Komatsu 6D125 Series Diesel Engine Shop Manual SEBE61500111

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBE61500111

- Format: PDF

- Size: 17.7MB

- Number of Pages: 404

Category: Komatsu Shop Manual PDF

-

Model List:

- 6D125 Series Diesel Engine

- 0.1. GENERAL ASSEMBLY DRAWING

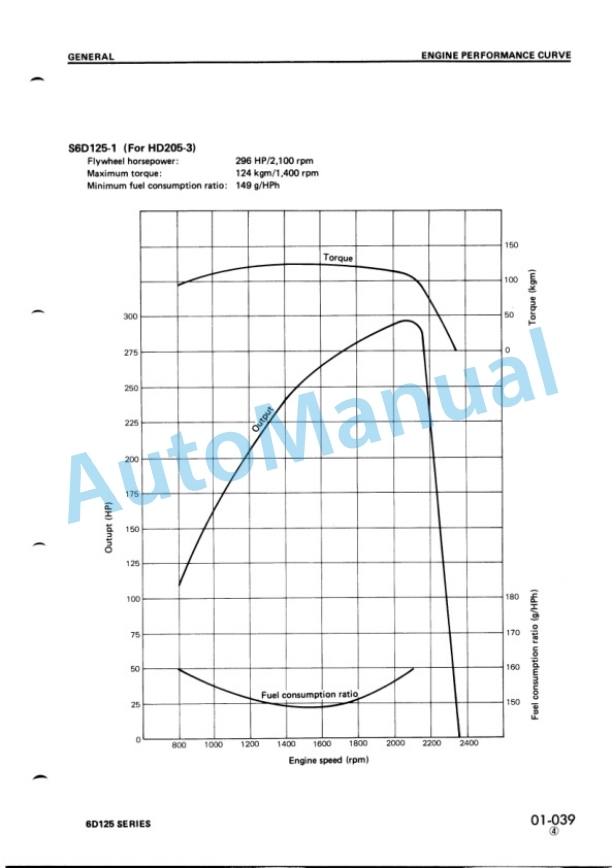

- 0.2. ENGINE PERFORMANCE CURVE

- 0.3. WEIGHT TABLE

- 1. STRUCTURE AND FUNCTION

- 1.1. GENERAL STRUCTURE

- 1.2. INTAKE AND EXHAUST SYSTEM

- 1.2.1. INTAKE AND EXHAUST SYSTEM

- 1.2.2. MAIN CIRCULATION PART

- 1.2.3. TIMING GEAR

- 1.2.4. FLYWHEEL AND FLYWHEEL HOUSING

- 1.3. LUBRICATION SYSTEM

- 1.3.1. LUBRICATION SYSTEM CHART

- 1.3.2. OIL PUMP

- 1.3.3. REGULATOR VALVE

- 1.3.4. OIL FILTER

- 1.3.5. OIL COOLER

- 1.4. FUEL SYSTEM

- 1.4.1. FUEL SYSTEM CHART

- 1.4.2. FUEL INJECTION PUMP

- 1.4.3. FUEL INJECTION NOZZLE

- 1.4.4. FUEL FILTER

- 1.4.5. MAGNETIC SWITCH (FUEL CUT SOLENOID)

- 1.5. COOLING SYSTEM

- 1.5.1. COOLING SYSTEM CHART

- 1.5.2. WATER PUMP

- 1.5.3. THERMOSTAT

- 1.5.4. CORROSION RESISTOR

- 1.6. ELECTRICAL SYSTEM

- 1.6.1. ALTERNATOR

- 1.6.2. STARTING MOTOR

- 1.6.3. ELECTRICAL INTAKE AIR HEATER

- 1.7. ACCESSORY

- 1.7.1. AIR COMPRESSOR

- 1.7.2. EXHAUST BRAKE

- 2. TESTING AND ADJUSTING

- 2.1. ENGINE BODY

- 2.1.1. ADJUSTING VALVE CLEARANCE

- 2.1.2. MEASURING COMPRESSION PRESSURE

- 2.2. FUEL SYSTEM

- 2.2.1. CHECKING AND ADJUSTING FUEL INJECTOIN TIMING

- 2.2.2. TESTING AND ADJUSTING FUEL CUT SOLENOID

- 2.2.3. ADJUSTING ENGINE STOP MOTOR CABLE

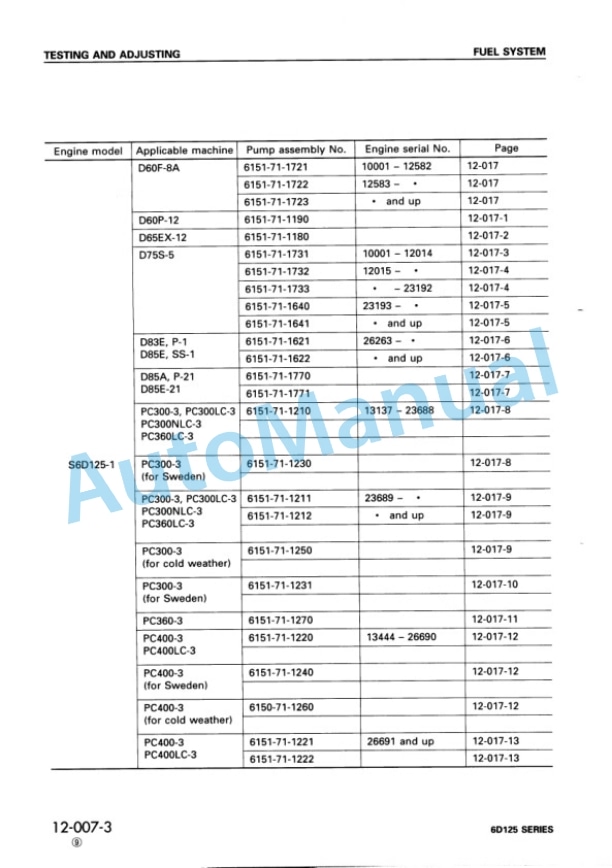

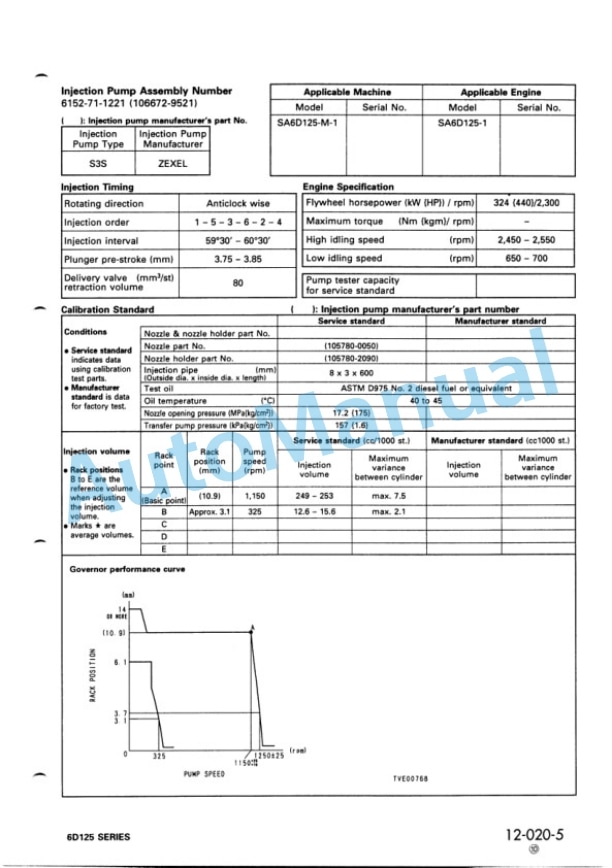

- 2.2.4. FUEL INJECTION PUMP CALIBRATION DATA

- 2.3. PERFORMANCE TEST

- 2.3.1. RUNIN STANDARD

- 2.3.2. PERFORMANCE TEST CRITERIA

- 2.3.3. TESTING AND ADJUSTING TOOL LIST

- 2.3.4. TESTING AND ADJUSTING DATA

- 2.4. TROUBLESHOOTING

- 2.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.4.2. METHOD OF USING TROUBLESHOOTING CHART

- 2.4.3. S1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)

- 2.4.4. S2 ENGINE DOES NOT START

- 2.4.4.1. ENGINE DOES NOT TURN

- 2.4.4.2. ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)

- 2.4.4.3. EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)

- 2.4.5. S3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOWUP IS POOR)

- 2.4.6. S4 ENGINE STOPS DURING OPERATIONS

- 2.4.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY

- 2.4.8. S6 ENGINE LACKS OUTPUT (NO POWER)

- 2.4.9. S7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)

- 2.4.10. S8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)

- 2.4.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 2.4.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 2.4.13. S11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN

- 2.4.14. S12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)

- 2.4.15. 13 OIL LEVEL RISES

- 2.4.16. S14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)

- 2.4.17. S15 ABNORMAL NOISE IS MADE

- 2.4.18. S16 VIBRATION IS EXCESSIVE

- 3. DISASSEMBLY AND ASSEMBLY

- 3.0.1. DISASSEMBLY AND ASSEMBLY

- 4. MAINTENANCE STANDARD

- 4.1. TURBOCHARGER

- 4.2. CYLINDER HEAD

- 4.3. VALVE AND VALVE GUIDE

- 4.4. ROCKER ARM SHAFT

- 4.5. CAM FOLLOWER AND PUSH ROD

- 4.6. PISTON, PISTON RING AND PISTON PIN

- 4.7. CONNECTING ROD

- 4.8. TIMING GEAR

- 4.9. FLYWHEEL AND FLYWHEEL HOUSING

- 4.10. VIBRATION DAMPER

- 4.11. WATER PUMP AND THERMOSTAT

- 4.12. OIL COOLER

- 4.13. OIL PUMP

- 4.14. MAIN RELIEF VALVE

- 4.15. REGULATOR VALVE AND SAFETY VALVE

- 4.16. AIR COMPRESSOR

- 5. REPAIR AND REPLACEMENT OF PARTS

- 5.1. REPLACING VALVE SEAT INSERTS

- 5.2. REPLACING NOZZLE HOLDER SLEEVE

- 5.3. REPLACING VALVE GUIDE

- 5.4. REPLACING CROSS HEAD GUIDE

- 5.5. GRINDING THE VALVE

- 5.6. REPLACING CAM BUSHING

- 5.7. REPLACING FLYWHEEL RING GEAR

- 5.8. REPLACING CAM GEAR

- 5.9. PRESSURE TEST

Rate this product

You may also like