New Holland 46D CVT, 54D CVT Boomer Tier 4B Final Compact Tractor Operation and Maintenance Manual 48028213

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 48028213

- Format: PDF

- Size: 30.7MB

- Number of Pages: 266

- Serial Number:

48028213

-

Model List:

- 46D CVT Boomer Tier 4B Final Compact Tractor

- 54D CVT Boomer Tier 4B Final Compact Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the owner

- 1.2. Intended use

- 1.3. ElectroMagnetic Compatibility (EMC)

- 1.4. Product Identification Number (PIN)

- 1.5. Operators manual storage on the machine

- 1.6. Machine orientation

- 1.7. Exhaust Gas Recirculation (EGR) exhaust treatment Product overview

- 2. SAFETY INFORMATION

- 2.1. Safety alert symbol and signal word definition

- 2.2. Safety rules

- 2.3. Roll Over Protective Structure (ROPS)

- 2.4. Ecology and the environment

- 2.5. Safety features

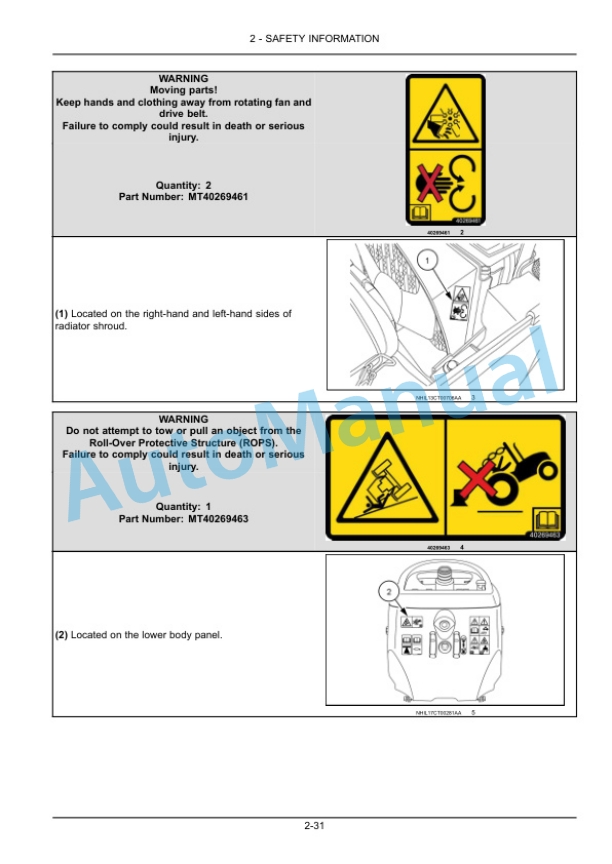

- 2.6. Safety signs

- 2.7. Instructional signs

- 2.8. International symbols

- 3. CONTROLS AND INSTRUMENTS

- 3.1. ACCESS TO OPERATORS PLATFORM

- 3.1.1. Doors

- 3.2. OPERATORS SEAT

- 3.2.1. Operators seat

- 3.2.2. Seat belt

- 3.2.3. Roll Over Protective Structure (ROPS)

- 3.3. FORWARD CONTROLS

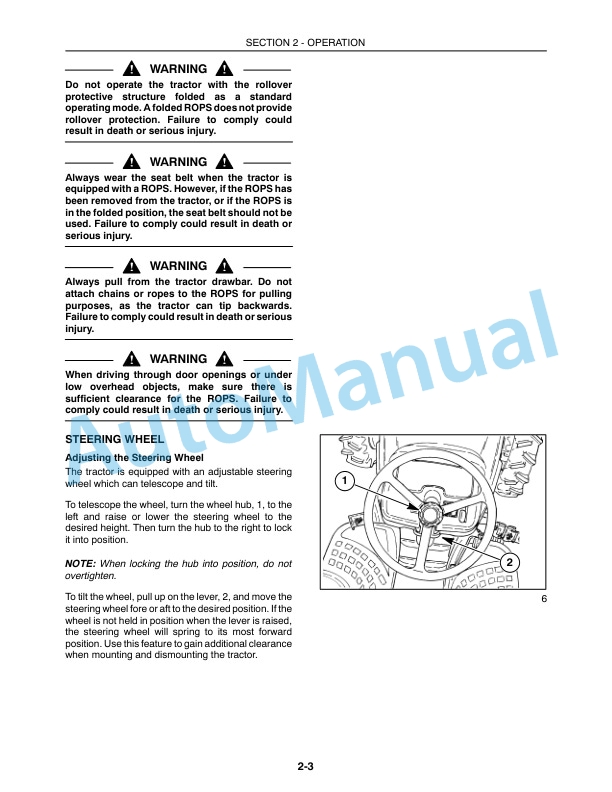

- 3.3.1. Steering wheel

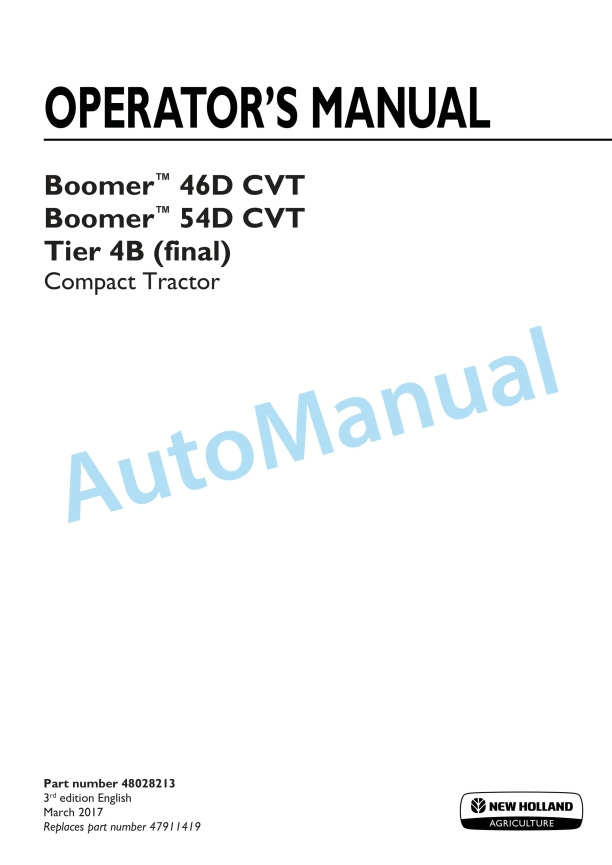

- 3.3.2. Instrument panel

- 3.3.3. Analog Digital Instrument Cluster (ADIC) programming

- 3.3.4. Analog Digital Instrument Cluster (ADIC) fault codes Transmission and PTO related

- 3.3.5. Analog Digital Instrument Cluster (ADIC) fault codes Engine related

- 3.3.6. Status and warning icons

- 3.3.7. Particulate Matter Catalyst

- 3.3.8. Hand throttle lever

- 3.3.9. Transmission shuttle shift lever

- 3.3.10. Multifunction light switch

- 3.3.11. Hazard lights switch

- 3.3.12. Work lights switch

- 3.4. LEFTHAND SIDE CONTROLS

- 3.4.1. Continuously Variable Transmission (CVT) controls

- 3.4.2. FourWheel Drive (4WD) control switch

- 3.4.3. Differential lock pedal

- 3.5. RIGHTHAND SIDE CONTROLS

- 3.5.1. Speed control pedal

- 3.5.2. Power TakeOff (PTO) controls

- 3.5.3. Hydraulic power lift (HPL)

- 3.5.4. Rear remote control valve(s)

- 3.5.5. Mid mount two spool control valve

- 3.6. REARWARD CONTROLS

- 3.6.1. Rear window

- 3.6.2. Auxiliary power outlet

- 3.6.3. Rear window wiper/washer (optional)

- 3.7. OVERHEAD CONTROLS

- 3.7.1. Cab climate control Overview

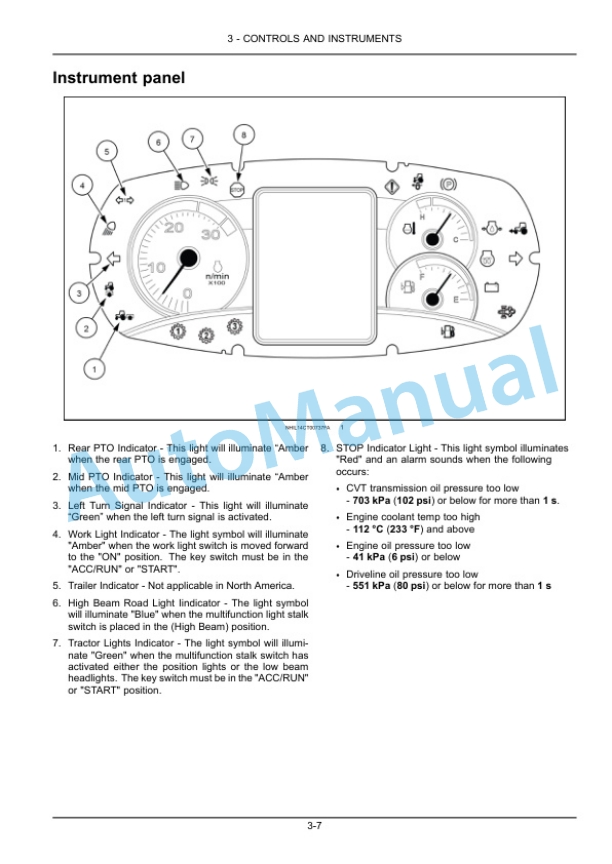

- 3.7.2. Air conditioning

- 3.7.3. Sun shades

- 3.7.4. Cab internal lighting

- 3.7.5. Cab external lighting

- 3.7.6. Front window wiper/washer

- 3.8. EXTERIOR CONTROLS

- 3.8.1. Hood latch

- 3.8.2. Rearview outside mirrors

- 3.8.3. Tool box

- 4. OPERATING INSTRUCTIONS

- 4.1. COMMISSIONING THE UNIT

- 4.1.1. CVT transmission controls (standard user interface) settings and adjustments

- 4.1.2. CVT transmission controls (enhanced user interface) settings and adjustments

- 4.1.3. Suggested operating mode settings Basic user interface

- 4.1.4. Suggested operating mode settings Enhanced user interface

- 4.1.5. Power TakeOff (PTO) operation

- 4.1.6. Extendable drawbar

- 4.1.7. Deluxe threepoint linkage

- 4.2. STARTING THE UNIT

- 4.2.1. Engine preheat system

- 4.2.2. Starting the engine

- 4.2.3. Starting the tractor with jumper cables

- 4.2.4. Low ambient temperature tractor warm up

- 4.3. STOPPING THE UNIT

- 4.3.1. Stopping the engine

- 4.3.2. Brakes

- 4.3.3. Park brake

- 5. TRANSPORT OPERATIONS

- 5.1. ROAD TRANSPORT

- 5.1.1. Front work and road lights

- 5.1.2. Hazard lights

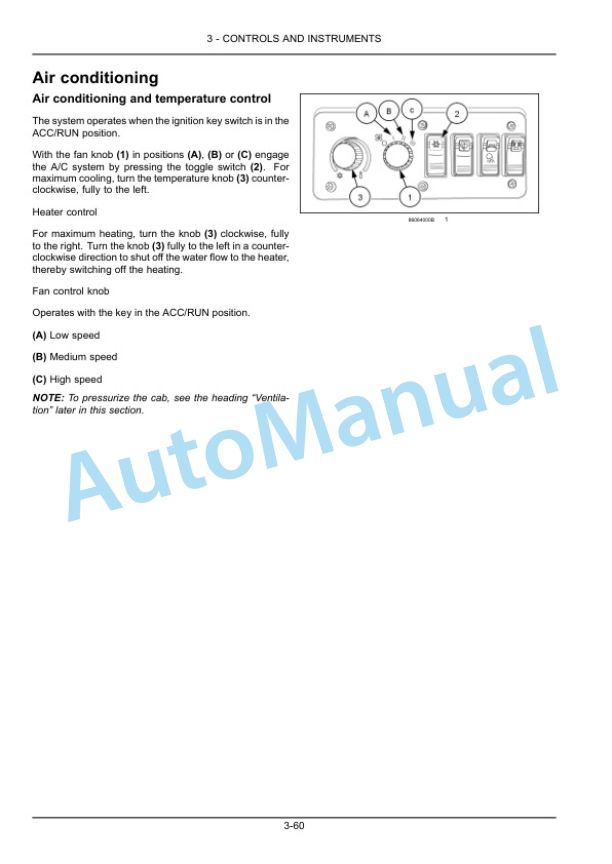

- 5.1.3. Tail/brake lights

- 5.1.4. Cab work lights

- 5.1.5. Roof beacon (optional)

- 5.1.6. Multifunction stalk switch

- 5.2. RECOVERY TRANSPORT

- 5.2.1. Preparation for towing

- 6. WORKING OPERATIONS

- 6.1. GENERAL INFORMATION

- 6.1.1. Filling the fuel tank

- 6.1.2. Engine Runningin Procedure

- 6.1.3. Driving the tractor

- 6.2. Tractor hydraulics

- 6.2.1. Hydraulic systems Safety rules

- 6.2.2. Hydraulic power lift (HPL)

- 6.2.3. Position control

- 6.2.4. Top link lift rocker

- 6.2.5. Hydraulic power lift (HPL) drop rate control valve

- 6.2.6. Rear remote control valve(s)

- 6.2.7. Mid mount two spool control valve

- 7. MAINTENANCE

- 7.1. GENERAL INFORMATION

- 7.1.1. General information

- 7.1.2. Torque Minimum tightening torques for normal assembly

- 7.1.3. Exhaust Gas Recirculation (EGR) exhaust treatment Product overview

- 7.1.4. Diesel fuel

- 7.1.5. Biodiesel fuel

- 7.1.6. Organic Acid Technology (OAT) coolant

- 7.1.7. Fluids and lubricants

- 7.1.8. Capacities

- 7.1.9. Jacking points

- 7.2. MAINTENANCE CHART

- 7.2.1. Maintenance chart

- 7.3. Every 10 hours or daily

- 7.3.1. Engine oil level

- 7.3.2. Engine coolant level

- 7.4. After first 50 hours

- 7.4.1. Engine oil and filter

- 7.4.2. Wheels bolt/nut

- 7.4.3. Roll Over Protective Structure (ROPS)

- 7.5. Every 50 hours

- 7.5.1. Lubrication points

- 7.5.2. Transmission oil level

- 7.5.3. Brake pedal free play

- 7.5.4. Engine belts

- 7.5.5. Tires

- 7.5.6. Front axle (4WD) oil level

- 7.6. Every 100 hours

- 7.6.1. Air cleaner primary element

- 7.6.2. Cab air filter

- 7.6.3. Engine and transmission coolers

- 7.7. Every 300 hours

- 7.7.1. Engine oil and filter

- 7.7.2. Hydraulic suction strainer

- 7.7.3. Hydraulic system pressure filter

- 7.7.4. Steering system pressure filter

- 7.7.5. Transmission control valve filter

- 7.8. Every 600 hours

- 7.8.1. Gerotor pump inner filter cleaning

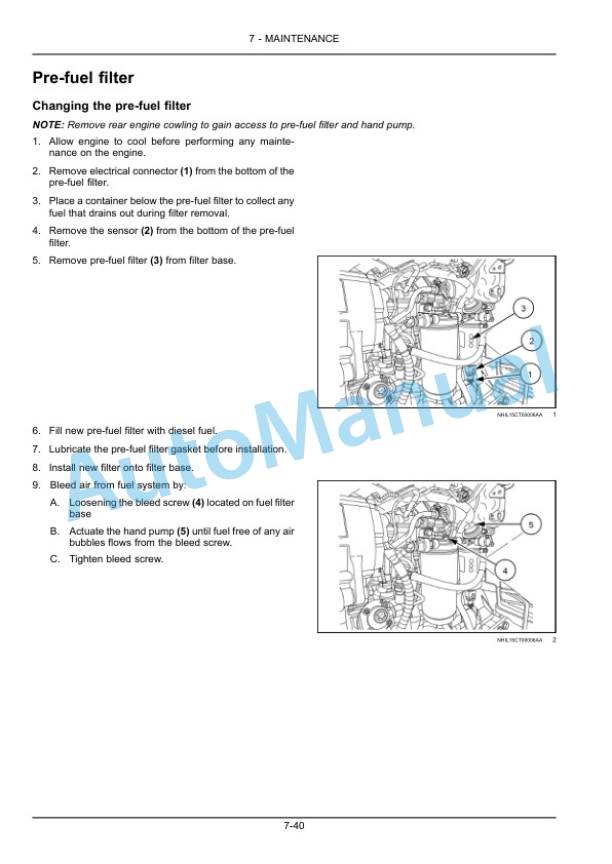

- 7.8.2. Prefuel filter

- 7.8.3. Fuel filter

- 7.8.4. Transmission fluid

- 7.8.5. Front axle (4WD) oil

- 7.9. Every 1000 hours

- 7.9.1. Air cleaner safety element Inner safety element

- 7.9.2. Cab air filter

- 7.9.3. Engine coolant

- 7.10. General maintenance

- 7.10.1. Turn signal/hazard light bulb

- 7.10.2. Cab Work Lights

- 7.10.3. Brake pedal free play

- 7.10.4. Park brake

- 7.10.5. Windshield wiper fluid reservoir

- 7.10.6. Steering stop bolts

- 7.10.7. Front wheel toein

- 7.11. STORAGE

- 7.11.1. Storing the tractor

- 7.11.2. Removal of tractor from storage

- 8. SPECIFICATIONS

- 8.1. Wheel tread settings

- 8.2. Tractor weighting

- 8.3. General specifications

- 8.4. Tractor dimensions

- 9. ACCESSORIES

- 9.1. Front end weights

- 9.2. Rear wheel weights

- 9.3. point hitch counter weight

- 9.4. Rear wheels liquid ballast

- 9.5. Tire inflation pressures

- 9.6. Dealer installed accessory (DIA)

- 9.7. Dealer installed winter packages

- 10. FORMS AND DECLARATIONS

- 10.1. Delivery report owner copy

- 10.2. Delivery report dealer copy

New Holland Operator Manual PDF

New Holland 230TL Loader Operation and Maintenance Manual 87541767

New Holland Operator Manual PDF

New Holland 2300BF With PTO Pump Operation and Maintenance Manual 86574145

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 51559567

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338

New Holland Operator Manual PDF

New Holland 160GMS Mower Deck Operation and Maintenance Manual 51410112

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Compact Tractor Operation and Maintenance Manual 47708986

New Holland Operator Manual PDF

New Holland 26 Rotary Tiller Attachment Operation Manual and Part List 42002611

New Holland Operator Manual PDF

New Holland 2030, 2035 Boomer Tractor Operation and Maintenance Manual 87477103

New Holland Operator Manual PDF

New Holland 100LC Loader Operation and Maintenance Manual 51410108

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058