Komatsu 330M Dump Truck Shop Manual DG666

$40.00

- Type Of Manual: Shop Manual

- Manual ID: DG666

- Format: PDF

- Size: 12.3MB

- Number of Pages: 571

Category: Komatsu Shop Manual PDF

-

Model List:

- 330M Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. A01001.pdf

- 3.1. MAJOR COMPONENTS SPECIFICATIONS A2

- 3.2. GENERAL SAFETY AND OPERATION A3

- 3.3. WARNINGS AND CAUTIONS A4

- 3.4. STANDARD TORQUE CHARTS AND CONVERSION TABLES A5

- 3.5. STORAGE PROCEDURES A7

- 4. A05002.pdf

- 4.1. STANDARD CHARTS AND TABLES

- 4.1.1. INDEX OF TABLES

- 4.1.1.1. Sealants and Adhesives

- 5. M08009.pdf

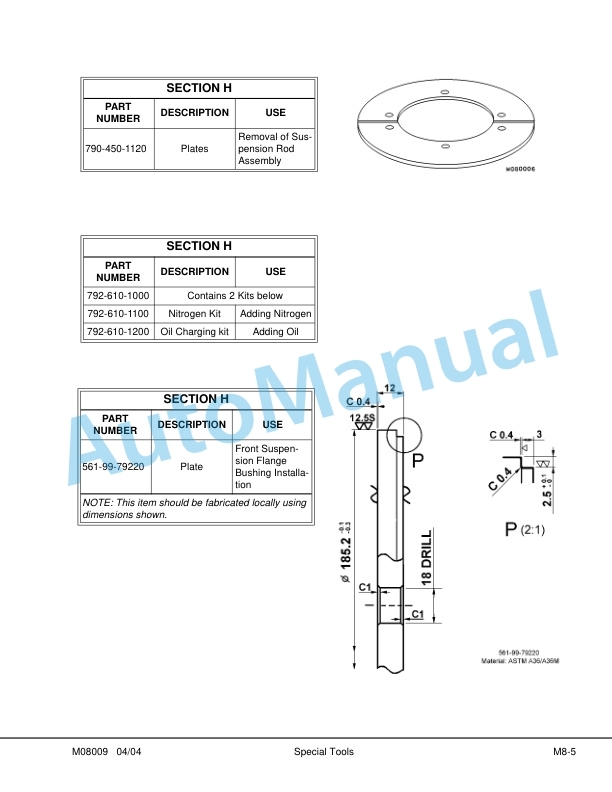

- 5.1. SPECIAL TOOLS

- 6. M09003.pdf

- 6.1. AIR CONDITIONING SYSTEM

- 6.1.1. ENVIRONMENTAL IMPACT

- 6.1.2. OPERATOR CAB AIR CONDITIONING

- 6.1.3. PRINCIPLES OF REFRIGERATION

- 6.1.3.1. Refrigeration The Act Of Cooling

- 6.1.3.2. The Refrigeration Cycle

- 6.1.4. AIR CONDITIONER SYSTEM COMPONENTS

- 6.1.4.1. Compressor (Refrigerant Pump)

- 6.1.4.2. Service Valves

- 6.1.4.3. Condenser

- 6.1.4.4. Filter Receiverdrier

- 6.1.4.5. Fusible Pressure Relief Plug

- 6.1.4.6. Thermostatic Expansion Valve

- 6.1.4.7. Evaporator

- 6.1.4.8. Superheat

- 6.1.5. ELECTRICAL CIRCUIT

- 6.1.5.1. Thermostat

- 6.1.5.2. Compressor Clutch

- 6.1.6. SAFETY SWITCHES (NOT USED IN ALL SYSTEMS)

- 6.1.6.1. Condenser Safety Switch (Overheat Switch)

- 6.1.6.2. Refrigerant Loss (Low Pressure) Switch

- 6.1.7. SYSTEM SERVICING

- 6.1.7.1. R12 Containers

- 6.1.8. SERVICE TOOLS AND EQUIPMENT

- 6.1.8.1. Recovery/recycle Station

- 6.1.9. MANIFOLD GAUGE SET

- 6.1.9.1. Low Side Gauge

- 6.1.9.2. High Side Gauge

- 6.1.9.3. Installing Manifold Gauge Set

- 6.1.9.4. Purging Air From Service Hoses

- 6.1.9.5. Adding Refrigerant to the System (without a charging station)

- 6.1.9.6. Stabilizing the AC System

- 6.1.9.7. Adding Refrigerant and Stabilizing the System (with a recovery/recycling station)

- 6.1.10. RECOVERING AND RECYCLING THE REFRIGERANT

- 6.1.10.1. Performing the Recovery Cycle

- 6.1.10.2. Performing the Recycling Procedure

- 6.1.10.3. Evacuating and Charging the AC System

- 6.1.10.4. Evacuating the System

- 6.1.10.5. Charging the AC System

- 6.1.11. SYSTEM PERFORMANCE TEST

- 6.1.12. SYSTEM LEAK TESTING

- 6.1.12.1. Electronic leak detector

- 6.1.12.2. Halide (propane) Torch

- 6.1.12.3. Tracer dyes

- 6.1.12.4. Soap and water

- 6.1.13. FLUSHING AIR CONDITIONER COMPONENTS

- 6.1.14. SYSTEM REPAIR

- 6.1.14.1. Hoses and Fittings

- 6.1.14.2. Lines

- 6.1.14.3. Expansion Valve

- 6.1.14.4. ReceiverDrier

- 6.1.14.5. Thermostat

- 6.1.14.6. Clutch

- 6.1.14.7. Compressor

- 6.1.15. CHECKING COMPRESSOR OIL LEVEL

- 6.1.15.1. York Compressor Oil Level Check (2 cylinder model)

- 6.1.15.2. Sanden Compressor Oil Level Check (5Cylinder)

- 6.1.16. EVACUATING THE SYSTEM

- 6.2. TROUBLESHOOTING

- 6.2.1. PREDIAGNOSIS CHECKS

- 6.2.2. PREPARING FOR DIAGNOSIS

- 6.2.3. PRELIMINARY STEPS

- 6.2.4. DIAGNOSIS OF GAUGE READINGS SYSTEM PERFORMANCE

- 6.3. TROUBLESHOOTING CHART

Rate this product

You may also like