New Holland TT55F, TT65F, TT75F, TT55, TT65, TT75 Tractor Operation and Maintenance Manual 48140374

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 48140374

- Format: PDF

- Size: 20.4MB

- Number of Pages: 214

- Serial Number:

48140374

-

Model List:

- TT55F Tractor

- TT65F Tractor

- TT75F Tractor

- TT55 Tractor

- TT65 Tractor

- TT75 Tractor

- 1. GENERAL INFORMATION

- 1.1. NOTE TO THE OWNER

- 1.2. Engine identification

- 1.3. Nameplate

- 1.4. Ecology and environment

- 1.5. Runin period of a new machine

- 1.6. Universal Symbols

- 1.7. Noise levels

- 2. SAFETY INFORMATION

- 2.1. Safety rules

- 2.2. Roll over protective struture (ROPS)

- 2.3. Operation on a slope

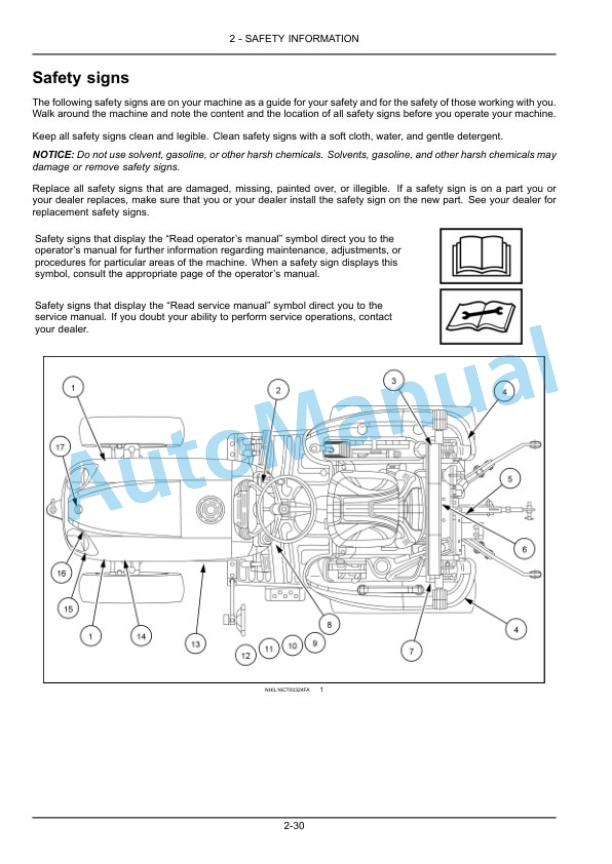

- 2.4. Safety decals Standard version

- 2.5. Safety decals Narrow Version

- 2.6. Before operating the tractor

- 2.7. Driving the vehicle

- 2.8. Machine operation

- 2.9. Power TakeOff (PTO) operation

- 2.10. Maintenance

- 2.11. Diesel fuel

- 2.12. Fire or Explosion Prevention

- 2.13. Intended use statement

- 3. CONTROLS AND INSTRUMENTS

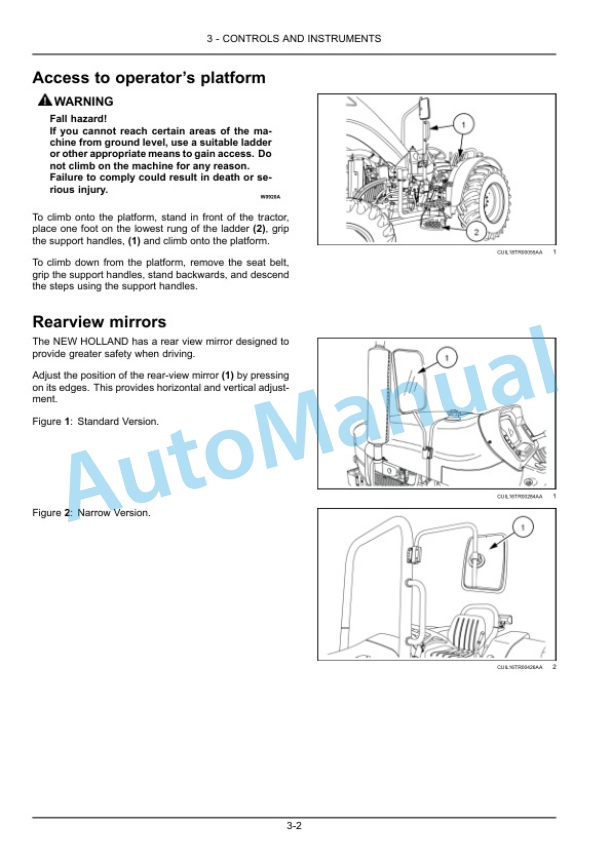

- 3.1. Access to operators platform

- 3.1.1. General check

- 3.1.2. Access to operators platform

- 3.1.3. Rearview mirrors

- 3.1.4. Overview Header Standard version

- 3.1.5. Overview Header Narrow Version

- 3.2. Operators seat

- 3.2.1. Operators seat

- 3.2.2. Shoulder belt

- 3.3. Forward controls

- 3.3.1. Ignition key

- 3.3.2. Work lamps

- 3.3.3. Hazard warning light switch

- 3.3.4. Horn switch

- 3.3.5. Clutch pedal

- 3.3.6. Brake pedals

- 3.3.7. Hand throttle

- 3.3.8. Controls valve

- 3.4. Lefthand side controls

- 3.4.1. Lefthand side controls

- 3.5. Righthand side controls

- 3.5.1. Parking brake

- 3.5.2. Hydraulic controls

- 3.6. Rearward controls

- 3.6.1. Hydraulic controls Narrow Version

- 3.7. Instrument cluster panel

- 3.7.1. Dashboard

- 3.7.2. Gauges

- 4. OPERATING INSTRUCTIONS

- 4.1. Commissioning the unit

- 4.1.1. General instructions

- 4.1.2. Filling the fuel tank

- 4.2. Starting the unit

- 4.2.1. Starting the engine

- 4.2.2. Booster battery procedure

- 4.3. Stopping the unit

- 4.3.1. Stopping the engine

- 4.4. Moving the unit

- 4.4.1. Driving the vehicle

- 5. TRANSPORT OPERATIONS

- 5.1. Preparing for road transport

- 5.1.1. Machine loading

- 5.2. Recovery transport

- 5.2.1. Machine towing

- 6. WORKING OPERATIONS

- 6.1. General information

- 6.1.1. Traction front wheel drive (FWD)

- 6.1.2. Differential lock

- 6.2. TRANSMISSION

- 6.2.1. Operation 8×2 Transmission

- 6.2.2. Travel speeds 8×2 Transmission

- 6.2.3. Operation 12×3 transmission with creeper (when equipped)

- 6.2.4. Decal information speeds

- 6.2.5. Foot throttle pedal

- 6.3. REAR POWER TAKEOFF

- 6.3.1. Safety rules Power TakeOff (PTO)

- 6.3.2. Power TakeOff (PTO) Operating Standard version

- 6.3.3. Power TakeOff (PTO) Operate Narrow Version

- 6.3.4. Operating speeds of the Power TakeOff (PTO)

- 6.4. REAR HITCH

- 6.4.1. Hydraulic system

- 6.4.2. Operation of the hydraulic system

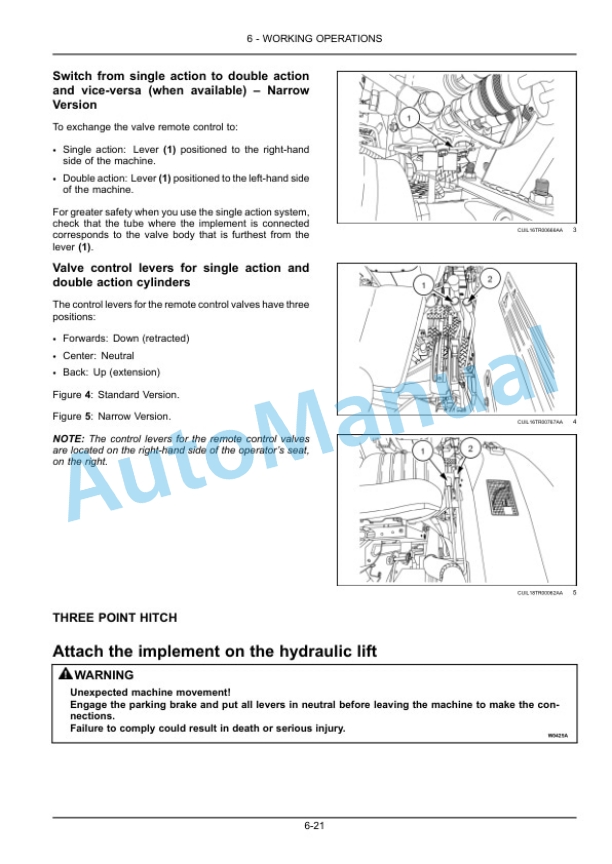

- 6.5. HYDRAULIC REMOTE CONTROL VALVES

- 6.5.1. Operation with remote valves

- 6.6. THREE POINT HITCH

- 6.6.1. Attach the implement on the hydraulic lift

- 6.6.2. Setups of the threepoint hydraulic lift

- 6.7. DRAWBARS AND TOWING ATTACHMENTS

- 6.7.1. General information

- 6.7.2. Safety chain

- 6.7.3. Attaching a trailer

- 6.7.4. Tractor drawbar

- 6.8. Tractor ballasting

- 6.8.1. Tire care Wheels

- 6.8.2. Tires Calibration and assembly safety

- 6.8.3. Tires Parts of the tire

- 6.8.4. Tire types For the application

- 6.8.5. Tires General features

- 6.8.6. Front wheels General specification Compatibility table

- 6.8.7. Assembly Tires

- 6.8.8. Tires Recommendations for calibration

- 6.8.9. Tires Calibration

- 6.8.10. Tire pressures and permissible loads

- 6.8.11. Tires Compatibility of front x rear tires

- 6.8.12. Tires Skid rate

- 6.8.13. Liquid ballast

- 6.8.14. Liquid ballast Capacity table

- 6.8.15. Rear Ballast solid

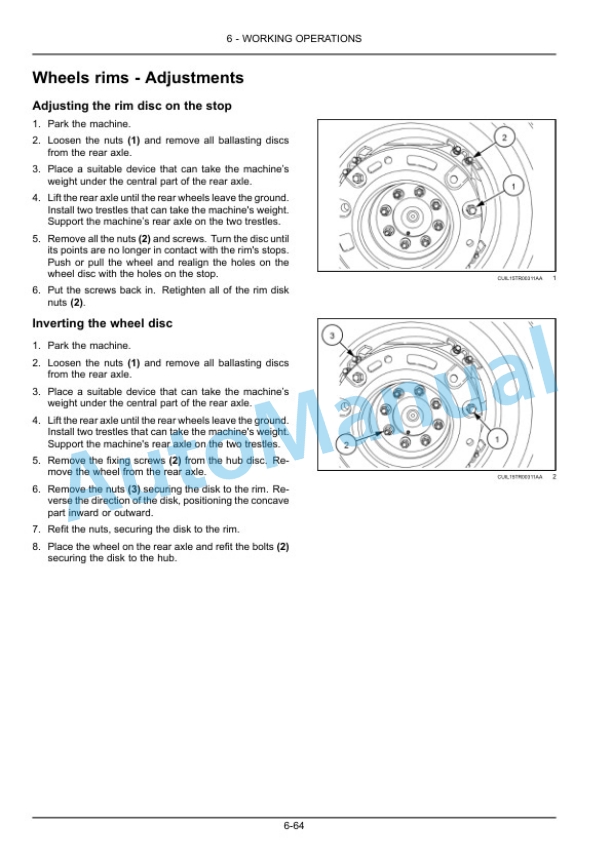

- 6.8.16. Wheels rims Adjustments

- 6.9. MECHANICAL FRONT DRIVE (MFD) AXLES

- 6.9.1. Steering stops

- 6.9.2. Wheels Mounting depth

- 6.9.3. Front wheel track adjustment

- 6.9.4. Powered front axle Alignment

- 6.10. Rear axle

- 6.10.1. Rear wheel track adjustment

- 7. MAINTENANCE

- 7.1. General information

- 7.1.1. Introduction

- 7.1.2. Fuel handling precautions

- 7.1.3. Diesel fuel

- 7.1.4. Specifications Biodiesel fuel

- 7.1.5. Organic Acid Technology (OAT) coolant

- 7.1.6. General instructions from the machine

- 7.1.7. Protective devices

- 7.2. Maintenance planning

- 7.2.1. Maintenance chart

- 7.3. WHEN THE WARNING LAMP LIGHTS

- 7.3.1. Air filter

- 7.4. EVERY 10 HOURS OR EACH DAY

- 7.4.1. Engine oil level

- 7.4.2. Engine coolant concentration level

- 7.4.3. Fuel prefilter/water separator

- 7.4.4. Fuel filter Standard version

- 7.4.5. Fuel filter Narrow Version

- 7.4.6. Battery

- 7.4.7. Cleaning the radiators

- 7.4.8. Wheel nuts torque

- 7.4.9. Lubrication points Standard version

- 7.4.10. Lubrication points Narrow Version

- 7.5. EVERY 300 HOURS

- 7.5.1. Fuel filter Standard version

- 7.5.2. Fuel filter Narrow Version

- 7.5.3. Fuel transfer pump

- 7.5.4. Fuel injection system Cleaning

- 7.5.5. Engine oil

- 7.5.6. Engine drive belts

- 7.5.7. Engine crankcase breather filter

- 7.5.8. Hydraulic system oil level Standard version

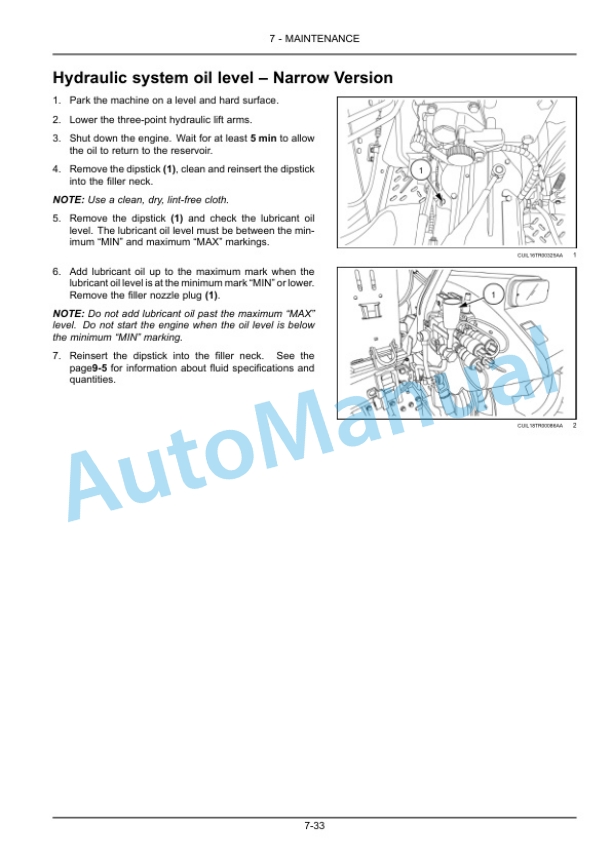

- 7.5.9. Hydraulic system oil level Narrow Version

- 7.5.10. Transmission oilfilter

- 7.5.11. Front axle oil Standard version

- 7.5.12. Front axle oil Narrow Version

- 7.6. EVERY 600 HOURS

- 7.6.1. Wheel hub oil Standard version

- 7.6.2. Wheel hub oil Narrow Version

- 7.6.3. Wheel nuts torque

- 7.7. EVERY 1200 HOURS OR ANNUALLY

- 7.7.1. Transmission oil

- 7.7.2. Front axle oil Standard version

- 7.7.3. Front axle oil Narrow Version

- 7.7.4. Fuel tank

- 7.7.5. Engine valves lash check adjust

- 7.7.6. Engine air filters

- 7.7.7. Front axle drive Shaft Check

- 7.8. Every 4000 hours or every 4 years

- 7.8.1. Engine coolant

- 7.9. GENERAL MAINTENANCE

- 7.9.1. Air filter dust unloading valve

- 7.9.2. Bleeding the fuel injection system Standard version

- 7.9.3. Bleeding the fuel injection system Narrow Version

- 7.9.4. Battery

- 7.9.5. Engine drive belt

- 7.9.6. Fuses and relays

- 7.9.7. Headlights

- 7.9.8. Work lights

- 7.9.9. Protecting the electronic and electrical systems during battery charging or welding

- 7.10. Storage

- 7.10.1. Storing the machine

- 7.10.2. Preparation for use after storage

- 8. TROUBLESHOOTING

- 8.1. Symptom(s)

- 8.1.1. Motor

- 8.1.2. Hydraulic systems

- 8.1.3. Threepoint hitch

- 8.1.4. Electrical

- 9. SPECIFICATIONS

- 9.1. Overall dimensions Standard version

- 9.2. Overall dimensions Narrow Version

- 9.3. Fluids and lubricants

- 9.4. Motor Standard version

- 9.5. Drive Standard version

- 9.6. Hydraulic system Standard version

- 9.7. Brakes Standard version

- 9.8. Electrical Standard version

- 9.9. Motor Narrow Version

- 9.10. Drive Narrow Version

- 9.11. Hydraulic System Narrow Version

- 9.12. Brakes Narrow Version

- 9.13. Electrical Narrow Version

New Holland Operator Manual PDF

New Holland 100LC Loader Operation and Maintenance Manual 51410108

New Holland Operator Manual PDF

New Holland 160GMS Mower Deck Operation and Maintenance Manual 51410112

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Compact Tractor Operation and Maintenance Manual 47708986

New Holland Operator Manual PDF

New Holland 2300BF With PTO Pump Operation and Maintenance Manual 86574145

New Holland Operator Manual PDF

New Holland 18LA Loader Operation and Maintenance Manual 87571257

New Holland Operator Manual PDF

New Holland 20, 25 Boomer Stage IIIA Compact Tractor Operation and Maintenance Manual 48116702

New Holland Operator Manual PDF

New Holland 140TL Loader Operation and Maintenance Manual 48070328

New Holland Operator Manual PDF

New Holland 250TLA Farm Loader Operation and Maintenance Manual 48077338

New Holland Operator Manual PDF

New Holland 2300BF With Auxiliary Hydraulic Operation and Maintenance Manual 86574146

New Holland Operator Manual PDF

New Holland 26 Rotary Tiller Attachment Operation Manual and Part List 42002611