Komatsu 3D95E-1 Series Engine Shop Manual SEN06834-03

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06834-03

- Format: PDF

- Size: 20.3MB

- Number of Pages: 386

Category: Komatsu Shop Manual PDF

-

Model List:

- 3D95E-1 Series Engine

- 1. COVER

- 2. INDEX AND FOREWORD

- 2.1. INDEX

- 2.2. FOREWORD, SAFETY, BASIC INFORMATION

- 2.2.1. HOW TO READ THE ENGINE SHOP MANUAL

- 2.2.2. SAFETY NOTICE FOR OPERATION

- 2.2.3. PRECAUTIONS TO PREVENT FIRE

- 2.2.4. ACTIONS IF FIRE OCCURS

- 2.2.5. PRECAUTIONS WHEN YOU DISPOSE OF WASTE MATERIALS

- 2.2.6. ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION

- 2.2.7. PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

- 2.2.8. PRECAUTIONS WHEN YOU DISCONNECT AND CONNECT PIPINGS

- 2.2.9. PRECAUTIONS WHEN YOU HANDLE ELECTRICAL EQUIPMENT

- 2.2.10. PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT

- 2.2.11. PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT

- 2.2.12. DISCONNECT AND CONNECT PUSHPULL TYPE COUPLER

- 2.2.12.1. METHOD FOR DISCONNECTING AND CONNECTING TYPE 1 PUSHPULL TYPE COUPLER

- 2.2.12.2. METHOD FOR DISCONNECTING AND CONNECTING TYPE 2 PUSHPULL TYPE COUPLER

- 2.2.12.3. METHOD FOR DISCONNECTING AND CONNECTING TYPE 3 PUSHPULL TYPE COUPLER

- 2.2.13. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS

- 2.2.14. METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR

- 2.2.15. METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR

- 2.2.16. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL

- 2.2.17. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH

- 2.2.18. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

- 2.2.19. STANDARD TIGHTENING TORQUE TABLE

- 2.2.20. CONVERSION TABLE

- 2.2.21. ABBREVIATION LIST

- 3. SPECIFICATION

- 3.1. CONTENTS

- 3.2. SPECIFICATIONS

- 3.2.1. OUTLINE OF EXHAUST GAS REGULATION

- 3.2.1.1. SYSTEM DIAGRAM OF ENGINE CONFORMED TO TIER4 REGULATION

- 3.2.2. LIST OF APPLICABLE MACHINES 3D95E1

- 3.2.3. SPECIFICATIONS

- 3.2.3.1. SPECIFICATIONS SAA3D95E1(PC78US11, PC78US11E0, PC88MR11, PC88MR11E0)

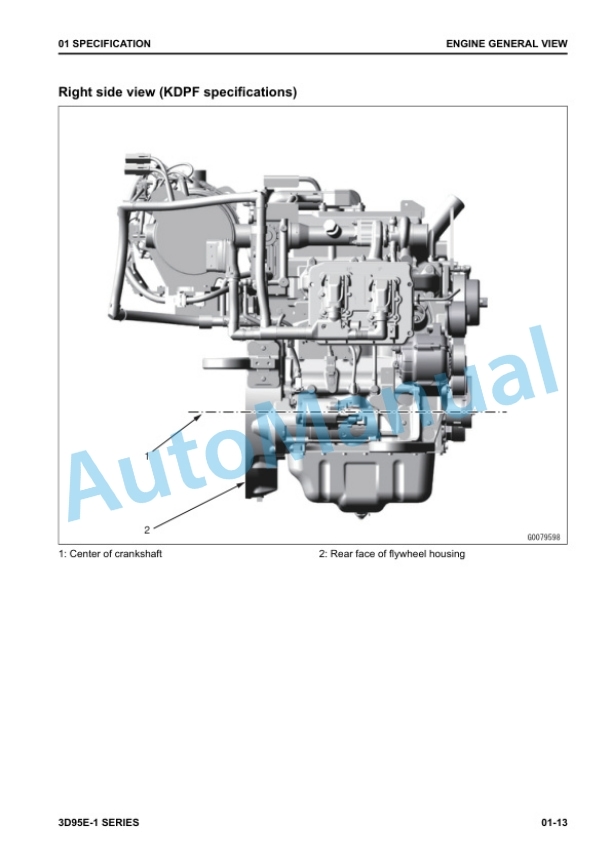

- 3.2.4. ENGINE GENERAL VIEW

- 3.2.4.1. ENGINE GENERAL VIEW SAA3D95E1(PC78US11, PC78US11E0, PC88MR11, PC88MR11E0)

- 3.2.5. WEIGHT TABLE

- 3.2.5.1. WEIGHT TABLE 3D95E1

- 3.2.6. ENGINE PERFORMANCE CURVE

- 3.2.6.1. ENGINE PERFORMANCE CURVE SAA3D95E1 (PC78US11, PC78US11E0, PC88MR11, PC88MR11E0)

- 4. STRUCTURE AND FUNCTION

- 4.1. CONTENTS

- 4.2. ENGINE SYSTEM

- 4.2.1. LAYOUT OF ENGINE COMPONENTS

- 4.2.1.1. LAYOUT DRAWING OF ENGINE COMPONENTS

- 4.2.2. INTAKE AND EXHAUST SYSTEM PARTS

- 4.2.2.1. LAYOUT DRAWING OF INTAKE AND EXHAUST SYSTEM

- 4.2.2.2. INTAKE AND EXHAUST SYSTEM CIRCUIT DIAGRAM

- 4.2.2.3. FUNCTION OF INTAKE AND EXHAUST SYSTEM

- 4.2.2.4. AIR CLEANER

- 4.2.2.5. INTAKE AIR HEATER

- 4.2.3. ENGINE MAIN BODY PARTS

- 4.2.3.1. CYLINDER HEAD

- 4.2.3.2. CYLINDER BLOCK

- 4.2.3.3. MAIN DRIVE PARTS

- 4.2.3.4. TIMING GEAR

- 4.2.3.5. FRONT COVER

- 4.2.3.6. VALVE SYSTEM

- 4.2.3.7. FLYWHEEL AND FLYWHEEL HOUSING

- 4.2.4. TURBOCHARGER SYSTEM

- 4.2.4.1. TURBOCHARGER

- 4.2.4.2. EGR SYSTEM

- 4.2.4.3. EGR VALVE

- 4.2.4.4. EGR COOLER

- 4.2.4.5. HIGH EFFICIENCY BREATHER SYSTEM

- 4.2.4.6. HIGH EFFICIENCY BREATHER

- 4.2.4.7. EXHAUST THROTTLE VALVE

- 4.2.4.8. KDOC

- 4.2.4.9. KDPF

- 4.2.5. LUBRICATION SYSTEM

- 4.2.5.1. LAYOUT DRAWING OF LUBRICATION SYSTEM PARTS

- 4.2.5.2. LUBRICATION SYSTEM CIRCUIT DIAGRAM

- 4.2.5.3. ENGINE OIL PUMP

- 4.2.5.4. ENGINE OIL FILTER

- 4.2.5.5. ENGINE OIL COOLER

- 4.2.5.6. ENGINE OIL PAN

- 4.2.6. FUEL SYSTEM

- 4.2.6.1. LAYOUT DRAWING OF FUEL SYSTEM PARTS

- 4.2.6.2. FUEL SYSTEM CIRCUIT DIAGRAM

- 4.2.6.3. CRI SYSTEM

- 4.2.6.4. SUPPLY PUMP

- 4.2.6.5. COMMON RAIL

- 4.2.6.6. INJECTOR

- 4.2.6.7. FUEL PREFILTER

- 4.2.6.8. FUEL MAIN FILTER

- 4.2.7. COOLING SYSTEM

- 4.2.7.1. LAYOUT DRAWING OF COOLING SYSTEM PARTS

- 4.2.7.2. COOLING SYSTEM CIRCUIT DIAGRAM

- 4.2.7.3. DRIVE PULLEY

- 4.2.7.4. WATER PUMP

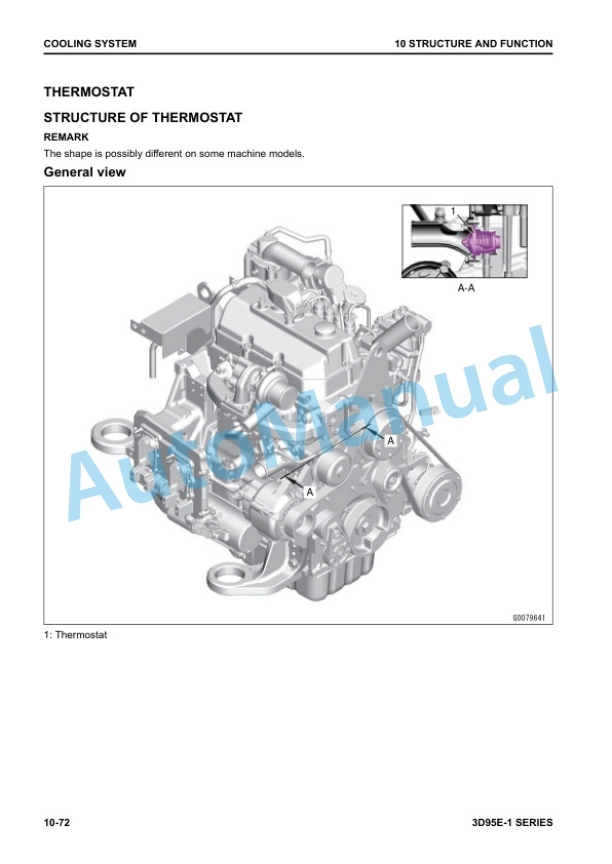

- 4.2.7.5. THERMOSTAT

- 4.3. ELECTRICAL SYSTEM

- 4.3.1. COMPONENT PARTS OF ELECTRICAL SYSTEM

- 4.3.1.1. ALTERNATOR

- 4.3.1.2. STARTING MOTOR

- 4.3.1.3. ENGINE WIRING HARNESS

- 4.3.1.4. ENGINE CONTROLLER

- 4.3.2. SENSOR

- 4.3.2.1. LAYOUT DRAWING OF ENGINE SENSOR

- 4.3.2.2. STRUCTURE OF AMBIENT PRESSURE SENSOR

- 4.3.2.3. FUNCTION OF AMBIENT PRESSURE SENSOR

- 4.3.2.4. STRUCTURE OF ENGINE OIL PRESSURE SWITCH

- 4.3.2.5. FUNCTION OF ENGINE OIL PRESSURE SWITCH

- 4.3.2.6. STRUCTURE OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR

- 4.3.2.7. FUNCTION OF CHARGE (BOOST) PRESSURE AND TEMPERATURE SENSOR

- 4.3.2.8. STRUCTURE OF COOLANT TEMPERATURE SENSOR

- 4.3.2.9. FUNCTION OF COOLANT TEMPERATURE SENSOR

- 4.3.2.10. STRUCTURE OF NE (CRANKSHAFT) SPEED SENSOR

- 4.3.2.11. FUNCTION OF NE (CRANKSHAFT) SPEED SENSOR

- 4.3.2.12. STRUCTURE OF Bkup (CAM) SPEED SENSOR

- 4.3.2.13. FUNCTION OF Bkup (CAM) SPEED SENSOR

- 4.3.2.14. STRUCTURE OF COMMON RAIL PRESSURE SENSOR

- 4.3.2.15. FUNCTION OF COMMON RAIL PRESSURE SENSOR

- 4.3.2.16. STRUCTURE OF MASS AIR FLOW AND TEMPERATURE SENSOR

- 4.3.2.17. FUNCTION OF MASS AIR FLOW AND TEMPERATURE SENSOR

- 4.3.2.18. STRUCTURE OF AIR CLEANER CLOGGING SENSOR

- 4.3.2.19. FUNCTION OF AIR CLEANER CLOGGING SENSOR

- 4.3.2.20. STRUCTURE OF EGR VALVE (WITH BUILTIN POSITION SENSOR)

- 4.3.2.21. FUNCTION OF EGR VALVE (WITH BUILTIN POSITION SENSOR)

- 4.3.2.22. STRUCTURE OF EXHAUST THROTTLE VALVE (WITH BUILTIN POSITION SENSOR)

- 4.3.2.23. FUNCTION OF EXHAUST THROTTLE VALVE (WITH BUILTIN POSITION SENSOR)

- 5. STANDARD VALUE TABLE

- 5.1. CONTENTS

- 5.2. STANDARD VALUE TABLE FOR ENGINE

- 5.2.1. STANDARD VALUE TABLE FOR ENGINE SAA3D95E1 (PC78US11, PC78US11E0, PC88MR11, PC88MR11E0)

- 5.3. PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD

- 5.3.1. PERFORMANCE TEST STANDARD AND STANDARD FOR OPERATION OF ENGINE FOR BREAK IN PERIOD SAA3D95E1 (PC78US11, PC78US11E0, PC88MR11, PC88MR11E0)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. CONTENTS

- 6.2. RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY

- 6.2.1. HOW TO READ THIS MANUAL

- 6.2.2. COATING MATERIALS LIST

- 6.2.3. SPECIAL TOOLS LIST

- 6.2.4. SKETCHES OF SPECIAL TOOLS

- 6.3. ENGINE RELATED

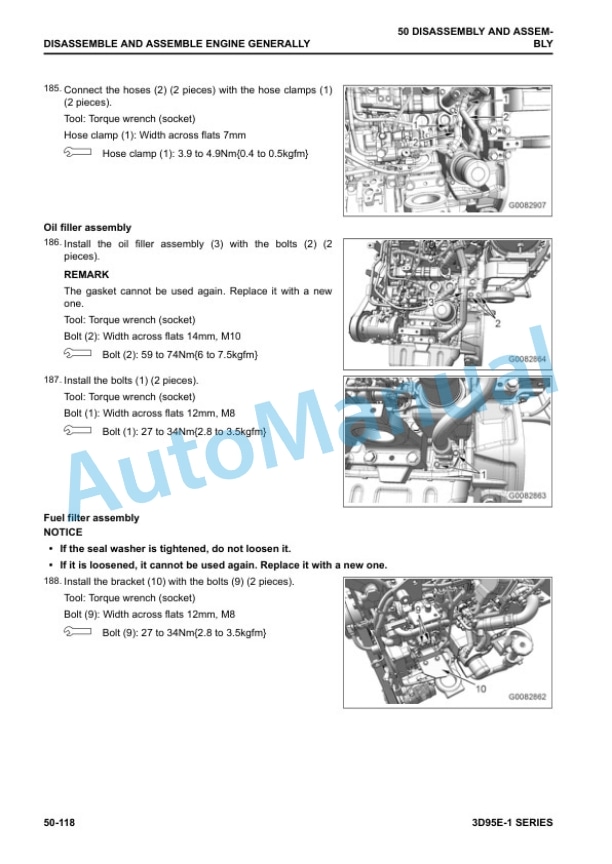

- 6.3.1. DISASSEMBLE AND ASSEMBLE ENGINE GENERALLY

- 6.3.1.1. DISASSEMBLE ENGINE GENERALLY

- 6.3.1.2. ASSEMBLE ENGINE GENERALLY

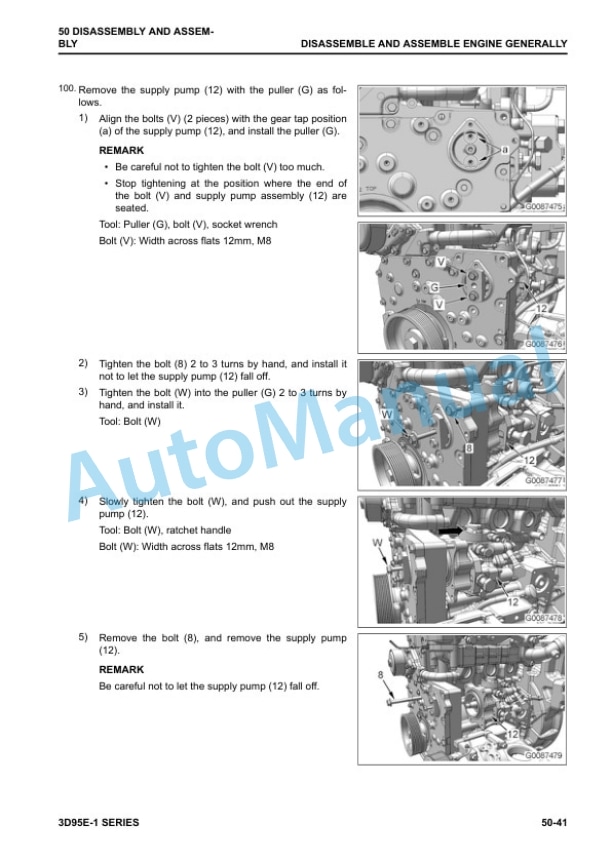

- 6.3.2. REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY

- 6.3.2.1. REMOVE SUPPLY PUMP ASSEMBLY

- 6.3.2.2. INSTALL SUPPLY PUMP ASSEMBLY

- 6.3.3. REMOVE AND INSTALL ENGINE FRONT OIL SEAL

- 6.3.3.1. REMOVE ENGINE FRONT OIL SEAL

- 6.3.3.2. INSTALL ENGINE FRONT OIL SEAL

- 7. MAINTENANCE STANDARD

- 7.1. CONTENTS

- 7.2. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 7.3. ENGINE SYSTEM

- 7.3.1. INTAKE AND EXHAUST SYSTEM PARTS

- 7.3.1.1. MAINTENANCE STANDARD OF TURBOCHARGER

- 7.3.2. ENGINE MAIN BODY PARTS

- 7.3.2.1. MAINTENANCE STANDARD OF CYLINDER HEAD

- 7.3.2.2. MAINTENANCE STANDARD OF CYLINDER BLOCK

- 7.3.2.3. MAINTENANCE STANDARD OF CRANKSHAFT

- 7.3.2.4. MAINTENANCE STANDARD OF PISTON

- 7.3.2.5. MAINTENANCE STANDARD OF CONNECTING ROD

- 7.3.2.6. MAINTENANCE STANDARD OF TIMING GEAR

- 7.3.2.7. MAINTENANCE STANDARD OF CAMSHAFT

- 7.3.2.8. MAINTENANCE STANDARD OF VALVE AND VALVE GUIDE

- 7.3.2.9. MAINTENANCE STANDARD OF ROCKER ARM

- 7.3.2.10. MAINTENANCE STANDARD OF TAPPET

- 7.3.2.11. MAINTENANCE STANDARD OF FLYWHEEL

- 7.3.3. LUBRICATION SYSTEM

- 7.3.3.1. MAINTENANCE STANDARD OF ENGINE OIL PUMP

- 8. INDEX

Rate this product

You may also like