- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

New Holland 810LA, 815LA, 830LA, 835LA, 850LA, 855LA, 857LA, 910LA, 915LA, 917LA, 935LA, 937LA, 975LA Farm Loader Service Manual 60034447

$30.00

- Type Of Manual: Service Manual

- Manual ID: 60034447

- Format: PDF

- Size: 43.1MB

- Number of Pages: 121

- Serial Number:

60034447

Category: New Holland Service Manual PDF

-

Model List:

- 810LA Farm Loader

- 815LA Farm Loader

- 830LA Farm Loader

- 835LA Farm Loader

- 850LA Farm Loader

- 855LA Farm Loader

- 857LA Farm Loader

- 910LA Farm Loader

- 915LA Farm Loader

- 917LA Farm Loader

- 935LA Farm Loader

- 937LA Farm Loader

- 975LA Farm Loader

- 1. Introduction

- 1.1. Necessary additional documentation

- 1.2. Identification

- 1.2.1. Model and serial number

- 1.3. Alignment reference

- 1.4. Setting joystick position

- 1.5. Subframe identification

- 1.6. Subframe identification DM/DL/DLM/DXL

- 2. Description and definitions

- 2.1. Description

- 2.2. Definitions

- 2.2.1. Third/fourth hydraulic function

- 2.2.2. Live3 (active third hydraulic function)

- 2.2.3. Implement lock

- 2.2.4. Hydro Quick / Multicoupler MC4

- 2.2.5. Single couplers

- 2.2.6. Multicoupler?2 (MC2)

- 2.2.7. Lock Go

- 2.2.8. Position indicator

- 2.2.9. Compact Valve Unit (CVU)

- 2.2.10. Hydraulic implement connection, Multicoupler

- 2.2.11. Hose kit

- 2.2.12. Soft Ride, Load Damping System

- 2.2.13. Material buckets

- 2.2.14. Heavy Duty Material Buckets

- 2.2.15. Construction Tooth Buckets

- 2.2.16. Light Material/ Snow Buckets

- 2.2.17. Fork Lifts

- 2.2.18. Log Grab Attachment for Fork Lifts

- 2.2.19. Bale spike

- 2.2.20. Big Bale Fork / with Backstop

- 2.2.21. Grapple with optional backscreen

- 2.2.22. Flexigrip 160, 200

- 2.2.23. Quadrogrip 200

- 2.2.24. Weld on Hook Set

- 2.2.25. Systems DM, DL and DXL

- 2.2.26. Mechanical Self Levelling loader, MSL

- 2.2.27. NonSelf Levelling loader, NSL

- 2.2.28. Tool carrier

- 2.2.29. Implement

- 2.2.30. Implement hooks

- 3. Safety instructions

- 3.1. General information

- 3.1.1. Guards

- 3.1.2. Warning, prohibition and information decals.

- 3.2. Explanation of warning levels

- 3.2.1. Symbol explanation

- 3.2.2. Responsibility

- 3.3. Installing the loader

- 3.4. Joystick operation

- 3.5. Protection equipment

- 3.5.1. Service

- 3.5.2. Welding

- 3.5.3. Safety belt

- 3.5.4. ROPS, Rollover protection structure

- 3.6. Operation

- 3.6.1. Before work

- 3.6.2. Operator/driver location

- 3.6.3. Connecting implement

- 3.6.4. Workplace

- 3.6.5. Stability

- 3.6.6. Tractor stability

- 3.7. Risk factors

- 3.7.1. During transport and work

- 3.7.2. During service

- 3.7.3. After work

- 3.8. Replacement parts

- 3.9. Location of warning, prohibition and information decals (EU)

- 3.10. Location of warning, prohibition and information decals (NAFTA)

- 3.11. Location of safety signs on implements

- 4. Installation subframe

- 4.1. Installation preparation subframe

- 4.2. Installation subframe on tractor

- 4.3. Installation checks subframe installation

- 5. Installation Front Loaders

- 5.1. Installation Preparation, Front Loaders

- 5.1.1. Lock Go

- 5.1.2. Position indicator

- 5.2. Connection Front loader with subframe

- 5.2.1. Connecting the loader using lifting equipment

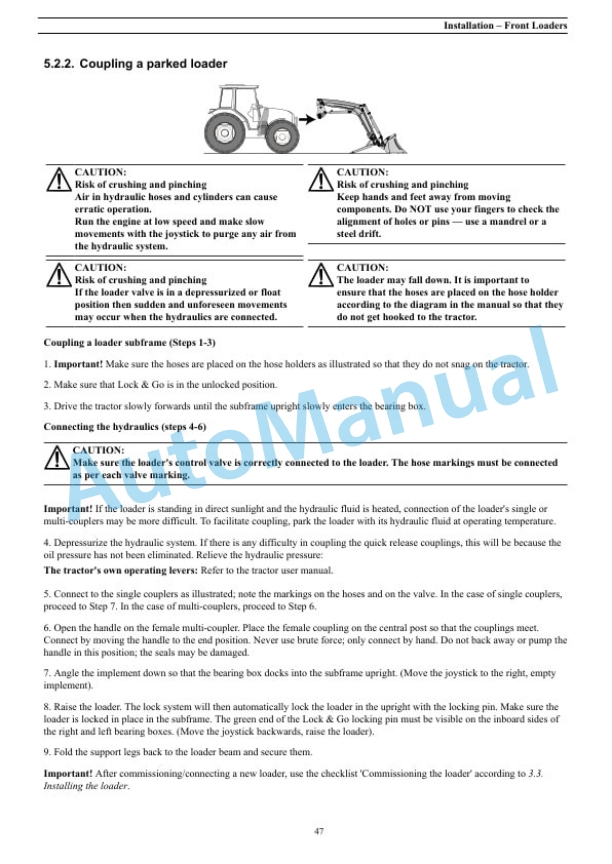

- 5.2.2. Coupling a parked loader

- 5.3. Checking front loader installation

- 5.4. DisconnectingFront loader with subframe

- 5.4.1. Unhitching the loader using lifting equipment

- 5.4.2. Disconnecting the loader

- 6. Installation Control system

- 6.1. Hose kit

- 6.2. Compact Valve Unit, CVU

- 6.2.1. CVU equipped with Basic NSL (no extra functions)

- 6.2.2. CVU equipped with Soft Ride shock valves (tilt)

- 6.2.3. CVU equipped with Third hydraulic function

- 6.2.4. CVU equipped with Third function Soft Ride

- 6.2.5. CVU equipped with Third function hydraulic implement lock

- 6.2.6. CVU equipped with Third function Soft Ride hydraulic implement lock

- 6.2.7. CVU equipped with Third and fourth hydraulic functions

- 6.2.8. CVU equipped with Live3

- 6.2.9. CVU equipped with Live3 Soft Ride shock valves (tilt)

- 6.2.10. CVU equipped with Live3 hydraulic implement lock

- 6.2.11. CVU equipped with Live3 Soft Ride hydraulic implement lock

- 6.2.12. The tractors own joystick

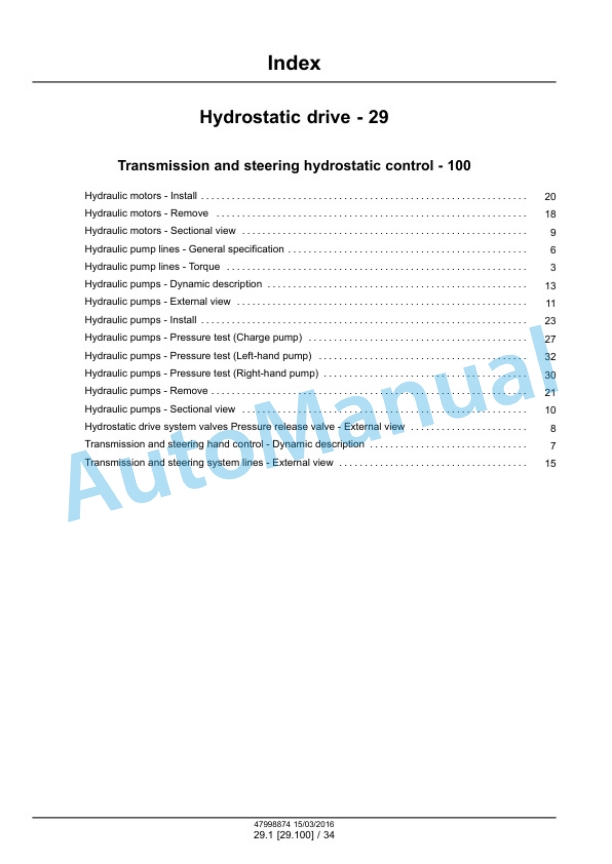

- 7. Service general

- 8. Service subframe

- 9. Service Front loaders

- 9.1. Lubrication

- 9.2. Tool carrier

- 9.3. Loaders

- 9.3.1. Pins and bushings

- 9.3.2. Tool carrier, replacing pins and bushings

- 9.3.3. Replacing the pins and bushings, triangular link

- 9.3.4. Replacing pins and bushings, lift cylinder and bearing box

- 9.4. Bearing box

- 10. Service Loader hydraulics

- 10.1. Hydraulic system

- 10.2. Hoses and connectors

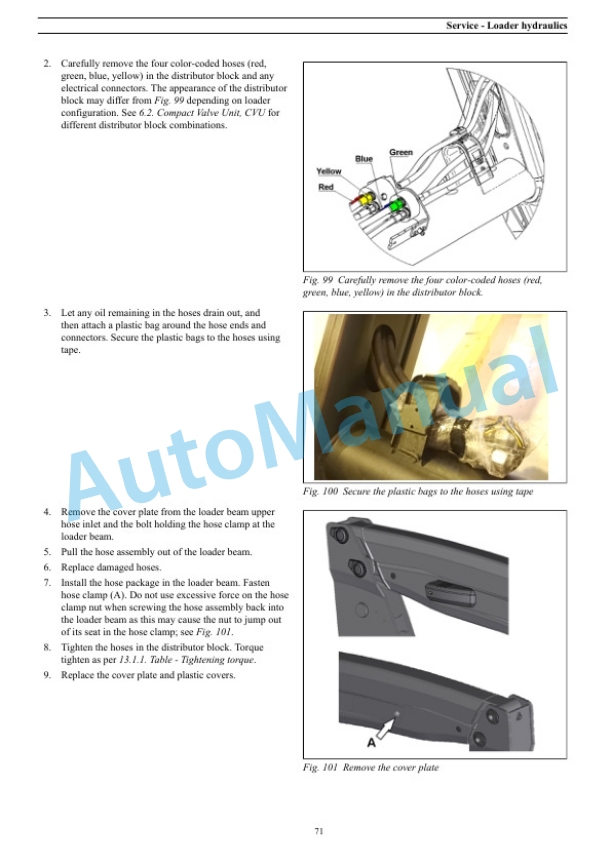

- 10.2.1. Replacing hoses or connectors

- 10.3. Main hose kit

- 10.4. Boom suspension

- 10.4.1. Replacing accumulators

- 10.5. Compact Valve Unit (CVU) with associated function modules

- 10.5.1. Module CB01 connecting block Basic

- 10.5.2. Module CB03 connecting block Soft Ride

- 10.5.3. Module CB04 connecting block Tilt

- 10.5.4. Module SV01 selector valve Third hydraulic function

- 10.5.5. Module SV02 selector valve fourth hydraulic function

- 10.5.6. Module IL01 Hydraulic lock valve

- 11. Service Cylinders

- 11.1. Tilt cylinder Mechanical Self Levelling loader, (MSL)

- 11.1.1. Tilt cylinder disassembly

- 11.1.2. Removing the piston

- 11.1.3. Remove the piston seals

- 11.1.4. Remove the top nut seals

- 11.1.5. Remove the bottom guide seals

- 11.1.6. Installing new sealing components on the piston

- 11.1.7. Installing new sealing components on the top nut

- 11.1.8. Installing new sealing components on the bottom guide

- 11.1.9. Installing the top nut, piston and bottom guide on the piston rod

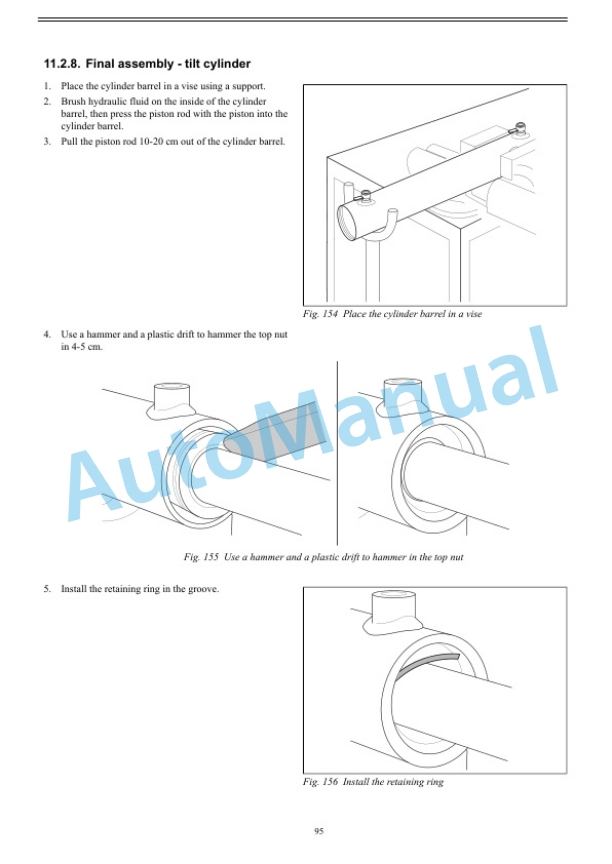

- 11.1.10. Final assembly tilt cylinder

- 11.2. Tilt cylinder NonSelf Levelling loader (NSL)

- 11.2.1. Tilt cylinder disassembly

- 11.2.2. Removing the piston

- 11.2.3. Remove the piston seals

- 11.2.4. Remove the top nut seals

- 11.2.5. Installing new sealing components on the piston

- 11.2.6. Installing new sealing components on the top nut

- 11.2.7. Installing the bearing and the piston on the piston rod

- 11.2.8. Final assembly tilt cylinder

- 11.3. Lift cylinder

- 11.3.1. Tilt cylinder disassembly

- 11.3.2. Removing the piston

- 11.3.3. Remove the piston seals

- 11.3.4. Remove the top nut seals

- 11.3.5. Installing new sealing components on the piston

- 11.3.6. Installing new sealing components on the top nut

- 11.3.7. Installing the bearing and the piston on the piston rod

- 11.3.8. Final assembly lift cylinder

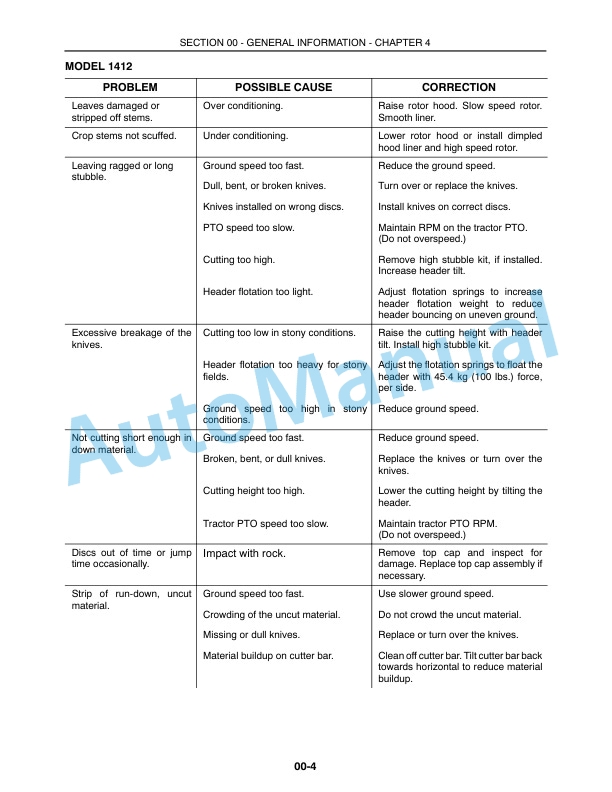

- 12. Troubleshooting

- 12.1. Troubleshooting table loaders

- 13. Tightening torques

- 13.1. Tightening torques

- 13.1.1. Table Tightening torque

- 14. Storage

- 15. Specifications

- 15.1. Mechanical self levelling, MSL

- 15.2. Non self levelling, NSL

- 16. Wiring diagram

- 16.1. Wiring diagram Loader

- 16.2. Wiring diagram Loader with Live3

- 16.3. Wiring diagram Loader with all hydraulic functions

Rate this product

You may also like

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 102, 103, 105 StackCruiser Tier 4B Final Bale Wagon Service Manual 48190534

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 1400, 1500 Combine Tractor Service Manual 40481300

$30.00

New Holland Service Manual PDF

New Holland 107M, 108M, 109M DuraDisc Disc Mower Service Manual 51594690

$30.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF