Komatsu 140E-5 Series Engine Shop Manual SEN00074-17

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN00074-17

- Format: PDF

- Size: 54.2MB

- Number of Pages: 764

Category: Komatsu Shop Manual PDF

-

Model List:

- 140E-5 Series Engine

- 1. COVER

- 2. Index and foreword

- 2.1. Index

- 2.1.1. Composition of shop manual

- 2.1.2. Table of contents

- 2.2. Foreword and general information

- 2.2.1. Safety notice

- 2.2.2. How to read the shop manual

- 2.2.3. Explanation of terms for maintenance standard

- 2.2.4. Handling of electric equipment and hydraulic component

- 2.2.5. Handling of connectors newly used for engines

- 2.2.6. How to read electric wire code

- 2.2.7. Precautions when carrying out operation

- 2.2.8. Method of disassembling and connecting pushpull type coupler

- 2.2.9. Standard tightening torque table

- 2.2.10. Conversion table

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. Outline

- 3.1.2. Specifications

- 3.1.3. General view

- 3.1.4. Dimensions table

- 3.1.5. Weight table

- 3.1.6. Engine performance curves

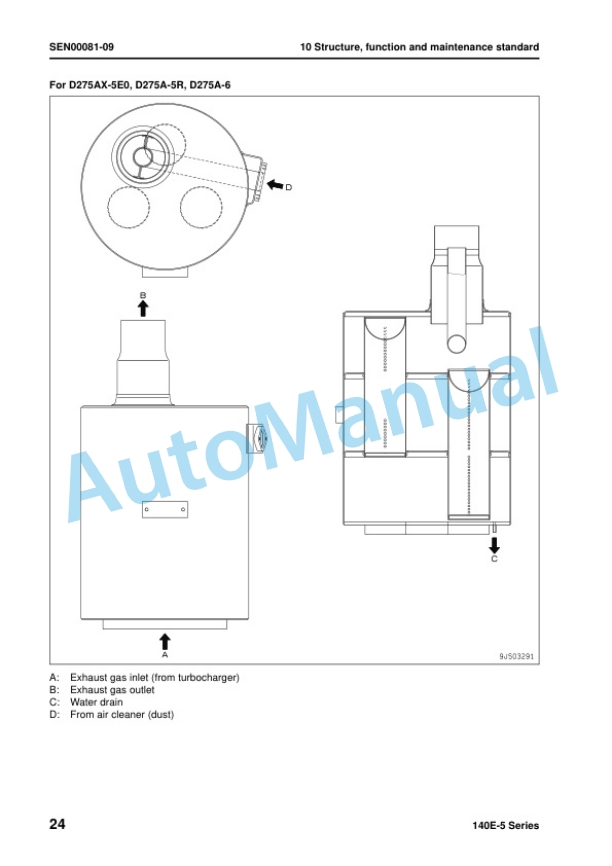

- 4. Structure, function and maintenance standard

- 4.1. Structure, function and maintenance standard, Part 1

- 4.1.1. Air intake and exhaust unit

- 4.1.2. Main moving parts

- 4.1.3. Crankshaft

- 4.1.4. Camshaft

- 4.1.5. Cam follower and push rod

- 4.1.6. Piston, piston ring and piston pin

- 4.1.7. Connecting rod

- 4.1.8. Flywheel and flywheel housing

- 4.1.9. Vibration damper

- 4.1.10. Timing gear

- 4.1.11. Valve system

- 4.1.12. Valve and valve guide

- 4.1.13. Rocker arm and shaft

- 4.1.14. Crosshead and guide

- 4.2. Structure, function and maintenance standard, Part 2

- 4.2.1. Lubrication system diagram

- 4.2.2. Oil pump

- 4.2.3. EGR oil pump

- 4.2.4. Oil filter

- 4.2.5. Oil cooler

- 4.2.6. CRI system diagram

- 4.2.7. Outline of CRI system

- 4.2.8. Structure and operation of CRI system

- 4.2.9. Structure and operation of component parts

- 4.2.10. Fuel piping

- 4.2.11. Fuel cooler

- 4.2.12. Fuel filter

- 4.2.13. Priming pump

- 4.2.14. Electric priming pump

- 4.2.15. Engine controller cooler

- 4.2.16. Cooling system diagram

- 4.2.17. Water pump

- 4.2.18. Water pump mounting

- 4.2.19. Thermostat

- 4.2.20. Corrosion resistor

- 4.2.21. Cooling fan drive

- 4.2.22. Front PTO

- 4.2.23. Alternator

- 4.2.24. Starting motor

- 4.2.25. Starting aid

- 4.2.26. Engine controller

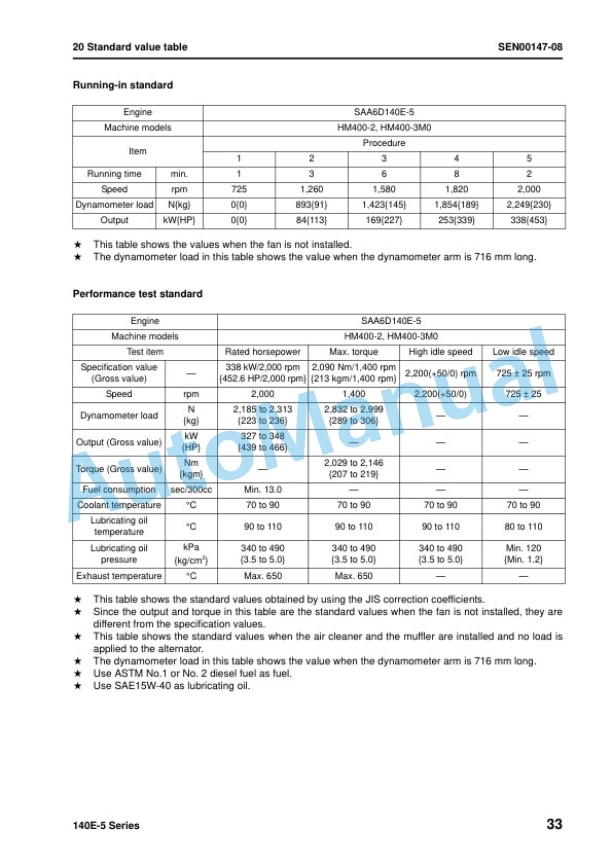

- 5. Standard value table

- 5.1. Standard service value table

- 5.1.1. Standard service value table for testing, adjusting, and troubleshooting

- 5.1.2. Runningin standard and performance test standard

- 6. Testing and adjusting

- 6.1. Testing and adjusting

- 6.1.1. Testing and adjusting (with EGR)

- 6.1.2. Testing and adjusting (EGRless)

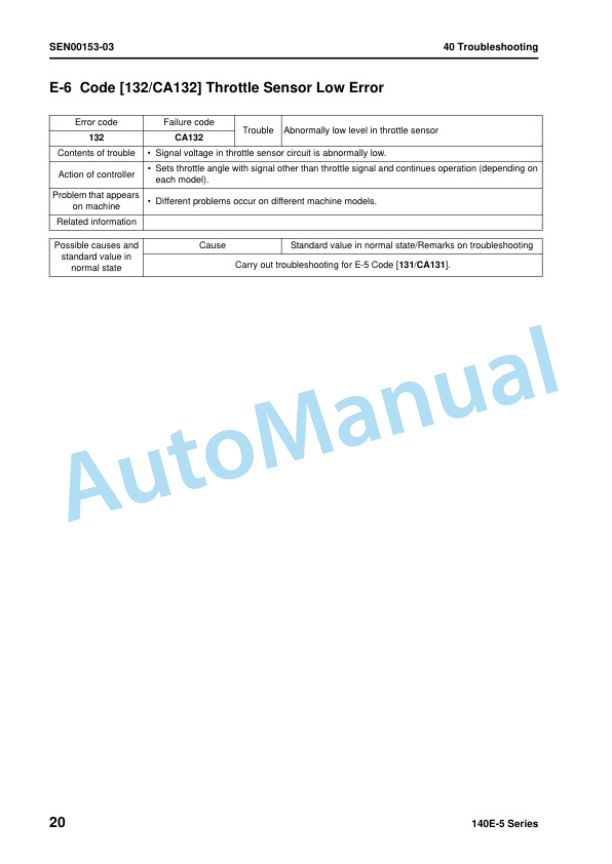

- 7. Troubleshooting

- 7.1. General information on troubleshooting

- 7.1.1. Points to remember when troubleshooting

- 7.1.2. Method of displaying trouble diagnosis lamps (Method of displaying error code)

- 7.1.3. Error codes and failure codes list

- 7.1.4. Information in troubleshooting table

- 7.1.5. Connection table for connector pin numbers

- 7.1.6. T branch box and T branch adapter table

- 7.2. Troubleshooting of mechanical system (Smode)

- 7.2.1. Troubleshooting of mechanical system (Smode)

- 7.3. Troubleshooting of electrical system (Emode), Part 1

- 7.3.1. Troubleshooting of electrical system (Emode), Part 1

- 7.4. Troubleshooting of electrical system (Emode), Part 2

- 7.4.1. Troubleshooting of electrical system (Emode), Part 2

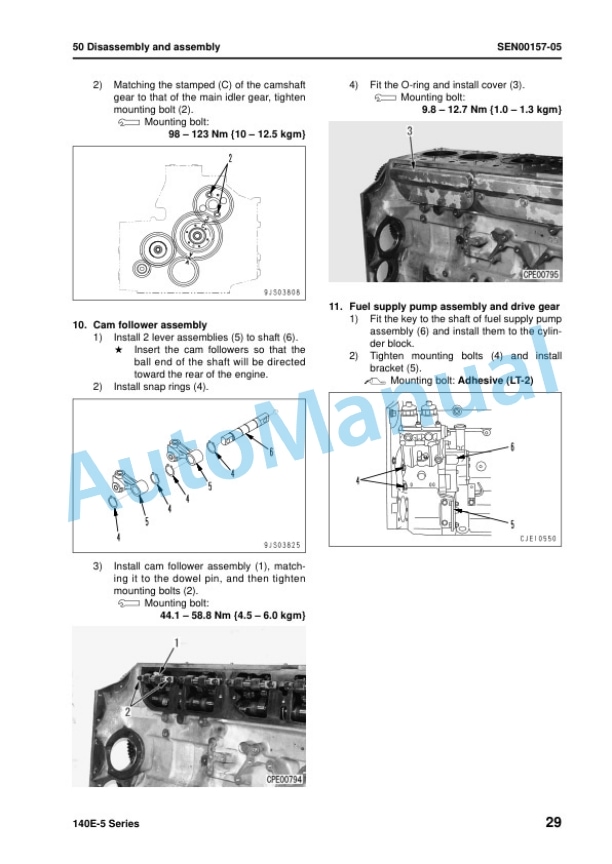

- 8. Disassembly and assembly

- 8.1. General information on disassembly and assembly

- 8.1.1. General information on disassembly and assembly

- 8.2. Disassembly and assembly, Part 1 (with EGR)

- 8.2.1. Disassembly and assembly, Part 1 (with EGR)

- 8.3. Disassembly and assembly, Part 2 (EGRless)

- 8.3.1. Disassembly and assembly, Part 2 (EGRless)

- 8.4. Disassembly and assembly, Part 3

- 8.4.1. Disassembly and assembly, Part 3

- 9. Repair and replacement of parts

- 9.1. Information related to repair and replacement

- 9.1.1. Flowchart

- 9.1.2. Special tool table

- 9.1.3. Special tool sketch

- 9.2. Cylinder head

- 9.2.1. Part names related to cylinder head

- 9.2.2. Testing and inspection of cylinder head

- 9.2.3. Pressure test of cylinder head

- 9.2.4. Replacement of valve guide

- 9.2.5. Replacement of valve seat insert

- 9.2.6. Replacement of crosshead guide

- 9.2.7. Repair of cylinder head mounting face by grinding

- 9.2.8. Repair of valve by grinding

- 9.3. Cylinder block

- 9.3.1. Part names related to cylinder block

- 9.3.2. Testing and inspection of cylinder block

- 9.3.3. Method of checking main bearing metal inside diameter with alignment bar

- 9.3.4. Part names related to crankshaft

- 9.3.5. Testing and inspection of crankshaft

- 9.3.6. Part names related to connecting rod

- 9.3.7. Testing and inspection of connecting rod

- 9.3.8. Replacement of flywheel ring gear

- 9.3.9. Replacement of crankshaft gear

- 9.3.10. Replacement of camshaft gear

- 9.3.11. Replacement of main bearing metal cap

- 9.3.12. Replacement of connecting rod small end bushing

- 9.3.13. Replacement of cam bushing

- 9.3.14. Repair of cylinder block top by grinding

- 9.3.15. Repair of counterbore by grinding

- 9.3.16. Check and identification after repair by grinding

- 9.3.17. Gasket sealant application procedure

- 9.3.18. Repair standard for cylinder liner Oring

- 9.3.19. Replacement of engine rear seal

- 9.3.20. Replacement of wear sleeve (when sleeve is installed)

- 9.3.21. Repair of crankshaft by grinding

- 9.3.22. Improvement of surface roughness of crankshaft journal

Rate this product

You may also like