Komatsu 730E Dump Truck Shop Manual DG708

$40.00

- Type Of Manual: Shop Manual

- Manual ID: DG708

- Format: PDF

- Size: 13.7MB

- Number of Pages: 862

Category: Komatsu Shop Manual PDF

-

Model List:

- 730E Dump Truck

- 1. COVER

- 2. FOREWARD

- 3. CONTENTS

- 3.1. GENERAL INFORMATION

- 3.1.1. CHARTS AND TABLES

- 3.1.2. STORAGE PROCEDURES

- 3.2. STRUCTURES

- 3.2.1. STRUCTURAL COMPONENTS

- 3.2.1.1. GRILLE AND HOOD

- 3.2.1.2. LADDERS

- 3.2.1.3. DECKS

- 3.2.1.4. BODY POSITION INDICATOR

- 3.2.1.5. ROCK EJECTORS

- 3.2.1.6. HOIST LIMIT SWITCHES

- 3.2.1.7. FUEL GAUGE SENDER

- 3.3. ENGINE, FUEL, COOLING, AND AIR CLEANER

- 3.3.1. POWER TRAIN

- 3.3.1.1. ALTERNATOR REMOVAL AND INSTALLATION PROCEDURE

- 3.3.1.2. ENGINE / ALTERNATOR MATING

- 3.3.1.3. ENGINE

- 3.3.2. AIR CLEANERS

- 3.3.2.1. FILTER ELEMENT REPLACEMENT

- 3.3.2.2. MAIN FILTER ELEMENT CLEANING

- 3.3.2.3. PRECLEANER SECTION

- 3.4. ELECTRIC PROPULSION AND CONTROL

- 3.4.1. E02011C1.pdf

- 3.4.1.1. ELECTRICAL PROPULSION COMPONENTS

- 3.4.1.2. PORTABLE TEST UNIT (PTU)

- 3.4.2. E02011C2.pdf

- 3.4.2.1. MISCELLANEOUS ELECTRICAL PROPULSION COMPONENTS

- 3.4.2.2. ELECTRICAL CONTROL CABINET

- 3.4.2.3. ABBREVIATIONS FOR STATEX III ELECTRIC DRIVE COMPONENTS

- 3.4.2.4. CARD IDENTIFICATION LIST GE17FL275 PANEL, STATEX III

- 3.4.2.5. DETROIT DIESEL ELECTRONIC ENGINE CONTROLS ABBREVIATIONS

- 3.4.3. ELECTRICAL CHECKOUT PROCEDURE

- 3.5. DRIVE AXLE, SPINDLES AND WHEELS

- 3.5.1. TIRES AND RIMS (G02012)

- 3.5.1.1. FRONT TIRES AND RIMS

- 3.5.1.2. REAR TIRES AND RIMS

- 3.5.2. FRONT WHEEL HUB AND SPINDLE ASSEMBLY (G03012)

- 3.5.2.1. WHEEL HUB AND SPINDLE ASSEMBLY

- 3.5.2.2. STEERING CYLINDERS AND TIE ROD

- 3.5.2.3. TOEIN ADJUSTMENT

- 3.5.3. REAR AXLE HOUSING ATTACHMENT (G04010)

- 3.5.4. REAR AXLE HOUSING (G05004)

- 3.5.4.1. REAR AXLE HOUSING

- 3.5.4.2. WHEEL MOTOR

- 3.6. BRAKE CIRCUIT

- 3.6.1. BRAKE CIRCUIT

- 3.6.1.1. SERVICE BRAKE CIRCUIT OPERATION

- 3.6.1.2. SECONDARY BRAKING AND AUTOMATIC APPLY

- 3.6.1.3. PARKING BRAKE CIRCUIT

- 3.6.1.4. BRAKE LOCK CIRCUIT

- 3.6.1.5. WARNING CIRCUIT

- 3.6.1.6. BRAKE VALVE CUTAWAY

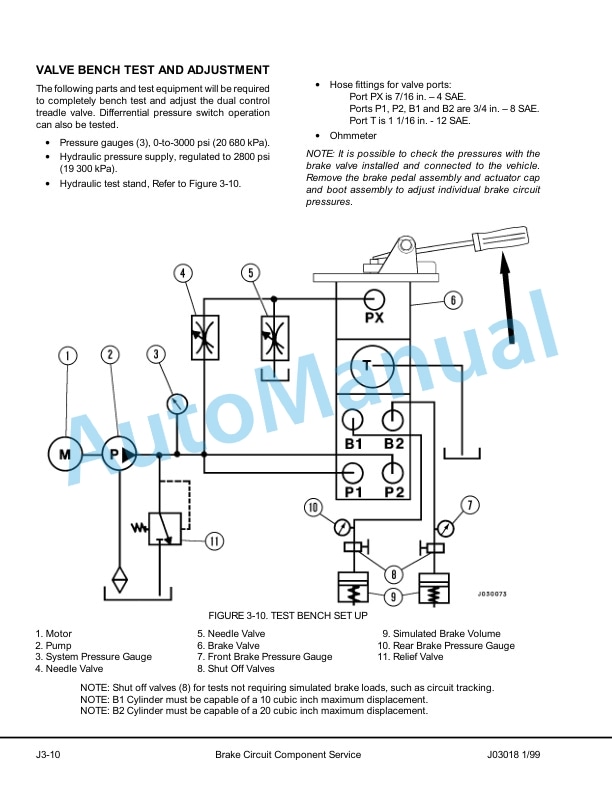

- 3.6.2. BRAKE CIRCUIT COMPONENT SERVICE

- 3.6.2.1. BRAKE VALVE

- 3.6.2.2. HYDRAULIC BRAKE ACCUMULATORS

- 3.6.3. BRAKE CIRCUIT CHECKOUT PROCEDURE

- 3.6.4. BRAKE CIRCUIT AND BRAKE VALVE TROUBLESHOOTING

- 3.6.5. HYDRAULIC BRAKE SYSTEM CHECKOUT PROCEDURE DATA SHEET

- 3.6.6. FRONT BRAKES (ROCKWELL)

- 3.6.6.1. BRAKE CALIPER

- 3.6.6.2. BRAKE LINING

- 3.6.6.3. BRAKE PAD CONDITIONING (BURNISHING) PROCEDURE

- 3.6.6.4. TEMPORARY BRAKE DISCONNECT (DISABLE) PROCEDURE

- 3.6.6.5. BRAKE BLEEDING PROCEDURE

- 3.6.7. REAR BRAKES (ROCKWELL)

- 3.6.7.1. BRAKE CALIPER, DISC AND PARKING BRAKE

- 3.6.7.2. CALIPER PISTON ASSEMBLY

- 3.6.7.3. BENCH TEST

- 3.6.7.4. BRAKE LINING

- 3.6.7.5. BRAKE PAD CONDITIONING (BURNISHNG) PROCEDURE

- 3.6.7.6. BRAKE BLEEDING PROCEDURE

- 3.6.8. PARKING BRAKE (ROCKWELL)

- 3.6.8.1. CALIPER STYLE IDENTIFICATION (SCL15 VS. SCL70)

- 3.6.9. PARKING BRAKE ADJUSTMENT (SCL 15)

- 3.6.9.1. PARK BRAKE CALIPER DISASSEMBLY

- 3.6.9.2. CLEANING AN INSPECTION

- 3.6.9.3. PARK BRAKE CALIPER ASSEMBLY

- 3.6.10. PARK BRAKE LINING

- 3.6.10.1. REPLACEMENT

- 3.6.10.2. CONDITIONING (BURNISHING PROCEDURE)

- 3.6.11. BRAKE BLEEDING PROCEDURE

- 3.7. OPTIONS AND SPECIAL TOOLS

- 3.7.1. FIRE CONTROL SYSTEMS

- 3.7.1.1. ANSUL FIRE CONTROL PNEUMATIC SYSTEM

- 3.7.1.2. ANSUL FIRE CONTROL ELECTRIC SYSTEM

- 3.7.1.3. ANSUL FIRE CONTROL SYSTEM MANUAL

- 3.7.2. ALTERNATOR AND WHEEL MOTOR COOLING AIR FILTER SYSTEM

- 3.7.2.1. SYSTEM ADJUSTMENT

- 3.7.2.2. PUMP

- 3.7.2.3. BLOWER DRIVE MOTOR

- 3.7.2.4. BLOWER BEARING REPAIR

- 3.7.2.5. AIR CLEANER

- 3.7.3. WIGGINS QUICK FILL FUEL SYSTEM

- 3.7.3.1. TANK BREATHER VALVE

- 3.7.3.2. FUEL RECEIVER

- 3.7.4. FAN DRIVE CLUTCH HYDRAULIC ACTUATED

- 3.7.4.1. GENERAL DESCRIPTION

- 3.7.4.2. MAINTENANCE

- 3.7.4.3. TROUBLESHOOTING

- 3.7.4.4. FIELD CHECK DIAGNOSIS

- 3.7.4.5. TROUBLESHOOTING CHART

- 3.7.4.6. DISASSEMBLY

- 3.7.4.7. REASSEMBLY

- 3.7.4.8. INSPECTION OF PARTS

- 3.7.4.9. REBUILD TOOLS

- 3.7.5. ENGINE COOLANT HEATER SYSTEM HOT START 220 VOLT

- 3.7.5.1. HEATING ELEMENT

- 3.7.5.2. THERMOSTAT

- 3.7.6. ENGINE OIL HEATERS HOT START 220 VOLT

- 3.7.6.1. TROUBLESHOOTING

- 3.7.6.2. HEATING ELEMENT

- 3.7.7. ENGINE AND COOLANT HEATERS 440 VOLT

- 3.7.7.1. TROUBLESHOOTING

- 3.7.7.2. COOLANT HEATING ELEMENT

- 3.7.7.3. OIL HEATING ELEMENT

- 3.7.8. SPECIAL TOOL GROUP

- 3.7.9. HEATER / AIR CONDITIONING SYSTEM

- 3.7.9.1. ENVIRONMENTAL IMPACT

- 3.7.9.2. OPERATOR CAB CONDITIONING

- 3.7.9.3. PRINCIPLES OF REFRIGERATION

- 3.7.9.4. MAJOR SYSTEM COMPONENTS

- 3.7.9.5. SYSTEM SERVICING

- 3.7.9.6. EVACUATING THE SYSTEM

- 3.7.9.7. SYSTEM TROUBLESHOOTING

- 3.7.10. VDC ELECTRIC SUPPLY SYSTEM

- 3.7.10.1. ELECTRICAL SYSTEM DESCRIPTION

- 3.7.10.2. BATTERY MAINTENANCE AND SERVICE

- 3.7.10.3. BATTERY CHARGING SYSTEM

- 3.7.11. NIEHOFF 250 AMP ALTERNATOR OVERHAUL MANUAL

- 3.7.11.1. DIMENSIONS

- 3.7.11.2. SPECIFICATIONS

- 3.7.11.3. SERVICE PARTS LIST

- 3.7.11.4. EXPLODED VIEW

- 3.7.11.5. ON VEHICLE TEST

- 3.7.11.6. BENCH TEST

- 3.7.11.7. STATIC TESTS

- 3.7.11.8. ALTERNATOR DISASSEMBLY

- 3.7.11.9. ALTERNATOR ASSEMBLY

- 3.7.11.10. SERVICE TOOL INSTRUCTIONS

- 3.7.12. FUEL WATER SEPARATOR

- 3.7.12.1. INSTALLATION

- 3.7.12.2. OPERATION

- 3.7.12.3. FILTER SERVICE

- 3.7.13. PAYLOAD METER II OBWS

- 3.7.13.1. TABLE OF CONTENTS

- 3.8. OPERATORS CAB

- 3.8.0.1. GLASS REPLACEMENT

- 3.8.1. CAB COMPONENTS

- 3.8.1.1. WINDSHIELD WIPER

- 3.8.1.2. WINDSHIELD WASHER

- 3.8.2. OPERATOR COMFORT

- 3.8.2.1. OPERATOR SEAT

- 3.8.2.2. HEATER/AIR CONDITIONER

- 3.8.2.3. HEATER COMPONENTS

- 3.8.2.4. AIR CONDITIONER COMPONENTS

- 3.9. LUBRICATION AND SERVICE

- 3.9.1. LUBRICATION AND SERVICE

- 3.9.2. LINCOLN AUTOMATIC LUBRICATION SYSTEM

- 3.9.3. MOTORIZED WHEEL MAINTENANCE SCHEDULE

- 3.10. ALPHABETICAL INDEX

- 3.11. SYSTEM SCHEMATICS

Rate this product

You may also like