Komatsu 4D98, 4D106, S4D106 Series Diesel Engine Shop Manual WEBM4D9801

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBM4D9801

- Format: PDF

- Size: 10.2MB

- Number of Pages: 204

Category: Komatsu Shop Manual PDF

-

Model List:

- 4D98 Series Diesel Engine

- 4D106 Series Diesel Engine

- S4D106 Series Diesel Engine

- 1. MAIN MENU

- 2. COVER

- 3. FOREWORD

- 4. FOR SAFE SERVICING

- 5. PRECAUTIONS FOR SAFE SERVICING

- 5.1. (A) SERVICE SHOP (PLACE)

- 5.2. (B) WORKING WEAR

- 5.3. (C) TOOLS TO BE USED

- 5.4. (D) USE OF GENUINE PARTS, OIL AND GREASE

- 5.5. (E) BOLT AND NUT TIGHTENING TORQUES

- 5.6. (F) ELECTRICAL PARTS

- 5.7. (G) WASTE TREATMENT

- 5.8. (H) HANDLING THE PRODUCT

- 6. CONTENTS

- 7. GENERAL

- 7.1. ENGINE NOMENCLATURE

- 7.2. SPECIFICATIONS

- 7.3. FUEL OIL, LUBRICATING OIL AND COOLING WATER

- 7.4. ENGINE EXTERNAL VIEWS

- 7.5. STRUCTURAL DESCRIPTION

- 7.6. HOW TO READ THIS MANUAL

- 7.6.1. RANGE OF OPERATION EXPLANATION

- 7.6.2. HOW TO READ THE EXPLANATIONS

- 7.6.3. DEFINITION OF TERMS

- 7.6.4. ABBREVIATIONS

- 7.7. PRECAUTIONS FOR SERVICE WORK

- 7.8. TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS

- 8. TROUBLESHOOTING

- 8.1. QUICK REFERENCE TABLE FOR TROUBLESHOOTING

- 8.2. TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

- 8.2.1. COMPRESSION PRESSURE MEASUREMENT METHOD

- 8.2.2. STANDARD COMPRESSION PRESSURE

- 8.2.3. ENGINE SPEED AND COMPRESSION PRESSURE

- 8.2.4. MEASURED VALUE AND TROUBLESHOOTING

- 9. INSPECTION AND ADJUSTMENT

- 9.1. OIL INSPECTION

- 9.2. COOLING WATER INSPECTION

- 9.3. INSPECTING WATER LEAK FROM COOLING WATER SYSTEM AND RADIATOR

- 9.4. FAN BELT TENSION INSPECTION AND ADJUSTMENT

- 9.5. ADJUSTING THE VALVE CLEARANCE

- 9.6. INSPECTING THE FUEL INJECTION VALVE INJECTION PRESSURE AND SPRAY PATTERN

- 9.7. FUEL INJECTION TIMING INSPECTION AND ADJUSTMENT

- 9.8. ADJUSTING THE NOLOAD MAXIMUM (OR MINIMUM) REVOLUTIONS

- 9.9. SENSOR INSPECTION

- 9.10. BATTERY INSPECTION

- 9.11. ADJUSTING OPERATION

- 9.12. LONG STORAGE

- 9.13. PERIODIC MAINTENANCE SCHEDULE

- 10. ENGINE BODY

- 10.1. INTRODUCTION

- 10.2. CYLINDER HEAD

- 10.2.1. COMPONENTS

- 10.2.2. DISASSEMBLY PROCEDURE

- 10.2.3. REASSEMBLY PROCEDURE

- 10.2.4. SERVICING POINTS

- 10.2.5. PARTS INSPECTION AND MEASUREMENT

- 10.2.6. VALVE SEAT CORRECTION

- 10.2.7. VALVE GUIDE REPLACEMENT

- 10.2.8. VALVE STEM SEAT REPLACEMENT

- 10.3. GEAR TRAIN AND CAMSHAFT

- 10.3.1. COMPONENTS

- 10.3.2. DISASSEMBLY PROCEDURE

- 10.3.3. REASSEMBLY PROCEDURE

- 10.3.4. SERVICING POINTS

- 10.3.5. PARTS INSPECTION AND MEASUREMENT

- 10.3.6. OIL SEAL REPLACEMENT

- 10.3.7. CAMSHAFT BUSHING REPLACEMENT

- 10.4. CYLINDER BLOCK

- 10.4.1. COMPONENTS

- 10.4.2. DISASSEMBLY PROCEDURE

- 10.4.3. REASSEMBLY PROCEDURE

- 10.4.4. SERVICING POINTS

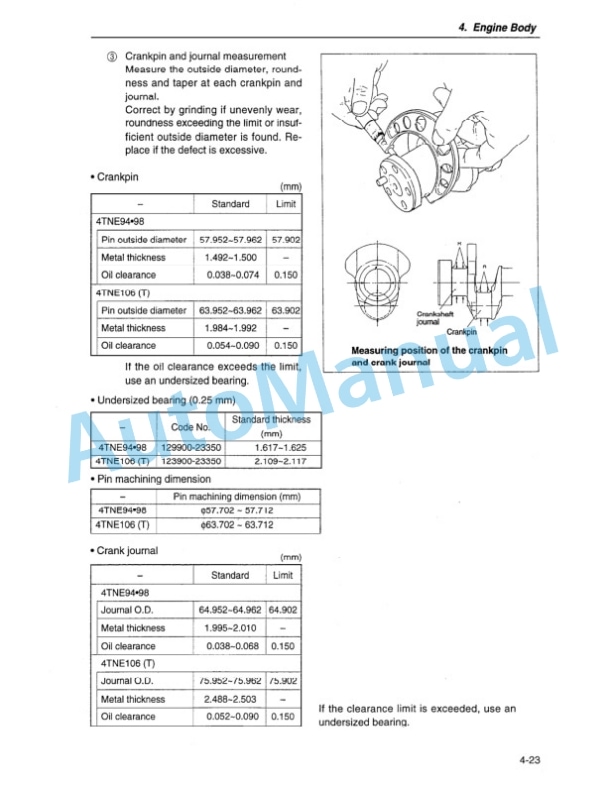

- 10.4.5. PARTS INSPECTION AND MEASUREMENT

- 10.4.6. CYLINDER BORE CORRECTION

- 10.4.7. PISTON PIN BUSHING REPLACEMENT

- 10.4.8. OIL SEAL REPLACEMENT

- 11. LUBRICATION SYSTEM

- 11.1. LUBRICATION SYSTEM DIAGRAM

- 11.2. TROCHOID PUMP COMPONENTS

- 11.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 11.4. SERVICING POINTS

- 11.5. PARTS INSPECTION AND MEASUREMENT

- 12. COOLING SYSTEM

- 12.1. COOLING WATER SYSTEM

- 12.2. COOLING WATER PUMP COMPONENTS

- 12.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 12.4. SERVICING POINTS

- 13. FUEL INJECTION PUMP/GOVERNOR

- 13.1. INTRODUCTION

- 13.2. FUEL INJECTION PUMP

- 13.2.1. FUEL SYSTEM DIAGRAM

- 13.2.2. COMPONENTS

- 13.2.3. DISASSEMBLY PROCEDURE

- 13.2.4. ASSEMBLY PROCEDURE

- 13.2.5. SERVICING POINTS

- 13.2.6. PARTS INSPECTION AND MEASUREMENT

- 13.3. FUEL INJECTION VALVE

- 13.4. FUEL FEED PUMP

- 13.4.1. COMPONENTS

- 13.4.2. DISASSEMBLY PROCEDURE

- 13.4.3. PARTS INSPECTION AND MEASUREMENT

- 13.5. GOVERNOR

- 13.5.1. COMPONENTS

- 13.5.2. DISASSEMBLY PROCEDURE

- 13.5.3. PARTS INSPECTION AND MEASUREMENT

- 13.6. SPECIAL SERVICE TOOLS FOR DISASSEMBLY/ASSEMBLY

- 14. TURBOCHARGER (FOR 4TNE106T)

- 14.1. STRUCTURE AND FUNCTIONS

- 14.1.1. STRUCTURAL AND FUNCTIONAL OUTLINE

- 14.1.2. STRUCTURE

- 14.1.3. COMPONENTS

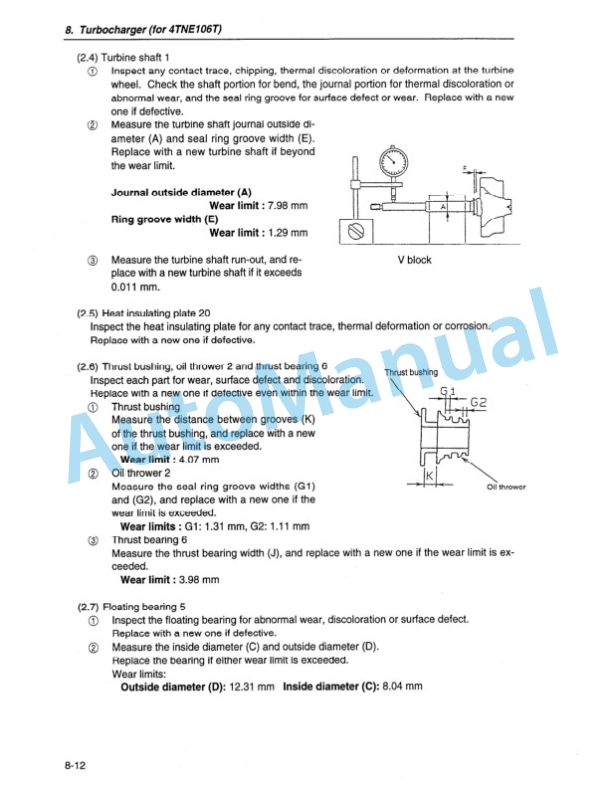

- 14.2. SERVICE STANDARDS

- 14.2.1. SERVICE STANDARDS

- 14.2.2. TIGHTENING TORQUE

- 14.3. PERIODIC INSPECTION PROCEDURE

- 14.3.1. PERIODIC INSPECTION INTERVALS

- 14.3.2. INSPECTION PROCEDURE

- 14.3.3. WASTE GATE VALVE ADJUSTMENT PROCEDURE

- 14.4. DISASSEMBLY PROCEDURE

- 14.4.1. PREPARATION FOR DISASSEMBLY

- 14.4.2. INSPECTION BEFORE DISASSEMBLY

- 14.4.3. DISASSEMBLY

- 14.5. WASHING AND INSPECTION PROCEDURE

- 14.5.1. WASHING

- 14.5.2. INSPECTION PROCEDURE

- 14.6. REASSEMBLY PROCEDURE

- 14.6.1. PREPARATION FOR REASSEMBLY

- 14.6.2. REASSEMBLY

- 14.7. HANDLING AFTER DISASSEMBLY AND REASSEMBLY

- 14.8. TROUBLESHOOTING

- 15. STARTING MOTOR

- 15.1. FOR 4TNE94/98

- 15.1.1. SPECIFICATIONS

- 15.1.2. COMPONENTS

- 15.1.3. TROUBLESHOOTING

- 15.1.4. NAMES OF PARTS AND DISASSEMBLY PROCEDURE

- 15.1.5. INSPECTION AND MAINTENANCE

- 15.1.5.1. ARMATURE

- 15.1.5.2. FIELD COIL

- 15.1.5.3. BRUSH

- 15.1.5.4. BRUSH HOLDER

- 15.1.5.5. MAGNETIC SWITCH

- 15.1.5.6. PINION CLUTCH

- 15.1.6. SERVICE STANDARDS

- 15.1.7. ASSEMBLY

- 15.1.8. CHARACTERISTIC TEST

- 15.2. FOR 4TNE106(T)

- 15.2.1. SPECIFICATIONS

- 15.2.2. CONFIGURATION DRAWING

- 15.2.3. TROUBLESHOOTING

- 15.2.4. COMPONENT NAMES AND DISASSEMBLY PROCEDURE

- 15.2.5. DISASSEMBLY PROCEDURE

- 15.2.6. INSPECTION AND MAINTENANCE

- 15.2.6.1. ARMATURE

- 15.2.6.2. FIELD COIL

- 15.2.6.3. BRUSH

- 15.2.6.4. MAGNETIC SWITCH CONTINUITY TEST

- 15.2.6.5. PINION

- 15.2.6.6. BALL BEARING

- 15.2.7. ASSEMBLY

- 15.2.8. ADJUSTMENT

- 15.2.9. SERVICE STANDARDS

- 16. ALTERNATOR

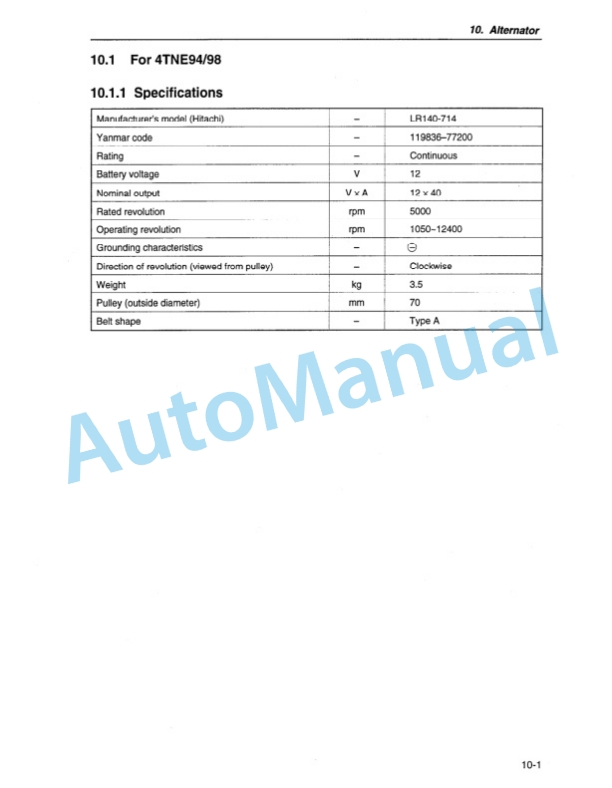

- 16.1. FOR 4TNE94/98

- 16.1.1. SPECIFICATIONS

- 16.1.2. SECTIONAL VIEW

- 16.1.3. TROUBLESHOOTING

- 16.1.4. PARTS NAMES AND DISASSEMBLY PROCEDURE

- 16.1.5. INSPECTION AND OVERHAUL

- 16.1.5.1. DIODE

- 16.1.5.2. ROTOR

- 16.1.5.3. STATOR

- 16.1.5.4. BRUSH

- 16.1.5.5. CHECK OF IC REGULATOR

- 16.1.6. ASSEMBLY

- 16.1.7. SERVICE STANDARDS

- 16.1.8. PERFORMANCE TEST

- 16.2. FOR 4TNE106(T)

- 16.2.1. SPECIFICATIONS

- 16.2.2. EXPLODED VIEW

- 16.2.3. TROUBLESHOOTING

- 16.2.4. DISASSEMBLY PROCEDURE

- 16.2.5. INSPECTION AND MAINTENANCE

- 16.2.6. REASSEMBLY PROCEDURE

- 16.2.7. PERFORMANCE TEST

- 17. SPECIAL SERVICE TOOLS

- 17.1. SPECIAL TOOLS

- 17.2. MEASURING INSTRUMENTS

- 18. SERVICE STANDARDS

- 18.1. ENGINE TUNING

- 18.2. ENGINE BODY

- 18.2.1. CYLINDER HEAD

- 18.2.2. GEAR TRAIN AND CAMSHAFT

- 18.2.3. CYLINDER BLOCK

- 18.3. LUBRICATING OIL SYSTEM (TROCHOID PUMP)

- 18.4. TIGHTENING TORQUES FOR MAIN BOLTS AND NUTS

Rate this product

You may also like