Komatsu 76E-6 Series Engine Shop Manual SEN05334-00

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN05334-00

- Format: PDF

- Size: 13.1MB

- Number of Pages: 271

Category: Komatsu Shop Manual PDF

-

Model List:

- 76E-6 Series Engine

- 1. COVER

- 2. Index and foreword

- 2.1. Index

- 2.1.1. Composition of shop manual

- 2.1.2. Table of contents

- 2.2. Foreword and general information

- 2.2.1. Introduction

- 2.2.2. Applicable machine model and serial number

- 2.2.3. Safety Statements

- 2.2.4. Safety Precautions

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. COMPONENT IDENTIFICATION

- 3.1.2. LOCATION OF LABELS

- 3.1.3. FUNCTION OF MAJOR ENGINE COMPONENTS

- 3.1.4. DIESEL FUEL

- 3.1.4.1. Diesel Fuel Specifications

- 3.1.4.2. Filling the Fuel Tank

- 3.1.4.3. Priming the Fuel System

- 3.1.5. ENGINE OIL

- 3.1.5.1. Engine Oil Specifications

- 3.1.5.2. Service Categories

- 3.1.5.3. Engine Oil Viscosity

- 3.1.5.4. Checking Engine Oil

- 3.1.5.5. Adding Engine Oil

- 3.1.5.6. Engine Oil Capacity (Typical)

- 3.1.6. ENGINE COOLANT

- 3.1.6.1. Engine Coolant Specifications

- 3.1.6.2. Filling Radiator with Engine Coolant

- 3.1.6.3. Engine Coolant Capacity (Typical)

- 3.1.7. SPECIFICATIONS

- 3.1.7.1. Description of Model Number

- 3.1.7.2. Engine Speed Specifications

- 3.1.7.3. Engine General Specifications

- 3.1.8. PRINCIPAL ENGINE SPECIFICATIONS

- 3.1.9. ENGINE SERVICE INFORMATION

- 3.1.10. TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS

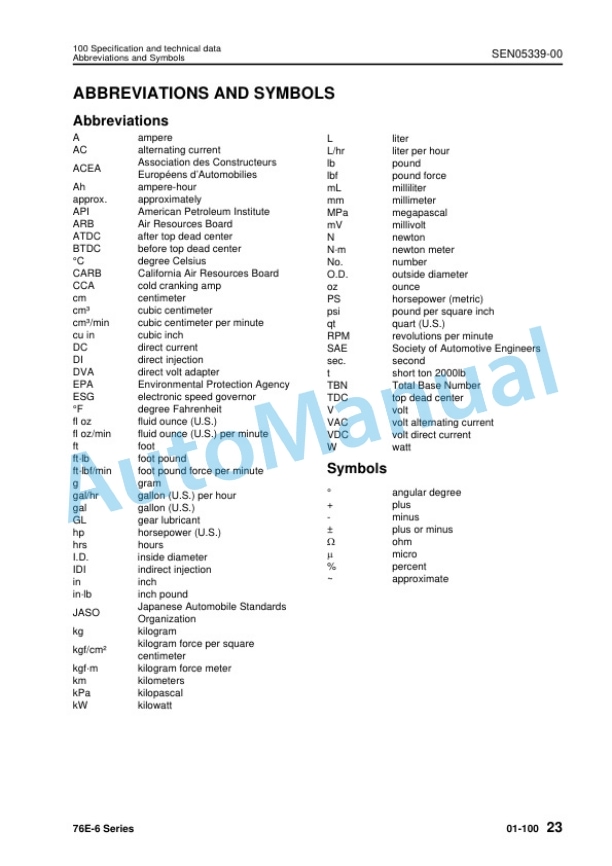

- 3.1.11. ABBREVIATIONS AND SYMBOLS

- 3.1.11.1. Abbreviations

- 3.1.11.2. Symbols

- 3.1.12. UNIT CONVERSIONS

- 3.1.12.1. Unit Prefixes

- 3.1.12.2. Units of Length

- 3.1.12.3. Units of Volume

- 3.1.12.4. Units of Mass

- 3.1.12.5. Units of Force

- 3.1.12.6. Units of Torque

- 3.1.12.7. Units of Pressure

- 3.1.12.8. Units of Power

- 3.1.12.9. Units of Temperature

- 4. Testing and adjusting

- 4.1. Testing and adjusting, Part 1

- 4.1.1. Periodic maintenance

- 4.1.1.1. INTRODUCTION

- 4.1.1.2. PRECAUTIONS

- 4.1.1.3. PERIODIC MAINTENANCE SCHEDULE

- 4.1.1.4. PERIODIC MAINTENANCE PROCEDURES

- 4.2. Testing and adjusting, Part 2

- 4.2.1. Engine

- 4.2.1.1. BEFORE YOU BEGIN SERVICING

- 4.2.1.2. INTRODUCTION

- 4.2.1.3. CYLINDER HEAD SPECIFICATIONS

- 4.2.1.4. CAMSHAFT AND TIMING GEAR TRAIN SPECIFICATIONS

- 4.2.1.5. CRANKSHAFT AND PISTONS SPECIFICATIONS

- 4.2.1.6. CYLINDER BLOCK SPECIFICATIONS

- 4.2.1.7. SPECIAL TORQUE CHART

- 4.2.1.8. SPECIAL SERVICE TOOLS

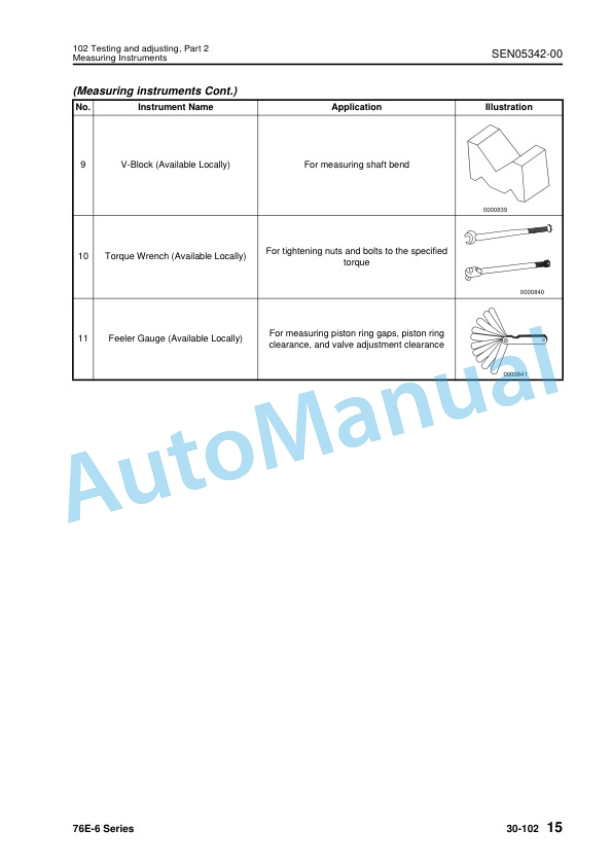

- 4.2.1.9. MEASURING INSTRUMENTS

- 4.2.1.10. CYLINDER HEAD

- 4.2.1.11. CYLINDER BLOCK

- 4.3. Testing and adjusting, Part 3

- 4.3.1. Fuel system

- 4.3.1.1. BEFORE YOU BEGIN SERVICING

- 4.3.1.2. INTRODUCTION

- 4.3.1.3. FUEL SYSTEM SPECIFICATIONS

- 4.3.1.4. SPECIAL SERVICE TOOLS

- 4.3.1.5. MEASURING INSTRUMENTS

- 4.3.1.6. FUEL SYSTEM DIAGRAM

- 4.3.1.7. FUEL SYSTEM COMPONENTS

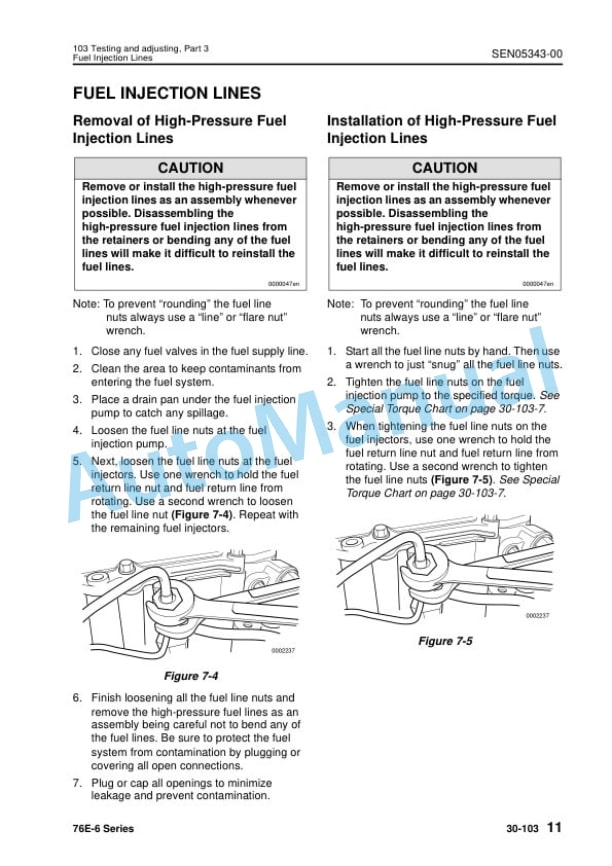

- 4.3.1.8. FUEL INJECTION LINES

- 4.3.1.9. FUEL INJECTION PUMP

- 4.3.1.10. CHECKING AND ADJUSTING FUEL INJECTION TIMING

- 4.3.1.11. FUEL INJECTORS

- 4.4. Testing and adjusting, Part 4

- 4.4.1. Cooling system

- 4.4.1.1. BEFORE YOU BEGIN SERVICING

- 4.4.1.2. INTRODUCTION

- 4.4.1.3. COOLING SYSTEM DIAGRAM

- 4.4.1.4. ENGINE COOLANT PUMP COMPONENTS

- 4.4.1.5. ENGINE COOLANT SYSTEM CHECK

- 4.4.1.6. ENGINE COOLANT PUMP

- 4.5. Testing and adjusting, Part 5

- 4.5.1. Lubrication system

- 4.5.1.1. BEFORE YOU BEGIN SERVICING

- 4.5.1.2. INTRODUCTION

- 4.5.1.3. OIL PUMP SERVICE INFORMATION

- 4.5.1.4. LUBRICATION SYSTEM DIAGRAM

- 4.5.1.5. CHECKING ENGINE OIL PRESSURE

- 4.5.1.6. TROCHOID OIL PUMP

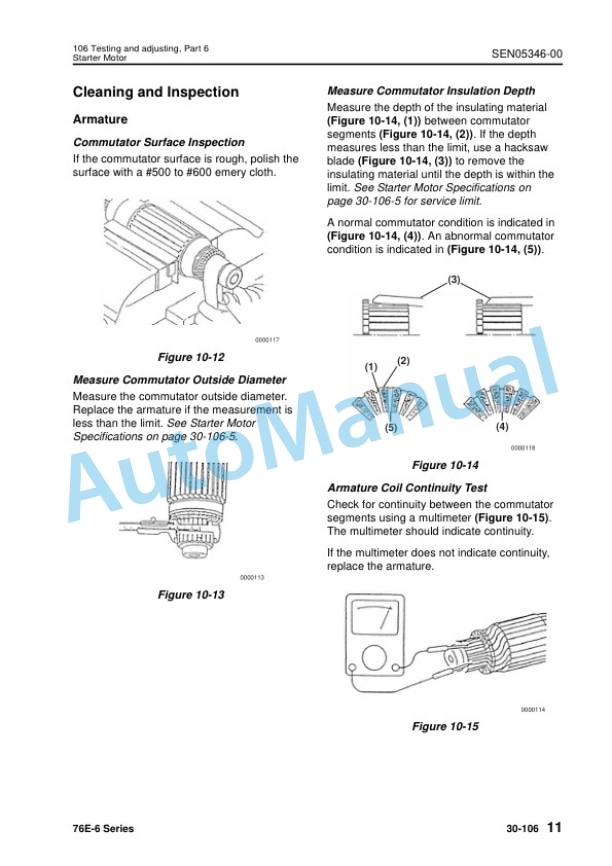

- 4.6. Testing and adjusting, Part 6

- 4.6.1. Starter

- 4.6.1.1. BEFORE YOU BEGIN SERVICING

- 4.6.1.2. INTRODUCTION

- 4.6.1.3. STARTER MOTOR INFORMATION

- 4.6.1.4. STARTER MOTOR SPECIFICATIONS

- 4.6.1.5. STARTER MOTOR TROUBLESHOOTING

- 4.6.1.6. STARTER MOTOR COMPONENTS

- 4.6.1.7. STARTER MOTOR

- 4.7. Testing and adjusting, Part 7

- 4.7.1. Alternator

- 4.7.1.1. BEFORE YOU BEGIN SERVICING

- 4.7.1.2. INTRODUCTION

- 4.7.1.3. STANDARD AND OPTIONAL ALTERNATOR INFORMATION

- 4.7.1.4. ALTERNATOR SPECIFICATIONS

- 4.7.1.5. ALTERNATOR TROUBLESHOOTING

- 4.7.1.6. ALTERNATOR COMPONENTS

- 4.7.1.7. ALTERNATOR WIRING DIAGRAM

- 4.7.1.8. ALTERNATOR STANDARD OUTPUT

- 4.7.1.9. ALTERNATOR

- 4.7.1.10. DYNAMO COMPONENT LOCATION

- 4.7.1.11. DYNAMO WIRING DIAGRAM

- 4.7.1.12. OPERATION OF DYNAMO

- 4.7.1.13. DYNAMO STANDARD OUTPUT

- 4.7.1.14. TESTING OF DYNAMO

- 4.7.1.15. DYNAMO

- 4.8. Testing and adjusting, Part 8

- 4.8.1. Electric wiring

- 4.8.1.1. ELECTRIC WIRING PRECAUTIONS

- 4.8.1.2. ELECTRIC WIRE RESISTANCE

- 4.8.1.3. BATTERY CABLE RESISTANCE

- 4.8.1.4. ELECTRICAL WIRE SIZES VOLTAGE DROP

- 4.8.1.5. CONVERSION OF AWG TO EUROPEAN STANDARDS

- 5. Troubleshooting

- 5.1. Troubleshooting of mechanical system

- 5.1.1. SPECIAL SERVICE TOOLS

- 5.1.2. TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

- 5.1.2.1. Compression Pressure Measurement Method

- 5.1.2.2. Standard Compression Pressure

- 5.1.2.3. Engine Speed and Compression Pressure (Use for Reference)

- 5.1.2.4. Measured Value and Troubleshooting

- 5.1.3. QUICK REFERENCE TABLE FOR TROUBLESHOOTING

- 5.1.3.1. Troubleshooting Charts

- 5.1.4. ELECTRIC WIRING

Rate this product

You may also like