Komatsu 3D82AE, 3D84E, 3D88E, 4D88E, 4D94E, 4D106, S4D84E, S4D98E, S4D106 Series Diesel Engine Shop Manual WEBMTNV000

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBMTNV000

- Format: PDF

- Size: 30.1MB

- Number of Pages: 280

Category: Komatsu Shop Manual PDF

-

Model List:

- 3D82AE Series Diesel Engine

- 3D84E Series Diesel Engine

- 3D88E Series Diesel Engine

- 4D88E Series Diesel Engine

- 4D94E Series Diesel Engine

- 4D106 Series Diesel Engine

- S4D84E Series Diesel Engine

- S4D98E Series Diesel Engine

- S4D106 Series Diesel Engine

- 1. Engine_TNV.pdf

- 1.1. COVER

- 1.2. General

- 1.2.1. Engine Nomenclature

- 1.2.2. Specifications

- 1.2.3. Fuel Oil, Lubricating Oil and Coolant Water

- 1.2.3.1. Fuel oil

- 1.2.3.2. Lubricating oil

- 1.2.3.3. Coolant water

- 1.2.4. Engine External Views

- 1.2.5. Structural Description

- 1.2.6. Exhaust gas emission regulation

- 1.2.6.1. The Emission Standard in USA

- 1.2.6.2. Engine identification

- 1.2.6.3. Guarantee Conditions for the EPA Emission Standard

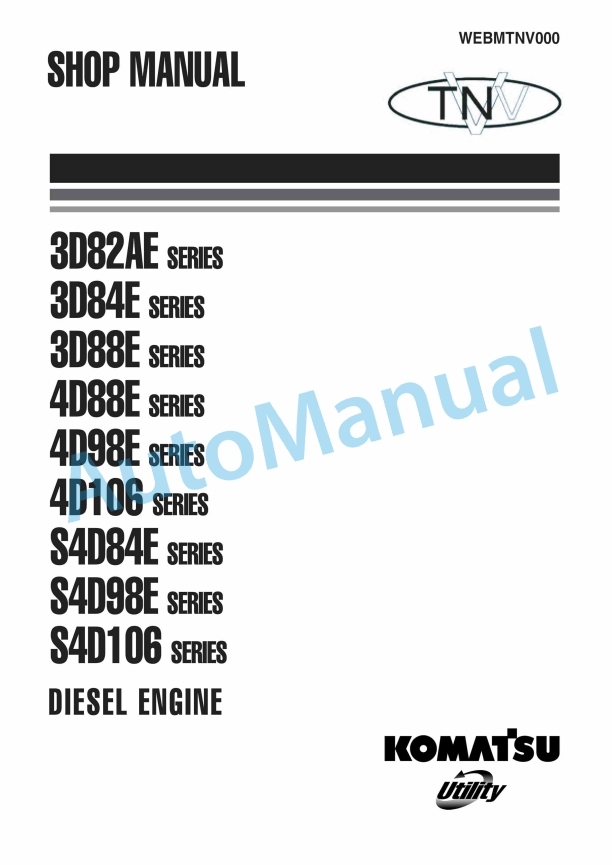

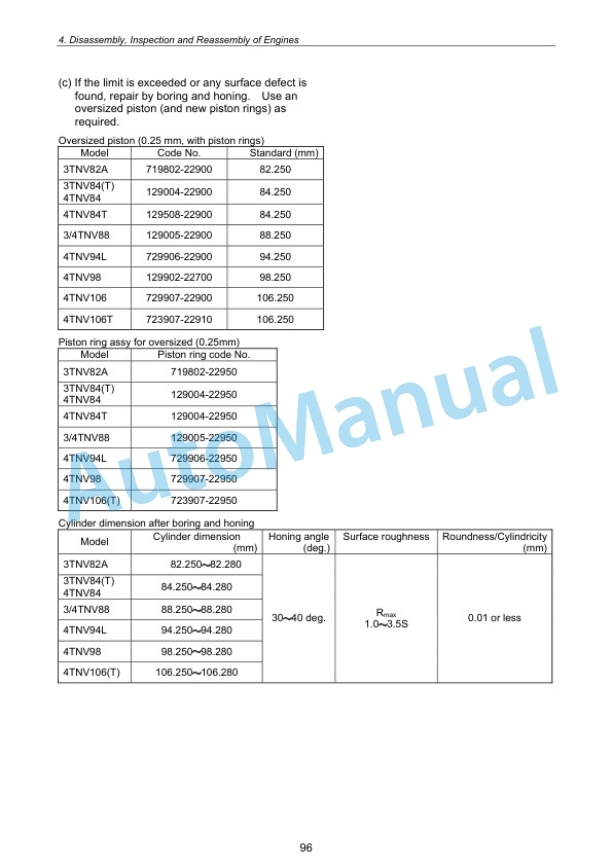

- 1.3. Inspection and Adjustment

- 1.3.1. Periodic Maintenance Schedule

- 1.3.2. Periodic Inspection and Maintenance Procedure

- 1.3.2.1. Check before Daily Operation

- 1.3.2.2. inspection after initial 50 hours operation

- 1.3.2.3. Inspection every 50 hours

- 1.3.2.4. Inspection every 250 hours or 3 months

- 1.3.2.5. Inspection every 500 hours or 6 months

- 1.3.2.6. Inspection every 1,000 hours or one year

- 1.3.2.7. Inspection every 2000 hours or 2 years

- 1.3.3. Adjusting the noload maximum or minimum speed

- 1.3.4. Sensor Inspection

- 1.3.4.1. Oil pressure switch

- 1.3.4.2. Thermo switch

- 1.3.5. Water leak check in cooling water system

- 1.3.6. Radiator cap inspection

- 1.3.7. Thermostat Inspection

- 1.3.8. Adjusting Operation

- 1.3.9. Long storage

- 1.4. TROUBLESHOOTING

- 1.4.1. Preparation before troubleshooting

- 1.4.2. Quick Reference Table for Troubleshooting

- 1.4.3. Troubleshooting by measuring Compression Pressure

- 1.5. Disassembly, Inspection and Reassembly of Engines

- 1.5.1. Complete disassembly and reassembly

- 1.5.1.1. Introduction

- 1.5.1.2. Special service tools

- 1.5.1.3. Complete disassembly

- 1.5.1.4. Precautions before and during reassembly

- 1.5.1.5. Adjusting operation

- 1.5.2. Cylinder Head Disassembly, Inspection and Reassembly

- 1.5.2.1. Components (2valve cylinder head)

- 1.5.2.2. Disassebly procedure

- 1.5.2.3. Reassembly procedure

- 1.5.2.4. Servicing points

- 1.5.2.5. Parts Inspection and measurement

- 1.5.2.6. Valve seat correction

- 1.5.2.7. Valve guide replacement

- 1.5.2.8. Valve stem seal replacement

- 1.5.3. Gear Train and Camshaft

- 1.5.3.1. Components

- 1.5.3.2. Disassembly procedure

- 1.5.3.3. Reassembly procedure

- 1.5.3.4. Servicing points

- 1.5.3.5. Parts inspection and measurement

- 1.5.3.6. Oil seal replacement (Gear case side)

- 1.5.3.7. Camshaft bushing replacement

- 1.5.4. Cylinder Block

- 1.5.4.1. Components

- 1.5.4.2. Disassembly procedure

- 1.5.4.3. Reassembly procedure

- 1.5.4.4. Servicing points

- 1.5.4.5. Parts inspection and measurement

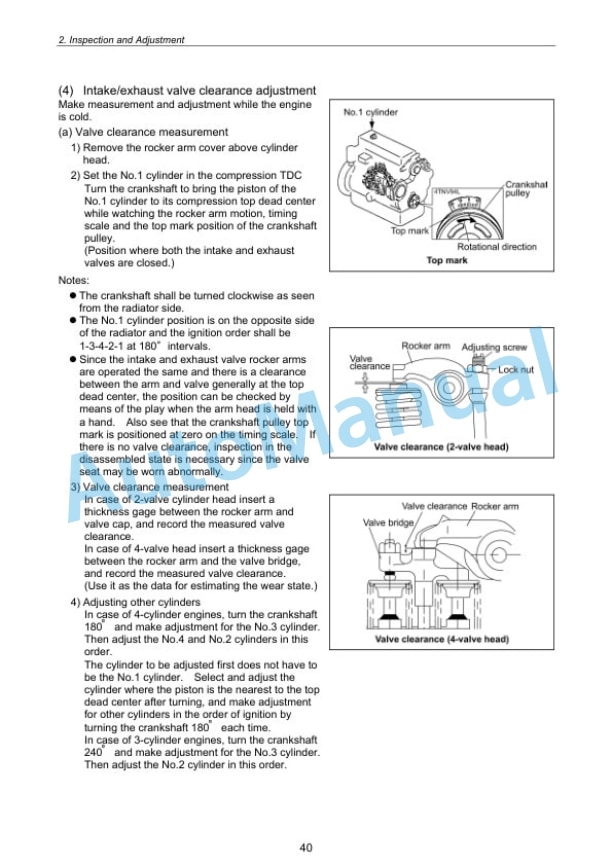

- 1.5.4.6. Cylinder bore correction

- 1.5.4.7. Piston pin bushing replacement

- 1.5.4.8. Oil seal replacement (Flywheel housing side)

- 1.6. LUBRICATION SYSTEM

- 1.6.1. Lubrication System Diagram

- 1.6.2. Trochoid Pump Components

- 1.6.3. Disassembly(Reverse the procedure below for assembly)

- 1.6.4. Servicing Points

- 1.6.5. Parts Inspection and Measurement

- 1.6.5.1. Trochoid pump inspection and measurement

- 1.7. COOLING SYSTEM

- 1.7.1. Cooling Water System

- 1.7.2. Cooling Water Pump Components

- 1.7.3. Disassembly (Reverse the procedure below for assembly)

- 1.7.4. Servicing Points

- 1.8. FUEL INJECTION PUMP/GOVERNOR

- 1.8.1. Introduction

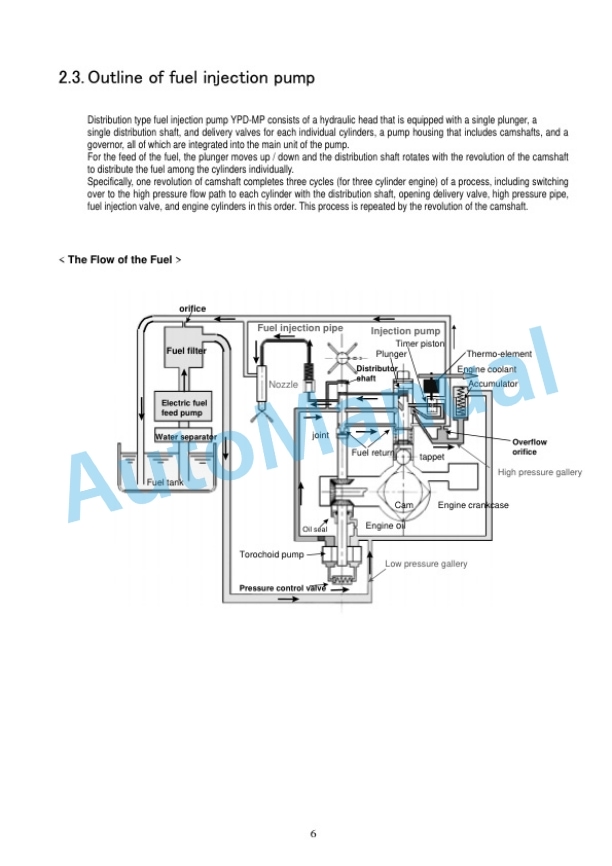

- 1.8.2. Fuel Injection Pump

- 1.8.2.1. Fuel system diagram

- 1.8.2.2. External view and components

- 1.8.2.3. Disassembly procedure

- 1.8.2.4. Assembly procedure

- 1.8.2.5. Servicing points

- 1.9. TURBOCHAGER Disassembly, inspection and reassembly

- 1.9.1. Structure and Functions

- 1.9.1.1. Main specifications

- 1.9.1.2. Construction

- 1.9.1.3. Structural and functional outline

- 1.9.1.4. Components

- 1.9.2. Service Standards and Tightening Torque

- 1.9.2.1. Service standards

- 1.9.2.2. Tightening torque

- 1.9.3. Periodic Inspection Procedure

- 1.9.3.1. Periodic inspection intervals

- 1.9.3.2. Inspection procedure

- 1.9.3.3. Waste gate valve adjustment procedure

- 1.9.4. Disassembly Procedure

- 1.9.4.1. Preparation for disassembly

- 1.9.4.2. Inspection before disassembly

- 1.9.4.3. Disassembly

- 1.9.5. Washing and Inspection procedure

- 1.9.5.1. Washing

- 1.9.5.2. Inspection procedure

- 1.9.6. Reassembly Procedure

- 1.9.6.1. Preparation for reassembly

- 1.9.6.2. Reassembly

- 1.9.7. Handling after Disassembly and Reassembly

- 1.9.7.1. Instructions for turbocharger installation

- 1.9.8. Troubleshooting

- 1.9.8.1. Excessively exhaust smoke

- 1.9.8.2. White smoke generation

- 1.9.8.3. Sudden oil decrease

- 1.9.8.4. Decrease in output

- 1.9.8.5. Poor (slow) response (starting) of turbocharger

- 1.9.8.6. Abnormal sound or vibration

- 1.10. STARTING MOTOR

- 1.10.1. For 4TNV94L/ 98

- 1.10.1.1. Specifications

- 1.10.1.2. Components

- 1.10.1.3. Troubleshooting

- 1.10.1.4. Names of parts and disassembly procedure

- 1.10.1.5. Inspection and Maintenance

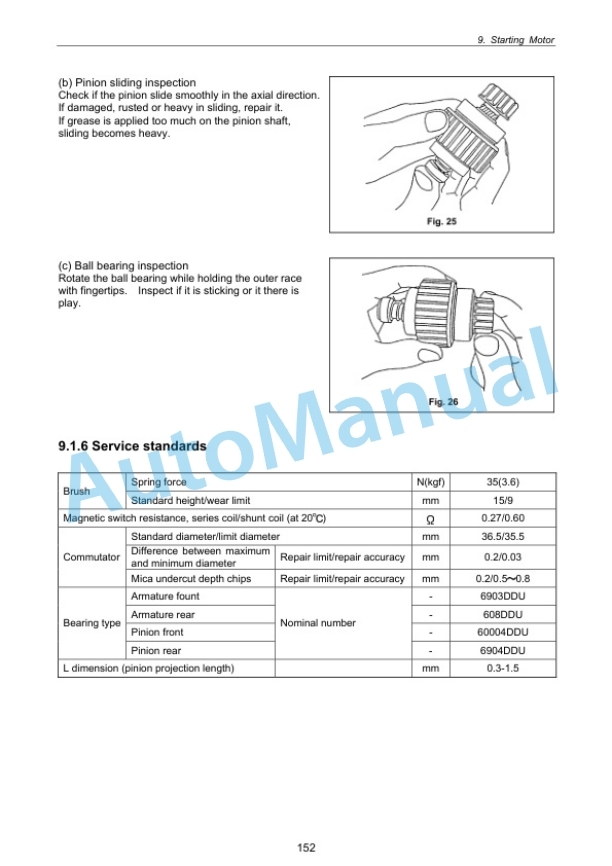

- 1.10.1.6. Service standards

- 1.10.1.7. Assembly

- 1.10.1.8. Characteristic test

- 1.10.2. For 4TNV106(T)

- 1.10.2.1. Specifications

- 1.10.2.2. Congiguration drawing

- 1.10.2.3. Troubleshooting

- 1.10.2.4. Component names and disassembly procedure

- 1.10.2.5. Disassembly procedure

- 1.10.2.6. Inspection and maintenance

- 1.10.2.7. Assembly

- 1.10.2.8. Adjustment

- 1.10.2.9. Service standards

- 1.11. ALTERNATOR

- 1.11.1. The 40A Alternator for 3TNV84 and other models

- 1.11.1.1. Components

- 1.11.1.2. Specifications

- 1.11.1.3. Wiring diagram

- 1.11.1.4. Standard output characteristics

- 1.11.1.5. Inspection

- 1.11.1.6. Troubleshooting

- 1.12. ELECTRIC WIRING

- 1.12.1. Electric Wiring Diagram

- 1.12.2. PRECAUTION ON ELECTRIC WIRING

- 1.12.2.1. Alternator

- 1.12.2.2. Starter

- 1.12.2.3. Current limiter

- 1.12.2.4. Section area and resistance of electric wire

- 1.13. SERVICE STANDARDS

- 1.13.1. Engine Tuning

- 1.13.2. Engine Body

- 1.13.2.1. Cylinder head

- 1.13.2.2. Gear train and camshaft

- 1.13.2.3. Cylinder block

- 1.13.3. Lubricating Oil System (Trochoid Pump)

- 1.14. TIGHTENING TORQUE for BOLTS and NUTS

- 1.14.1. Tightening Torques for Main Bolts and Nuts

- 1.14.2. Tightening Torques for Standard Bolts and Nuts

- 1.15. BACKADDRESS

Rate this product

You may also like