Komatsu 6D140-1 Series Diesel Engine Shop Manual SEBE62120112

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBE62120112

- Format: PDF

- Size: 26.0MB

- Number of Pages: 376

Category: Komatsu Shop Manual PDF

-

Model List:

- 6D140-1 Series Diesel Engine

- 0.1. SPECIFICATIONS

- 0.2. GENERAL ASSEMBLY DRAWING

- 0.3. ENGINE PERFORMANCE CURVE

- 0.4. WEIGHT TABLE

- 1. STRUCTURE AND FUNCTION

- 1.1. GENERAL STRUCTURE

- 1.2. INTAKE AND EXHAUST SYSTEM

- 1.2.1. INTAKE AND EXHAUST SYSTEM

- 1.2.2. CYLINDER BLOCK

- 1.2.3. MAIN CIRCULATION SYSTEM

- 1.2.4. TIMING GEAR

- 1.2.5. FLYWHEEL AND FLYWHEEL HOUSING

- 1.3. LUBRICATION SYSTEM

- 1.3.1. LUBRICATION SYSTEM CHART

- 1.3.2. OIL PUMP

- 1.3.3. REGULATOR VALVE AND PISTON COOLING VALVE

- 1.3.4. OIL FILTER

- 1.3.5. OIL COOLER

- 1.4. FUEL SYSTEM

- 1.4.1. FUEL SYSTEM CHART

- 1.4.2. FUEL INJECTION PUMP

- 1.4.3. FUEL INJECTION NOZZLE

- 1.4.4. BOOST COMPENSATOR DEVICE

- 1.4.5. FUEL FILTER

- 1.4.6. FUEL SOLENOID

- 1.4.7. ENGINE STOP MOTOR

- 1.5. COOLING SYSTEM

- 1.5.1. COOLING SYSTEM CHART

- 1.5.2. WATER PUMP

- 1.5.3. THERMOSTAT

- 1.5.4. CORROSION RESISTOR

- 1.6. ELECTRICAL SYSTEM

- 1.6.1. ALTERNATOR MOUNTING

- 1.6.2. ALTERNATOR

- 1.6.3. STARTING MOTOR

- 1.6.4. ELECTRICAL INTAKE AIR HEATER

- 1.7. ACCESSORY

- 1.7.1. AIR COMPRESSOR

- 1.7.2. EXHAUST BRAKE

- 1.7.3. EXHAUST BRAKE BUTTERFLY VALVE

- 2. TESTING AND ADJUSTING

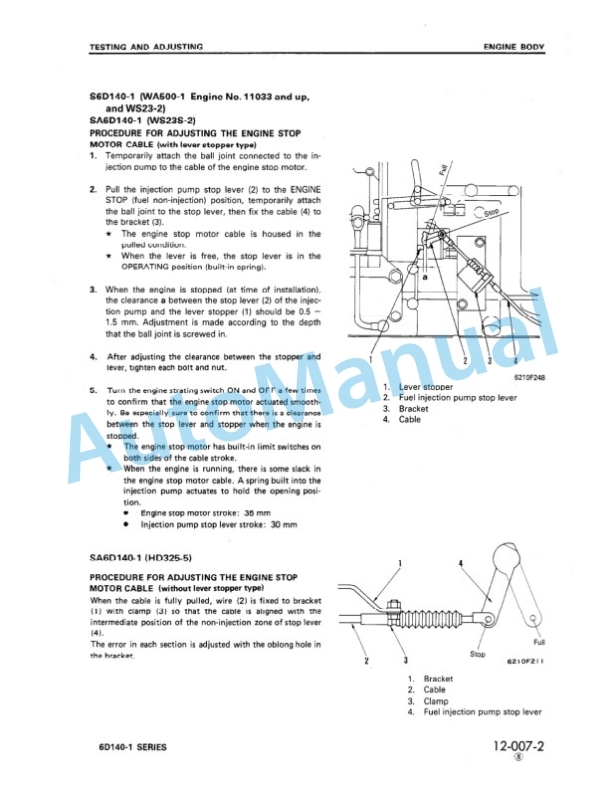

- 2.1. ENGINE BODY

- 2.1.1. ADJUSTING VALVE CLEARANCE

- 2.1.2. MEASURING COMPRESSION PRESSURE

- 2.2. FUEL SYSTEM

- 2.2.1. CHECKING AND ADJUSTING FUEL INJECTION TIMING

- 2.2.2. ADJUSTING FUEL INJECTION PRESSURE

- 2.2.3. ADJUSTING FUEL CUT SOLENOID

- 2.3. COOLING SYSTEM

- 2.3.1. CHECKING AND ADJUSTING VBELT TENSION

- 2.4. FUEL INJECTION PUMP CALIBRATION DATA

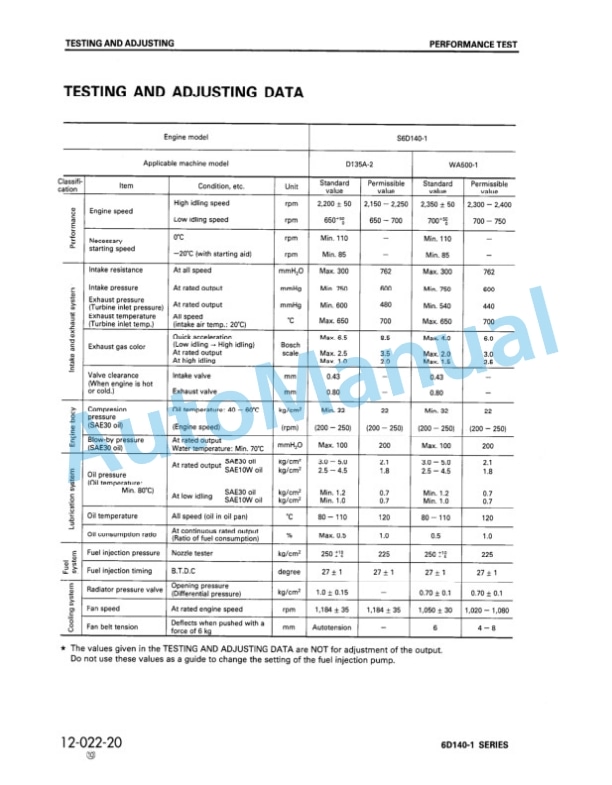

- 2.5. PERFORMANCE TEST

- 2.5.1. RUNIN STANDARD

- 2.5.2. PERFORMANCE TEST CRITERIA

- 2.5.3. TESTING AND ADJUSTING TOOL LIST

- 2.5.4. TESTING AND ADJUSTING DATA

- 2.6. TROUBLESHOOTING

- 2.6.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.6.2. METHOD OF USING TROUBLESHOOTING CHART

- 2.6.3. TROUBLESHOOTING TABLE

- 2.6.4. S1 Starting performance is poor (Starting always takes time)

- 2.6.5. S2 Engine does not start

- 2.6.5.1. Engine does not turn

- 2.6.5.2. Engine turns but no exhaust gas comes out (Fuel is not being injected)

- 2.6.5.3. Exhaust gas comes out but engine does not start (Fuel is being injected)

- 2.6.6. S3 Engine does not pick up smoothly (Followup is poor)

- 2.6.7. S4 Engine stops during operations

- 2.6.8. S5 Engine does not rotate smoothly (hunting)

- 2.6.9. S6 Engine lacks output (no power)

- 2.6.10. S7 Exhaust gas is black (incomplete combustion)

- 2.6.11. S8 Oil consumption is excessive (or exhaust gas is blue)

- 2.6.12. S9 Oil becomes contaminated quickly

- 2.6.13. S10 Fuel consumption is excessive

- 2.6.14. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 2.6.15. S12 Oil pressure lamp lights up (drop in oil pressure)

- 2.6.16. S13 Oil level rises

- 2.6.17. S14 Water temperature becomes too high (overheating)

- 2.6.18. S15 Abnormal noise is made

- 2.6.19. S16 Vibration is excessive

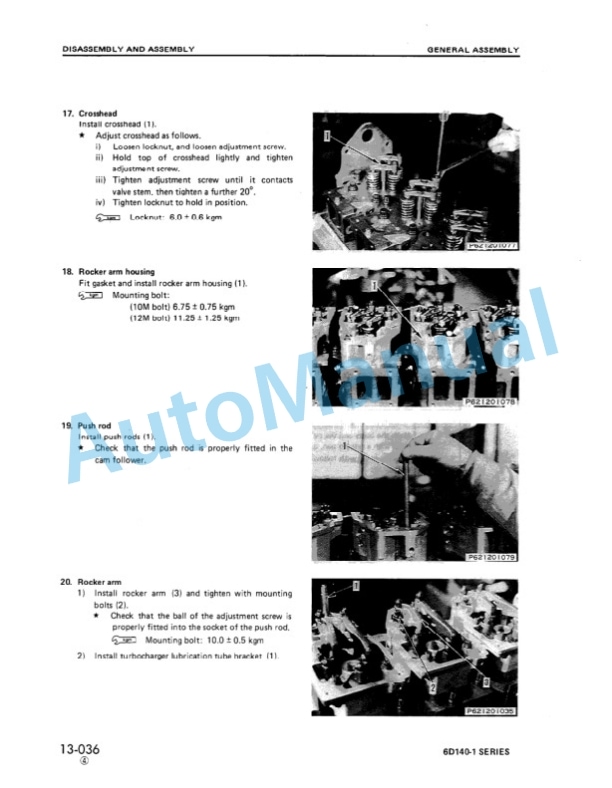

- 3. DISASSEMBLY AND ASSEMBLY

- 3.0.1. DISASSEMBLY AND ASSEMBLY

- 4. MAINTENANCE STANDARD

- 4.1. INTAKE AND EXHAUST SYSTEM

- 4.1.1. TURBOCHARGER

- 4.2. ENGINE BODY

- 4.2.1. CYLINDER HEAD

- 4.2.2. VALVE, VALVE SPRING AND VALVE GUIDE

- 4.2.3. ROCKER ARM AND SHAFT

- 4.2.4. CROSSHEAD AND GUIDE

- 4.2.5. CYLINDER BLOCK

- 4.2.6. CYLINDER LINER

- 4.2.7. CRANKSHAFT

- 4.2.8. CAMSHAFT

- 4.2.9. CAM FOLLOWER AND PUSH ROD

- 4.2.10. CONNECTING ROD

- 4.2.11. PISTON, PISTON RING AND PISTON PIN

- 4.2.12. TIMING GEAR

- 4.2.13. FLYWHEEL AND FLYWHEEL HOUSING

- 4.3. LUBRICATION SYSTEM

- 4.3.1. OIL PUMP AND MAIN RELIEF VALVE

- 4.3.2. REGULATOR VALVE AND SAFETY VALVE

- 4.3.3. OIL COOLER

- 4.4. COOLING SYSTEM

- 4.4.1. WATER PUMP

- 4.4.2. THERMOSTAT

- 5. REPAIR AND REPLACEMENT OF PARTS

- 5.1. CYLINDER HEAD

- 5.1.1. GRINDING CYLINDER HEAD MOUNTING FACE

- 5.1.2. REPLACING VALVE SEAT INSERT

- 5.1.3. REPLACING CROSSHEAD GUIDE

- 5.1.4. REPLACING VALVE GUIDE

- 5.1.5. GRINDING VALVE

- 5.1.6. PRESSURE TEST

- 5.2. CYLINDER BLOCK

- 5.2.1. REPLACING CAM BUSHING

- 5.2.2. REPLACING CRANKSHAFT GEAR

- 5.2.3. REPLACING CAM GEAR

- 5.2.4. REPLACING FLYWHEEL RING GEAR

- 5.2.5. REPLACING CONNECTING ROD SMALL BUSHING

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00