Komatsu 450FXL-1 Crawler Feller Buncher Shop Manual CEBM023102

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM023102

- Format: PDF

- Size: 107.6MB

- Number of Pages: 411

Category: Komatsu Shop Manual PDF

-

Model List:

- 450FXL-1 Crawler Feller Buncher

- 1. CEBM023102 450FXL1

- 1.1. CONTENTS

- 1.2. FOREWORD

- 1.2.1. Safety Notice

- 1.2.1.1. Important Safety Notice

- 1.2.1.2. General Precautions

- 1.2.1.3. Preparations For Work

- 1.2.1.4. Precautions During Work

- 1.2.2. GENERAL

- 1.2.2.1. HOW TO READ THE SHOP MANUAL

- 1.2.2.2. HOISTING INSTRUCTIONS

- 1.2.2.3. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 1.2.2.4. PUSH PULL COUPLER

- 1.2.2.5. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.2.2.6. STANDARD TIGHTENING TORQUE

- 1.2.2.7. GENERAL INSTRUCTIONS

- 1.2.2.8. CONVERSION TABLES

- 1.2.2.9. COATING MATERIALS

- 1.3. GENERAL

- 1.3.1. SPECIFICATIONS

- 1.3.1.1. Dimensions

- 1.3.2. BOOM AND ARM SWEEP DIAGRAMS

- 1.3.3. SPECIFICATIONS

- 1.3.3.1. Engine

- 1.3.3.2. Hydraulic and Engine Oil Selection, Lubricating Oils, and Grease

- 1.3.3.3. Hydraulic Oil Viscosity Selection

- 1.3.3.4. Hydraulic System

- 1.3.3.5. Lubricant and Fill Capacities

- 1.4. TESTING AND ADJUSTING

- 1.4.1. TESTING AND ADJUSTING

- 1.4.1.1. FIRE SUPPRESSION SYSTEM (OPTIONAL)

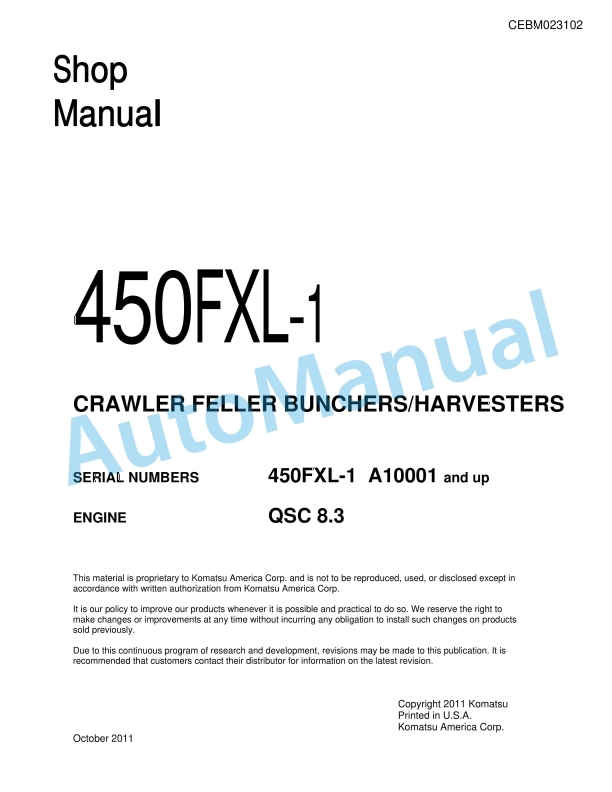

- 1.4.1.2. HYDRAULIC PRESSURE SETTINGS

- 1.4.1.3. CONTROL VALVE CIRCUIT PRESSURE ADJUSTMENTS

- 1.5. TROUBLESHOOTING

- 1.5.1. RELAY FUSE LOCATIONS

- 1.5.1.1. Relay Location and Identification

- 1.5.1.2. Mini Fuse Bank A Location and Identification

- 1.5.1.3. Mini Fuse Bank A Location

- 1.5.1.4. Mini Fuse Bank B Location and Identification

- 1.5.1.5. Mini Fuse Bank B Location

- 1.5.1.6. Maxi Fuse Bank C Location and Identification

- 1.5.1.7. Maxi Fuse Bank D Location and Identification

- 1.5.2. GENERAL INFORMATION

- 1.5.2.1. Points to Remember

- 1.5.2.2. Sequence of Events

- 1.5.2.3. Handling Electric Equipment and Hydraulic Components

- 1.5.2.4. Connectors for Tier 3 Engines

- 1.5.2.5. Checks Before Troubleshooting

- 1.5.3. GENERAL HYDRAULIC PROBLEMS

- 1.5.4. MACHINE OVERHEAT PROBLEMS

- 1.5.5. IMPLEMENT FUNCTION PROBLEMS

- 1.5.6. TRACK DRIVE PROBLEMS

- 1.5.7. ENGINE PROBLEMS

- 1.5.8. ELECTRICAL PROBLEMS

- 1.5.9. AIR CONDITIONER / HEATER PROBLEMS

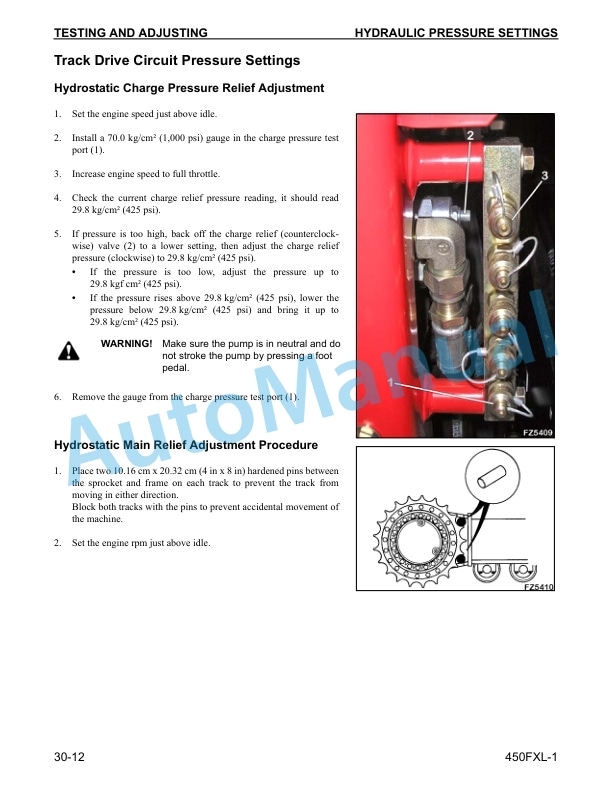

- 1.5.10. DISC SAW CIRCUIT PROBLEMS

- 1.6. DISASSEMBLY AND ASSEMBLY

- 1.6.1. HOW TO READ THIS MANUAL

- 1.6.1.1. Removal And Installation Of Assemblies

- 1.6.1.2. Disassembly And Assembly Of Assemblies

- 1.6.2. SPECIAL TOOLS LIST

- 1.6.3. CONNECTOR REPAIR PROCEDURES

- 1.6.3.1. Stripping Insulation

- 1.6.3.2. Wire Inspection

- 1.6.3.3. Contact Terminal Removal (HD30 Type)

- 1.6.3.4. Crimping Contact Terminal (HD30 Type)

- 1.6.3.5. Insertion Of Contact Terminal (HD30 Type)

- 1.6.3.6. Contact Terminal Removal (DT Type)

- 1.6.3.7. Crimping Contact Terminal (DT Type)

- 1.6.3.8. Insertion Of Contact Terminal (DT Type)

- 1.6.4. PRECAUTIONS DURING OPERATION

- 1.6.4.1. Precautions when Performing Removal Work

- 1.6.4.2. Precautions when Performing Installation Work

- 1.6.4.3. Precautions when Completing The Operations

- 1.6.4.4. Other Precautions

- 1.6.4.5. Tool Tilt Cylinder

- 1.6.4.6. Stick Cylinder

- 1.6.4.7. Main Boom Cylinder

- 1.6.5. HYDRAULIC SYSTEM

- 1.6.5.1. Hydraulic Oil Tank

- 1.6.5.2. Auxiliary Oil Cooler

- 1.6.5.3. Hydraulic Tank Vacuum Pump

- 1.6.5.4. Machine StartUp After Hydraulic Component Replacement

- 1.6.5.5. Rotary Manifold

- 1.6.5.6. Swing Motor

- 1.6.5.7. Swing Motor AntiCavitation Valve

- 1.6.5.8. Swing Motor Gearbox Brake

- 1.6.5.9. Swing Motor/Gearbox Assembly

- 1.6.6. SWING BEARING

- 1.6.6.1. Removal

- 1.6.6.2. Installation

- 1.6.7. LEVELING COMPONENTS

- 1.6.7.1. Leveling Cylinder Removal

- 1.6.7.2. Leveling Cylinder Installation

- 1.6.7.3. Turntable Casting

- 1.6.7.4. Intermediate Leveler

- 1.6.7.5. Auxiliary Pump

- 1.6.7.6. Implement Pump

- 1.6.7.7. Auxiliary Oil Cooler Fan Pump

- 1.6.7.8. Charge Pump

- 1.6.7.9. Right Side Drive Pump

- 1.6.7.10. Left Side Drive Pump

- 1.6.8. FINAL DRIVE ASSEMBLY

- 1.6.8.1. Removal

- 1.6.8.2. Disassembly

- 1.6.8.3. Disassembly of Number 1 Carrier

- 1.6.8.4. Assembly of Number 1 Carrier

- 1.6.8.5. Disassembly of Number 2 Carrier

- 1.6.8.6. Assembly of Number 2 Carrier

- 1.6.8.7. Assembly

- 1.6.8.8. Installation

- 1.6.9. MAIN CONTROL VALVE

- 1.6.10. CHARGE MANIFOLD HEATER

- 1.6.10.1. Removal

- 1.6.10.2. Installation

- 1.6.11. CHARGE FILTER MANIFOLD

- 1.6.11.1. Removal

- 1.6.11.2. Installation

- 1.6.12. PILOT PRESSURE MANIFOLD

- 1.6.12.1. Removal and Installation

- 1.6.13. RETURN OIL MANIFOLD (LOGIC BLOCK)

- 1.6.14. SAW STOP VALVE

- 1.6.14.1. Removal and Installation

- 1.6.15. ENGINE FLEXPLATE

- 1.6.15.1. Remove Hydraulic Pumps

- 1.6.15.2. Separate Pump Drive From Engine

- 1.6.15.3. Flexplate Removal

- 1.6.15.4. Flexplate Installation

- 1.6.15.5. Pump Drive Installation

- 1.6.15.6. Install Hydraulic Pumps

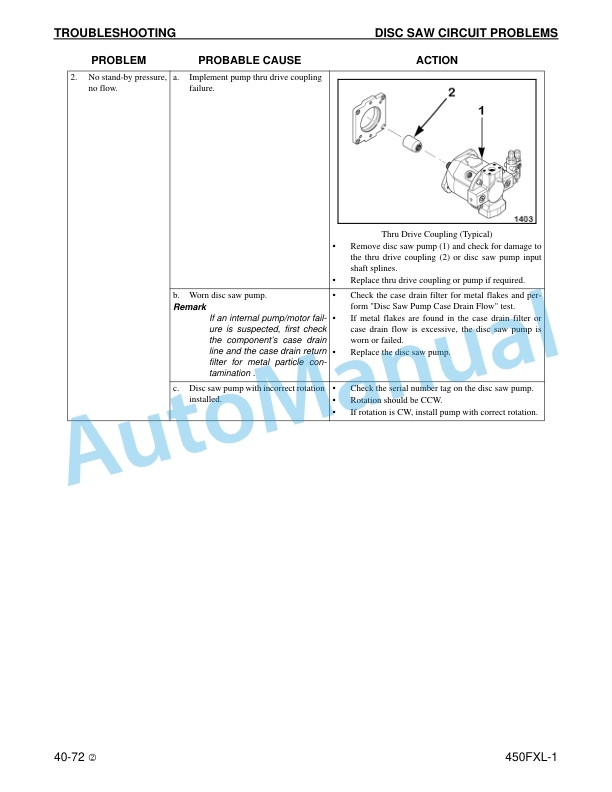

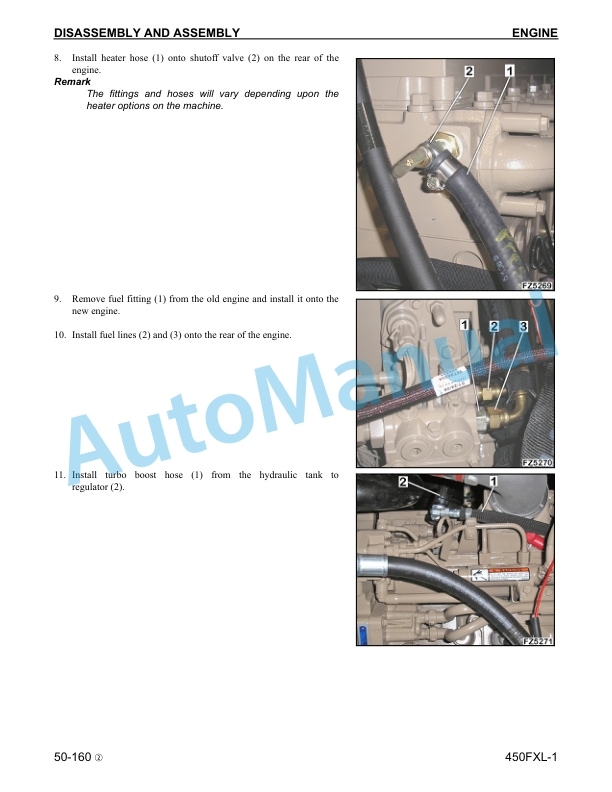

- 1.6.16. ENGINE

- 1.6.16.1. Removal

- 1.6.16.2. Installation Preparation

- 1.6.16.3. Installation

- 1.6.17. TRACK SYSTEM

- 1.6.17.1. Track Tension

- 1.6.17.2. Track Shoe Removal and Installation

- 1.6.17.3. Track Removal and Installation

- 1.6.17.4. Idler Wheel, Recoil Spring and Track Adjuster Assembly

- 1.6.17.5. Final Drive Sprocket

- 1.6.17.6. Track Slider

- 1.6.17.7. Upper Track Roller

- 1.7. AIR CONDITIONER

- 1.7.1. AIR CONDITIONER/HEATER

- 1.7.1.1. CHARGING AIR CONDITIONING SYSTEM

- 1.7.1.2. Air Conditioner/Heater Access

- 1.8. DIAGRAMS AND SCHEMATICS

- 1.8.1. TRACK DRIVE CIRCUIT 83381 REV. A

- 1.8.2. COMBINATION BAR SAW AND DISC SAW 83382B

- 1.8.3. DISC SAW 83383B

- 1.8.4. DUAL FLOW PROCESSOR 2 83385B

- 1.8.5. COMBINED FLOW PROCESSOR 3 83386B

- 1.8.6. COMBINED FLOW PROCESSOR 4 83387B

- 1.8.7. INTERMITTENT DISC SAW 83388B

- 1.8.8. BAR SAW 83389B

- 1.8.9. DUAL FLOW PROCESSOR 5 85801A

- 1.8.10. ELECTRICAL MAXI HEAD COMPUTER 00860148 1/2

- 1.8.11. ELECTRICAL MAXI HEAD COMPUTER 00860148 2/2

- 1.8.12. ELECTRICAL 00860154 1/2

- 1.8.13. ELECTRICAL 00860154 2/2

- 1.8.14. HYDRAULIC 00860150

- 1.8.15. MAIN ELECTRICAL CTR, FUSE LEGEND 28606E 1/2

- 1.8.16. MAIN ELECTRICAL CTR, FUSE LEGEND 28606E 2/2

- 1.8.17. DASH PANEL 28411A

- 1.8.18. UPPER CAB HARNESS 28413A

- 1.8.19. RADIO ADAPTER 28414B

- 1.8.20. REAR UPPER LIGHT HARNESS 28415A

- 1.8.21. LOWER CAB SUB HARNESS (SHIFT COIL) 28416A

- 1.8.22. LOWER CAB HARNESS 28417A

- 1.8.23. FOPS LIGHT HARNESS 28418A

- 1.8.24. ENGINE HARNESS 28703B

- 1.8.25. VISOR LIGHT HARNESS 28422B

- 1.8.26. MAXI INTERFACE HARNESS 83093A

- 1.8.27. VAC/VENT SUB HARNESS 27309

- 1.8.28. ROLLY II INSTALLATION KIT, FUSE RELAY 28701 REV A

- 1.8.29. CUMMINS QSC ENGINE SCHEMATIC 83093A

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00