New Holland TT4.55, TT4.65, TT4.75 Tractor Operation and Maintenance Manual 48135179

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 48135179

- Format: PDF

- Size: 7.3MB

- Number of Pages: 134

- Serial Number:

48135179

-

Model List:

- TT4.55 Tractor

- TT4.65 Tractor

- TT4.75 Tractor

- 1. GENERAL INFORMATION

- 1.1. Note to the Owner

- 1.2. General information and safety

- 1.3. Product Identification

- 1.4. Ecology and the Environment

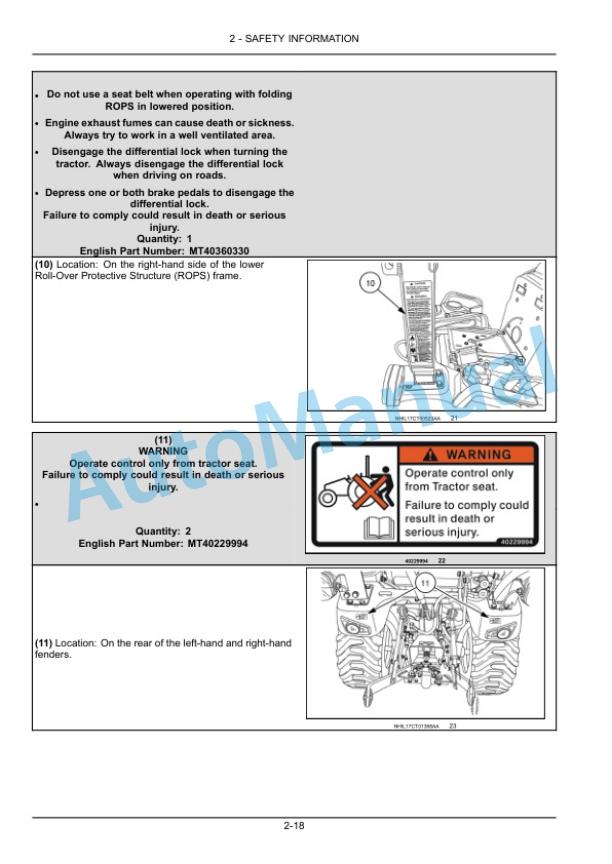

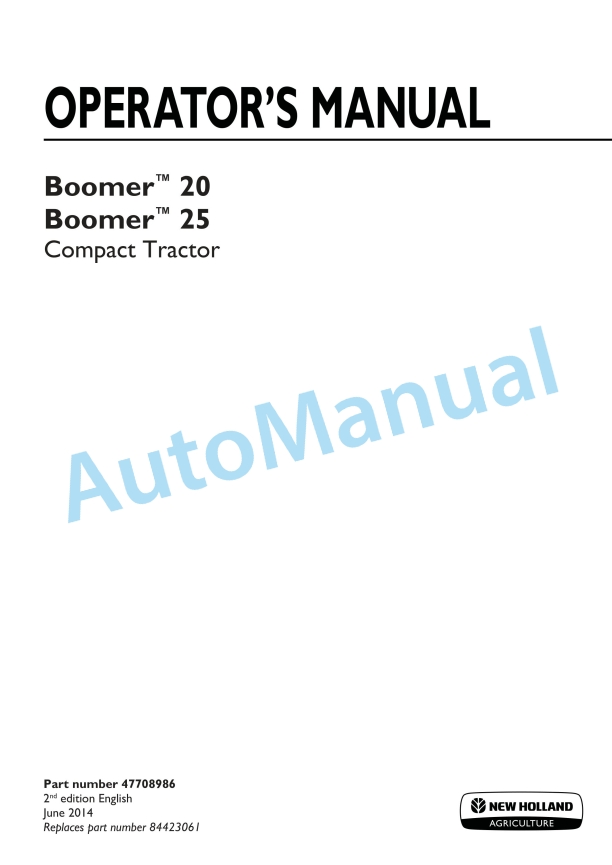

- 2. SAFETY INFORMATION

- 2.1. Safety rules

- 2.2. Safety precautions

- 2.3. Personal safety

- 2.4. Driving the tractor

- 2.5. Operating the tractor

- 2.6. Operating the Power TakeOff (PTO)

- 2.7. Servicing the tractor

- 2.8. Diesel fuel

- 2.9. Trailer hitching

- 2.10. General and Safety Decals

- 2.11. International symbols

- 2.12. Fuel saving tips for optimum performance

- 3. CONTROLS AND INSTRUMENTS

- 3.1. Access to operators platform

- 3.1.1. Before Operating

- 3.2. Operators seat

- 3.2.1. Operators seat

- 3.2.2. Operators seat belt

- 3.3. Forward controls

- 3.3.1. Instrument cluster

- 3.3.2. Hand controls and switches

- 3.3.3. Hydrostatic Steering

- 3.3.4. Transmission shuttle shift lever

- 3.4. Lefthand side controls

- 3.4.1. Clutch Pedal

- 3.4.2. Parking Brake

- 3.4.3. Creeper lever (where fitted)

- 3.4.4. Splitter lever (where fitted)

- 3.4.5. Power TakeOff (PTO) Control identification

- 3.4.6. D Lever

- 3.5. Righthand side controls

- 3.5.1. Foot Accelerator

- 3.5.2. Differential lock pedal Control identification

- 3.5.3. Foot Brake Pedal

- 3.6. Overhead controls

- 3.6.1. Roll Over Protective Structure (ROPS) frame Position

- 3.7. Transmission

- 3.7.1. Transmission Control identification

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. Before Operating

- 4.1.2. RunningIn Procedure

- 4.2. Starting the unit

- 4.2.1. Starting the tractor with jumper cables

- 4.2.2. Starting the Engine

- 4.3. Stopping the unit

- 4.3.1. Stopping the engine

- 5. TRANSPORT OPERATIONS

- 5.1. Road transport

- 5.1.1. Carrying the tractor on a transporter

- 5.2. Recovery transport

- 5.2.1. Towing the tractor

- 6. WORKING OPERATIONS

- 6.1. INTER COOLER TURBO CHARGER LDA

- 6.1.1. Intercooler

- 6.1.2. Turbocharger Control identification

- 6.1.3. Oil cooler

- 6.2. POWER TAKE OFF (PTO)

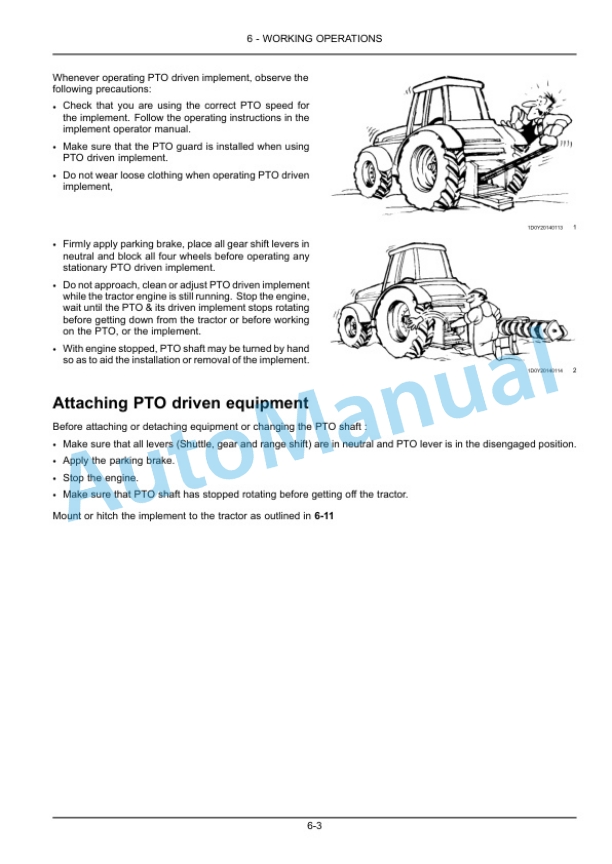

- 6.2.1. Power TakeOff (PTO) operating precautions

- 6.2.2. Attaching PTO driven equipment

- 6.2.3. Power TakeOff (PTO) Control identification

- 6.2.4. Power TakeOff (PTO) protective cap and guard

- 6.2.5. Ground drive PTO (where fitted)

- 6.3. Threepoint linkage

- 6.3.1. Threepoint hitch Control identification

- 6.3.2. Attaching 3point implements

- 6.3.3. Threepoint hitch adjustments

- 6.3.4. Remote Valves (If fitted)

- 6.3.5. Drawbars and towing hitches Adjust TOWING ATTACHMENTS

- 6.4. HYDRAULIC SYSTEM

- 6.4.1. Hydraulic systems Check

- 6.4.2. Position control operation

- 6.4.3. Draft Control Operation

- 6.4.4. Combined position and Draft control Mixed control

- 6.4.5. Float Operation

- 6.4.6. LiftOMatic Button

- 6.4.7. Height Limiter Lift O Matic (If fitted)

- 6.4.8. Sensitivity Control

- 6.4.9. Response Control or Drop rate Control

- 6.4.10. Divert Valve External Supply Port or Tap off

- 6.5. WHEEL TRACK ADJUSTMENT

- 6.5.1. FRONT WHEEL TRACK ADJUSTMENT (two wheel drive)

- 6.5.2. Hydrostatic Steering Right side illustrated

- 6.5.3. Reassembly After Setting Track Width

- 6.5.4. Front wheel track adjustment 4WD

- 6.5.5. Front wheels toein

- 6.5.6. Rear wheel track adjustment

- 6.6. BALLASTING AND TIRES

- 6.6.1. Ballasting of Tires

- 6.6.2. Rear wheel weights

- 6.6.3. Front Weights

- 6.6.4. Liquid ballast

- 6.6.5. Tire inflation

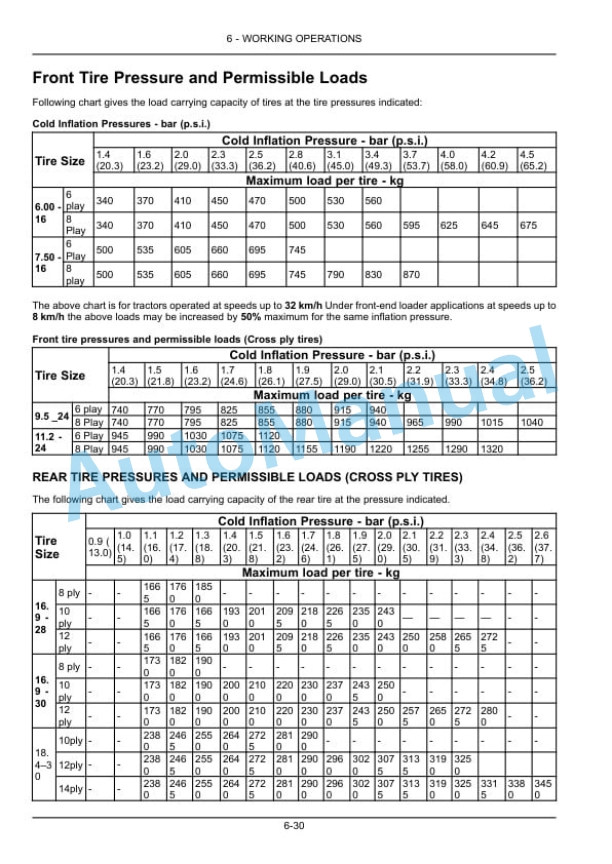

- 6.6.6. Front Tire Pressure and Permissible Loads

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. Introduction

- 7.1.2. Safety precautions

- 7.1.3. During the first 50 hour operation

- 7.1.4. The First 50 Hours Service

- 7.1.5. Preventing System Contamination

- 7.1.6. Flexibility of Maintenance Intervals

- 7.1.7. Lubrication and maintenance chart

- 7.1.8. Fueling the tractor

- 7.1.9. Fuel Requirements

- 7.1.10. Diesel fuel quality specifications

- 7.1.11. Fuel storage

- 7.1.12. Guards

- 7.2. Maintenance planning

- 7.2.1. Maintenance chart

- 7.3. Every 10 Hours of Operation or Daily (Whichever Occurs First)

- 7.3.1. Check engine oil level

- 7.3.2. Radiator coolant level check

- 7.3.3. Air precleaner Cleaning (If fitted)

- 7.3.4. Drain water from Fuel Filter

- 7.3.5. Water Separator

- 7.4. EVERY 50 HOURS

- 7.4.1. Air precleaner Cleaning

- 7.4.2. Clutch pedal free play check

- 7.4.3. Brake pedal free play check

- 7.4.4. Wheel nut and bolt torque

- 7.4.5. Tire pressure and condition

- 7.4.6. Fan/alternator belt adjustment

- 7.4.7. Grease fittings

- 7.4.8. Grease fittings FourWheel Drive (4WD)

- 7.4.9. Battery electrolyte level Check

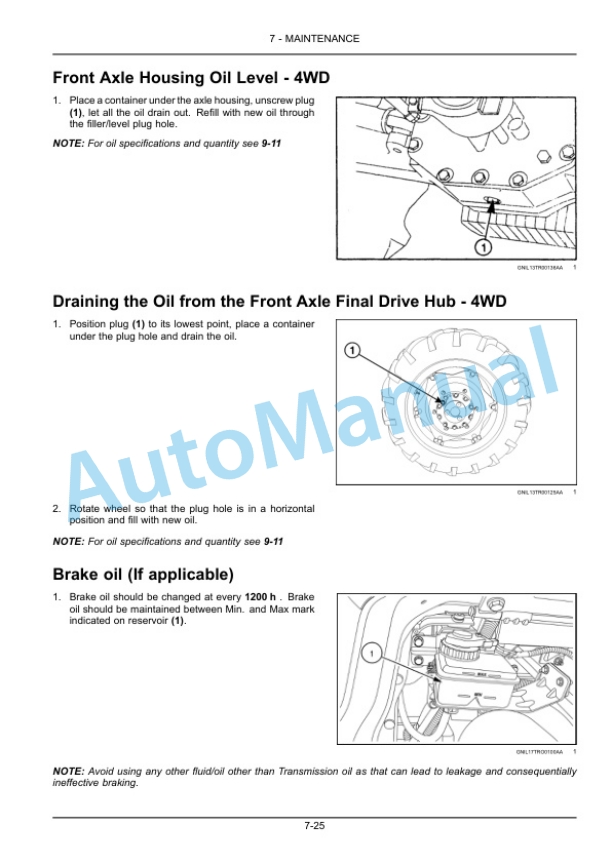

- 7.4.10. Front Axle Housing Oil Level 4WD

- 7.5. EVERY 300 HOURS

- 7.5.1. SERVICE THE ENGINE AIR CLEANER OUTER ELEMENT

- 7.5.2. Change the fuel filter (Primary)

- 7.5.3. Fuel injection system Bleed

- 7.5.4. Fuel Feed Pump Filter

- 7.5.5. Change engine oil

- 7.5.6. Change Engine Oil Filter

- 7.5.7. Transmission oil Common oil level (Transmission/Hydraulic/Steering)

- 7.5.8. Hydraulic oil filter

- 7.5.9. Front Axle Reduction Hubs 4WD

- 7.5.10. D front axle swivel bearings

- 7.5.11. Drive Shaft Sleeve for 4WD Front Axle Connection

- 7.5.12. PTO clutch lever free play

- 7.6. EVERY 600 HOURS

- 7.6.1. Replacing the fuel filters

- 7.6.2. Check the valve tappet clearance

- 7.6.3. Transmission housing breather Check

- 7.6.4. Clean, Regrease and Adjust Front Wheel Bearing

- 7.6.5. Fuel injectors servicing

- 7.6.6. Toein adjustment

- 7.7. EVERY 1200 HOURS OR ANNUALLY

- 7.7.1. Hydraulic/Transmission Fluid Change

- 7.7.2. Radiator Drain and Refill the Cooling System

- 7.7.3. Front Axle Housing Oil Level 4WD

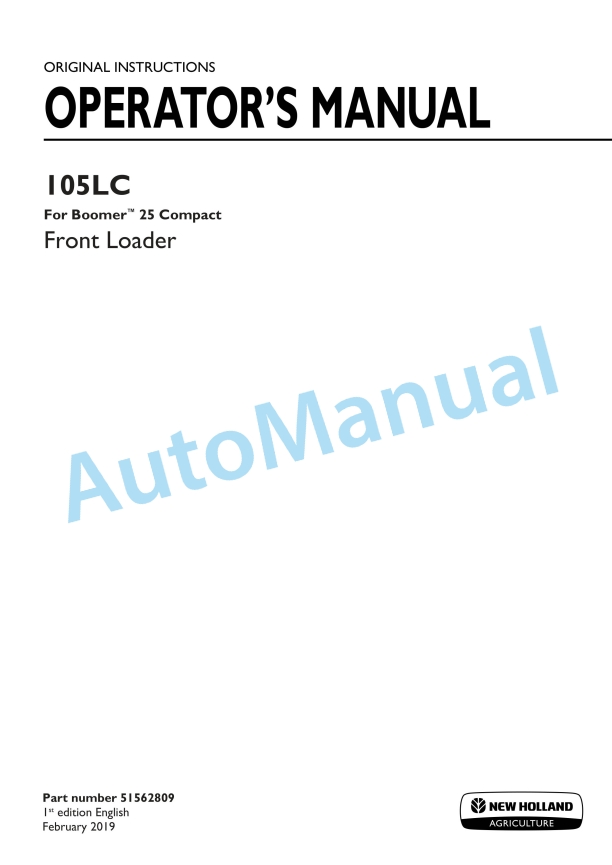

- 7.7.4. Draining the Oil from the Front Axle Final Drive Hub 4WD

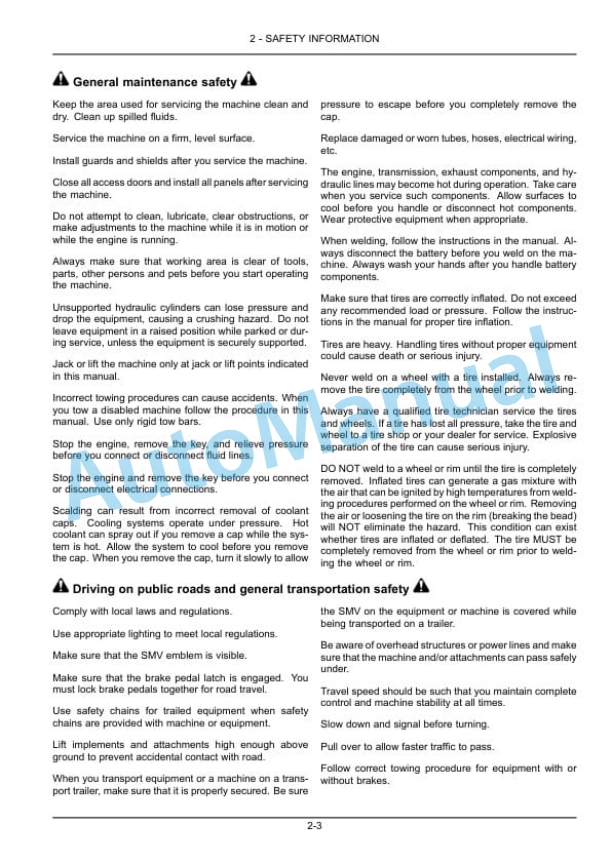

- 7.7.5. Brake oil (If applicable)

- 7.7.6. Fuel tanks Cleaning

- 7.8. GENERAL MAINTENANCE

- 7.8.1. Bleeding the fuel injection system

- 7.8.2. Engine idle speed

- 7.8.3. Headlight Check

- 7.8.4. Work lamps

- 7.8.5. Position Lights

- 7.8.6. Canopy lights Adjust

- 7.8.7. Fuse replacement

- 7.8.8. Battery Welding PROTECTING THE ELECTRONIC AND ELECTRICAL SYSTEMS DURING BATTERY CHARGING OR WELDING

- 7.8.9. Dust screen

- 7.9. Storage

- 7.9.1. Tractor storage

- 8. TROUBLESHOOTING

- 8.1. Fault code resolution

- 8.1.1. Maintenance Troubleshooting

- 9. SPECIFICATIONS

- 9.1. General dimensions

- 9.2. Engine

- 9.3. Cooling System

- 9.4. Clutch System

- 9.5. Power TakeOff (PTO)

- 9.6. Threepoint linkage

- 9.7. Hydraulic System

- 9.8. Electrical System

- 9.9. Steering

- 9.10. Brakes

- 9.11. Transmission Speeds

- 9.12. Lubricants and coolants

New Holland Operator Manual PDF

New Holland 105LC For Boomer 25 Compact Front Loader Operation and Maintenance Manual 51562809

New Holland Operator Manual PDF

New Holland 230TL Loader Operation and Maintenance Manual 87541767

New Holland Operator Manual PDF

New Holland 200LC Loader Operation and Maintenance Manual 51421058

New Holland Operator Manual PDF

New Holland 250TL For Boomer 8N Tractor Operation and Maintenance Manual 84207117

New Holland Operator Manual PDF

New Holland 1530, 1630, 1725, 1925 Feature Product Manual 86560392

New Holland Operator Manual PDF

New Holland 2330BF Adapter Frame Operation and Maintenance Manual 87716208

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338

New Holland Operator Manual PDF

New Holland 25S Workmaster Tier 4B Final Compact Tractor Operation and Maintenance Manual 51409930

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Compact Tractor Operation and Maintenance Manual 47708986