Komatsu 12V170-1 Series Diesel Engine Shop Manual SEBM028506

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM028506

- Format: PDF

- Size: 16.8MB

- Number of Pages: 321

Category: Komatsu Shop Manual PDF

-

Model List:

- 12V170-1 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATIONS

- 3.2. ENGINE PERFORMANCE CURVE

- 3.3. WEIGHT TABLE

- 4. STRUCTURE AND FUNCTION

- 4.1. GENERAL STRUCTURE

- 4.2. INTAKE AND EXHAUST SYSTEM

- 4.2.1. MAIN REVOLVING PART

- 4.2.2. TIMING GEAR

- 4.2.3. FLYWHEEL AND FLYWHEEL HOUSING

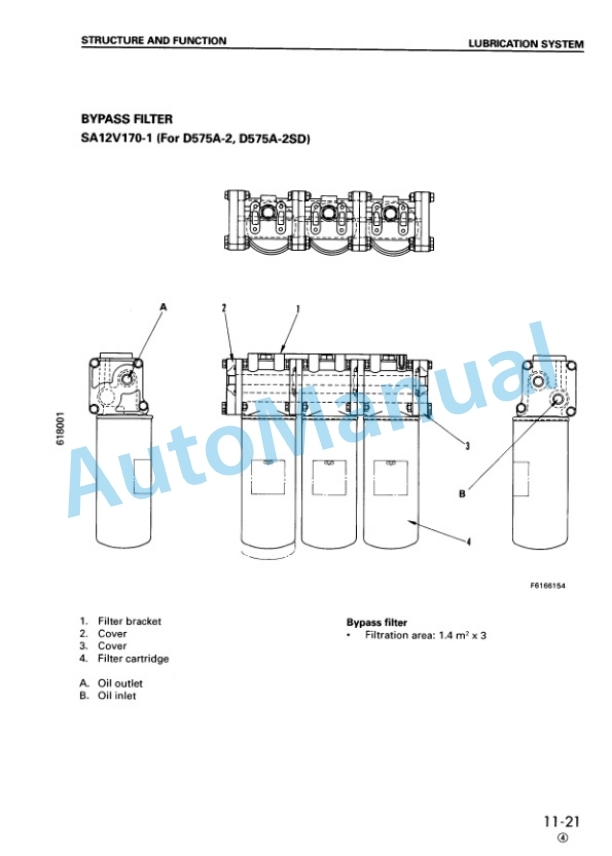

- 4.3. LUBRICATION SYSTEM

- 4.3.1. LUBRICATION SYSTEM CHART

- 4.3.2. OIL PUMP

- 4.3.3. OIL FILTER

- 4.3.4. OIL COOLER

- 4.3.5. OIL COOLER BYPASS VALVE

- 4.3.6. PISTON COOLING VALVE

- 4.3.7. MECHANICAL PUMP

- 4.4. FUEL SYSTEM

- 4.4.1. FUEL SYSTEM CHART

- 4.4.2. FUEL INJECTION PUMP

- 4.4.3. FEED PUMP

- 4.4.4. FUEL INJECTION NOZZLE

- 4.4.5. FUEL INJECTION PUMP DRIVE

- 4.4.6. FUEL FILTER

- 4.4.7. INJECTION PUMP RACK CONTROLLER

- 4.4.8. AUTOMATIC TIMER

- 4.4.9. FUEL SOLENOID

- 4.4.10. ENGINE STOP MOTOR

- 4.5. COOLING SYSTEM

- 4.5.1. COOLING SYSTEM CHART

- 4.5.2. WATER PUMP

- 4.5.3. WATER PUMP DRIVE

- 4.5.4. FAN DRIVE AND TENSION PULLEY

- 4.5.5. CORROSION RESISTOR

- 4.5.6. THERMOSTAT

- 4.6. ACCESSORY

- 4.6.1. AIR COMPRESSOR MOUNTING

- 4.6.2. AIR COMPRESSOR

- 4.6.3. ALTERNATOR WITH REGULATOR

- 4.6.4. STARTING MOTOR

- 4.6.5. AIR STARTING MOTOR

- 5. TESTING AND ADJUSTING

- 5.1. COOLING SYSTEM

- 5.1.1. CHECKING AND ADJUSTING FAN BELT TENSION

- 5.1.2. CHECKING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.2. ENGINE BODY

- 5.2.1. ADJUSTING VALVE CLEARANCE

- 5.2.2. MEASURING COMPRESSION PRESSURE

- 5.2.3. MEASURING BLOWBY

- 5.3. FUEL SYSTEM

- 5.3.1. TESTING AND ADJUSTING OF FUEL INJECTION TIMING

- 5.3.2. ADJUSTING FUEL INJECTION PUMP RACK LINKAGE

- 5.3.3. ADJUSTING ENGINE STOP MOTOR

- 5.3.4. ADJUSTING ENGINE SPEED SENSOR

- 5.3.5. ADJUSTING FUEL INJECTION PRESSURE (VALVE CRACKING PRESSURE)

- 5.3.6. FUEL INJECTION PUMP CALIBRATION DATA

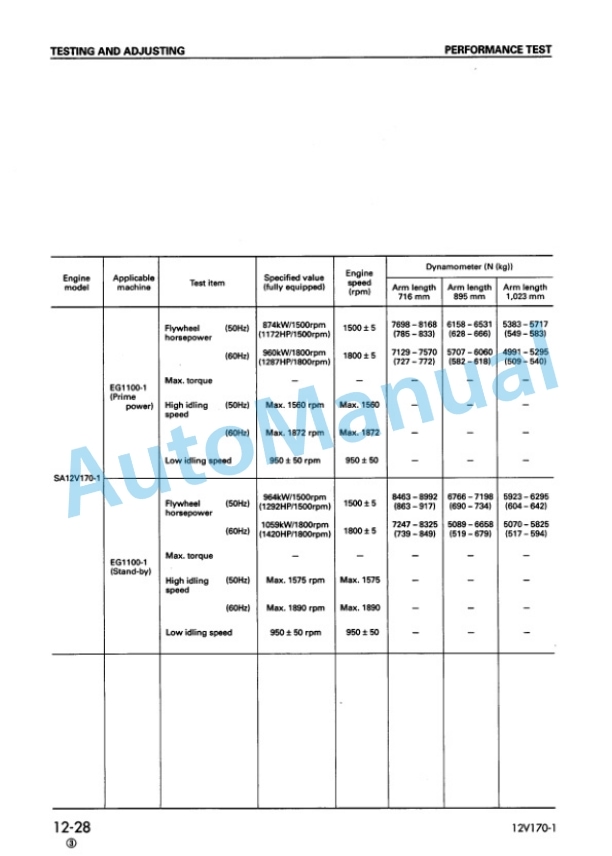

- 5.4. PERFORMANCE TEST

- 5.4.1. RUNIN STANDARD

- 5.4.2. PERFORMANCE TEST CRITERIA

- 5.4.3. TESTING AND ADJUSTING DATA

- 5.4.4. TESTING AND ADJUSTING TOOL LIST

- 5.5. TROUBLESHOOTING

- 5.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.5.2. METHOD OF USING TROUBLESHOOTING CHART

- 5.5.3. S1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME)

- 5.5.4. S2 ENGINE DOES NOT START

- 5.5.4.1. ENGINE DOES NOT TURN

- 5.5.4.2. ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)

- 5.5.4.3. EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)

- 5.5.5. S3 ENGINE DOES NOT PICKUP SMOOTHLY(FOLLOWUP IS POOR)

- 5.5.6. S4 ENGINE STOPS DURING OPERATIONS

- 5.5.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)

- 5.5.8. S6 ENGINE LACKS OUTPUT (NOT POWER)

- 5.5.9. S7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)

- 5.5.10. S8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)

- 5.5.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 5.5.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 5.5.13. S11 OIL IS COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN

- 5.5.14. S12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)

- 5.5.15. S13 OIL LEVEL RISES

- 5.5.16. S14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING)

- 5.5.17. S15 ABNORMAL NOISE IS MADE

- 5.5.18. S16 VIBRATION IS EXCESSIVE

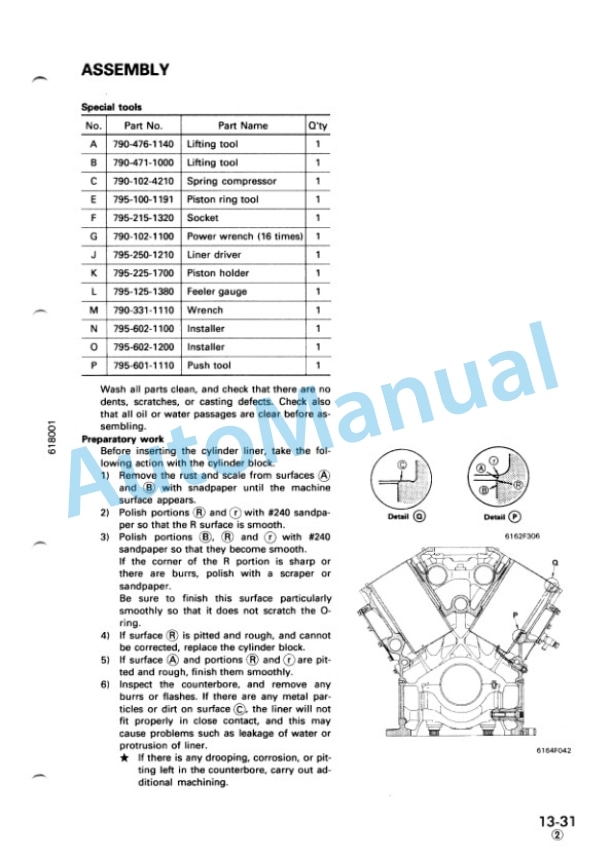

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. GENERAL DISASSEMBLY CONTENTS

- 6.2. DISASSEMBLY

- 6.3. ASSEMBLY

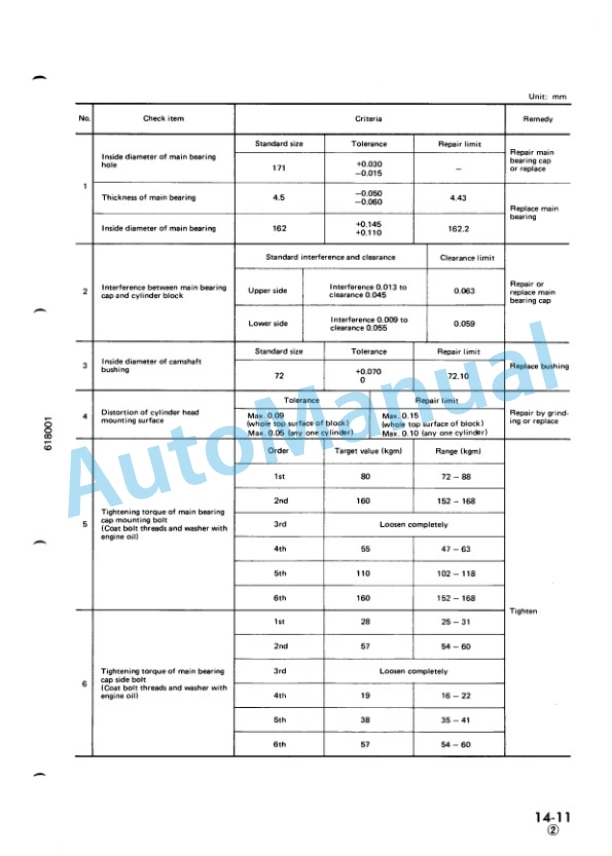

- 7. MAINTENANCE STANDARD

- 7.1. INTAKE AND EXHAUST SYSTEM

- 7.1.1. TURBOCHARGER

- 7.1.2. VALVE AND VALVE GUIDE

- 7.1.3. VALVES AND VALVE GUIDE

- 7.1.4. CROSSHEAD AND CROSSHEAD GUIDE

- 7.1.5. ROCKER ARM SHAFT

- 7.1.6. PUSH ROD AND CAM FOLLOWER

- 7.1.7. FLYWHEEL, FLYWHEEL HOUSING

- 7.2. LUBRICATION SYSTEM

- 7.2.1. OIL PUMP

- 7.2.2. MAIN RELIEF VALVE, POSITION COOLNG VALVE AND OIL COOLER BYPASS VAVLE

- 7.3. COOLING SYSTEM

- 7.3.1. WATER PUMP

- 8. REPAIR AND REPLACEMENT OF PARTS

- 8.1. TABLE OF SPECIAL TOOLS

- 8.2. TESTING AND INSPECTING CYLINDER HEAD

- 8.3. REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

- 8.4. REPLACING VALVE SEAT INSERTS

- 8.5. REPLACING NOZZLE HOLDER SLEEVE

- 8.6. CYLINDER HEAD PRESSURE TEST METHOD

- 8.7. REPLACING VALVE GUIDE

- 8.8. REPLACING CROSS HEAD GUIDE

- 8.9. GRINDING VALVE

- 8.10. TESTING AND INSPECTING CYLINDER BLOCK

- 8.11. GRINDING TOP SURFACE OF CYLINDING BLOCK

- 8.12. REPLACING MAIN BEARING CAP

- 8.13. REPLACING CAM BUSHING

- 8.14. TESTING CRANKSHAFT

- 8.15. CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

- 8.16. GRINDING CRANKSHAFT

- 8.17. TESTING AND INSPECTING CONNECTING ROD

- 8.18. REPLACING CONNECTING ROD SMALL END BUSHING

- 8.19. REPLACING CAMSHAFT GEAR

- 8.20. REPLACING FLYWHEEL RING GEAR

Rate this product

You may also like