Komatsu 82E-6, 98E-6 Series Engine Shop Manual SEN04211-04

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN04211-04

- Format: PDF

- Size: 15.7MB

- Number of Pages: 386

Category: Komatsu Shop Manual PDF

-

Model List:

- 82E-6 Series Engine

- 98E-6 Series Engine

- 1. Cover

- 2. Index and foreword

- 2.1. Index

- 2.1.1. Composition of shop manual

- 2.1.2. Table of contents

- 2.2. Foreword and general information

- 2.2.1. Introduction

- 2.2.2. Applicable machine model and serial number

- 2.2.3. Safety Statements

- 2.2.4. Safety Precautions

- 3. Specification

- 3.1. Specification and technical data

- 3.2. Component identification

- 3.3. Function of major engine components

- 3.4. Main electronic control components and features

- 3.5. Function of cooling system components

- 3.6. Diesel fuel

- 3.6.1. Diesel fuel specifications

- 3.6.2. Filling the fuel tank

- 3.6.3. Priming the fuel system

- 3.7. Engine oil

- 3.7.1. Engine oil specifications

- 3.7.2. Checking engine oil

- 3.7.3. Adding engine oil

- 3.7.4. Engine oil capacity (typical)

- 3.8. Engine coolant

- 3.8.1. Engine coolant specifications

- 3.8.2. Filling radiator with engine coolant

- 3.8.3. Engine coolant capacity (typical)

- 3.9. Specifications

- 3.9.1. Description of Model Number

- 3.9.2. Engine speed specifications

- 3.9.3. Engine general specifications

- 3.10. Principal engine specifications

- 3.10.1. E ( EPA Tier2)

- 3.10.2. ( EPA Tier2)

- 3.10.3. S3D84E ( EPA Tier2)

- 3.10.4. ( EPA Tier2)

- 3.10.5. ( EPA Tier2)

- 3.10.6. S4D84E ( EPA Tier2)

- 3.10.7. ( EPA Tier2)

- 3.10.8. E ( EPA Tier2)

- 3.10.9. ( EPA Tier2)

- 3.10.10. S4D98E ( EPA Tier2)

- 3.10.11. EB (complies with EPA Interim Tier4)

- 3.10.12. U (complies with EPA Interim Tier4)

- 3.10.13. S4D84EZ (complies with EPA Interim Tier4)

- 3.10.14. U (complies with EPA Interim Tier4)

- 3.10.15. B (complies with EPA Interim Tier4)

- 3.10.16. E (complies with EPA Interim Tier4)

- 3.10.17. Z (complies with EPA Interim Tier4)

- 3.10.18. S4D98EZ (complies with EPA Tier3)

- 3.11. Engine service standards

- 3.12. Tightening torques for standard bolts and nuts

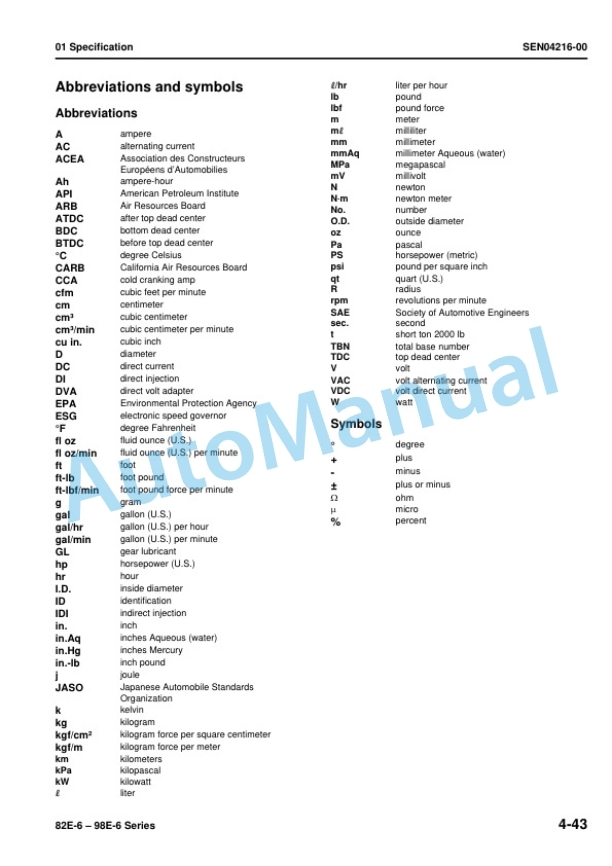

- 3.13. Abbreviations and symbols

- 3.13.1. Abbreviations

- 3.13.2. Symbols

- 3.14. Unit conversions

- 3.14.1. Unit prefixes

- 3.14.2. Units of length

- 3.14.3. Units of volume

- 3.14.4. Units of mass

- 3.14.5. Units of force

- 3.14.6. Units of torque

- 3.14.7. Units of pressure

- 3.14.8. Units of power

- 3.14.9. Units of temperature

- 4. Testing and adjusting

- 4.1. Testing and adjusting, Part 1

- 4.1.1. Before you begin servicing

- 4.1.2. Introduction

- 4.1.3. Periodic maintenance schedule

- 4.1.4. Periodic maintenance procedures

- 4.2. Testing and adjusting, Part 2

- 4.2.1. Before you begin servicing

- 4.2.2. Introduction

- 4.2.3. Cylinder head specifications

- 4.2.4. Camshaft and timing gear train specifications

- 4.2.5. Crankshaft and piston specifications

- 4.2.6. Cylinder block specifications

- 4.2.7. Special torque chart

- 4.2.8. Special service tools

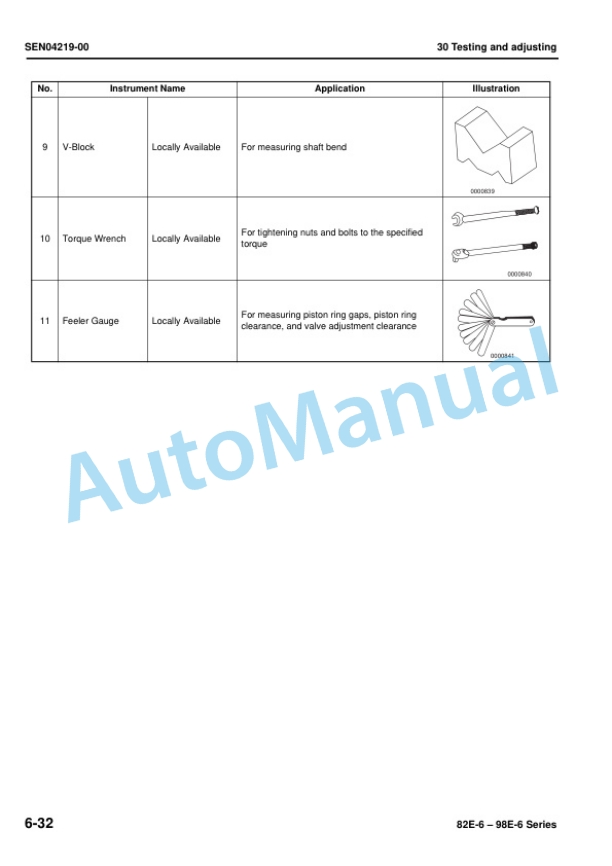

- 4.2.9. Measuring instruments

- 4.2.10. valve cylinder head

- 4.2.11. valve cylinder head

- 4.2.12. valve cylinder head components

- 4.2.13. Measuring and adjusting valve clearance

- 4.2.14. Crankshaft and camshaft components

- 4.2.15. EGR system

- 4.3. Testing and adjusting, Part 3

- 4.3.1. Before you begin servicing

- 4.3.2. Introduction

- 4.3.3. Fuel system specifications

- 4.3.4. Special service tools

- 4.3.5. Measuring instruments

- 4.3.6. Fuel system diagram

- 4.3.7. Fuel system components

- 4.3.8. Fuel injection pump

- 4.3.9. Checking and adjusting fuel injection timing

- 4.3.10. Fuel injectors

- 4.4. Testing and adjusting, Part 4

- 4.4.1. Before you begin servicing

- 4.4.2. Introduction

- 4.4.3. Cooling system diagram

- 4.4.4. Engine coolant pump components

- 4.4.5. Engine coolant system check

- 4.4.6. Engine coolant pump

- 4.5. Testing and adjusting, Part 5

- 4.5.1. Before you begin servicing

- 4.5.2. Introduction

- 4.5.3. Oil pump service information

- 4.5.4. Lubrication system diagram

- 4.5.5. Checking engine oil pressure

- 4.5.6. Trochoid oil pump

- 4.5.7. Trochoid oil pump

- 4.5.8. Trochoid oil pump

- 4.6. Testing and adjusting, Part 6

- 4.6.1. Before you begin servicing

- 4.6.2. Introduction

- 4.6.3. Specifications

- 4.6.4. Troubleshooting

- 4.6.5. Turbocharger components

- 4.6.6. Turbocharger component functions

- 4.6.7. Waste gate modulation

- 4.6.8. Periodic inspection

- 4.7. Testing and adjusting, Part 7

- 4.7.1. Before you begin servicing

- 4.7.2. Introduction

- 4.7.3. Starter motor information

- 4.7.4. Starter motor specifications

- 4.7.5. Starter motor troubleshooting

- 4.7.6. Starter motor components

- 4.7.7. Starter motor

- 4.8. Testing and adjusting, Part 8

- 4.8.1. Before you begin servicing

- 4.8.2. Introduction

- 4.8.3. Dynamo and alternator information

- 4.8.4. Alternator specifications

- 4.8.5. Dynamo specifications

- 4.8.6. Alternator troubleshooting

- 4.8.7. Alternator components

- 4.8.8. Alternator wiring diagram

- 4.8.9. Alternator standard output

- 4.8.10. Alternator

- 4.8.11. Dynamo component location

- 4.8.12. Dynamo wiring diagram

- 4.8.13. Operation of dynamo

- 4.8.14. Dynamo standard output

- 4.8.15. Testing of dynamo

- 4.8.16. Dynamo

- 5. Troubleshooting

- 5.1. Troubleshooting of mechanical system

- 5.1.1. Special service tools

- 5.1.2. Troubleshooting by measuring compression pressure

- 5.1.3. Quick reference table for troubleshooting

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00