Komatsu 107E-5 Series Engine Shop Manual SEN06896-02

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06896-02

- Format: PDF

- Size: 15.6MB

- Number of Pages: 340

Category: Komatsu Shop Manual PDF

-

Model List:

- 107E-5 Series Engine

- 1. COVER

- 2. INDEX AND FOREWORD

- 2.1. INDEX

- 2.2. FOREWORD, SAFETY, BASIC INFORMATION

- 2.2.1. HOW TO READ THE ENGINE SHOP MANUAL

- 2.2.2. SAFETY NOTICE FOR OPERATION

- 2.2.3. PRECAUTIONS TO PREVENT FIRE

- 2.2.4. ACTIONS IF FIRE OCCURS

- 2.2.5. PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS

- 2.2.6. ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION

- 2.2.7. PRECAUTIONS FOR DEF

- 2.2.8. STORE AdBlue/DEF

- 2.2.9. PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

- 2.2.10. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS

- 2.2.11. PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

- 2.2.12. PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT

- 2.2.13. PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT

- 2.2.14. DISCONNECT AND CONNECT PUSHPULL TYPE COUPLER

- 2.2.15. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS

- 2.2.16. METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR

- 2.2.17. METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR

- 2.2.18. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL

- 2.2.19. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH

- 2.2.20. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

- 2.2.21. HOW TO READ ELECTRICAL WIRE CODE

- 2.2.22. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 2.2.23. STANDARD TIGHTENING TORQUE TABLE

- 2.2.24. CONVERSION TABLE

- 2.2.25. ABBREVIATION LIST

- 3. SPECIFICATIONS

- 3.1. CONTENTS

- 3.2. SPECIFICATIONS

- 3.2.1. OUTLINE OF EXHAUST GAS REGULATION

- 3.2.2. LIST OF APPLICABLE MACHINES 107E5

- 3.2.3. SPECIFICATIONS

- 3.2.4. ENGINE GENERAL VIEW

- 3.2.5. ENGINE PERFORMANCE CURVE

- 4. STRUCTURE AND FUNCTION

- 4.1. CONTENTS

- 4.2. UREA SCR SYSTEM

- 4.2.1. LAYOUT DRAWING OF UREA SCR SYSTEM

- 4.2.2. UREA SCR SYSTEM DIAGRAM

- 4.2.3. FUNCTION OF UREA SCR SYSTEM

- 4.2.4. COMPONENT PARTS OF UREA SCR SYSTEM

- 4.3. ENGINE SYSTEM

- 4.3.1. LAYOUT OF ENGINE COMPONENTS

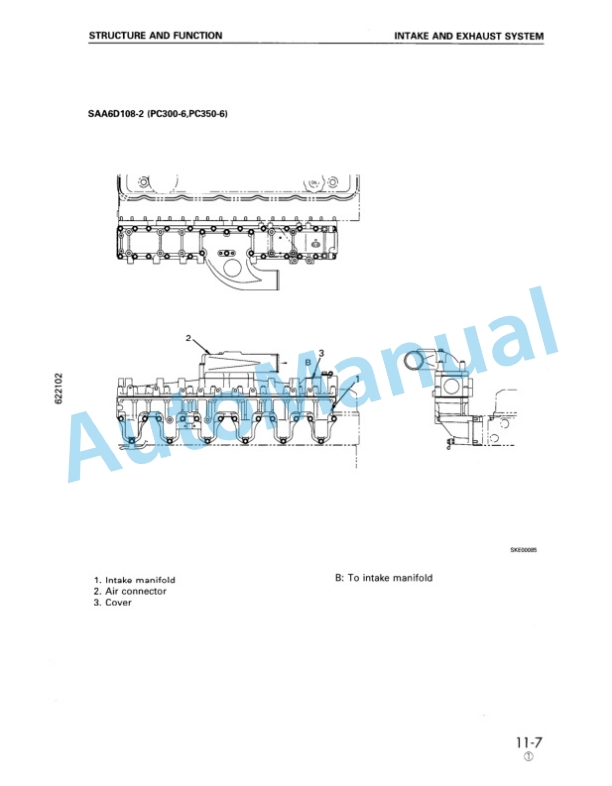

- 4.3.2. INTAKE AND EXHAUST SYSTEM PARTS

- 4.3.3. ENGINE MAIN BODY PARTS

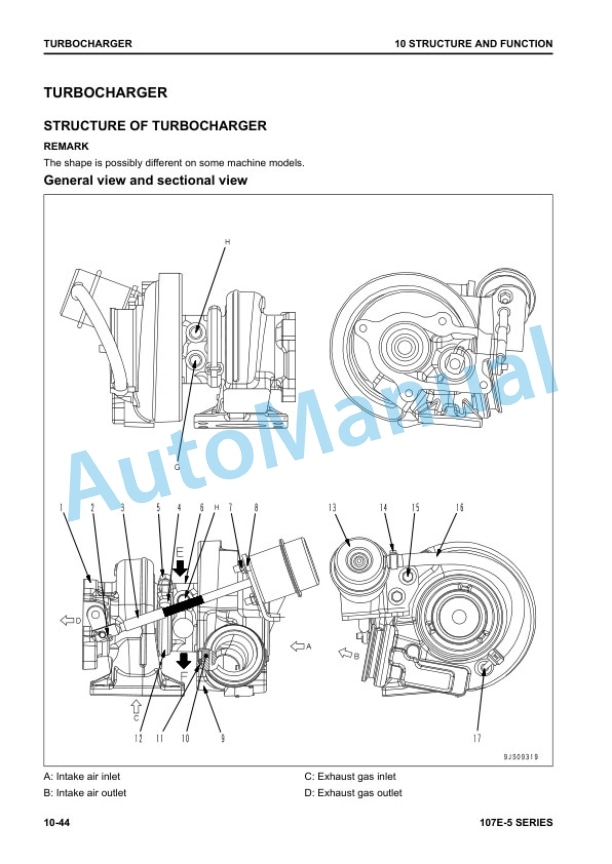

- 4.3.4. TURBOCHARGER

- 4.3.5. CRANKCASE VENTILATION SYSTEM

- 4.3.6. IMPACTOR (FILTERLESS)

- 4.3.7. EXHAUST THROTTLE VALVE

- 4.3.8. KDPF

- 4.3.9. LUBRICATION SYSTEM

- 4.3.10. FUEL SYSTEM

- 4.3.11. COOLING SYSTEM

- 4.4. ELECTRICAL SYSTEM

- 4.4.1. COMPONENT PARTS OF ELECTRICAL SYSTEM

- 4.4.2. SENSOR

- 5. STANDARD VALUE TABLE

- 5.1. CONTENTS

- 5.2. STANDARD VALUE TABLE FOR ENGINE

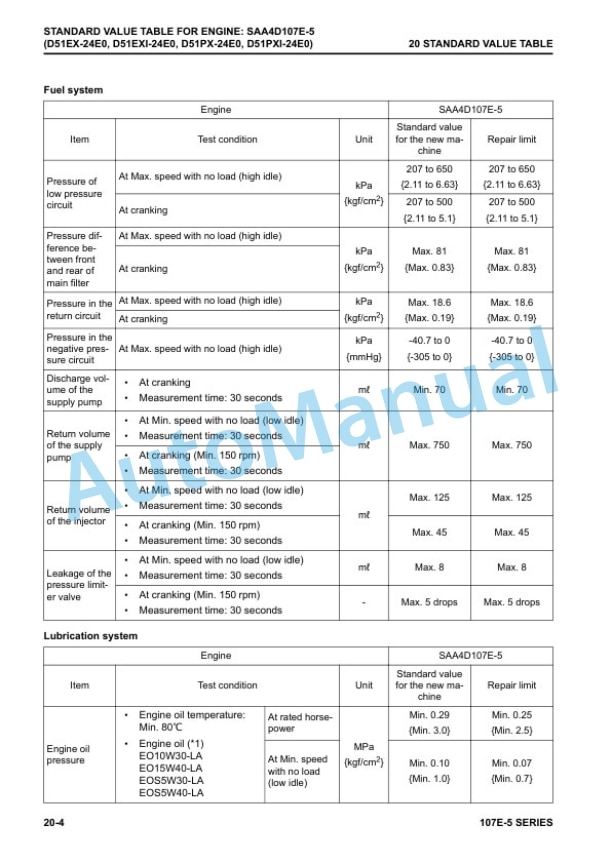

- 5.2.1. STANDARD VALUE TABLE FOR ENGINE SAA4D107E5 (D51EX24E0, D51EXI24E0, D51PX24E0, D51PXI24E0)

- 5.2.2. STANDARD VALUE TABLE FOR ENGINE SAA4D107E5 (WA2008E0)

- 5.3. RUNNINGIN STANDARD AND PERFORMANCE TEST STANDARD

- 5.3.1. PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD SAA4D107E5 (D51EX24E0, D51EXI24E0, D51PX24E0, D51PXI24E0)

- 5.3.2. PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD SAA4D107E5 (WA2008E0)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. CONTENTS

- 6.2. RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY

- 6.2.1. HOW TO READ THIS MANUAL

- 6.2.2. COATING MATERIALS LIST

- 6.2.3. SPECIAL TOOLS LIST

- 6.2.4. SKETCHES OF SPECIAL TOOLS

- 6.3. ENGINE SYSTEM

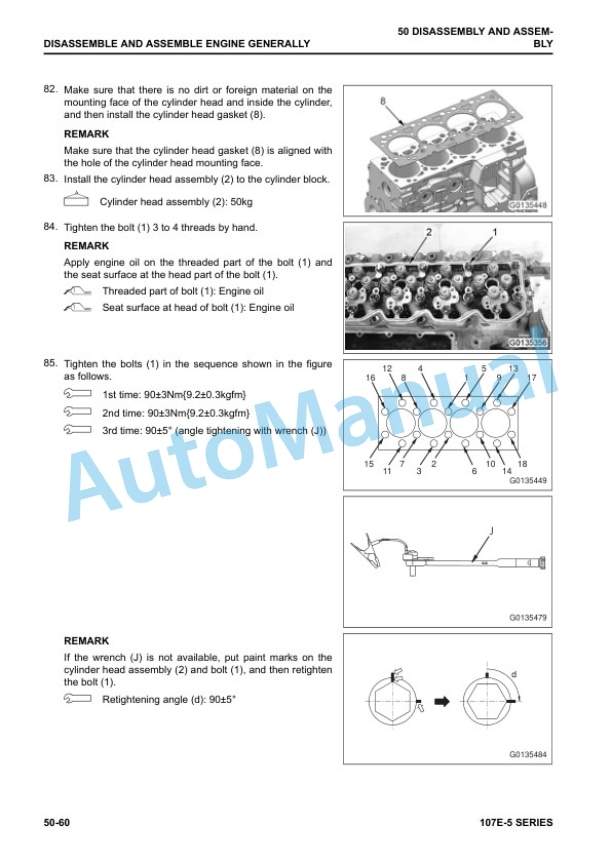

- 6.3.1. DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY

- 6.3.2. REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY

- 6.3.3. REMOVE AND INSTALL ENGINE FRONT OIL SEAL

- 6.3.4. REMOVE AND INSTALL ENGINE REAR OIL SEAL

- 7. MAINTENANCE STANDARD

- 7.1. CONTENTS

- 7.2. ENGINE SYSTEM

- 7.2.1. INTAKE AND EXHAUST SYSTEM PARTS

- 7.2.2. ENGINE MAIN BODY PARTS

- 7.2.3. LUBRICATION SYSTEM

- 8. INDEX

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00