Komatsu 330M Dump Truck Shop Manual DG728

$40.00

- Type Of Manual: Shop Manual

- Manual ID: DG728

- Format: PDF

- Size: 13.6MB

- Number of Pages: 895

Category: Komatsu Shop Manual PDF

-

Model List:

- 330M Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. TABLE OF CONTENTS

- 4. A GENERAL INFORMATION

- 4.1. MAJOR COMPONENTS SPECIFICATIONS

- 4.2. GENERAL SAFETY

- 4.3. WARNINGS CAUTIONS

- 4.4. STANDARD CHARTS TABLES

- 4.5. STANDARD VALUE TABLES

- 5. B STRUCTURES

- 5.1. GRILLE AND HOOD

- 5.2. DECKS

- 5.3. LEFT DECK CAB

- 5.4. RIGHT DECK STRUCTURE

- 5.5. CENTER DECK STRUCTURE

- 5.6. DUMP BODY REMOVAL

- 5.7. DUMP BODY INSTALLATION

- 5.8. QUICK FUEL OPTION

- 6. C ENGINE, RADIATOR AIR CLEANER

- 6.1. RADIATOR

- 6.2. BRAKE OIL COOLER

- 6.3. DRIVE LINE ADAPTER

- 6.4. AIR FILTRATION SYSTEM

- 6.5. MAIN FILTER ELEMENT

- 7. D ELECTRICAL SYSTEM

- 7.1. DC ELECTRICAL SUPPLY SYSTEM

- 7.2. DC ELECTRICAL SYSTEM COMPONENTS

- 7.3. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 7.4. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 7.5. CHECKS BEFORE TROUBLESHOOTING

- 7.6. TYPE OF CONNECTOR POSITION OF INSTALLATION

- 7.7. FOR ARSC (AUTOMATIC RETARDER SPEED CONTROL)

- 7.8. CONNECTOR PIN ALLOCATION CHART

- 7.9. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 7.10. EXPLANATIONS OF FUNCTIONS (CONTROL MECHANISM) OF ELECTRICAL SYSTEM

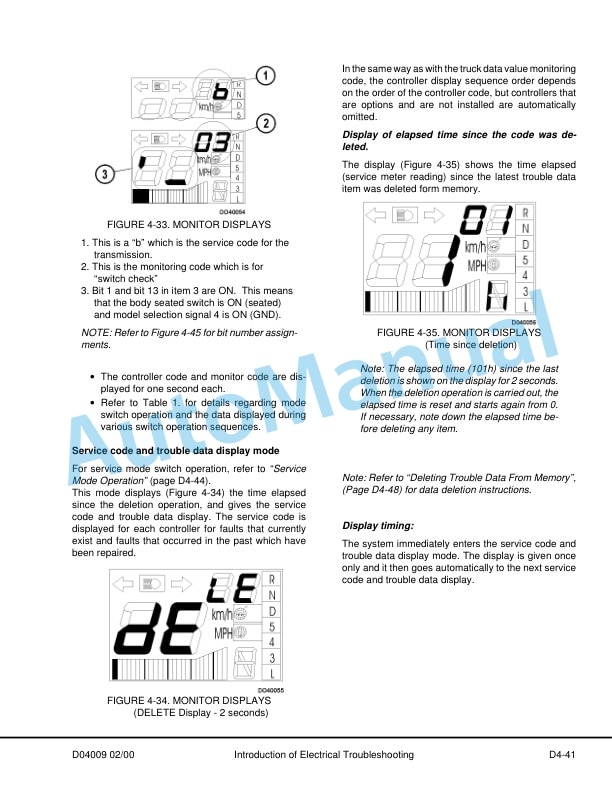

- 7.11. MONITOR PANEL ACTION CODES SERVICE MODE

- 7.12. SELFDIAGNOSTIC DISPLAY METHOD FOR MONITOR PANEL CONTROLLERS

- 7.13. TABLE OF SERVICE CODES ACTION CODES

- 7.14. METHOD OF USING TABLE

- 7.15. METHOD OF USING TROUBLESHOOTING CHARTS

- 7.16. ADJUSTING ELECTRONIC MONITOR (SPEEDOMETER, MODULE)

- 7.17. SETTING ROTARY SWITCH (MODEL NETWORK DATA) WHEN REPLACING TRANSMISSION CONTROLLER

- 7.18. METHOD OF DELETING DATA FROM TRANSMISSION CONTROLLER MEMORY

- 7.19. TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM

- 7.20. MONITOR PANEL TROUBLESHOOTING

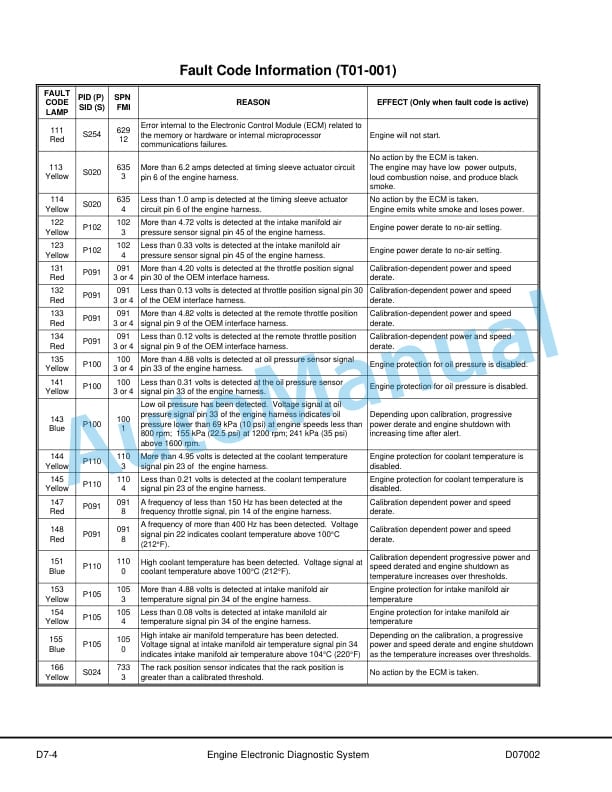

- 7.21. ENGINE ELECTRONIC DIAGNOSTIC SYSTEM

- 7.22. ELECTRICAL SPECIFICATIONS

- 7.23. HYDRAULIC MECHANICAL SYSTEMS TROUBLESHOOTING

- 7.24. SUSPENSION CONTROLLER SYSTEM TROUBLESHOOTING (OPTIONAL) SP DIAGNOSTIC FLOWCHART

- 8. F TRANSMISSION

- 8.1. TORQUE CONVERTER OPERATION

- 8.2. TRANSMISSION OPERATION

- 8.3. TRANSMISSION

- 8.4. TRANSMISSION FILTER

- 8.5. TRANSMISSION OIL COOLER

- 8.6. TRANSMISSION OIL STRAINER

- 8.7. TORQUE CONVERTER CONTROL VALVE

- 8.8. DRIVELINES UJOINTS

- 8.9. AUTOMATIC SHIFT CONTROL SYSTEM

- 9. G WHEELS, SPINDLES FINAL DRIVE

- 9.1. TIRES RIMS

- 9.2. FRONT TIRE RIM

- 9.3. REAR TIRE RIM

- 9.4. TIRE MATCHING

- 9.5. FRONT WHEEL HUB SPINDLES

- 9.6. FRONT WHEEL HUB

- 9.7. FRONT WHEEL BEARING BRAKE DISC REPLACEMENT

- 9.8. FRONT WHEEL HUB INSTALLATION BEARING ADJUSTMENT

- 9.9. AFRAME

- 9.10. CENTER TIE ROD PIVOT

- 9.11. FINAL DRIVE ATTACHMENTS

- 9.12. FINAL DRIVE CENTER CASE ASSEMBLY

- 9.13. DIFFERENTIAL ASSEMBLY

- 9.14. FINAL DRIVE PLANETARIES WHEEL HUBS

- 10. H SUSPENSIONS

- 10.1. FRONT SUSPENSION

- 10.2. REAR SUSPENSION

- 10.3. OILING CHARGING PROCEDURES

- 11. J BRAKE SYSTEM

- 11.1. BRAKE CIRCUIT OPERATION

- 11.2. BRAKE CIRCUIT COMPONENT SERVICE

- 11.3. BRAKE CIRCUIT CHECKOUT AND ADJUSTMENT

- 11.4. FRONT BRAKES

- 11.5. REAR BRAKES

- 11.6. PARKING BRAKE

- 11.7. PARKING BRAKE RELEASE AFTER EMERGENCY APPLY

- 12. K AIR SYSTEM

- 12.1. AIR SYSTEM OPERATION

- 12.2. COMPONENT DESCRIPTION

- 12.3. AIR SYSTEM COMPONENT REPAIR

- 13. L HYDRAULIC SYSTEM

- 13.1. HYDRAULIC SYSTEM OPERATION

- 13.2. HYDRAULIC SYSTEM COMPONENT REPAIR

- 13.3. STEERING CIRCUIT

- 13.4. STEERING VALVE ASSEMBLY

- 13.5. STEERING CIRCUIT COMPONENT REPAIR

- 13.6. HOIST CIRCUIT OPERATION COMPONENT DESCRIPTION

- 13.7. HOIST CIRCUIT COMPONENT REPAIR

- 13.8. HYDRAULIC SYSTEM CHECKOUT

- 14. M OPTIONS SPECIAL TOOLS

- 14.1. QUICK FUEL SYSTEM

- 14.2. SPECIAL TOOLS

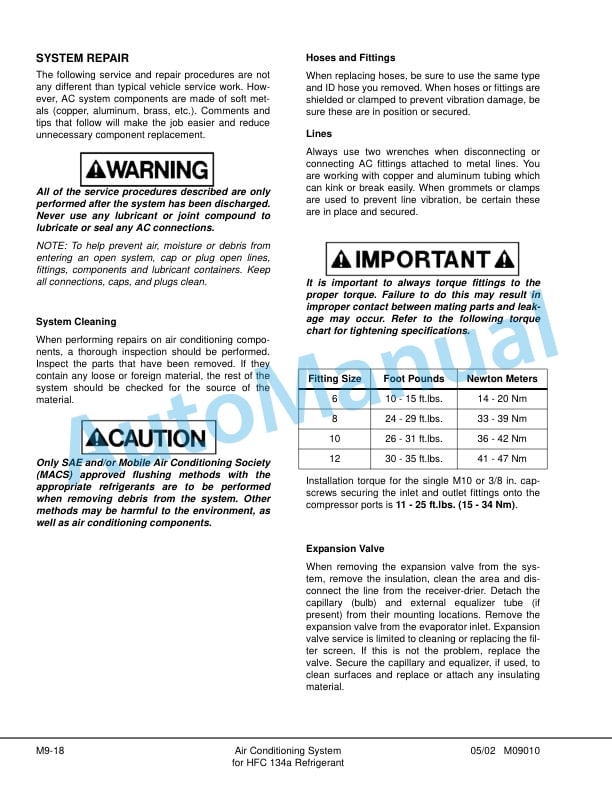

- 14.3. AIR CONDITIONING SYSTEM

- 14.4. PAYLOAD METER II

- 14.5. EXHAUST BRAKE

- 15. N OPERATORS CAB

- 15.1. TRUCK CAB

- 15.2. CAB COMPONENTS

- 15.3. OPERATOR COMFORT

- 15.4. OPERATOR CAB CONTROLS

- 16. P LUBRICATION SERVICE

- 16.1. LUBRICATION SERVICE

- 16.2. LUBRICATION SPECIFICATIONS CHARTS

- 16.3. HOUR (DAILY) LUBRICATION MAINTENANCE CHECKS

- 16.4. FLUID LEVELS OTHER CHECKS

- 16.5. ENGINE

- 16.6. WHEELS AND TIRES

- 16.7. OPERATIONAL CHECKS

- 16.8. HOUR LUBRICATION MAINTENANCE CHECKS

- 16.9. INITIAL 250 HOUR SERVICE

- 16.10. EVERY 250 HOUR SERVICE

- 16.11. HOUR LUBRICATION MAINTENANCE CHECKS

- 16.12. HOUR LUBRICATION MAINTENANCE CHECKS

- 16.13. HOUR LUBRICATION MAINTENANCE CHECKS

- 16.14. EVERY 5000 HOUR SERVICE

- 16.15. HYDRAULIC TANK SERVICE FILLING INSTRUCTIONS

- 16.16. HYDRAULIC FILTERS

- 16.17. HYDRAULIC TANK BREATHER

- 16.18. HIGH PRESSURE HYDRAULIC FILTER SERVICE

- 16.19. TRANSMISSION FILTER SERVICE

- 16.20. PERIODIC REPLACEMENT OF COMPONENT PARTS FOR SAFETY DEVICES

- 17. Q ALPHABETICAL INDEX

- 18. R SYSTEM SCHEMATICS

- 18.1. HA204 AIR CIRCUIT PIPING

- 18.2. HA203 AIR SYSTEM SCHEMATIC

- 18.3. HH339 HYDRAULIC SYSTEM SCHEMATIC

- 18.4. HH340 HYDRAULIC SYSTEM PIPING

- 18.5. KTT01 TRANSMISSION CROSS SECTION VIEW

- 18.6. HE462 ELECTRICAL WIRING SCHEMATIC

Rate this product

You may also like