Komatsu 114E-3 Series Engine Shop Manual SEN00169-18

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN00169-18

- Format: PDF

- Size: 36.3MB

- Number of Pages: 490

Category: Komatsu Shop Manual PDF

-

Model List:

- 114E-3 Series Engine

- 1. Cover

- 2. Index and foreword

- 2.1. Index

- 2.1.1. Composition of shop manual

- 2.1.2. Table of contents

- 2.2. Foreword and general information

- 2.2.1. Safety notice

- 2.2.2. How to read the shop manual

- 2.2.3. Explanation of terms for maintenance standard

- 2.2.4. Handling of electric equipment and hydraulic component

- 2.2.5. Handling of connectors newly used for engines

- 2.2.6. How to read electric wire code

- 2.2.7. Precautions when carrying out operation

- 2.2.8. Method of disassembling and connecting pushpull type coupler

- 2.2.9. Standard tightening torque table

- 2.2.10. Conversion table

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. General

- 3.1.2. pecifications

- 3.1.3. General view

- 3.1.4. Dimensions table

- 3.1.5. Engine performance curves

- 4. Structure, function and maintenance standard

- 4.1. Structure, function and maintenance standard

- 4.1.1. Intake, exhaust system

- 4.1.2. Lubricating oil system

- 4.1.3. Cooling system

- 4.1.4. Fuel system (common rail)

- 4.1.5. Maintenance standard

- 5. Standard value table

- 5.1. Standard service value table

- 5.1.1. Standard value table for testing, adjusting and troubleshooting

- 5.1.2. Runin standard and performance test criteria

- 6. Testing and adjusting

- 6.1. Testing and adjusting

- 6.1.1. Testing and adjusting tools list

- 6.1.2. Sketches of special tools

- 6.1.3. Testing air boost pressure

- 6.1.4. Adjusting valve clearance

- 6.1.5. Testing compression pressure

- 6.1.6. Testing blowby pressure

- 6.1.7. Testing oil pressure

- 6.1.8. Handling fuel system parts

- 6.1.9. Releasing residual pressure in fuel system

- 6.1.10. Testing fuel pressure

- 6.1.11. Reduced cylinder mode operation

- 6.1.12. Noinjection cranking

- 6.1.13. Testing leakage from pressure limiter and return rate from injector

- 6.1.14. Bleeding air from fuel circuit

- 6.1.15. Testing fuel system for leakage

- 6.1.16. Handling controller highvoltage circuit

- 6.1.17. Replacing alternator belt

- 7. Troubleshooting

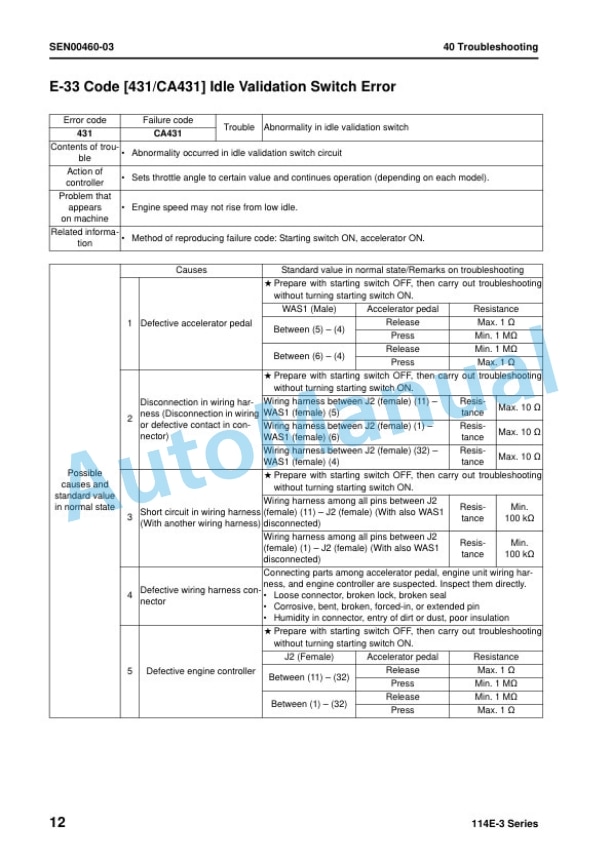

- 7.1. General Information on troubleshooting

- 7.1.1. Points on troubleshooting

- 7.1.2. Error and failure code table

- 7.1.3. Information in troubleshooting table

- 7.1.4. Connection table for connector pin numbers

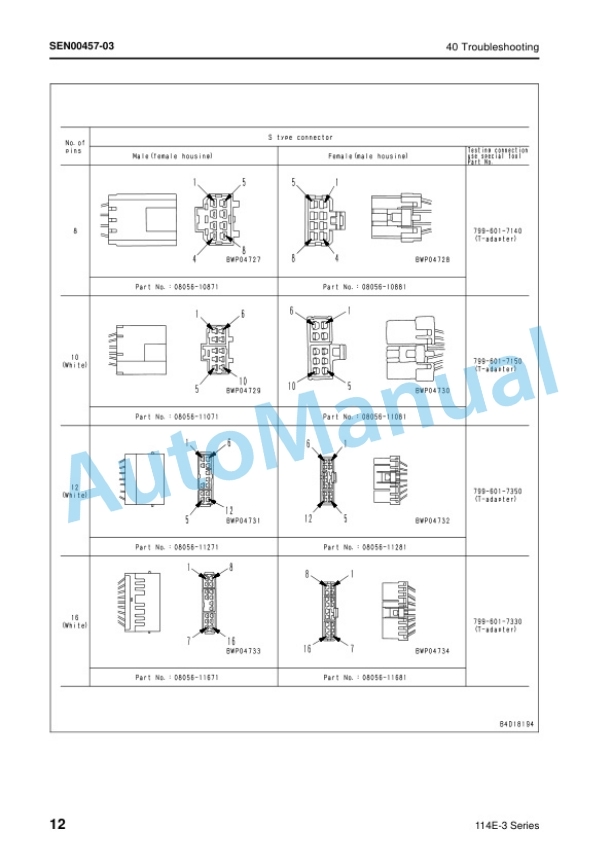

- 7.1.5. T branch box and T branch adapter table

- 7.2. Troubleshooting of electrical system (Emode), Part 1

- 7.2.1. Troubleshooting of electrical system (Emode), Part 1

- 7.3. Troubleshooting of electrical system (Emode), Part 2

- 7.3.1. Troubleshooting of electrical system (Emode), Part 2

- 7.4. Troubleshooting of mechanical system (Smode)

- 7.4.1. Troubleshooting of mechanical system (Smode)

- 8. Disassembly and assembly

- 8.1. General information on disassembly and assembly

- 8.1.1. How to read this manual

- 8.1.2. Coating materials list

- 8.1.3. Special tool list

- 8.2. Disassembly and assembly, Part 1

- 8.2.1. Disassembly and assembly

- 8.3. Disassembly and assembly, Part 2

- 8.3.1. Disassembly and assembly

- 8.4. Disassembly and assembly, Part 3

- 8.4.1. Disassembly and assembly

- 9. Repair and Replacement of parts

- 9.1. Information related repair and replacement

- 9.1.1. Special tool table

- 9.2. Parts related to cylinder head

- 9.2.1. Dimensions of cylinder heads

- 9.2.2. Checking of valves

- 9.2.3. Pressure test

- 9.2.4. Vacuum test of valve seat insert

- 9.2.5. Cleaning and checking of cylinder head bolts

- 9.3. Parts related to cylinder block

- 9.3.1. Replacement of camshaft bushings

- 9.3.2. Cleaning and checking of cylinder liners before reuse

- 9.3.3. Cleaning and checking of pistons before reuse

- 9.3.4. Cleaning and checking of crankshafts before reuse

- 9.3.5. Replacement of crankshaft gears

- 9.3.6. Cleaning and checking of main bearings before reuse

- 9.3.7. Cleaning and checking of main bearing metal caps and mounting bolts before reuse

- 9.3.8. Cleaning and checking of connecting rod bearings before reuse

- 9.3.9. Cleaning and checking of connecting rods before reuse

- 9.3.10. Checking of connecting rods for bending and twisting

- 9.3.11. Replacement of connecting rod bushings

Rate this product

You may also like