New Holland 35, 40 Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51485746

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 51485746

- Format: PDF

- Size: 24.4MB

- Number of Pages: 236

- Serial Number:

51485746

-

Model List:

- 35 Workmaster Tier 4B Final Compact Tractor

- 40 Workmaster Tier 4B Final Compact Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the owner

- 1.2. Intended use

- 1.3. Electromagnetic Compatibility (EMC)

- 1.4. Product identification

- 1.5. Operators manual storage

- 1.6. Machine orientation

- 1.7. Emissions overview

- 2. SAFETY INFORMATION

- 2.1. Safety rules and signal word definitions

- 2.2. Safety rules

- 2.3. Do not operate tag

- 2.4. Roll Over Protective Structure (ROPS) frame Personal safety

- 2.5. Ecology and the environment

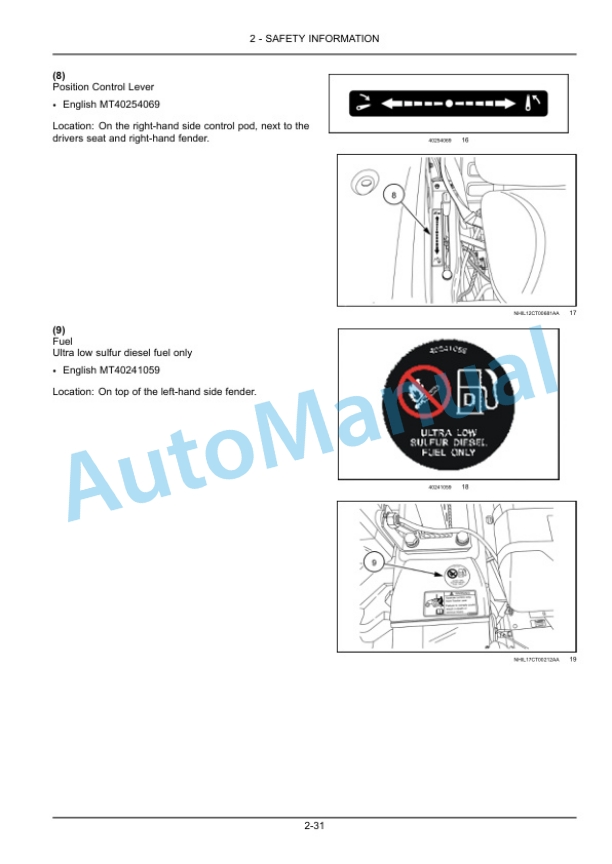

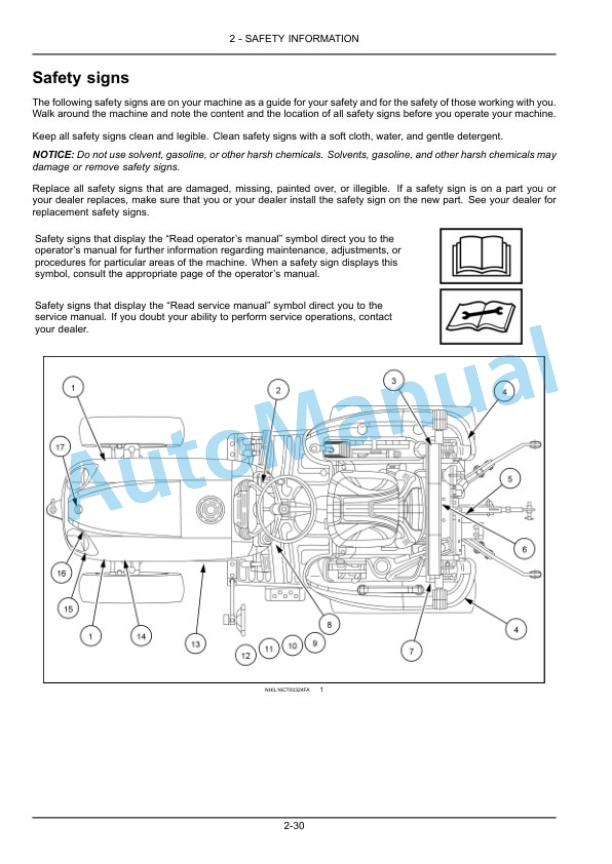

- 2.6. Safety signs

- 2.7. Instructional signs

- 2.8. Safety features

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Access to operators platform

- 3.2. Operators seat

- 3.2.1. Seat belt

- 3.2.2. Mechanically adjusted operator seat

- 3.2.3. Roll Over Protective Structure (ROPS)

- 3.3. Forward controls

- 3.3.1. Instrument panel

- 3.3.2. Engine fault code display

- 3.3.3. Hydrostatic transmission Operate

- 3.3.4. Shuttle lever

- 3.3.5. Clutch pedal

- 3.3.6. Brake pedal

- 3.3.7. Foot throttle pedal

- 3.3.8. Hand throttle lever

- 3.3.9. Horn switch (optional)

- 3.3.10. Power TakeOff (PTO) switch

- 3.3.11. Key switch

- 3.3.12. Differential lock lever Operating

- 3.3.13. Hydrostatic transmission pedal Operating

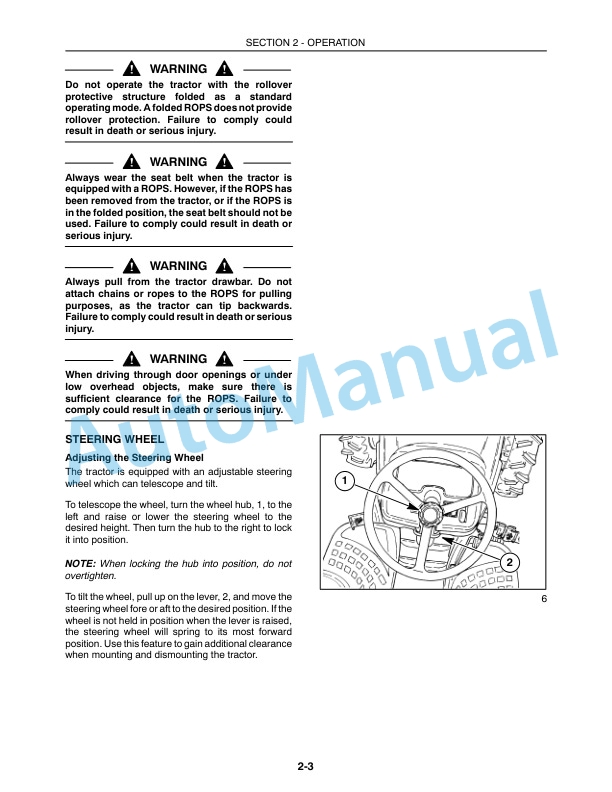

- 3.3.14. Tilt steering lever Operating

- 3.3.15. Multifunction light switch

- 3.3.16. Engine Speed Management (ESM) switch

- 3.3.17. Engine Speed Management (ESM) Up/Down switch

- 3.3.18. DPF switch

- 3.4. Lefthand side controls

- 3.4.1. Transmission range lever

- 3.4.2. Park brake

- 3.4.3. FourWheel Drive(4WD) lever

- 3.4.4. Mid Power TakeOff (PTO) (optional)

- 3.5. Righthand side controls

- 3.5.1. Hydraulic Power Lift (HPL)

- 3.5.2. Rear remote control valve(s) optional

- 3.5.3. Midmount control valve

- 3.5.4. Mechanical transmission lever

- 3.6. Exterior controls

- 3.6.1. Hood release latch

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. Engine breakin procedure

- 4.1.2. Diesel Particulate Filter (DPF) regeneration

- 4.1.3. Engine speed management

- 4.1.4. Power TakeOff (PTO) operation

- 4.1.5. Threepoint hitch

- 4.1.6. Attaching threepoint equipment

- 4.1.7. Drawbar Operating

- 4.1.8. Top link installation

- 4.1.9. Drop rate control valve

- 4.2. Starting the unit

- 4.2.1. Key switch Operating

- 4.2.2. Glow plugs Cold start aid

- 4.2.3. Starting the engine (Mechanical)

- 4.2.4. Starting the engine (Hydrostatic transmission)

- 4.2.5. Starting the engine with jumper cables

- 4.3. Stopping the unit

- 4.3.1. Stopping the engine

- 4.3.2. Emergency stopping the engine

- 4.3.3. Brakes

- 4.4. Moving the unit

- 4.4.1. Steering wheel Adjust

- 4.4.2. Steering Operation

- 4.4.3. Transmission Warmup

- 4.4.4. Hydrostatic transmission Operation

- 4.4.5. Mechanical transmission external controls Operation

- 4.5. Parking the unit

- 4.5.1. Parking the tractor

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. External lighting

- 5.1.2. Turn signal / Hazard lights Identification

- 5.1.3. Turn signal / Hazard lights Operation

- 5.1.4. Road lights Operation

- 5.1.5. Work lights Operation

- 5.1.6. External lighting Operation (optional)

- 5.1.7. Brakes and controls Driving

- 5.2. Shipping transport

- 5.2.1. Transporting by truck or trailer

- 5.3. Recovery transport

- 5.3.1. Brakes and controls Towing

- 6. WORKING OPERATIONS

- 6.1. General information

- 6.1.1. Ballast

- 6.1.2. Ballast weight requirements

- 6.1.3. Liquid ballast

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. General information

- 7.1.2. General specification Diesel fuel

- 7.1.3. General specification Biodiesel fuels

- 7.1.4. Refueling the tractor

- 7.1.5. Change engine coolant to Organic Acid Technology (OAT) coolant

- 7.1.6. Fluids and lubricants

- 7.1.7. Capacities

- 7.2. Maintenance planning

- 7.2.1. Maintenance chart

- 7.3. Every 10 hours or daily

- 7.3.1. Engine oil level Check

- 7.3.2. Engine cooling system Check

- 7.4. After first 50 hours

- 7.4.1. Engine oil and oil filter Change

- 7.4.2. Hydraulic oil filter Replace

- 7.4.3. Hydrostatic transmission oil filter Replace

- 7.4.4. Roll Over Protective Structure (ROPS) Check

- 7.4.5. Wheels Bolts and Nuts Tighten

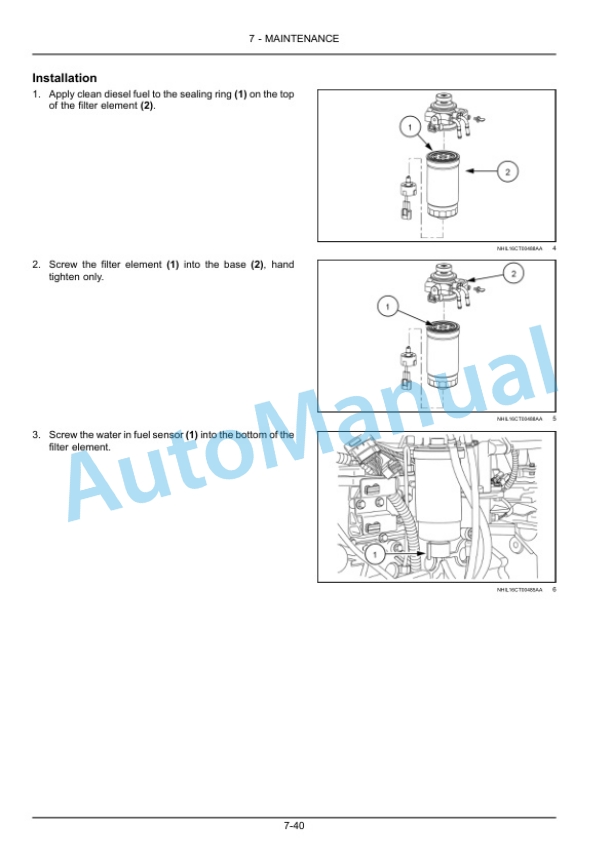

- 7.4.6. Fuel water seperator filter Replace

- 7.5. Every 50 hours

- 7.5.1. Grease fittings Lubricate

- 7.5.2. Transmission fluid level Check

- 7.5.3. Clutch pedal free play Adjust

- 7.5.4. Brake pedal free play Adjust

- 7.5.5. Hydrostatic Transmission (HST) neutral position Check and Adjust

- 7.5.6. Tire inflation pressure Check

- 7.5.7. Front axle and differential oil level Check

- 7.5.8. Air cleaner Clean Primary element

- 7.6. Every 100 hours

- 7.6.1. Fuel filter Drain

- 7.7. Every 300 hours

- 7.7.1. Engine oil and oil filter Change

- 7.7.2. Oil filter Replace

- 7.7.3. Hydrostatic Transmission (HST) oil filter Replace HST system

- 7.7.4. Wheel bolts and nuts Check

- 7.7.5. Air cleaner primary element Replace

- 7.8. Every 500 hours

- 7.8.1. Fuel filter water separator Replace

- 7.9. Every 600 hours

- 7.9.1. Front axle and differential fluid Change

- 7.9.2. Transmission fluid Change

- 7.10. Every 1000 hours

- 7.10.1. Air cleaner inner element Replace

- 7.11. Every 1500 hours

- 7.11.1. Engine coolant Draining and flushing

- 7.12. General maintenance

- 7.12.1. Fuel water separator filter Bleed

- 7.12.2. Hydrostatic transmission (HST) neutral adjustment Check

- 7.12.3. Engine belts Adjust

- 7.12.4. Roll Over Protective Structure (ROPS) Replace Possible damage

- 7.12.5. Battery

- 7.12.6. Alternator

- 7.12.7. Headlight bulb Replace

- 7.12.8. Turn signal/Hazard light bulb replacement

- 7.12.9. Flasher unit bulb Replace

- 7.12.10. Wheels Bolts and Nuts Tighten

- 7.12.11. Front wheel toein Adjust

- 7.12.12. Brake pedal free play Adjust

- 7.12.13. Clutch pedal free play Adjust

- 7.13. Fuse and relay locations

- 7.13.1. Fuse and relay locations

- 7.14. Storage

- 7.14.1. Tractor storage

- 7.14.2. Removal of tractor from storage

- 8. TROUBLESHOOTING

- 8.1. Symptom(s)

- 8.1.1. Engine Troubleshooting

- 8.1.2. Hydraulic Lift System Troubleshooting

- 8.1.3. Steering Troubleshooting

- 8.1.4. Hydrostatic transmission Troubleshooting

- 8.1.5. Electrical system Troubleshooting

- 9. SPECIFICATIONS

- 9.1. Tire inflation pressures

- 9.2. Rear wheel liquid ballast

- 9.3. General specification

- 9.4. Dimensions

- 10. ACCESSORIES

- 10.1. Accessories

- 11. FORMS AND DECLARATIONS

- 11.1. Delivery report owner copy

- 11.2. Delivery report dealer copy

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48005950

New Holland Operator Manual PDF

New Holland 2030, 2035 Boomer Tractor Operation and Maintenance Manual 87477103

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48116702

New Holland Operator Manual PDF

New Holland 18LA Loader Operation and Maintenance Manual 87571257

New Holland Operator Manual PDF

New Holland 16LA, 17LA Loader Operation and Maintenance Manual 87571253

New Holland Operator Manual PDF

New Holland 2300BF With PTO Pump Operation and Maintenance Manual 86574145

New Holland Operator Manual PDF

New Holland 250TL For Boomer 8N Tractor Operation and Maintenance Manual 84207117

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Compact Tractor Operation and Maintenance Manual 47578934

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328

New Holland Operator Manual PDF

New Holland 1530, 1630, 1725, 1925 Feature Product Manual 86560392