New Holland 25 Boomer Tier 3 Compact Tractor Operation and Maintenance Manual 48098985

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 48098985

- Format: PDF

- Size: 18.7MB

- Number of Pages: 188

- Serial Number:

48098985

-

Model List:

- 25 Boomer Tier 3 Compact Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the owner

- 1.2. Intended use

- 1.3. ElectroMagnetic Compatibility (EMC)

- 1.4. Product Identification Number (PIN)

- 1.5. Operators manual storage

- 1.6. Machine orientation

- 2. SAFETY INFORMATION

- 2.1. Safety rules and signal word definitions

- 2.2. Safety rules

- 2.3. Starting up the machine safely

- 2.4. Stopping the machine safely

- 2.5. Do not operate tag

- 2.6. Ecology and the environment

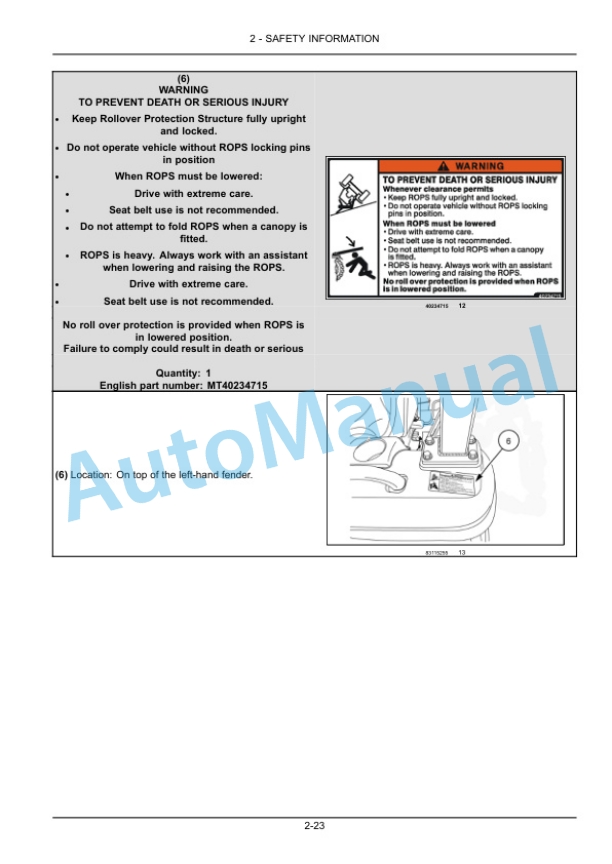

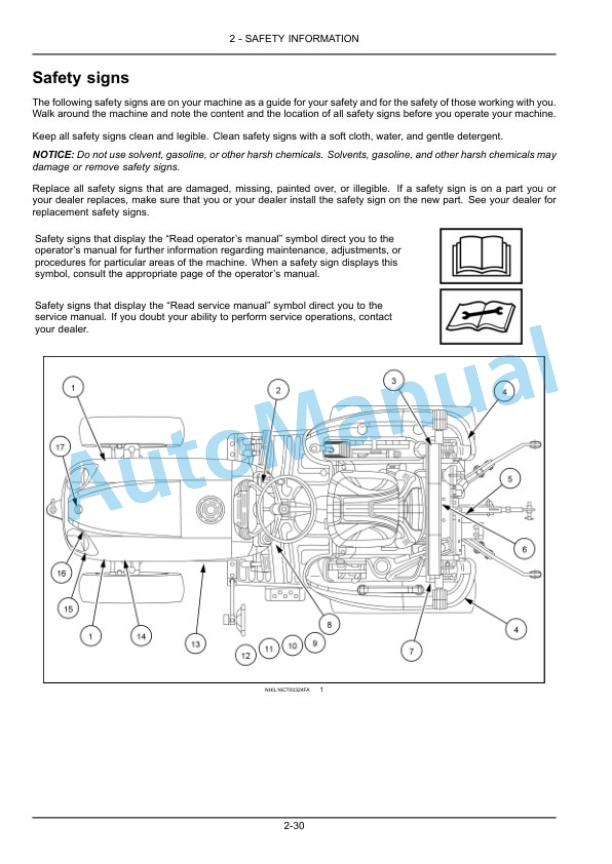

- 2.7. Safety signs

- 2.8. Instructional signs

- 2.9. International symbols

- 2.10. Safety features

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Access to operators platform

- 3.2. Operators seat

- 3.2.1. Seat belt

- 3.2.2. Mechanically adjusted operators seat

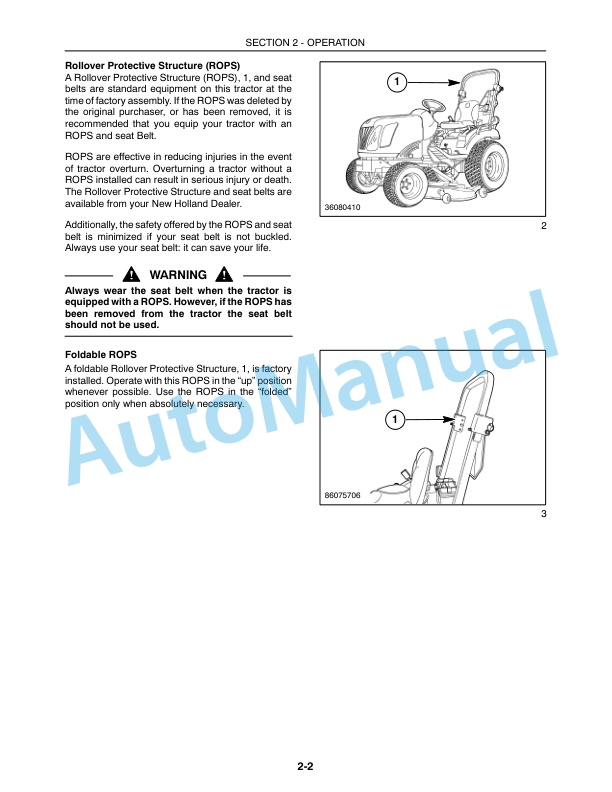

- 3.2.3. Roll Over Protective Structure (ROPS)

- 3.3. Forward controls

- 3.3.1. Instrument panel

- 3.3.2. Clutch pedal

- 3.3.3. Brake pedals

- 3.3.4. Park brake

- 3.3.5. Foot throttle pedal

- 3.3.6. Hand throttle lever

- 3.3.7. Power TakeOff (PTO) switch

- 3.3.8. Key switch

- 3.3.9. Differential lock pedal

- 3.3.10. Multifunction light switch

- 3.4. Lefthand side controls

- 3.4.1. Transmission range lever

- 3.4.2. Transmission range lever

- 3.4.3. FourWheel Drive (4WD)

- 3.5. Righthand side controls

- 3.5.1. Transmission main shift lever

- 3.5.2. Hydraulic Power Lift (HPL)

- 3.5.3. Hydraulic Power Lift (HPL) drop rate control valve

- 3.5.4. Rear remote hydraulic valve(s) (optional)

- 3.5.5. Mid mount two spool hydraulic valve (optional)

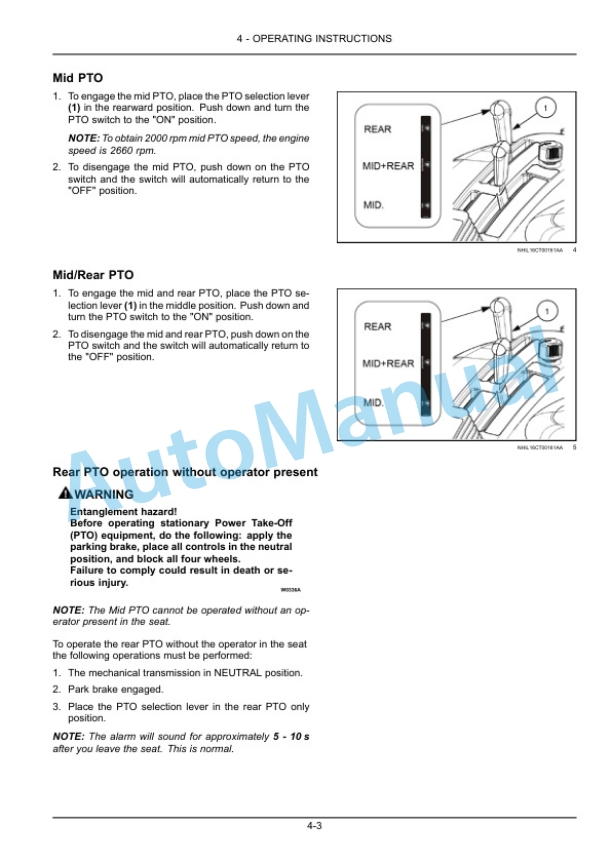

- 3.5.6. Power Take Off (PTO) Selection lever

- 3.6. Exterior controls

- 3.6.1. Hood latch

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. Engine breakin procedure

- 4.1.2. Power Take Off (PTO)

- 4.1.3. Threepoint hitch

- 4.1.4. Threepoint hitch adjustments

- 4.1.5. Tractor drawbar

- 4.1.6. Hydraulic lift rocker

- 4.2. Starting the unit

- 4.2.1. Key switch

- 4.2.2. Cold starting aids

- 4.2.3. Starting the engine

- 4.2.4. Starting the tractor with jumper cables

- 4.3. Stopping the unit

- 4.3.1. Stopping the engine

- 4.3.2. Emergency stopping

- 4.3.3. Brakes

- 4.3.4. Park brake

- 4.4. Moving the unit

- 4.4.1. Steering operation

- 4.4.2. Transmission operation at low ambient temperatures

- 4.4.3. Mechanical transmission operation

- 4.5. Parking the unit

- 4.5.1. Parking the unit

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. Transport lighting

- 5.1.2. Hazard warning light operation

- 5.1.3. Turn signal operation

- 5.1.4. Work lights operation

- 5.1.5. Brake light operation

- 5.1.6. Rear work light (optional)

- 5.1.7. Driving the vehicle

- 5.2. Shipping transport

- 5.2.1. Carrying the tractor on a transporter

- 5.3. Recovery transport

- 5.3.1. Towing the tractor

- 6. WORKING OPERATIONS

- 6.1. General information

- 6.1.1. Tractor ballasting

- 6.1.2. Tractor ballasting weights

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. General information

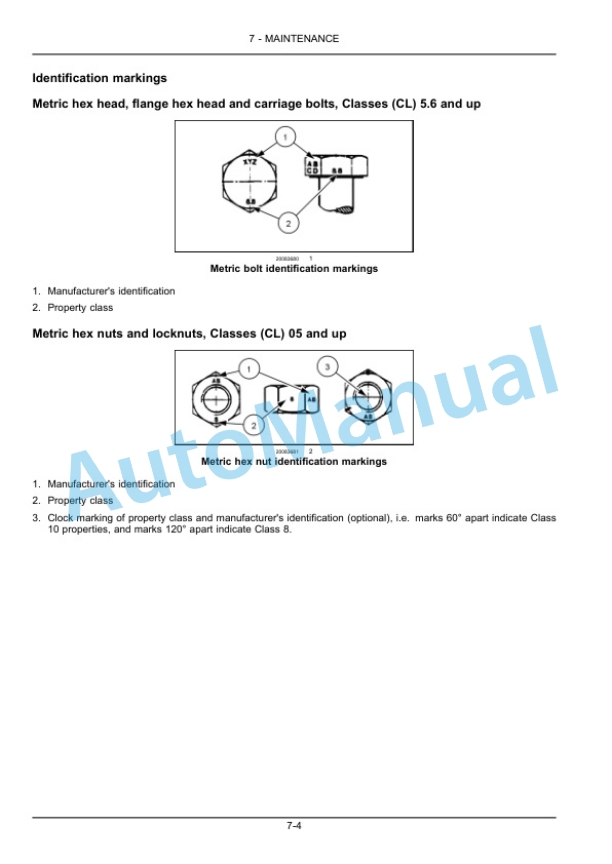

- 7.1.2. Torque Minimum tightening torques for normal assembly

- 7.1.3. Standard torque data for hydraulics Standard torque data for hydraulics

- 7.1.4. Biodiesel fuel

- 7.1.5. General specification Diesel fuel

- 7.1.6. Refueling the tractor

- 7.1.7. Tractor jacking points

- 7.1.8. Fluids and lubricants

- 7.1.9. Capacities

- 7.1.10. Organic Acid Technology (OAT) coolant

- 7.1.11. Engine oils

- 7.2. Maintenance planning

- 7.2.1. Maintenance planning

- 7.3. Every 10 hours or daily

- 7.3.1. Engine oil level Check

- 7.3.2. Engine cooling system Check

- 7.4. After the first 50 hours of operation

- 7.4.1. Engine oil and oil filter Change

- 7.4.2. Fuel filter Replace

- 7.4.3. Hydraulic oil filter Replace

- 7.4.4. Roll Over Protective Structure (ROPS) Check

- 7.4.5. Wheel bolts and nuts Check

- 7.5. Every 50 hours

- 7.5.1. Grease fitting Lubrication

- 7.5.2. Transmission fluid level Check

- 7.5.3. Brake pedal free play Adjust

- 7.5.4. Fan belt Check

- 7.5.5. Tire pressure Check

- 7.5.6. Front axle differential fluid level Check

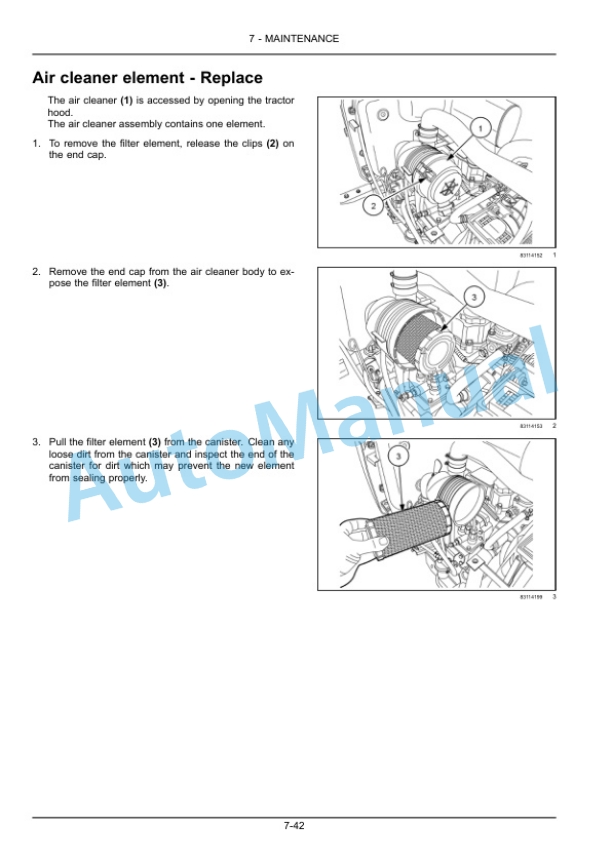

- 7.5.7. Air cleaner Clean

- 7.6. Every 100 hours

- 7.6.1. Fuel filter water separator Drain fluid

- 7.7. Every 300 hours

- 7.7.1. Engine oil and oil filter Change

- 7.7.2. Hydraulic oil filter Replace

- 7.7.3. Fuel filter Replace

- 7.7.4. Fan belt Adjust

- 7.7.5. Roll Over Protective Structure (ROPS) Check

- 7.7.6. Wheel bolts and nuts Check

- 7.7.7. Front wheel toe in Check

- 7.7.8. Air cleaner element Replace

- 7.8. Every 600 hours

- 7.8.1. Front axle differential oil Change fluid

- 7.8.2. Transmission fluid Change

- 7.9. Every 1000 hours

- 7.9.1. Engine coolant Change

- 7.10. General maintenance

- 7.10.1. Fuel injection system Bleed

- 7.10.2. Fuel injectors Bleed

- 7.10.3. Fan belt Adjust

- 7.10.4. Roll Over Protective Structure (ROPS) Check

- 7.10.5. Battery Test

- 7.10.6. Alternator and drive belt Check

- 7.10.7. Fuses Check

- 7.10.8. Maxi fuse Replace

- 7.10.9. Headlight bulb Replace

- 7.10.10. Tail/brake light bulb Replace

- 7.10.11. Turn signal/hazard light bulb Replace

- 7.10.12. Wheel bolt / nut Check

- 7.10.13. Front wheel toe in Check

- 7.10.14. Brake pedal free play Adjust

- 7.10.15. Clutch pedal free play Adjust

- 7.11. Storage

- 7.11.1. Preparing for storage

- 7.11.2. Removal from storage Tractor

- 8. TROUBLESHOOTING

- 8.1. Symptom(s)

- 8.1.1. Engine Troubleshooting

- 8.1.2. Hydraulic service brakes Troubleshooting

- 8.1.3. Regulated/Low pressure system Troubleshooting

- 8.1.4. Steering Troubleshooting

- 8.1.5. Electrical system Troubleshooting

- 9. SPECIFICATIONS

- 9.1. Tire inflation pressures

- 9.2. General specifications

- 9.3. Tractor dimensions

- 10. FORMS AND DECLARATIONS

- 10.1. Predelivery report Owner copy

- 10.2. Predelivery report Dealer copy

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058

New Holland Operator Manual PDF

New Holland 24 Boomer Compact Tractor Operation and Maintenance Manual 47727071

New Holland Operator Manual PDF

New Holland 1720 Tractor Operation and Maintenance Manual 42172010

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48116702

New Holland Operator Manual PDF

New Holland 16LA, 17LA Loader Operation and Maintenance Manual 87571253

New Holland Operator Manual PDF

New Holland 105LC For Boomer 25 Compact Front Loader Operation and Maintenance Manual 51562809

New Holland Operator Manual PDF

New Holland 100LC Loader Operation and Maintenance Manual 51410108

New Holland Operator Manual PDF

New Holland 1030, 230GM Boomer Operation and Maintenance Manual 87487351

New Holland Operator Manual PDF

New Holland 1530, 1630, 1725, 1925 Feature Product Manual 86560392

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338