New Holland 25S Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51409930

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 51409930

- Format: PDF

- Size: 16.3MB

- Number of Pages: 172

- Serial Number:

51409930

-

Model List:

- 25S Workmaster Tier 4B Final Compact Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the Owner

- 1.2. Intended use

- 1.3. ElectroMagnetic Compatibility (EMC)

- 1.4. Product Identification Number (PIN)

- 1.5. Operators manual storage on the machine

- 1.6. Machine orientation

- 1.7. Note to the Owner

- 2. SAFETY INFORMATION

- 2.1. Safety rules and signal word definitions

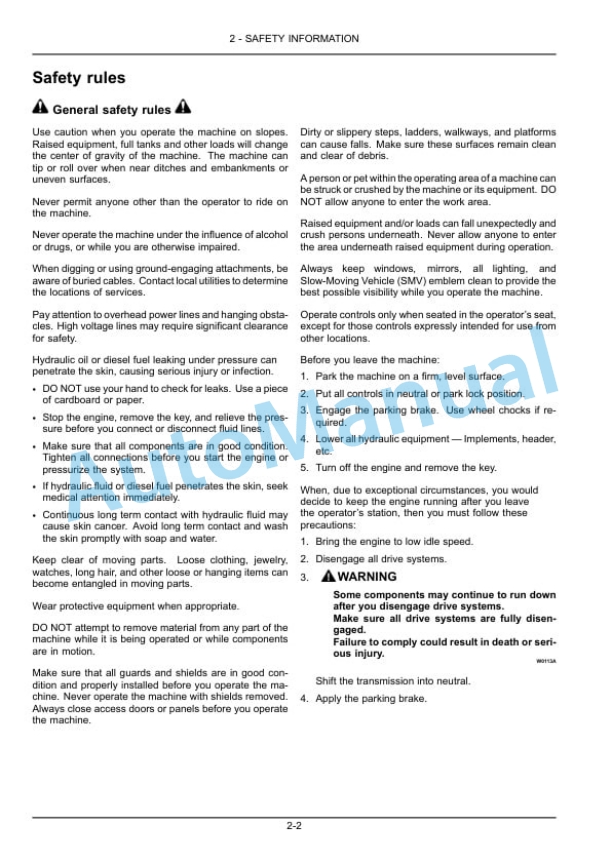

- 2.2. Safety rules

- 2.3. Do not operate tag

- 2.4. Ecology and the environment

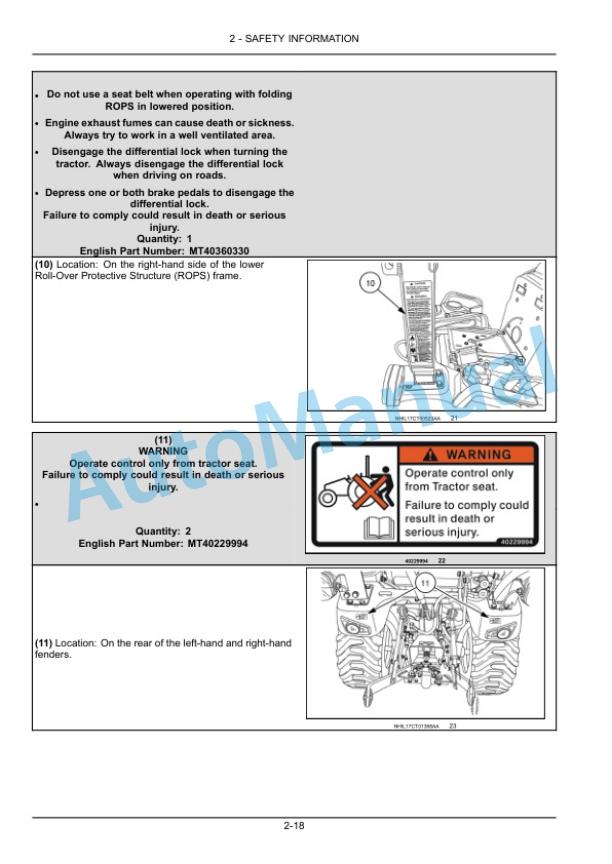

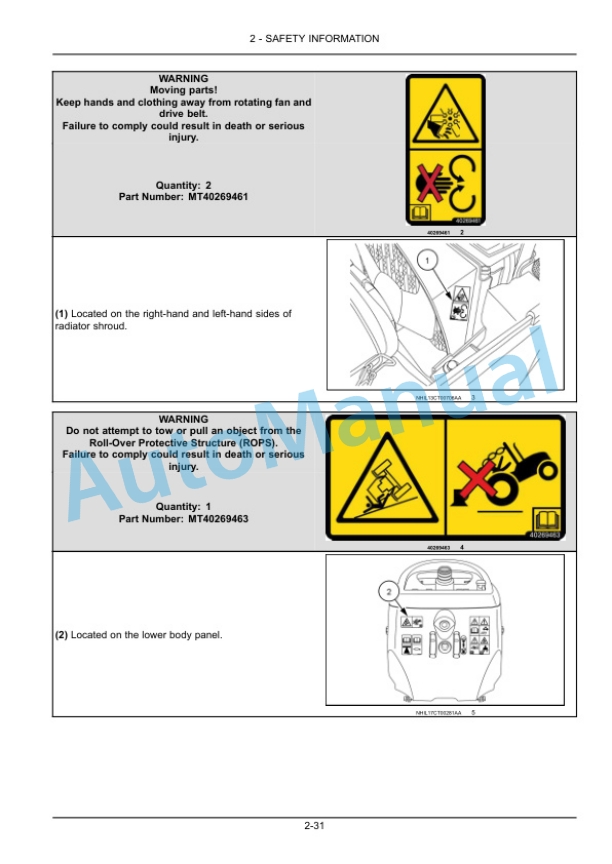

- 2.5. Safety signs

- 2.6. Instructional signs

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Access to operators platform

- 3.2. Operators seat

- 3.2.1. Seat belt

- 3.2.2. Operators seat Adjust

- 3.3. Forward controls

- 3.3.1. Multifunction light switch

- 3.3.2. Instrument cluster panel

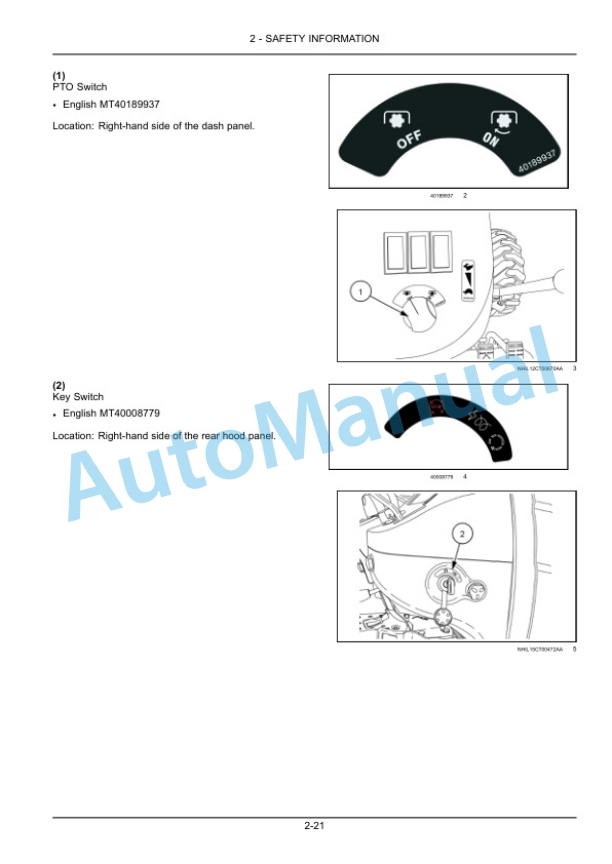

- 3.3.3. Power TakeOff (PTO) switch

- 3.3.4. Midmount twospool control valve lever

- 3.3.5. Hand throttle lever

- 3.3.6. Forward travel pedal

- 3.3.7. Reverse travel pedal

- 3.3.8. Cruise control switch

- 3.3.9. Key switch

- 3.3.10. Park brake lever

- 3.3.11. Service brake pedal

- 3.4. Lefthand side controls

- 3.4.1. Auxiliary power outlet

- 3.4.2. Power TakeOff (PTO) shift lever

- 3.5. Righthand side controls

- 3.5.1. FourWheel Drive (4WD) lever

- 3.5.2. Transmission range lever

- 3.5.3. Hydraulic Power Lift (HPL) lever

- 3.6. Rearward controls

- 3.6.1. Hydraulic Power Lift (HPL) drop rate control valve

- 3.6.2. Midmount mower deck height adjustment knob

- 3.6.3. Differential lock pedal

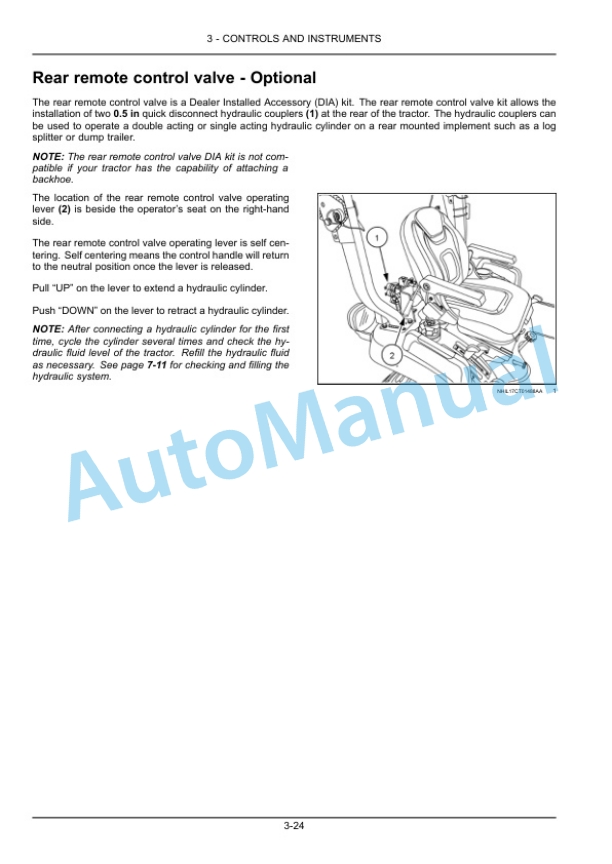

- 3.6.4. Rear remote control valve Optional

- 3.7. Exterior controls

- 3.7.1. Hood release latch

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. Engine Runningin Procedure

- 4.1.2. Safety rules Diesel fuel

- 4.1.3. General specification Biodiesel fuels

- 4.1.4. Refueling the tractor

- 4.2. Starting the unit

- 4.2.1. Starting the engine

- 4.2.2. Cold starting aids

- 4.2.3. Starting the tractor with jumper cables

- 4.3. Stopping the unit

- 4.3.1. Stopping the engine

- 4.3.2. Stopping the unit Brakes

- 4.3.3. Emergency stopping

- 4.4. Moving the unit

- 4.4.1. Steering Operation

- 4.4.2. Hydrostatic Transmission (HST) Operation

- 4.4.3. Transmission operation at low ambient temperatures

- 4.5. Parking the unit

- 4.5.1. Park brake Operation

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. Road transport Overview

- 5.2. Shipping transport

- 5.2.1. Carrying the tractor on a transporter

- 6. WORKING OPERATIONS

- 6.1. General information

- 6.1.1. External lighting Operating

- 6.1.2. Roll Over Protective Structure (ROPS) Fold up/down

- 6.1.3. Ballasting the tractor

- 6.1.4. Tractor ballasting weights

- 6.1.5. Operator presence system

- 6.2. General field operation

- 6.2.1. Hydraulic Power Lift (HPL) Operation

- 6.2.2. Rear threepoint hitch Overview

- 6.2.3. Attaching threepoint hitch equipment

- 6.2.4. Drawbar Operation

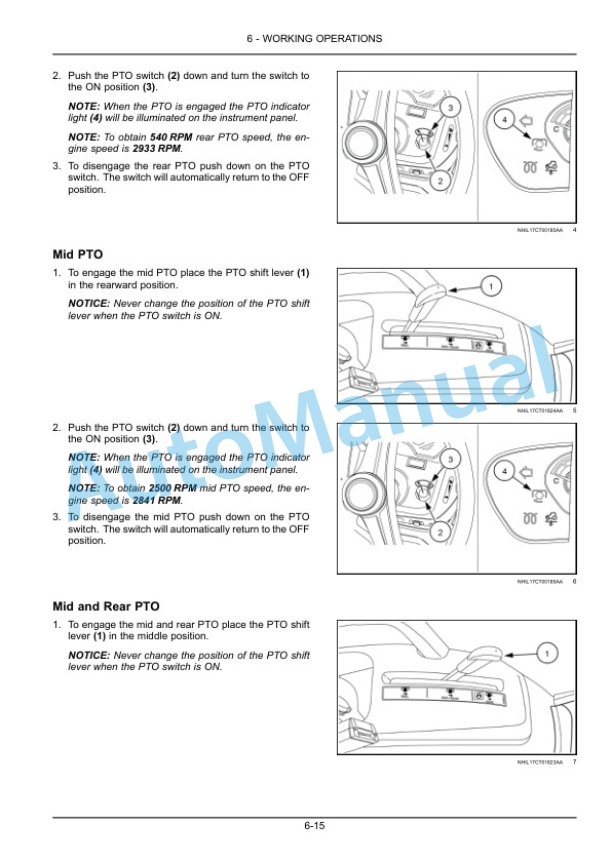

- 6.2.5. Power TakeOff (PTO) Operation

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. Safety rules

- 7.1.2. Engine cooling system Basic instructions

- 7.1.3. Engine side panel remove and install

- 7.1.4. Battery location and service

- 7.1.5. Consumables

- 7.2. Maintenance planning

- 7.2.1. Maintenance chart

- 7.3. Every 8 hours or daily

- 7.3.1. Engine lubrication system Check

- 7.3.2. Engine cooling system Check

- 7.3.3. Transmission Check

- 7.3.4. Radiator screen cleaning

- 7.4. After the first 50 hours of operation

- 7.4.1. Engine Change fluid

- 7.4.2. Fuel filters Replace

- 7.4.3. Prefilter Replace

- 7.4.4. Hydraulic oil suction filter Replace

- 7.4.5. Hydrostatic Transmission (HST) oil filter Replace

- 7.4.6. Roll Over Protective Structure (ROPS) frame Check

- 7.4.7. Wheel hardware Check

- 7.5. Every 50 hours

- 7.5.1. Transmission Check

- 7.5.2. Mechanical service brakes Check

- 7.5.3. Hydrostatic transmission (HST) neutral adjustment Check

- 7.5.4. Belt Check

- 7.5.5. Tire pressure Check

- 7.5.6. Front axle differential fluid level Check

- 7.5.7. Air cleaner Cleaning

- 7.6. Every 250 hours

- 7.6.1. Engine Change fluid

- 7.6.2. Oil filter Replace

- 7.6.3. Oil filter Replace

- 7.6.4. Roll Over Protective Structure (ROPS) frame Check

- 7.6.5. Front wheels Tighten

- 7.6.6. Front wheels toein Check

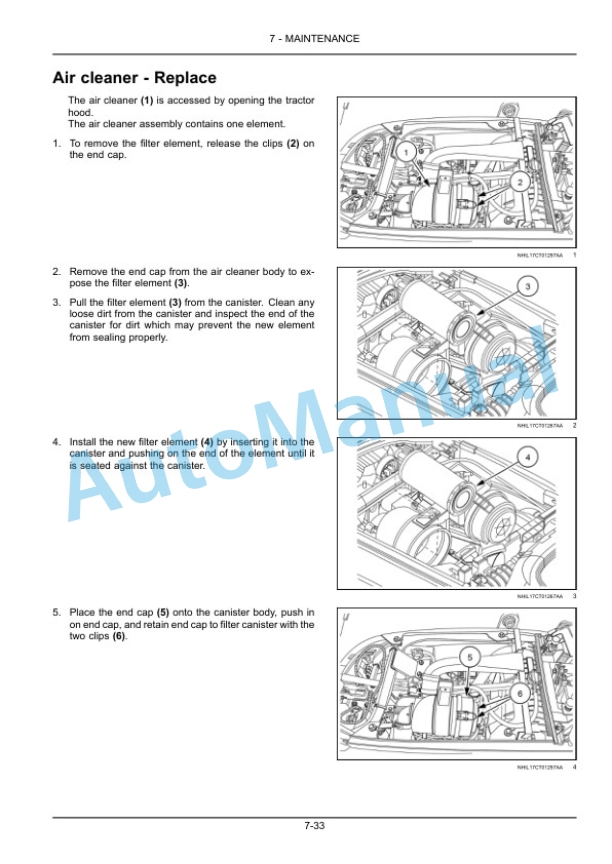

- 7.6.7. Air cleaner Replace

- 7.7. Every 500 Hours

- 7.7.1. Front axle differential fluid Change

- 7.7.2. Transmission Change fluid

- 7.7.3. Fuel filters Replace

- 7.7.4. Prefilter Replace

- 7.8. Every 1000 hours

- 7.8.1. Engine valve clearance Check and adjust

- 7.9. Every two years

- 7.9.1. Engine cooling system Drain fluid And flush

- 7.10. General maintenance

- 7.10.1. Fuel injection system Bleed

- 7.10.2. Belt Adjust

- 7.10.3. Battery Test

- 7.10.4. Fuses Check

- 7.10.5. Main fuse Check

- 7.10.6. Headlight Replace

- 7.10.7. Turn signal and hazard bulb Replace

- 7.10.8. Front wheels Tighten

- 7.11. Storage

- 7.11.1. Storage Storing

- 7.11.2. Storage Check

- 8. TROUBLESHOOTING

- 8.1. Symptom(s)

- 8.1.1. Troubleshooting Foreword

- 8.1.2. Engine Troubleshooting

- 8.1.3. Mechanical service brakes Troubleshooting

- 8.1.4. Regulated/Low pressure system Troubleshooting

- 8.1.5. Steering Troubleshooting

- 8.1.6. Hydrostatic transmission Troubleshooting

- 8.1.7. Electrical system Troubleshooting

- 9. SPECIFICATIONS

- 9.1. Tractor general specifications

- 9.2. Tractor dimensions

- 10. FORMS AND DECLARATIONS

- 10.1. Predelivery report Dealers copy

- 10.2. Predelivery report Owners copy

New Holland Operator Manual PDF

New Holland 1720 Tractor Operation and Maintenance Manual 42172010

New Holland Operator Manual PDF

New Holland 230TL Loader Operation and Maintenance Manual 87541767

New Holland Operator Manual PDF

New Holland 100LC Loader Operation and Maintenance Manual 51410108

New Holland Operator Manual PDF

New Holland 1530, 1630, 1725, 1925 Feature Product Manual 86560392

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 51559567

New Holland Operator Manual PDF

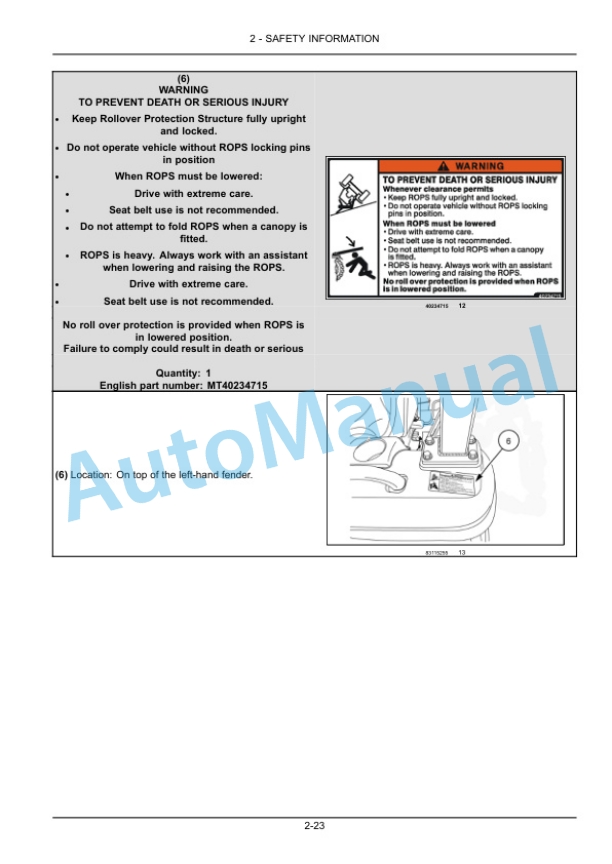

New Holland 25 Boomer Tier 3 Compact Tractor Operation and Maintenance Manual 48098985

New Holland Operator Manual PDF

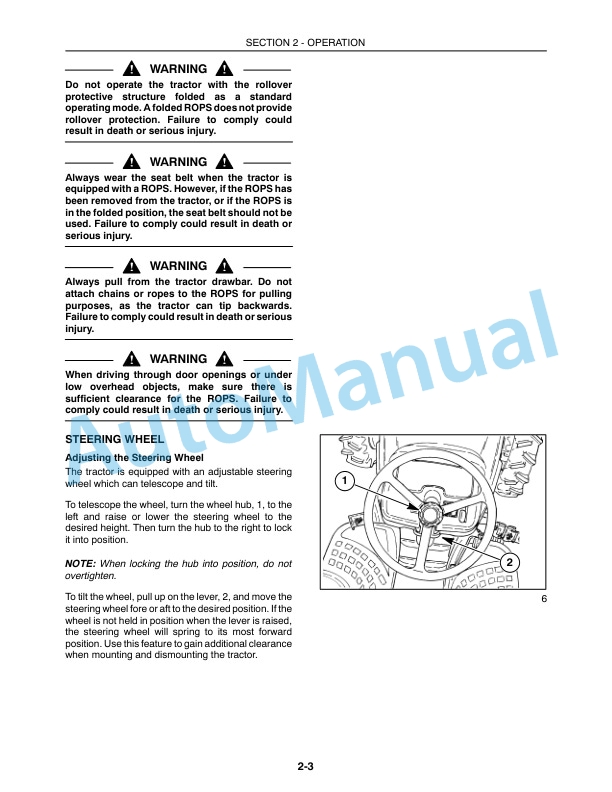

New Holland 2300BF With Auxiliary Hydraulic Operation and Maintenance Manual 86574146

New Holland Operator Manual PDF

New Holland 2030, 2035 Boomer Tractor Operation and Maintenance Manual 87477103

New Holland Operator Manual PDF

New Holland 25 Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51414247

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058