XP

6.5.3 BASELINE HD

Settings in the terminal

Checklist for the first start-up of the base station

Prepare the charger

Charge the base station battery

Connect the base station

Power the base station with an external battery

Modify base station frequency

6.5.4 RTK

6.5.5 RTKNET

6.6 GPS PILOT

6.6.1 GPS PILOT

Start switch in field trip position

6.6.2 GPS status = “operational”

7 Management

7.1 General data

7.1.1 General warnings

7.2 BASELINE HD base station

7.2.1 Assemble the base ion

7.2.2 Connect the base station

7.3 Field trip with GPS PILOT

7.3.1 Order management

Create new job

7.3.2 Settings

Adjust the width of the device

Adjust overlap/gap

Adjust left/right scrolling

Adjust forward/backward shifting

7.3.3 Display of partial widths

Partial width display / CONEC preview

Display of partial widths / preview DESC

Display of partial widths / overlap

Display of partial widths / number of partial widths

Display of partial widths / width

Field path with partial width display

7.3.4 Summary of types of field trips

7.3.5 Use straight line guide

Create an A-B footprint

Set points A and B

Set points A and B and then learn point B again

Performing the following passes

Commutation

Pass numbering

Fix point A and learn the angle (angle AB)

Realization with several machines

Move lines A+B

Open the return points and go to them

7.3.6 Using contour line guidance

Performing the start step

Making a new start pass

Commutation

Padlock function

Surface counter

7.3.7 Using the A-B contour line guide

Performing the start step

Performing the following passes

7.3.8 Using circle line guidance

Performing the start step

7.3.9 Use e-Dif

Use for e-Dif work

7.3.10 Auto Spin

General instructions

Automatic spin calibration

Left turning radius

Right turning radius

Confirm turning radii

Duration menu activation

Driving speed adjustment

Next footprint setting

Representation of turning processes

Automatic turn input indication

Execution of a turning process

7.3.11 GPS PILOT / disconnection options

Activation button

Other disconnection conditions

8 Incident and solution

8.1 General data

8.1.1 General warnings

8.2 Errors and measures to take

8.2.1 Faulty first start-up (after installation)

8.2.2 Faulty system startup

8.2.3 Defective GPS

8.2.4 Defective EGNOS correction signal

8.2.5 Defective BASELINE HD correction signal

8.2.6 Defective OMNISTAR HP/XP correction signal

8.2.7 Defective RTK correction signal

8.2.8 Erroneous RTK NET correction signal

8.2.9 Error activating the automatic steering system

8.2.10 Error disabling auto steering

8.2.11 Error in footprint guidance

8.2.12 Distribution valve unit intermittent code error

9 Maintenance

9.1 General data

9.1.1 General warnings

9.2 Electrical/electronic installation

9.2.1 Battery

9.2.2 Removing/installing the base station battery

9.3 Maintenance instructions

9.3.1 Maintenance intervals

10 Service

10.1 General data

10.1.1 Spare parts and technical queries

11 Decommissioning and waste disposal

11.1 General data

11.1.1 Decommissioning and waste disposal

12 EU declaration of conformity

12.1 GPS PILOT – B82

12.1.1 EC declaration of conformity

13 Homologation

13.1 GPS PILOT – B82

13.1.1 Homologation

14 Technical dictionary and abbreviations

14.1 GPS PILOT

14.1.1 Abbreviations

00 1402 657 1.pdf:

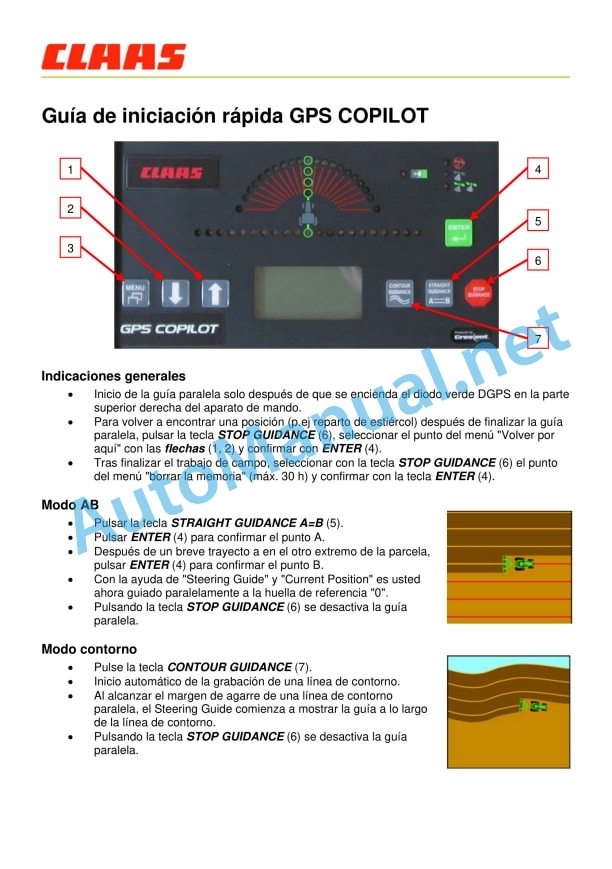

COPILOT GPS Quick Start Guide

General indications

Contour mode

Changing the working width

Change of signal type

Surface measurement

Automatic movement of lines A-B

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98