Komatsu 76E-5 Series Diesel Engine Shop Manual SEBM037700

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM037700

- Format: PDF

- Size: 37.1MB

- Number of Pages: 146

Category: Komatsu Shop Manual PDF

-

Model List:

- 76E-5 Series Diesel Engine

- 1. MAIN MENU

- 2. COVER

- 3. PREFACE

- 4. SAFETY LABELS

- 5. SAFETY PRECAUTIONS

- 6. PRECAUTIONS FOR SERVICE WORK

- 7. HOW TO READ THIS MANUAL

- 8. APPLICATION CATEGORY

- 9. APPLICABLE MACHINE, SERIAL NUMBER

- 10. CONTENTS

- 11. GENERAL

- 11.1. SPECIFICATIONS

- 11.2. ENGINE EXTERNAL VIEWS

- 11.3. STRUCTURAL DESCRIPTION

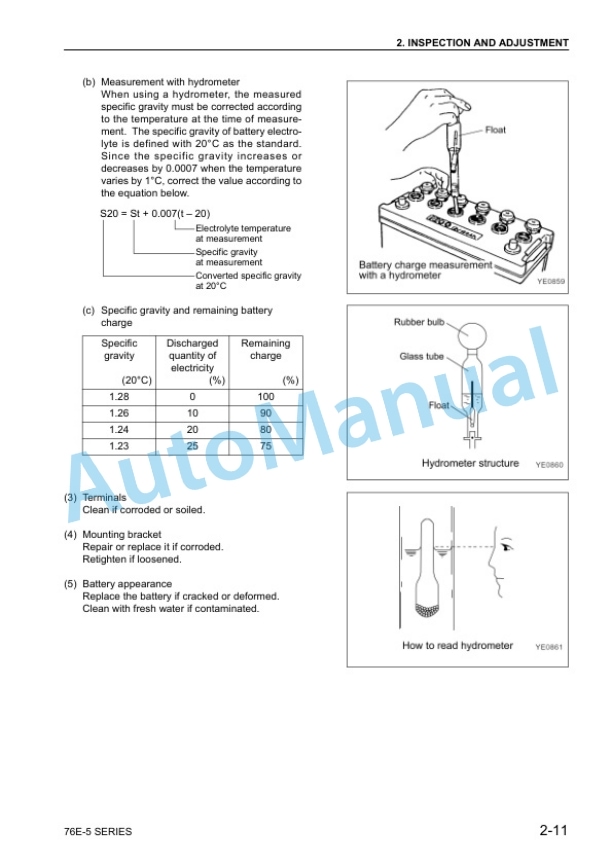

- 12. INSPECTION AND ADJUSTMENT

- 12.1. PERIODIC MAINTENANCE SCHEDULE

- 12.2. PERIODIC INSPECTION AND MAINTENANCE PROCEDURE

- 12.2.1. CHECK BEFORE DAILY OPERATION

- 12.2.2. INSPECTION AFTER INITIAL 50 HOURS OPERATION

- 12.2.3. INSPECTION EVERY 50 HOURS

- 12.2.4. INSPECTION EVERY 250 HOURS OR 3 MONTHS

- 12.2.5. INSPECTION EVERY 500 HOURS OR 6 MONTHS

- 12.2.6. INSPECTION EVERY 1000 HOURS OR ONE YEAR

- 12.2.7. INSPECTION EVERY 2000 HOURS OR 2 YEARS

- 12.3. ADJUSTING THE NOLOAD MAXIMUM OR MINIMUM SPEED

- 12.4. SENSOR INSPECTION

- 12.4.1. OIL PRESSURE SWITCH

- 12.4.2. THERMO SWITCH

- 12.5. WATER LEAK CHECK IN COOLING WATER SYSTEM

- 12.6. RADIATOR CAP INSPECTION

- 12.7. THERMOSTAT INSPECTION

- 12.8. ADJUSTING OPERATION

- 12.9. LONG STORAGE

- 13. TROUBLESHOOTING

- 13.1. PREPARATION BEFORE TROUBLSHOOTING

- 13.2. QUICK REFERENCE TABLE FOR TROUBLESHOOTING

- 13.3. TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

- 14. DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

- 14.1. COMPLETE DISASSEMBLY AND REASSEMBLY

- 14.1.1. INTRODUCTION

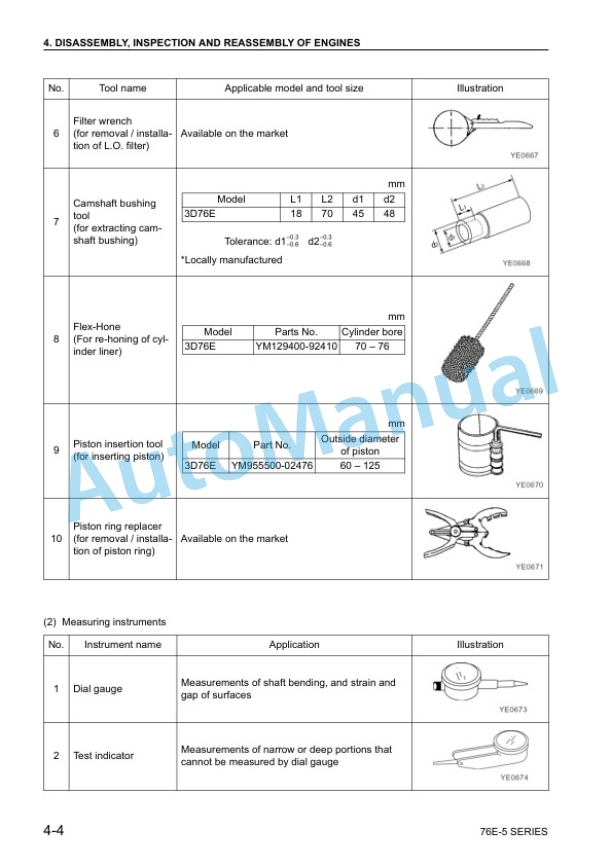

- 14.1.2. SPECIAL SERVICE TOOLS

- 14.1.3. COMPLETE DISASSEMBLY

- 14.1.4. PRECAUTIONS BEFORE AND DURING REASSEMBLY

- 14.1.5. ADJUSTING OPERATION

- 14.2. CYLINDER HEAD DISASSEMBLY, INSPECTION AND REASSEMBLY

- 14.2.1. COMPONENTS (2VALVE CYLINDER HEAD)

- 14.2.2. DISASSEMBLY PROCEDURE

- 14.2.3. REASSEMBLY PROCEDURE

- 14.2.4. SERVICING POINTS

- 14.2.5. PARTS INSPECTION AND MEASUREMENT

- 14.2.6. VALVE SEAT CORRECTION

- 14.2.7. VALVE GUIDE REPLACEMENT

- 14.2.8. VALVE STEM SEAL REPLACEMENT

- 14.3. GEAR TRAIN AND CAMSHAFT

- 14.3.1. COMPONENTS

- 14.3.2. DISASSEMBLY PROCEDURE

- 14.3.3. REASSEMBLY PROCEDURE

- 14.3.4. SERVICING POINTS

- 14.3.5. PARTS INSPECTION AND MEASUREMENT

- 14.3.6. OIL SEAL REPLACEMENT (GEAR CASE SIDE)

- 14.3.7. CAMSHAFT BUSHING REPLACEMENT

- 14.4. CYLINDER BLOCK

- 14.4.1. COMPONENTS

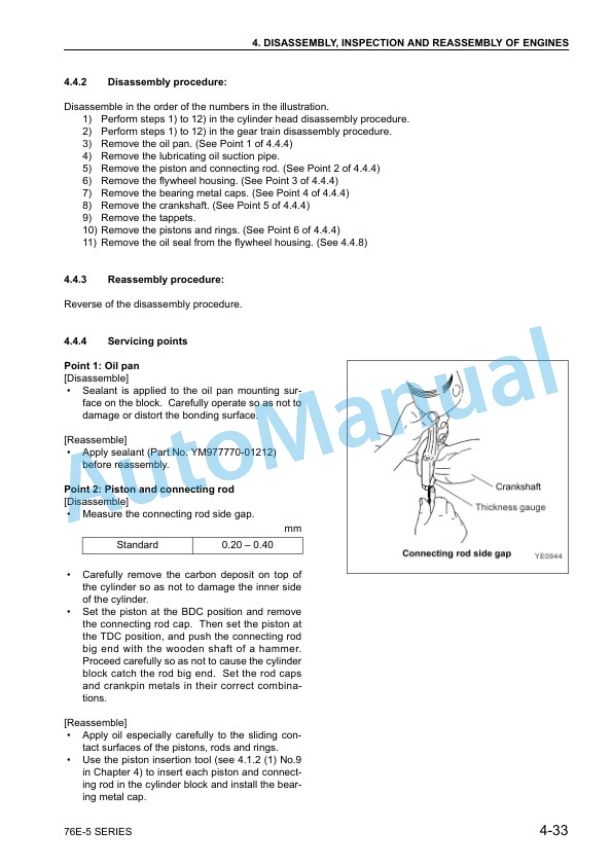

- 14.4.2. DISASSEMBLY PROCEDURE

- 14.4.3. REASSEMBLY PROCEDURE

- 14.4.4. SERVICING POINTS

- 14.4.5. PARTS INSPECTION AND MEASUREMENT

- 14.4.6. CYLINDER BORE CORRECTION

- 14.4.7. PISTION PIN METAL REPLACEMENT

- 14.4.8. OIL SEAL REPLACEMENT (FLYWHEEL HOUSING SIDE)

- 15. LUBRICATION SYSTEM

- 15.1. LUBRICATION SYSTEM DIAGRAM

- 15.2. TROCHOID PUMP COMPONENTS

- 15.3. DISASSEMBLY (REVERSE THE PROCEDURE BLEWO FOR ASSEMBLY)

- 15.4. SERVICING POINTS

- 15.5. PARTS INSPECTION AND MEASUREMENT

- 16. COOLING SYSTEM

- 16.1. COOLING WATER SYSTEM

- 16.2. COOLING WATER PUMP COMPONENTS

- 16.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 16.4. SERVICING POINTS

- 17. FUEL INJECTION PUMP/GOVERNOR

- 17.1. INTRODUCTION

- 17.2. FUEL INJECTION PUMP

- 17.2.1. FUEL SYSTEM DIAGRAM

- 17.2.2. EXTERNAL VIEW AND COMPONENTS

- 17.2.3. DISASSEMBLY PROCEDURE

- 17.2.4. ASSEMBLY PROCEDURE

- 17.2.5. CONFIRMATION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 17.2.6. CONFIRMATIONAND ADJUSTMENT OF NOLOAD MAXIMUM AND MINIMUM SPEED

- 18. THE SPECIFICATIONS OF A STARTING MOTOR AND THE CHARACTERISTICS

- 18.1. THE SPECIFICATIONS AND THE CHARACTERISTICS

- 18.1.1. SPECIFICATIONS

- 18.1.2. CHARACTERISTICS

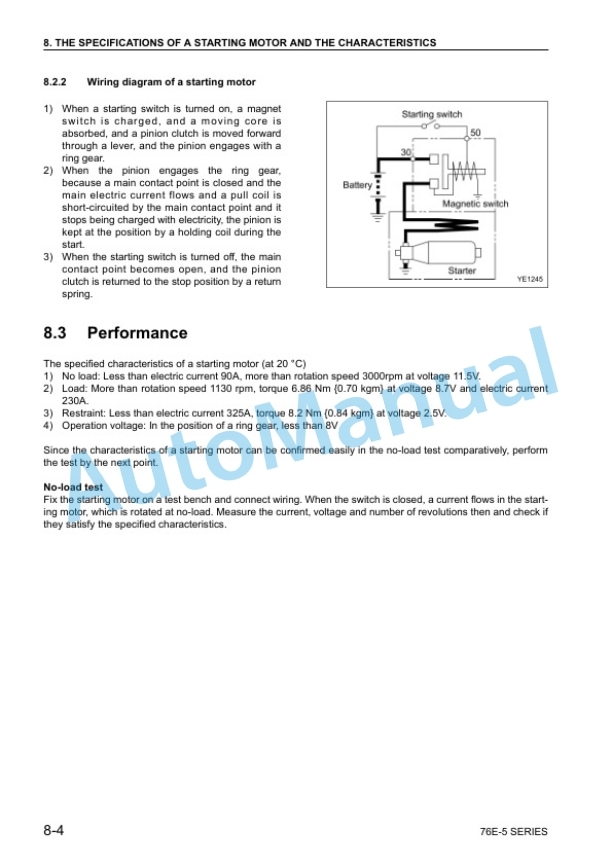

- 18.2. THE STRUCTURE OF A STARTING MOTOR AND THE WIRING DIAGRAM

- 18.2.1. STRUCTURE

- 18.2.2. WIRING DIAGRAM OF A STARTING MOTOR

- 18.3. PERFORMANCE

- 19. ALTERNATOR

- 19.1. ALTERNATOR

- 19.1.1. SPECIFICATIONS

- 19.1.2. STRUCTURE

- 19.1.3. WIRING DIAGRAM

- 19.1.4. STANDARD OUTPUT CHARACTERISTICS

- 19.1.5. INSPECTION

- 19.2. TROUBLESHOOTING

- 19.3. ALTERNATOR

- 19.3.1. COMPONENTS

- 19.3.2. SPECIFICATIONS

- 19.3.3. WIRING DIAGRAM

- 19.3.4. STANDARD OUTPUT CHARACTERISTICS

- 19.3.5. INSPECTION

- 19.3.6. TROUBLESHOOTING

- 20. ELECTRIC WIRING

- 20.1. ELECTRIC WIRING DIAGRAM

- 20.2. PRECAUTION ON ELECTRIC WIRING

- 20.2.1. ALTERNATOR

- 20.2.2. STARTING MOTOR

- 20.2.3. CURRENT LIMITOR

- 20.2.4. SECTION AREA AND RESISTANCE OF ELECTRIC WIRE

- 21. SERVICE STANDARDS

- 21.1. ENGINE TUNING

- 21.2. ENGINE BODY

- 21.2.1. CYLINDER HEAD

- 21.2.2. GEAR TRAIN AND CAMSHAFT

- 21.2.3. CYLINDER BLOCK

- 21.3. LUBRICATING OIL SYSTEM (TROCHIOD PUMP)

- 22. TIGHTENING TORQUE FOR BOLTS AND NUTS

- 22.1. TIGHTENING TOQUES FOR MAIN BOLTS AND NUTS

- 22.2. TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00