Komatsu 560C Wheel Loader Service Manual SM560C99_1E

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM560C99_1E

- Format: PDF

- Size: 13.0MB

- Number of Pages: 500

Category: Komatsu Service Manual PDF

-

Model List:

- 560C Wheel Loader

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. INTRODUCTION

- 4.1. SAFETY PRECAUTIONS

- 4.1.1. GENERAL

- 4.1.2. OPERATION

- 4.1.3. MAINTENANCE

- 4.2. SHIPPING SPECIFICATIONS

- 4.2.1. DIMENSIONS

- 4.2.2. SYSTEM REFILL CAPACITIES (APROXIMATE)

- 4.3. SERVICE INFORMATION

- 4.3.1. SERVICE PARTS

- 4.3.2. SERIAL NUMBERS

- 4.3.3. INSPECTION AND REPAIR

- 4.4. LOCTITE USAGE

- 4.4.1. SURFACE PREPARATION

- 4.4.2. APPLICATION

- 4.4.3. SETTING TIME (BEFORE PLACING IN OPERATION)

- 4.4.4. REMOVAL

- 4.4.5. APPPLICATION AT LOW TEMPERATURES

- 4.5. STANDARD TORQUES

- 4.5.1. BOLT IDENTIFICATION CHART

- 4.5.2. TORQUE VALUES FOR STANDARD FASTENERS

- 4.5.3. SPLIT FLANGE CONNECTIONS

- 4.5.4. HYDRAULIC TUBES AND FITTINGS

- 4.5.5. HOSE CLAMPS

- 4.6. SERVICE/SPECIAL TOOLS

- 4.6.1. SERVICE/SPECIAL TOOLS

- 5. BRAKES

- 5.1. WHEEL BRAKE

- 5.1.1. DESCRIPTION

- 5.1.2. OPERATIONAL TEST

- 5.1.3. SERVICE DIAGNOSIS

- 5.2. PARKING BRAKE

- 5.2.1. DESCRIPTION

- 5.2.2. SPECIFICATIONS

- 5.2.3. SERVICE DIAGNOSIS

- 5.2.4. ADJUSTING AND OPERATIONAL TEST OF THE BRALE

- 5.2.5. REMOVAL AND DISASSEMBLY

- 5.2.6. INSPECTION AND REPAIR

- 5.2.7. REASSEMBLY AND INSTALLATION

- 5.3. SERVICE BRAKE WARNING LIGHT E AND SWITCHES

- 5.3.1. DESCRIPTION

- 5.4. COOLING BRAKE LOW PRESSURE SWITCH AND BRAKE SYSTEM OIL FILTER WARNING LIGHT SWITCH

- 5.4.1. DESCRIPTION

- 5.5. BRAKE PUMP

- 5.5.1. DESCRIPTION

- 5.5.2. REMOVAL

- 5.5.3. DISASSEMBLY

- 5.5.4. INSPECTION AND REPAIR

- 5.5.5. REASSEMBLY

- 5.5.6. INSTALLATION

- 5.6. BRAKE COOLING PUMP

- 5.7. BRAKE ACCUMULATOR

- 5.7.1. CHECK THE ACCUMULATOR CONDITION

- 5.7.2. CHECKING NITROGEN CHARGE IN ACCUMULATOR

- 5.7.3. CHARGING ACCUMULATOR WITH NITROGEN

- 5.8. CHECK PERFORMANCE OF MAIN BRAKES

- 5.8.1. CHECK THE BRAKES EFFECTIVENESS

- 6. STEERING

- 6.1. GENERAL

- 6.1.1. SPECIFICATIONS

- 6.1.2. SERVICE DIAGNOSIS

- 6.1.3. LINKAGE ADJUSTMENT

- 6.2. STEERING COLUMN

- 6.2.1. DESCRIPTION AND OPERATION

- 6.2.2. SPECIFICATIONS

- 6.2.3. REMOVAL

- 6.2.4. DISASSEMBLY

- 6.2.5. INSPECTION AND REPAIR

- 6.2.6. REASSEMBLY

- 6.2.7. INSTALLATION

- 6.3. STEERING GEAR

- 6.3.1. DESCRIPTION

- 6.3.2. THEORY OF OPERATION

- 6.3.3. SPECIFICATIONS

- 6.3.4. WORM BEARING PRELOAD ADJUSTMENT

- 6.3.5. PITMAN SHAFT PRELOAD ADJUSTMENT

- 6.3.6. REMOVAL

- 6.3.7. DISASSEMBLY

- 6.3.8. INSPECTION AND REPAIR

- 6.3.9. REASSEMBLY

- 6.3.10. INSTALLATION

- 7. COOLING

- 7.1. GENERAL

- 7.1.1. DESCRIPTION

- 7.1.2. OPERATION

- 7.1.3. SPECIFICATIONS

- 7.1.4. SERVICE DIAGNOSIS

- 7.2. STEERING OIL COOLER

- 7.2.1. REMOVAL

- 7.2.2. INSTALLATION

- 7.3. RADIATOR

- 7.3.1. REMOVAL

- 7.3.2. DISASSEMBLY

- 7.3.3. INSPECTION AND REPAIR

- 7.3.4. REASSEMBLY AND INSTALLATION

- 7.4. TRANSMISSION OIL COOLER

- 7.4.1. REMOVAL

- 7.4.2. INSTALLATION

- 8. DRIVE TRAIN

- 8.1. DESCRIPTION

- 8.2. HYDRAULIC OIL FLOW

- 8.3. SPECIFICATIONS

- 8.4. SERVICE DIAGNOSIS

- 8.5. CHECKING THE CHARGING PUMP FLOW RATE

- 8.6. CHECKING TRANSMISSION AND TORQUE CONVERTER PRESSURES

- 8.7. TORQUE CONVERTER

- 8.7.1. GENERAL

- 8.7.2. TORQUE CONVERTER

- 8.7.3. CHARGING PUMP

- 8.8. TRANSMISSION

- 8.8.1. GENERAL

- 8.8.2. TRANSMISSION

- 8.8.3. CLUTCH PACKS

- 8.8.4. CONTROL VALVE

- 8.9. DRIVE AXLE AND DIFFERENTIAL

- 8.9.1. GENERAL

- 8.9.2. DRIVE SHAFTS

- 8.9.3. TRANSFER DRIVE

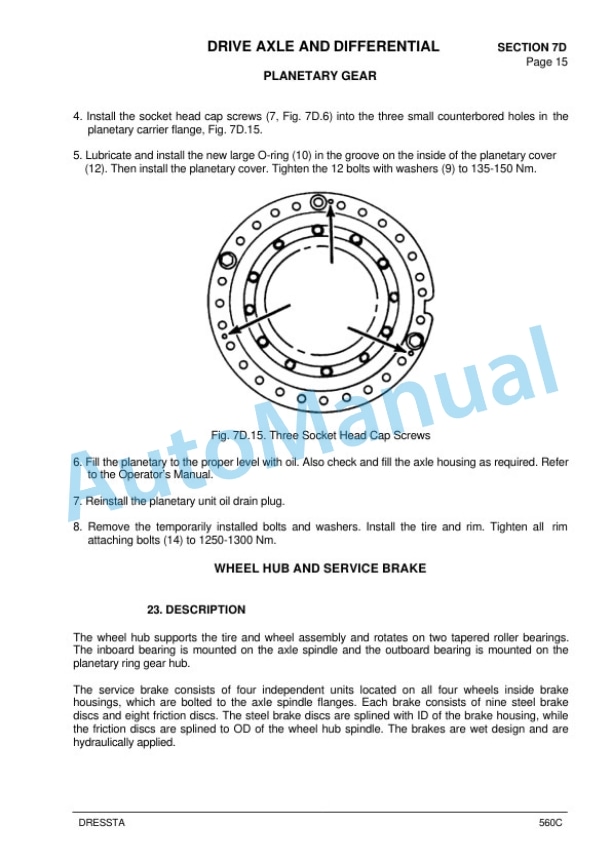

- 8.9.4. PLANETARY GEAR

- 8.9.5. WHEEL HUB AND SERVICE BRAKES

- 8.9.6. DIFFERENTIAL

- 8.9.7. DRIVE AXLE

- 9. ELECTRICAL

- 9.1. GENERAL

- 9.1.1. DESCRIPTION

- 9.2. WIRING DIAGRAM

- 9.2.1. ELECTRICAL LOADER SYSTEM

- 9.2.2. SERVICE DIAGNOSIS

- 9.3. ALTERNATOR

- 9.3.1. SPECIFICATION

- 9.3.2. INTRODUCTION

- 9.3.3. OPERATING PRINCIPLES

- 9.3.4. TROUBLESHOOTING PROCEDURES

- 9.3.5. INTEGRAL CHARGING SYSTEM REPAIR

- 9.4. BATTERY

- 9.4.1. SAFETY PRECAUTIONS

- 9.4.2. ELECTROLYTE STATE OF CHARGE

- 9.4.3. ELECTROLYTE IN TROPICAL AND ARCTIC CLIMATES

- 9.4.4. TESTING AND MAINTENANCE OF THE BATTERY

- 9.4.5. BATTERY CHARGING GUIDE

- 9.4.6. BATTERY STORAGE

- 9.4.7. BATTERY PRIMARY RATINGS

- 9.4.8. COLD ENGINE CRANKING PERFORMANCE

- 9.4.9. DRY CHARGE ACTIVATION

- 9.4.10. TYPICAL CAUSE OF BATTERY FAILURE

- 9.4.11. VISUAL INSPECTION OF BATTERY

- 9.5. CRANKING MOTOR

- 9.5.1. SPECIFICATION

- 9.5.2. INTRODUCTION

- 9.5.3. OPERATION

- 9.5.4. TROUBLESHOOTING THE CRANKING CIRCUIT

- 10. FRAME

- 10.1. DESCRIPTION AND OPERATION

- 10.2. SPECIFICATIONS

- 10.3. MAINTENANCE

- 10.4. WELDING

- 10.5. CHECKING HINGE VERTICAL MOVEMENT

- 10.6. DISASSEMBLY

- 10.7. INSPECTION AND REPAIR

- 10.8. REASSEMBLY

- 11. HYDRAULIC

- 11.1. GENERAL

- 11.1.1. DESCRIPTION

- 11.1.2. THEORY OF OPERATION

- 11.1.3. SPECIFICATIONS

- 11.1.4. SERVICE DIAGNOSIS

- 11.2. TEST AND ADJUSTMENT

- 11.2.1. STEERING SYSTEM PERFORMANCE TEST

- 11.2.2. HYDRAULIC SYSTEM PERFORMANCE TEST

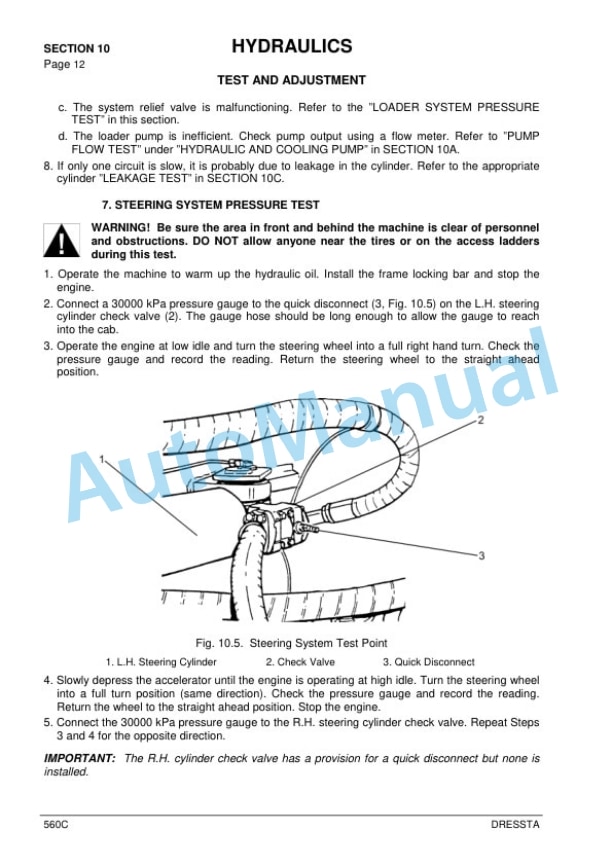

- 11.2.3. STEERING SYSTEM PRESSURE TEST

- 11.2.4. HYDRAULIC SYSTEM PRESSURE TEST

- 11.2.5. SUCTION LINE LEAKAGE TEST

- 11.2.6. HYDRAULIC CONTROL LEVER LEAKAGE ADJUSTMENT

- 11.3. PUMPS

- 11.3.1. STEERING/SWITCH PUMP

- 11.3.2. HYDRAULIC AND BRAKE COOLING PUMP

- 11.3.3. GROUND DRIVEN STEERING PUMP (IF EQUIPPED)

- 11.4. VALVES

- 11.4.1. STEERING VALVE

- 11.4.2. PILOT CONTROL VALVE

- 11.4.3. HYDRAULIC CONTROL VALVE

- 11.4.4. STEERING CYLINDER CHECK VALVES

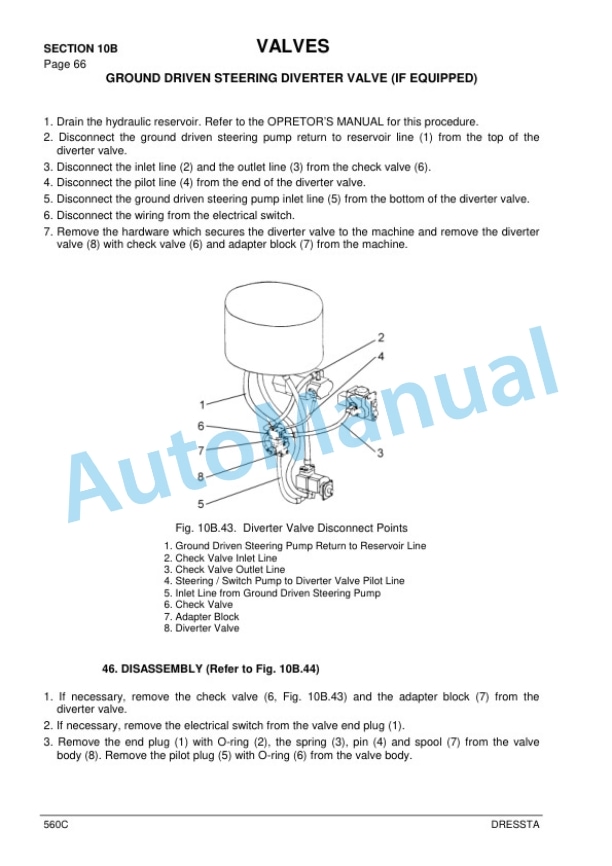

- 11.4.5. GROUND DRIVEN STEERING DIVERTER VALVE (IF EQUIPPED)

- 11.4.6. GROUND DRIVEN STEERING CHECK VALVE

- 11.4.7. STEERING RETURN SURGE VALVE

- 11.5. CYLINDERS

- 11.5.1. BUCKET CYLINDER

- 11.5.2. BOOM CYLINDERS

- 11.5.3. STEERING CYLINDERS

- 11.6. RESERVOIRS AND FILTER

- 11.6.1. DESCRIPTION

- 11.6.2. OPERATION

- 11.6.3. SPECIFICATION

- 11.6.4. LOADER RETURN SURGE VALVE TEST

- 11.6.5. REMOVAL

- 11.6.6. DISASSEMBLY

- 11.6.7. INSPECTION AND REPAIR

- 11.6.8. REASSEMBLY

- 11.6.9. INSTALLATION

- 12. POWER

- 12.1. DESCRIPTION

- 12.2. SPECIFICATIONS

- 12.3. SERVICE DIAGNOSIS

- 12.4. AIR INTAKE SYSTEM TEST

- 12.5. ENGINE CONTROLS ADJUSTMENT

- 12.6. REMOVAL

- 12.7. ENGINE REPAIR

- 12.8. ENGINE INSTALLATION

- 13. SUPERSTRUCTURE

- 13.1. GENERAL

- 13.1.1. SPECIFICATIONS

- 13.2. CAB WINDOW GLASS

- 13.2.1. REPLACEMENT

- 13.3.1. REMOVAL

- 13.3.2. INSTALLATION

- 14. SUSPENSION

- 14.1. DESCRIPTION

- 14.2. SPECIFICATION

- 14.3. REMOVAL

- 14.4. BOLSTER REPAIR

- 14.5. INSTALLATION

- 15. WHEELS AND TRACKS

- 15.1. DESCRIPTION

- 15.2. OPERATION

- 15.3. WHEEL REMOVAL

- 15.4. WHEEL DISASSEMBLY AND ASSEMBLY

- 15.5. WHEEL INSTALLING

- 16. MOUNTED EQUIPMENT

- 16.1. GENERAL

- 16.1.1. SAFETY PRECAUTIONS

- 16.1.2. DESCRIPTION AND OPERATION

- 16.2. LOADER LINKAGE PIVOTS

- 16.2.1. SPECIFICATIONS

- 16.2.2. REMOVAL AND DISASSEMBLY

- 16.2.3. REASSEMBLY AND INSTALLATION

- 16.3. BUCKET

- 16.3.1. SPECIFICATIONS

- 16.3.2. REMOVAL

- 16.3.3. INSTALLATION

- 16.3.4. CUTTING EDGE REPLACEMENT

- 16.3.5. TOOTH AND ADAPTOR INSTALLATION

Rate this product

You may also like

Komatsu Service Manual PDF

Komatsu ASX Stand-up Counterbalanced Electric Forklift Truck Service Manual SM401

$30.00

Komatsu Service Manual PDF

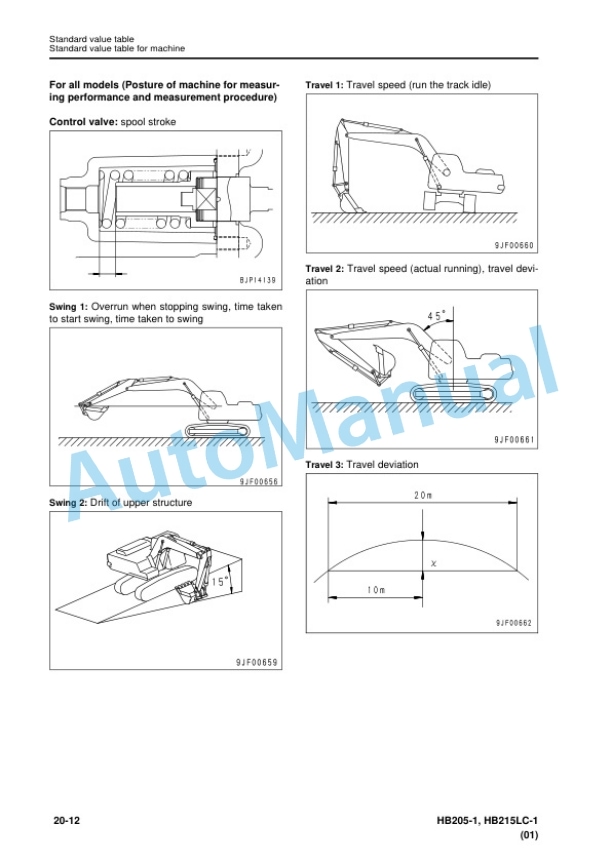

Komatsu HB205-1, HB215LC-1 Hydraulic Excavator Service Manual SEN05393-10

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu 4TNE94.98.106T Diesel Engine Service Manual HINSHI-H8013-R1

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00