Komatsu 125-2 Series Diesel Engine Shop Manual SEBM006411

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM006411

- Format: PDF

- Size: 13.0MB

- Number of Pages: 388

Category: Komatsu Shop Manual PDF

-

Model List:

- 125-2 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGE

- 4. SAFETY

- 4.1. SAFETY NOTICE

- 5. FOREWORD

- 5.1. GENERAL

- 5.2. HOW TO READ THE SHOP MANUAL

- 5.3. HOISTING INSTRUCTIONS

- 5.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 5.5. COATING MATERIALS

- 5.6. STANDARD TIGHTENING TORQUE

- 5.7. ELECTRIC WIRE CODE

- 5.8. CONVERSION TABLE

- 5.9. UNITS

- 6. General

- 6.1. APPLICABLE MACHINE

- 6.2. SPECIFICATIONS

- 6.3. GENERAL ASSEMBLY DRAWING

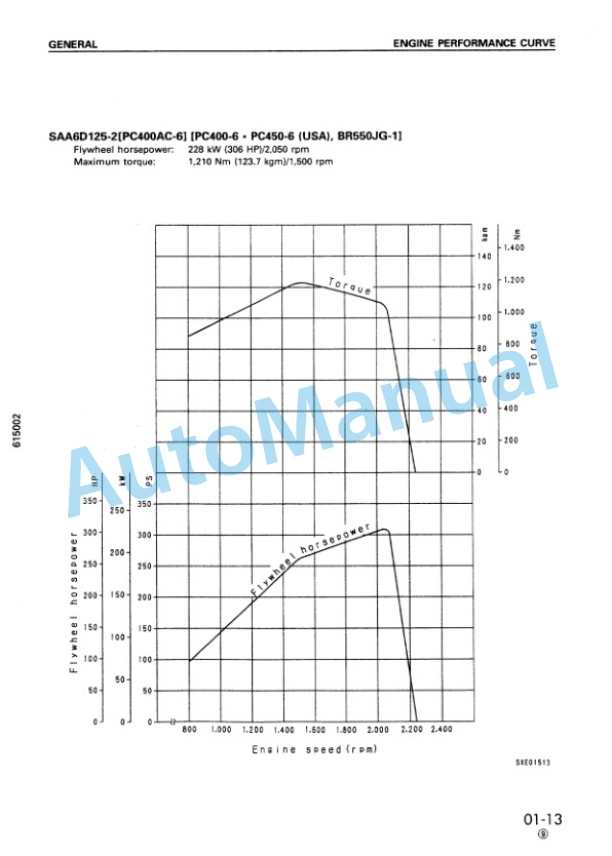

- 6.4. ENGINE PERFORMANCE CURVE

- 6.5. WEIGHT TABLE

- 7. STRUCTURE AND FUNCTION

- 7.1. GENERAL STRUCTURE

- 7.2. INTAKE AND EXHAUST SYSTEM

- 7.2.1. INTAKE AND EXHAUST SYSTEM

- 7.2.2. MAIN CIRCULATION PART

- 7.2.3. TIMING GEAR

- 7.2.4. VALVE SYSTEM

- 7.2.5. FLYWHEEL AND FLYWHEEL HOUSING

- 7.3. LUBRICATION SYSTEM

- 7.3.1. LUBRICATION SYSTEM CHART

- 7.3.2. OIL PUMP

- 7.3.3. REGULATOR VALVE

- 7.3.4. OIL FILTER

- 7.3.5. BYPASS FILTER

- 7.3.6. OIL COOLER

- 7.4. FUEL SYSTEM

- 7.4.1. FUEL SYSTEM CHART

- 7.4.2. FUEL INJECTION PUMP

- 7.4.3. FUEL 2STAGE SET CONTROL MOTOR MOUNT

- 7.4.4. ENGINE STOP MOTOR, 2STAGE SET CONTROL MOTOR

- 7.4.5. MAGNETIC SWITCH AND FUEL SOLENOID

- 7.4.6. BOOST COMPENSATOR

- 7.4.7. FUEL INJECTION NOZZLE

- 7.4.8. FUEL FILTER

- 7.5. COOLING SYSTEM

- 7.5.1. COOLING SYSTEM CHART

- 7.5.2. WATER PUMP

- 7.5.3. THERMOSTAT

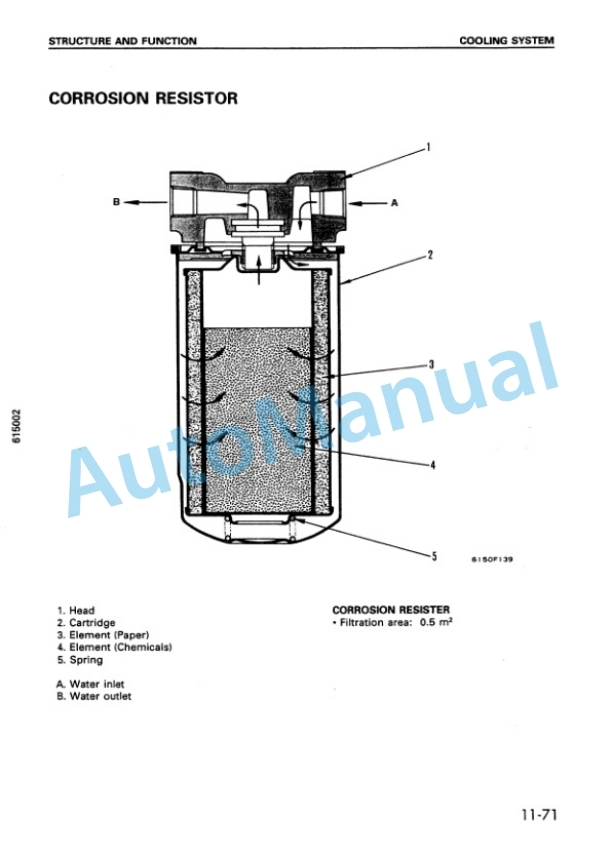

- 7.5.4. CORROSION RESISTOR

- 7.5.5. FAN DRIVE

- 7.6. ELECTRICAL SYSTEM

- 7.6.1. ALTERNATOR

- 7.6.2. STARTING MOTOR

- 7.6.3. ELECTRICAL INTAKE AIR HEATER

- 7.7. ACCESSORY

- 7.7.1. AIR COMPRESSOR

- 8. TESTING AND ADJUSTING

- 8.1. ADJUSTING ENGINE SPEED SENSOR

- 8.2. ENGINE BODY

- 8.2.1. ADJUSTING VALVE CLEARANCE

- 8.2.2. MEASURING COMPRESSION PRESSURE

- 8.3. FUEL SYSTEM

- 8.3.1. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 8.3.2. TESTING AND ADJUSTING FUEL CUT SOLENOID

- 8.3.3. ADJUSTING ENGINE STOP MOTOR LEVER

- 8.3.4. FUEL INJECTION PUMP CALIBRATION DATA

- 8.4. PERFORMANCE TEST

- 8.4.1. RUNIN STANDARD

- 8.4.2. PERFORMANCE TEST CRITERIA

- 8.5. TROUBLESHOOTING

- 8.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 8.5.2. METHOD OF USING TROUBLESHOOTING CHART

- 8.5.3. S1 Starting performance is poor (Starting always takes time)

- 8.5.4. S2 Engine does not start

- 8.5.4.1. Engine does not turn

- 8.5.4.2. Engine turns but no exhaust comes out (Fuel is not being injected)

- 8.5.4.3. Exhaust gas comes out but engine does not start (Fuel is being injected)

- 8.5.5. S3 Engine does not pick up smoothly (Followup is poor)

- 8.5.6. S4 Engine stops during operations

- 8.5.7. S5 Engine does not rotate smoothly (hunting)

- 8.5.8. S6 Engine lacks output (no power)

- 8.5.9. S7 Exhaust smoke is black (incomplete combustion)

- 8.5.10. S8 Oil consumption is excessive (or exhaust smoke is blue)

- 8.5.11. S9 Oil becomes contaminated quickly

- 8.5.12. S10 Fuel consumption is excessive

- 8.5.13. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 8.5.14. S12 Oil pressure caution lamp lights up (drop in oil pressure)

- 8.5.15. S13 Oil level rises

- 8.5.16. S14 Water temperature becomes too high (overheating)

- 8.5.17. S15 Abnormal noise is made

- 8.5.18. S16 Vibration is excessive

- 8.6. TESTING AND ADJUSTING TOOL LIST

- 8.7. TESTING AND ADJUSTING DATA

- 9. DISASSEMBLY AND ASSEMBLY

- 9.1. DISASSEMBLY

- 9.1.1. SPECIAL TOOL LIST

- 9.1.2. Starting motor assembly

- 9.1.3. Engine oil cooler assembly

- 9.1.4. Setting to tool A1 (overhaul stand)

- 9.1.6. Engine mounts

- 9.1.7. Air cleaner, bracket assembly

- 9.1.8. Turbocharger, exhaust manifold assembly

- 9.1.9. Corrosion resistor and piping, wiring

- 9.1.10. Engine oil filter

- 9.1.11. Lubrication valve

- 9.1.12. Fuel filter

- 9.1.13. Fuel injection pipes

- 9.1.14. Aftercooler assembly

- 9.1.15. Fuel injection pump assembly

- 9.1.16. Alternator assembly

- 9.1.17. Thermostat housing, water pump

- 9.1.18. Fan pulley, drive assembly

- 9.1.19. Front support

- 9.1.20. Crankshaft pulley, vibration damper

- 9.1.21. Air vent tube, spill pipe

- 9.1.22. Head covers

- 9.1.23. Nozzle holders

- 9.1.24. Rocker arms

- 9.1.25. Crossheads

- 9.1.26. Push rods

- 9.1.27. Rocker arm housings

- 9.1.28. Cylinder head assemblies

- 9.1.29. Oil pan

- 9.1.30. Flywheel

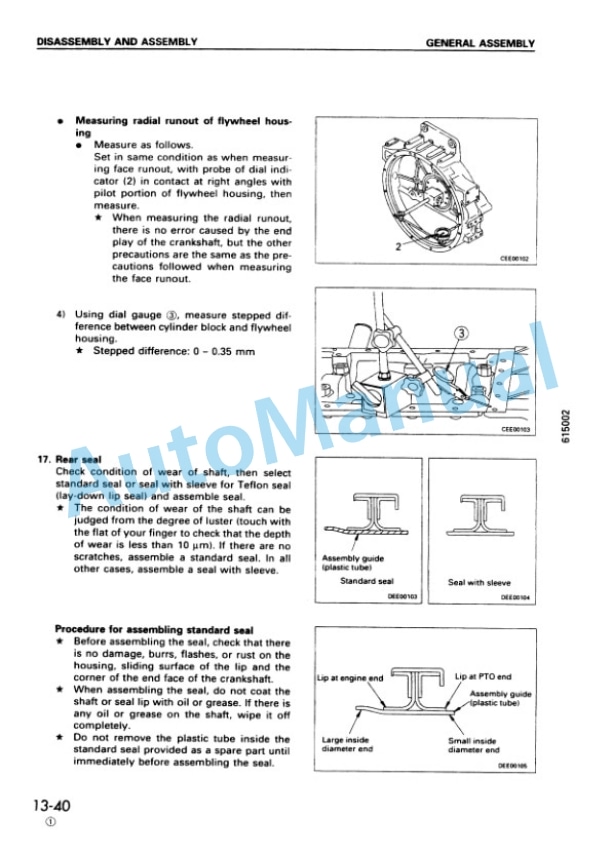

- 9.1.31. Rear seal

- 9.1.32. Flywheel housing

- 9.1.33. Front cover

- 9.1.34. Fuel injection pump drive gear

- 9.1.35. Cam follower covers

- 9.1.36. Cam followers

- 9.1.37. Camshaft

- 9.1.38. Oil pump

- 9.1.39. Idler gear

- 9.1.40. Oil suction pipe

- 9.1.41. Piston and connecting rod assembly

- 9.1.42. Crankshaft

- 9.1.43. Piston cooling nozzle

- 9.1.44. Cylinder liner

- 9.2. ASSEMBLY

- 9.2.1. Cylinder liner

- 9.2.2. Piston cooling nozzle

- 9.2.3. Crankshaft

- 9.2.4. Piston and connecting rod assembly

- 9.2.5. Oil suction pipe

- 9.2.6. Idler gear

- 9.2.7. Oil pump

- 9.2.8. Camshaft

- 9.2.9. Cam followers

- 9.2.10. Cam follower covers

- 9.2.11. Drive gear of fuel injection pump

- 9.2.12. Fuel injection pump assembly

- 9.2.13. Adjusting fuel injection timing

- 9.2.14. Front cover

- 9.2.15. Crankshaft pulley, vibration damper

- 9.2.16. Flywheel housing

- 9.2.17. Rear seal

- 9.2.18. Flywheel

- 9.2.19. Oil pan

- 9.2.20. Cylinder head assemblies

- 9.2.21. Rocker arm housings

- 9.2.22. Push rods

- 9.2.23. Crossheads

- 9.2.24. Rocker arms

- 9.2.25. Adjusting valve clearance

- 9.2.26. Nozzle holders

- 9.2.27. Head covers

- 9.2.28. Spill pipe, air vent tube

- 9.2.29. Pulley, front support

- 9.2.30. Drive sensor, tubes, bracket

- 9.2.31. Water pump, thermostat housing

- 9.2.32. Alternator assembly

- 9.2.33. Adjusting Vbelts

- 9.2.34. Aftercooler assembly

- 9.2.35. Fuel injection pump pipes

- 9.2.36. Lubrication valve

- 9.2.37. Engine oil filter

- 9.2.38. Corrosion resistor

- 9.2.39. Turbocharger, exhaust manifold assembly

- 9.2.40. Air cleaner

- 9.2.41. Engine mounts

- 9.2.43. Resetting engine in engine stand

- 9.2.44. Engine oil cooler assembly

- 9.2.45. Starting motor assembly

- 9.2.46. Filling with oil

- 10. MAINTENANCE STANDARD

- 10.1. INTAKE AND EXHAUST SYSTEM

- 10.1.1. TURBOCHARGER

- 10.2. ENGINE BODY

- 10.2.1. CYLINDER HEAD

- 10.2.2. VALVE AND VALVE GUIDE

- 10.2.3. ROCKER ARM SHAFT

- 10.2.4. CAM FOLLOWER AND PUSH ROD

- 10.2.5. TIMING GEAR

- 10.2.6. PISTON, PISTON RING AND PISTON PIN

- 10.2.7. CONNECTING ROD

- 10.2.8. VIBRATION DAMPER

- 10.2.9. FLYWHEEL AND FLYWHEEL HOUSING

- 10.3. COOLING SYSTEM

- 10.3.1. WATER PUMP AND THERMOSTAT

- 10.3.2. OIL COOLER

- 10.4. LUBRICATION SYSTEM

- 10.4.1. OIL PUMP

- 10.4.2. MAIN RELIEF VALVE

- 10.4.3. REGULATOR VALVE AND SAFETY VALVE

- 10.5. ACCESSORY

- 10.5.1. AIR COMPRESSOR

- 11. REPAIR AND REPLACEMENTOF PARTS

- 11.1. REPLACING VALVE SEAT INSERTS

- 11.2. REPLACING NOZZLE HOLDER SLEEVE

- 11.3. REPLACING VALVE GUIDE

- 11.4. REPLACING CROSS HEAD GUIDE

- 11.5. GRINDING THE VALVE

- 11.6. GRINDING THE FITTING FACE OF CYLINDER HEAD

- 11.7. REPLACING CAM BUSHING

- 11.8. REPLACING CAM GEAR

- 11.9. REPLACING FLYWHEEL RING GEAR

- 11.10. PRESSURE TEST

- 11.11. REPLACING ENGINE REAR SEAL

- 11.12. REPLACING CONNECTING ROD SMALL END BUSHING

- 11.13. REPLACING MAIN BEARING CAP

- 11.14. GRINDING CRANKSHAFT

- 11.15. REPLACING WEAR SLEEVE (When equipped with sleeve)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00