- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

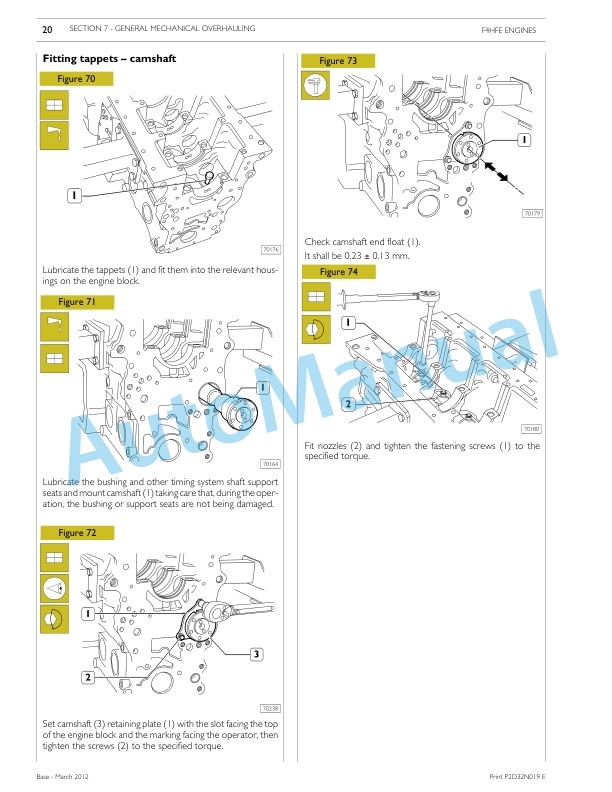

New Holland N45, N67 ENT Series NEF Tier 4i Industrial Application Technical and Repair Manual P2D32N019E

$30.00

- Type Of Manual: Technical and Repair Manual

- Manual ID: P2D32N019E

- Format: PDF

- Size: 35.5MB

- Number of Pages: 298

- Serial Number:

P2D32N019E

Category: New Holland Service Manual PDF

-

Model List:

- N45 ENT Series NEF Tier 4i Industrial Application

- N67 ENT Series NEF Tier 4i Industrial Application

- 1. SERIES NEF TIER 4i

- 1.1. Technical and Repair manual

- 1.1.1. PREFACE

- 1.1.2. SYMBOLS Warnings

- 1.1.3. GENERALWARNINGS

- 1.1.4. GENERALWARNINGS ON THE ELECTRIC SYSTEM

- 1.1.4.1. Bonding and screening

- 1.1.5. OPTIONAL ELECTRICAL AND MECHANICAL PARTS INSTALLATIONS

- 1.1.6. CONVERSIONS BETWEEN THE MAIN UNITS OF MEASUREMENT OF THEINTERNATIONAL SYSTEM AND MOST USED DERIVED QUANTITIES

- 1.1.7. KEY OF LECTURE OF THE HEADINGS AND FOOTNOTES

- 1.1.8. F4HFE ENGINES

- 1.1.8.1. Part 1 F4HFE ENGINES

- 1.1.8.1.1. UPDATING

- 1.1.8.1.2. SECTION 1 General specifications

- 1.1.8.1.2.1. CORRESPONDENCE BETWEEN TECHNICAL CODE AND COMMERCIAL CODE

- 1.1.8.1.2.2. ENGINE VIEWS

- 1.1.8.1.2.3. ENGINE VIEWS

- 1.1.8.1.2.4. ENGINE VIEWS

- 1.1.8.1.2.5. ENGINE VIEWS

- 1.1.8.1.2.6. GENERAL CHARACTERISTICS

- 1.1.8.1.3. SECTION 2 Operational diagrams

- 1.1.8.1.3.1. HIGH PRESSURE ELECTRONIC INJECTION FUEL SYSTEM (COMMON RAIL)

- 1.1.8.1.3.2. ELECTRIC SYSTEM

- 1.1.8.1.3.3. HYDRAULIC SYSTEM

- 1.1.8.1.3.4. FUEL SUPPLY SYSTEM COMPONENTS

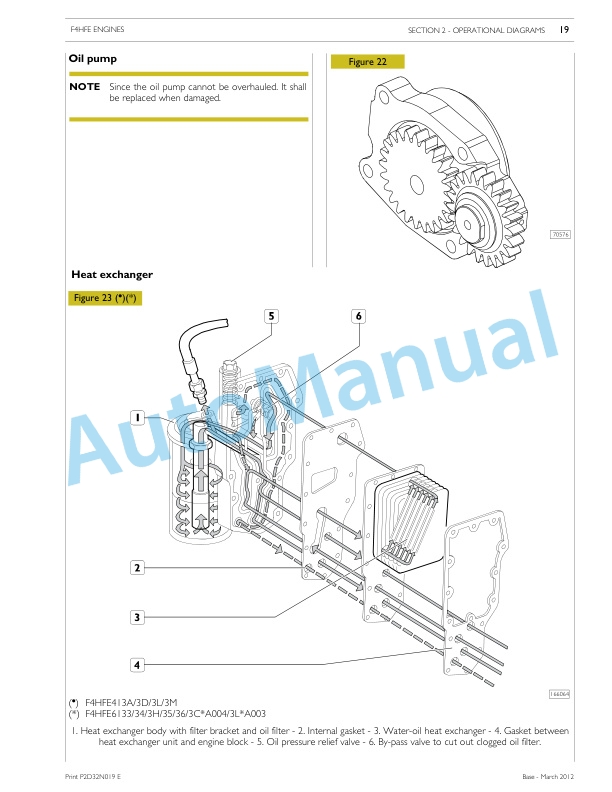

- 1.1.8.1.3.5. LUBRICATION

- 1.1.8.1.3.6. OIL VAPOUR RECYCLING

- 1.1.8.1.3.7. COOLING SYSTEM

- 1.1.8.1.3.8. TURBOCHARGER

- 1.1.8.1.3.9. DeNOx 2 SYSTEM

- 1.1.8.1.4. SECTION 3 Electrical equipment

- 1.1.8.1.4.1. LOCATION OF THE MAIN ELECTRICAL COMPONENTS

- 1.1.8.1.4.2. ENGINE CABLE

- 1.1.8.1.4.3. ECU ELECTRONIC CONTROL UNIT (EDC7UC31)

- 1.1.8.1.4.4. FUEL SUPPLY SYSTEM ELECTRICAL COMPONENTS

- 1.1.8.1.5. SECTION 4 Scheduled maintenance

- 1.1.8.1.5.1. SCHEDULED MAINTENANCE

- 1.1.8.1.5.2. MAINTENANCE PROCEDURES

- 1.1.8.1.6. SECTION 5 Diagnostics

- 1.1.8.1.6.1. PREFACE

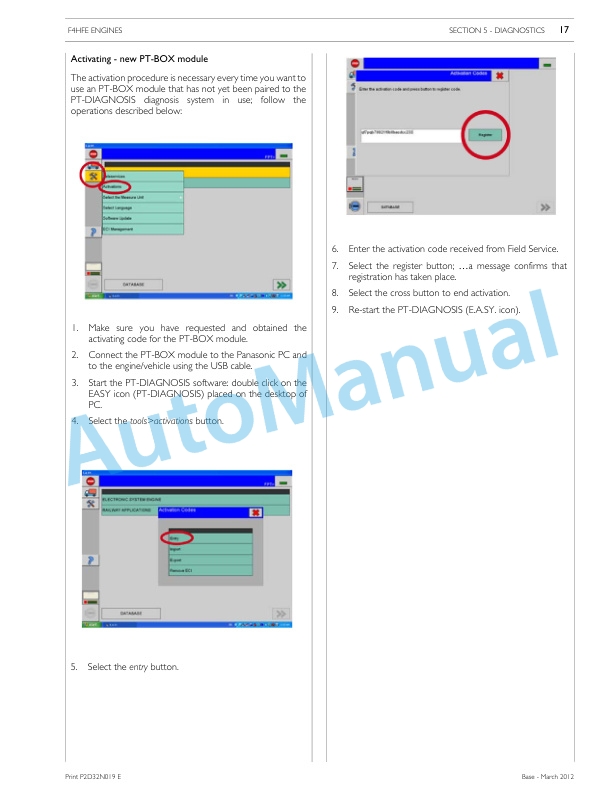

- 1.1.8.1.6.2. PT BOX

- 1.1.8.1.6.3. PTBOX INSTRUCTIONS

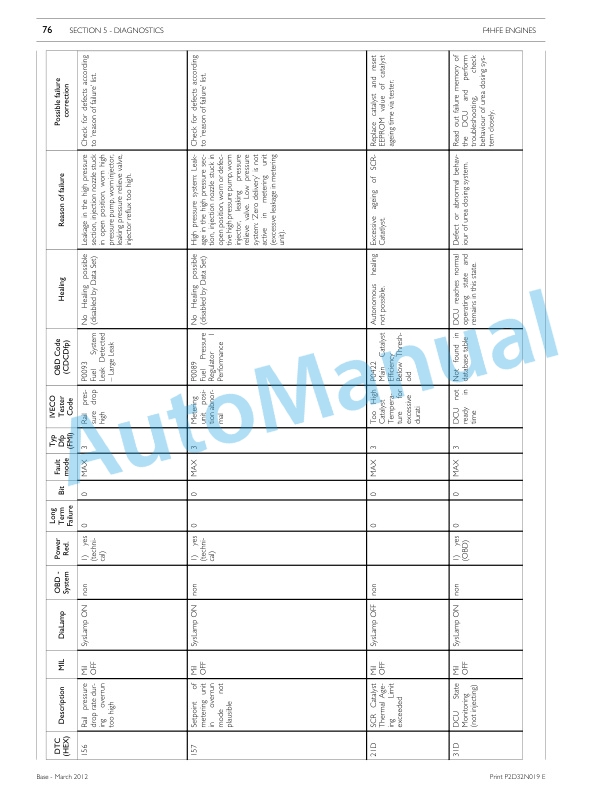

- 1.1.8.1.6.4. FAULT CODES

- 1.1.8.1.6.5. GUIDE TO DIAGNOSIS THROUGH SYMPTOMS

- 1.1.8.1.7. SECTION 6 Removal and installation of maincomponents

- 1.1.8.1.7.1. REMOVAL AND INSTALLATION AUXILIARYDRIVE BELT

- 1.1.8.1.7.2. REMOVAL AND INSTALLATION AUXILIARYDRIVE BELT

- 1.1.8.1.7.3. COOLANT PUMP REMOVAL AND INSTALLATION

- 1.1.8.1.7.4. THERMOSTAT REMOVAL AND INSTALLATION

- 1.1.8.1.7.5. REMOVAL AND INSTALLATION STARTERMOTOR

- 1.1.8.1.7.6. ENGINE CABLE REMOVAL AND INSTALLATION

- 1.1.8.1.7.7. REMOVAL AND INSTALLATION LOWPRESSUREFUEL LINES

- 1.1.8.1.7.8. REMOVAL AND INSTALLATION FUELHOSE FROM HIGH PRESSURE PUMP TOCOMMON RAIL

- 1.1.8.1.7.9. ENGINE CONTROL UNIT REMOVAL ANDINSTALLATION

- 1.1.8.1.7.10. FUEL FILTER REMOVAL AND INSTALLATION

- 1.1.8.1.7.11. INJECTION PUMP REMOVAL ANDINSTALLATION

- 1.1.8.1.7.12. STACCORIATTACCO COMMON RAIL

- 1.1.8.1.7.13. OIL VAPOUR RECIRCULATION (BLOWBY)SYSTEM REMOVAL AND INSTALLATION

- 1.1.8.1.7.14. TAPPET COVER REMOVAL AND INSTALLATION

- 1.1.8.1.7.15. INJECTOR WIRING SUPPORT REMOVALAND INSTALLATION

- 1.1.8.1.7.16. REMOVAL AND INSTALLATION ROCKERARM ASSEMBLY

- 1.1.8.1.7.17. INJECTORREMOVALANDINSTALLATION

- 1.1.8.1.7.18. TURBOCHARGER REMOVAL AND INSTALLATION

- 1.1.8.1.7.19. EXHAUST MANIFOLD REMOVAL ANDINSTALLATION

- 1.1.8.1.7.20. INTAKE MANIFOLD REMOVAL ANDINSTALLATION

- 1.1.8.1.7.21. COLD START AIR HEATER REMOVAL AND INSTALLATION (only for HFE6132/39/3A/ 3CA002 3/3LA0012 engines)

- 1.1.8.1.7.22. CYLINDER HEAD REMOVAL AND INSTALLATION

- 1.1.8.1.7.23. ENGINE OIL FILTER REMOVAL ANDINSTALLATION

- 1.1.8.1.7.24. REMOVAL AND INSTALLATION ENGINEOIL HEAT EXCHANGER

- 1.1.8.1.7.25. OIL SUMP REMOVAL AND INSTALLATION

- 1.1.8.1.8. SECTION 7 General mechanical overhauling

- 1.1.8.1.8.1. INTRODUCTION

- 1.1.8.1.8.2. FITTING THE ENGINE TO THE ROTATINGSTAND

- 1.1.8.1.8.3. REMOVAL OF MAIN COMPONENTS

- 1.1.8.1.8.4. BENCH ENGINE BLOCK DISASSEMBLY

- 1.1.8.1.8.5. CRANKCASE

- 1.1.8.1.8.6. TIMING SYSTEM

- 1.1.8.1.8.7. BUSH

- 1.1.8.1.8.8. TAPPETS

- 1.1.8.1.8.9. CRANKSHAFT

- 1.1.8.1.8.10. CONNECTING ROD PISTON ASSEMBLY

- 1.1.8.1.8.11. BENCH ENGINE BLOCK ASSEMBLY

- 1.1.8.1.8.12. CYLINDER HEAD DISMANTLING

- 1.1.8.1.8.13. VALVES

- 1.1.8.1.8.14. VALVE GUIDES

- 1.1.8.1.8.15. VALVE SEATS

- 1.1.8.1.8.16. VALVE SPRINGS

- 1.1.8.1.8.17. ASSEMBLING CYLINDER HEAD

- 1.1.8.1.8.18. REFITTING MAIN COMPONENTS

- 1.1.8.1.8.19. REMOVING THE ENGINE FROM THEROTATING STAND

- 1.1.8.1.8.20. COMPLETING ENGINE ASSEMBLY

- 1.1.8.1.8.21. CHECKS AND INSPECTIONS

- 1.1.8.1.9. SECTION 8 Technical specifications

- 1.1.8.1.9.1. GENERAL SPECIFICATIONS

- 1.1.8.1.9.2. CLEARANCE DATA

- 1.1.8.1.9.3. TIGHTENING TORQUE

- 1.1.8.1.10. SECTION 9 Tools

- 1.1.8.1.10.1. TOOLS

- 1.1.8.1.11. Appendix

- 1.1.8.1.11.1. SAFETY PRESCRIPTIONS

Rate this product

You may also like

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 12-Row, 5-Row, 6-Row, 8-Row Maize Header Service Manual 84314507A

$30.00

New Holland Service Manual PDF

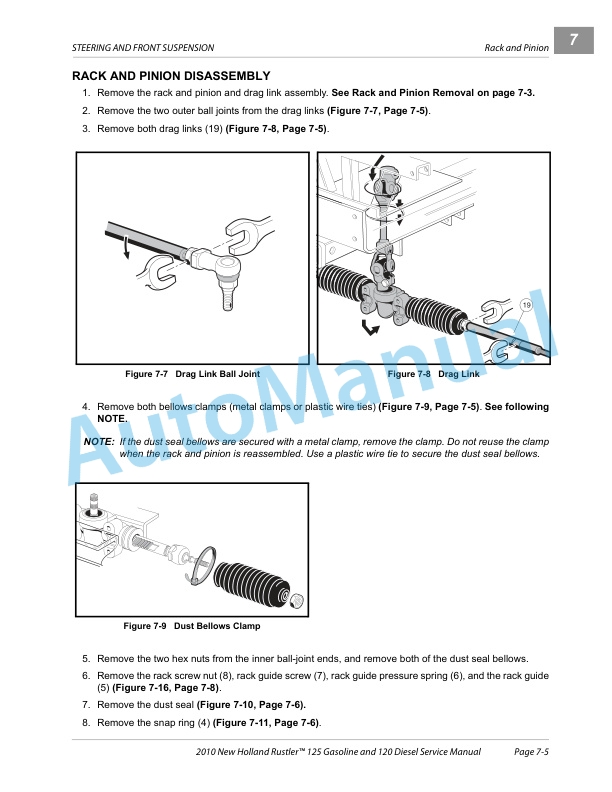

New Holland 120, 125 Rustler Tractor Service Manual CLC103700628

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

$30.00

New Holland Service Manual PDF

New Holland 12HS, 14HS, 16HS, 18HS Sickle Header Service Manual 47851907

$30.00

New Holland Service Manual PDF

$20.00

New Holland Service Manual PDF

New Holland 1320, 1520, 1620, 1715, 1720 Tractor Service Manual 40132030

$30.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF