Komatsu 140-3 Series Diesel Engine Shop Manual SEBM022213

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM022213

- Format: PDF

- Size: 26.1MB

- Number of Pages: 357

Category: Komatsu Shop Manual PDF

-

Model List:

- 140-3 Series Diesel Engine

- 0.1. OVERALL DRAWING

- 0.2. WEIGHT TABLE

- 0.3. ENGINE PERFORMANCE CURVE

- 1. STRUCTURE AND FUNCTION,MAINTENANCE STANDARD

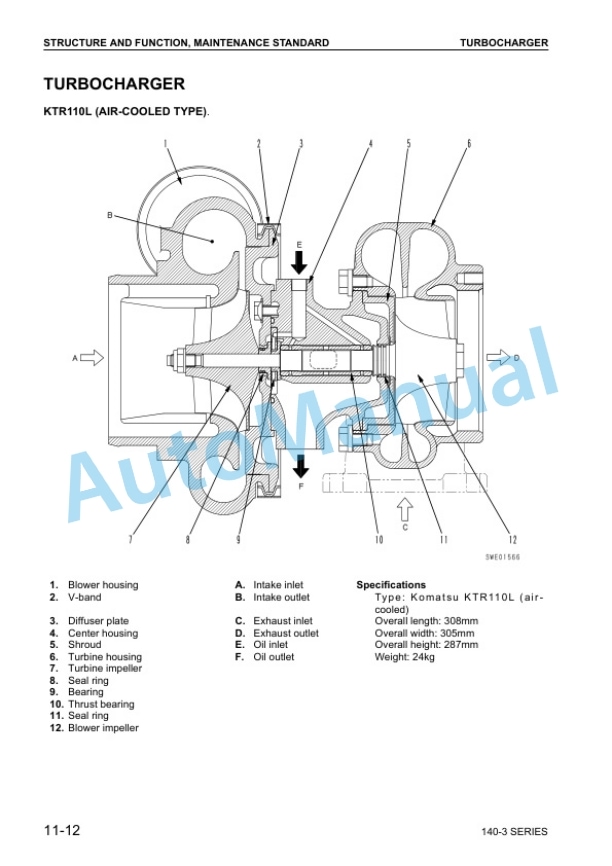

- 1.1. INTAKE,EXHAUST SYSTEM

- 1.1.1. INTAKE,EXHAUST EQUIPMENT

- 1.1.2. MAIN MOVING PARTS

- 1.1.3. CRANKSHAFT

- 1.1.4. CAMSHAFT

- 1.1.5. CAM FOLLOWER AND PUSH ROD

- 1.1.6. PISTONPISTON RINGPISTON PIN

- 1.1.7. CONNECTING ROD

- 1.1.8. FLYWHEEL,FLYWHEEL HOUSING

- 1.1.9. VIBRATION DAMPER

- 1.1.10. TIMING GEAR

- 1.1.11. VALVE SYSTEM

- 1.1.12. VALVE,VALVE GUIDE

- 1.1.13. ROCKER ARM AND SHAFT

- 1.1.14. CROSSHEAD AND GUIDE

- 1.2. LUBRICATION SYSTEM

- 1.2.1. LUBRICATION SYSTEM DIAGRAM

- 1.2.2. OIL PUMP

- 1.2.3. OIL FILTER

- 1.2.4. OIL COOLER

- 1.3. FUEL SYSTEM

- 1.3.1. FUEL SYSTEM DIAGRAM

- 1.3.2. OUTLINE OF CRI SYSTEM

- 1.3.3. FUEL PIPING

- 1.3.4. FUEL COOLER

- 1.3.5. FUEL FILTER

- 1.4. COOLANT SYSTEM

- 1.4.1. COOLING SYSTEM DIAGRAM

- 1.4.2. WATER PUMP

- 1.4.3. THERMOSTAT

- 1.4.4. CORROSION RESISTOR

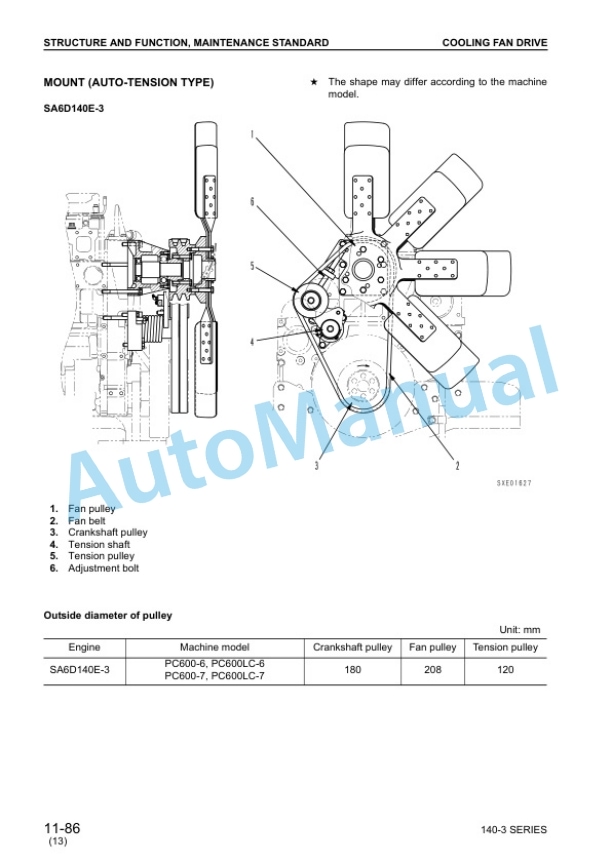

- 1.4.5. COOLING FAN DRIVE

- 1.5. ACCESSORIES

- 1.5.1. FRONT PTO

- 1.5.2. AIR COMPRESSOR

- 1.5.3. EXHAUST BRAKE

- 1.6. ELECTRICAL COMPONENTS

- 1.6.1. ALTERNATOR

- 1.6.2. STARTING MOTOR

- 1.6.3. STARTING AID

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALUE TABLE FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 2.2. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 2.3. TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 2.4. MEASURING INTAKE AIR PRESSURE(BOOST PRESSURE)

- 2.5. MEASURING EXHAUST TEMPERATURE

- 2.6. ADJUSTING VALVE CLEARANCE

- 2.7. MEASURING COMPRESSION PRESSURE

- 2.8. MEASURING BLOWBY PRESSURE

- 2.9. MEASURING OIL PRESSURE

- 2.10. HANDLING EQUIPMENT IN FUEL CIRCUIT

- 2.11. RELEASING REMAINING PRESSURE IN FUEL SYSTEM

- 2.12. MEASURING FUEL PRESSURE

- 2.13. REDUCED CYLINDER MODE OPERATION

- 2.14. BLEEDING AIR FROM FUEL SYSTEM

- 2.15. CHECK FOR LEAKAGE IN FUEL SYSTEM

- 2.16. ADJUSTING SPEED SENSOR

- 2.17. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 2.18. TESTING AND ADJUSTING FAN BELT TENSION

- 2.19. HANDLING CONTROLLER HIGH VOLTAGE CIRCUIT

- 2.20. RUNIN STANDARD

- 2.21. PERFORMANCE TEST STANDARDS

- 2.22. TROUBLESHOOTING OF ENGINE SYSTEM(S MODE)

- 2.22.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.22.2. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.22.3. S1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME)

- 2.22.4. S2 ENGINE DOES NOT START

- 2.22.5. S3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOWUP IS POOR)

- 2.22.6. S4 ENGINE STOPS DURING OPERATIONS

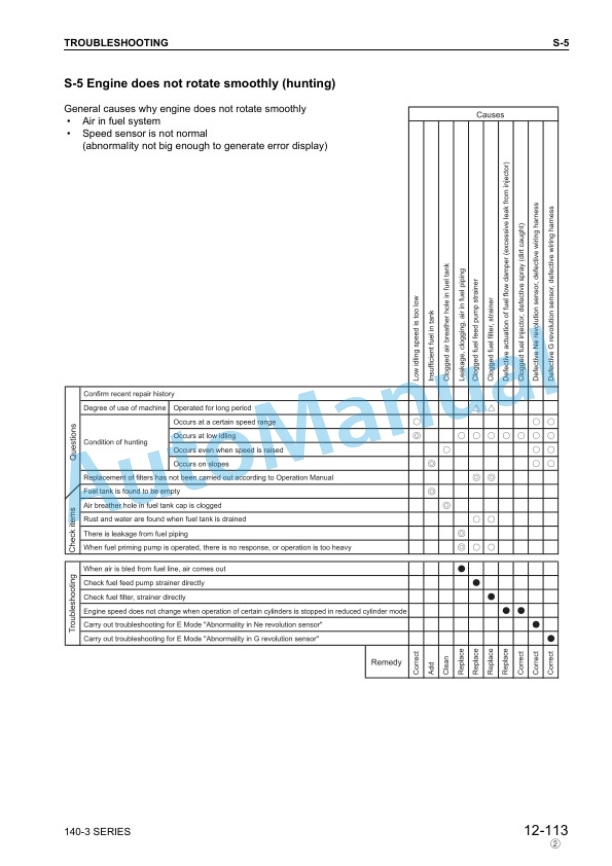

- 2.22.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING)

- 2.22.8. S6 ENGINE LACKS OUTPUT(OR LACKS POWER)

- 2.22.9. S7 EXHAUST SMOKE IS BLACK(INCOMPLETE COMBUSTION)

- 2.22.10. S8 OIL CONSUMPTION IS EXCESSIVE(OR EXHAUST SMOKE IS BLUE)

- 2.22.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 2.22.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 2.22.13. S11 OIL IS IN COOLING WATER(OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN)

- 2.22.14. S12 OIL PRESSURE CAUTION LAMP LIGHTS UP(DROP IN OIL PRESSURE)

- 2.22.15. S13 OIL LEVEL RISES(WATER,FUEL IN OIL)

- 2.22.16. S14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)

- 2.22.17. S15 ABNORMAL NOISE IS MADE

- 2.22.18. S16 VIBRATION IS EXCESSIVE

- 2.23. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 2.23.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.23.2. METHOD OF USING TROUBLESHOOTING FLOWCHART

- 2.23.3. ERROR CODE DISPLAYS AND POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.23.4. ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

- 2.23.5. E1 ERROR CODE E1b ABNORMALITY IN NE REVOLUTION SENSOR SYSTEM

- 2.23.6. E2 ERROR CODE E1C ABNORMALITY IN G REVOLUTION SENSOR SYSTEM

- 2.23.7. E3 ERROR CODE E20 ABNORMALITY IN MODEL SELECTION SYSTEM

- 2.23.8. E4 ERROR CODE E22 OVERRUN

- 2.23.9. E5 ERROR CODE E23 OVERHEAT

- 2.23.10. E6 ERROR CODE E24 DROP IN OIL PRESSURE

- 2.23.11. E7 ERROR CODE E30 ABNORMALITY IN IDLING VALIDATION SIGNAL SYSTEM

- 2.23.12. E8 ERROR CODE E31 ABNORMALITY IN THROTTLE SENSOR SYSTEM

- 2.23.13. E9 ERROR CODE E34 ABNORMALITY IN WATER TEMPERATURE HIGHTEMPERATURE SENSOR SYSTEM

- 2.23.14. E10 ERROR CODE E36 ABNORMALITY IN OIL PRESSURE SWITCH SYSTEM

- 2.23.15. E11 ERROR CODE E3C ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM

- 2.23.16. E12 ERROR CODE E3D ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM

- 2.23.17. E13 ERROR CODE E50 ABNORMALITY IN PREHEATING RELAY CONNECTING POINT SYSTEM

- 2.23.18. E14 ERROR CODE E51 ABNORMALITY IN PREHEAT RELAY COIL SYSTEM

- 2.23.19. E15 ERROR CODE E54 SHORT CIRCUIT IN STARTING SWITCH C SYSTEM

- 2.23.20. E16 ERROR CODE E56 POWER SOURCE SYSTEM ABNORMALITY 1

- 2.23.21. E17 ERROR CODE E57 POWER SOURCE SYSTEM ABNORMALITY 2

- 2.23.22. E18 ERROR CODE E5A ABNORMALITY IN FUEL INJECTION QUANTITY CONTROL SWITCH SIGNAL

- 2.23.23. E19 ERROR CODE E6A ABNORMALITY IN WATER TEMPERATURE LOWTEMPERATURE SENSOR SYSTEM

- 2.23.24. E20 ERROR CODE E70 EXCESS CURRENT IN FUEL SUPPLY PUMP PCV1 SYSTEM

- 2.23.25. E21 ERROR CODE E71 EXCESS CURRENT IN FUEL SUPPLY PUMP PCV2 SYSTEM

- 2.23.26. E22 ERROR CODE E74 DISCONNECTION IN FUEL SUPPLY PUMP PCV1 SYSTEM

- 2.23.27. E23 ERROR CODE E75 DISCONNECTION IN FUEL SUPPLY PUMP PCV2 SYSTEM

- 2.23.28. E24 ERROR CODE E77 ABNORMALITY IN COMMON RAIL FUEL PRESSURE SENSOR SYSTEM

- 2.23.29. E25 ERROR CODE E79 COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 1ERROR CODE E7A COMMON RAIL FUEL HIGH PRESSURE ABNORMALITY 2

- 2.23.30. E26 ERROR CODE E7b FUEL SUPPLY PUMP NONFORCE FEED 1ERROR CODE E7C FUEL SUPPLY PUMP NONFORCE FEED 2

- 2.23.31. E27 ERROR CODE E7d ABNORMALITY IN COMMON RAIL FUEL PRESSURE

- 2.23.32. E28 ERROR CODE E80 DEFECTIVE CONTROLLER

- 2.23.33. E29 ERROR CODE E81 DISCONNECTION IN NO.1 FUEL INJECTOR SYSTEM

- 2.23.34. E30 ERROR CODE E82 DISCONNECTION IN NO.2 FUEL INJECTOR SYSTEM

- 2.23.35. E31 ERROR CODE E83 DISCONNECTION IN NO.3 FUEL INJECTOR SYSTEM

- 2.23.36. E32 ERROR CODE E84 DISCONNECTION IN NO.4 FUEL INJECTOR SYSTEM

- 2.23.37. E33 ERROR CODE E85 DISCONNECTION IN NO.5 FUEL INJECTOR SYSTEM

- 2.23.38. E34 ERROR CODE E86 DISCONNECTION IN NO.6 FUEL INJECTOR SYSTEM

- 2.23.39. E35 ERROR CODE E8A SHORT CIRCUIT IN NO.1,NO.2,NO.3 FUEL INJECTOR SYSTEM

- 2.23.40. E36 ERROR CODE E8b SHORT CIRCUIT IN NO.4,NO.5,NO.6 FUEL INJECTOR SYSTEM

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. GENERAL DISASSEMBLY OF ENGINE

- 3.5. GENERAL ASSEMBLY OF ENGINE

- 3.6. PROCEDURE FOR REMOVING AND INSTALLING FUEL SUPPLY PUMP UNIT

- 4. REPAIR AND REPLACEMENT OF PARTS

- 4.1. CYLINDER HEAD

- 4.1.1. GRINDING OF FITTING FACE OF CYLINDER HEAD

- 4.1.2. REPLACING VALVE SEAT INSERT

- 4.1.3. PRESSURE TEST

- 4.1.4. REPLACING VALVE GUIDE

- 4.1.5. REPLACING CROSSHEAD GUIDE

- 4.1.6. GRINDING VALVE

- 4.2. CYLINDER BLOCK

- 4.2.1. REPLACING CAM BUSHING

- 4.2.2. REPLACING CRANKSHAFT GEAR

- 4.2.3. REPLACING CAM GEAR

- 4.2.4. REPLACING FLYWHEEL RING GEAR

- 4.2.5. REPLACING CONNECTING ROD SMALL END BUSHING

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00