Komatsu 82E-98E Series Diesel Engine Shop Manual SEBM035103

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM035103

- Format: PDF

- Size: 9.5MB

- Number of Pages: 197

Category: Komatsu Shop Manual PDF

-

Model List:

- 82E-98E Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATIONS

- 3.2. ENGINE EXTERNAL VIEWS

- 3.3. STRUCTURAL DESCRIPTION

- 4. INSPECTION ANG ADJUSTMENT

- 4.1. PERIODIC MAINTENANCE SCHEDULE

- 4.2. PERIODIC INSPECTION AND MAINTENANCE PROCEDURE

- 4.2.1. CHECK BEFORE DAILY OPERATION

- 4.2.2. INSPECTION AFTER INITIAL 50 HOURS OPERATION

- 4.2.3. INSPECTION EVERY 50 HOURS

- 4.2.4. INSPECTION EVERY 250 HOURS OR 3 MONTHS

- 4.2.5. INSPECTION EVERY 500 HOURS OR 6 MONTHS

- 4.2.6. INSPECTION EVERY 1000 HOURS OR ONE YEAR

- 4.2.7. INSPECTION EVERY 2000 HOURS OR 2 YEARS

- 4.3. ADJUSTING THE NOLOAD MAXIMUM OR MINIMUM SPEED

- 4.4. SENSOR INSPECTION

- 4.4.1. OIL PRESSURE SWITCH

- 4.4.2. THERMO SWITCH

- 4.5. WATER LEAK CHECK IN COOLING WATER SYSTEM

- 4.6. RADIATOR CAP INSPECTION

- 4.7. THERMOSTAT INSPECTION

- 4.8. ADJUSTING OPERATION

- 4.9. LONG STORAGE

- 5. TROUBLESHOOTING

- 5.1. PREPARATION BEFORE TROUBLESHOOTING

- 5.2. QUICK REFERENCE TABLE FOR TROUBLESHOOTING

- 5.3. TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

- 6. DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

- 6.1. COMPLETE DISASSEMBLY AND REASSEMBLY

- 6.1.1. INTRODUCTION

- 6.1.2. SPECIAL SERVICE TOOLS

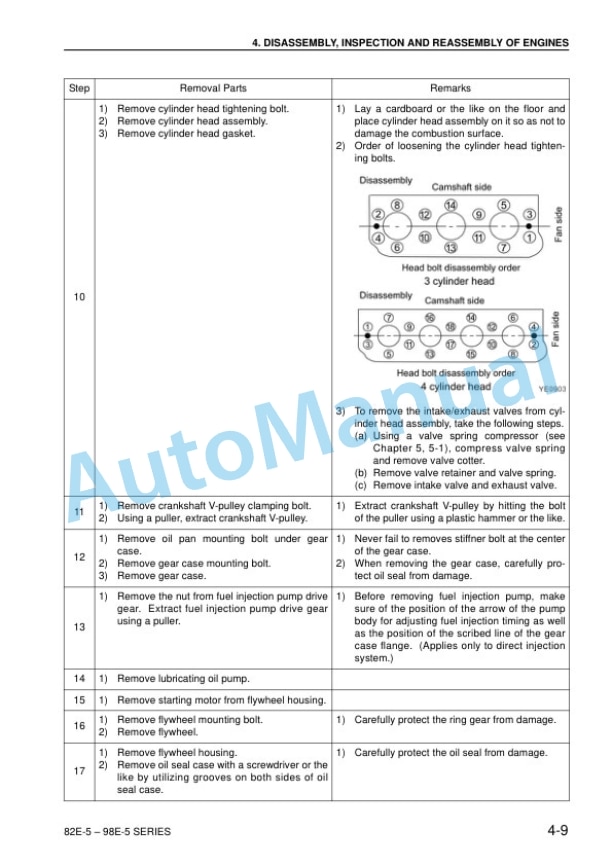

- 6.1.3. COMPLETE DISASSEMBLY

- 6.1.4. PRECAUTIONS BEFORE AND DURING REASSEMBLY

- 6.1.5. ADJUSTING OPERATION

- 6.2. CYLINDER HAED DISASSEMBLY, INSPECTION AND REASSEMBLY

- 6.2.1. COMPONENTS(2VALVE CYLINDER HAED)

- 6.2.2. DISASSEMBLY PROCEDURE

- 6.2.3. REASSEMBLY PROCEDURE

- 6.2.4. SERVICING POINTS

- 6.2.5. PARTS INSPECTION AND MEASUREMENT

- 6.2.6. VALVE SEAT CORRECTION

- 6.2.7. VALVE GUIDE REPLACEMENT

- 6.2.8. VALVE STEM SEAL REPLACEMENT

- 6.3. GEAR TRAIN AND CAMSHAFT

- 6.3.1. COMPONENTS

- 6.3.2. DISASSEMBLY PROCEDURE

- 6.3.3. REASSEMBLY PROCEDURE

- 6.3.4. SERVICING POINTS

- 6.3.5. PARTS INSPECTION AND MEASUREMENT

- 6.3.6. OIL SEAL REPLACEMENT (GEAR CASE SIDE)

- 6.3.7. CAMSHAFT BUSHING REPLACEMENT

- 6.4. CYLINDER BLOCK

- 6.4.1. COMPONENTS

- 6.4.2. DISASSEMBLY PROCEDURE

- 6.4.3. REASSEMBLY PROCEDURE

- 6.4.4. SERVICING POINTS

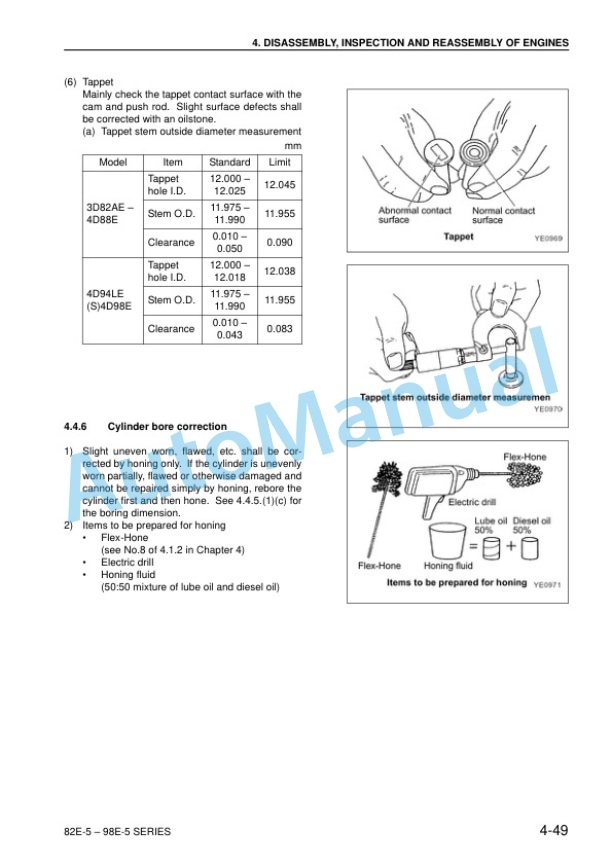

- 6.4.5. PARTS INSPECTION AND MEASUREMENT

- 6.4.6. CYLINDER BORE CORRECTION

- 6.4.7. PISTON PIN BUSHING REPLACEMENT

- 6.4.8. OIL SEAL REPLACEMENT (FLYWHEEL HOUSING SIDE)

- 7. LUBRICATION SYSTEM

- 7.1. LUBRICATION SYSTEM DIAGRAM

- 7.2. TROCHOID PUMP COMPONENTS

- 7.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 7.4. SERVICING POINTS

- 7.5. PARTS INSPECTION AND MEASUREMENT

- 8. COOLING SYSTEM

- 8.1. COOLING WATER SYSTEM

- 8.2. COOLING WATER PUMP COMPONENTS

- 8.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 8.4. SERVICING POINTS

- 9. FUEL INJECTION PUMP/GOVERNOR

- 9.1. INTRODUCTION

- 9.2. FUEL INJECTION PUMP

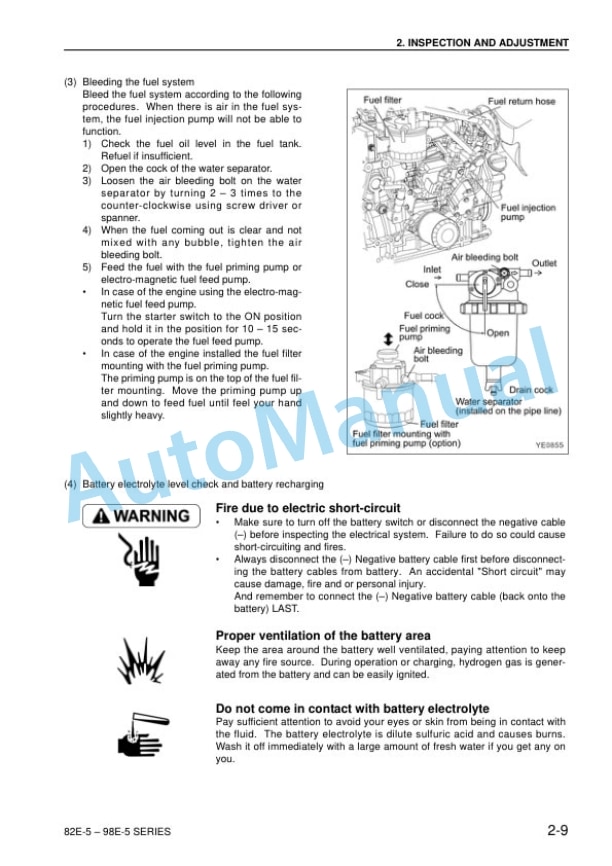

- 9.2.1. FUEL SYSTEM DIAGRAM

- 9.2.2. EXTERNAL VIEW AND COMPONENTS

- 9.2.3. DISASSEMBLY PROCEDURE

- 9.2.4. ASSEMBLY PROCEDURE

- 9.2.5. SERVICING POINTS

- 10. TURBOCHARGER

- 10.1. STRUCTURE AND FUNCTIONS

- 10.1.1. MAIN SPECIFICATIONS

- 10.1.2. CONSTRUCTION

- 10.1.3. STRUCTURAL AND FUNCTIONAL OUTLINE

- 10.1.4. COMPONENTS

- 10.1.5. COMPONENTS

- 10.2. SERVICE STANDARDS AND TIGHTENING TORQUE

- 10.2.1. SERVICE STANDARDS

- 10.2.2. TIGHTENING TORQUE

- 10.3. PERIODIC INSPECTION PROCEDURE

- 10.3.1. PERIODIC INSPECTION INTERVALS

- 10.3.2. INSPECTION PROCEDURE

- 10.3.3. WASTE GATE VALVE ADJUSTMENT PROCEDURE

- 10.4. DISASSEMBLY PROCEDURE

- 10.4.1. PREPARATION FOR DISASSEMBLY

- 10.4.2. INSPECTION BEFORE DISASSEMBLY

- 10.4.3. DISASSEMBLY

- 10.5. WASHING AND INSPECTION PROCEDURE

- 10.5.1. WASHING

- 10.5.2. INSPECTION PROCEDURE

- 10.6. REASSEMBLY PROCEDURE

- 10.6.1. PREPARATION FOR REASSEMBLY

- 10.6.2. REASSEMBLY

- 10.7. HANDING AFTER DISASSEMBLY AND REASSEMBLY

- 10.7.1. INSTRUCTIONS FOR TURBOCHARGER INSTALLATION

- 10.8. TROUBLESHOOTING

- 10.8.1. EXCESSIVELY EXHAUST SMOKE

- 10.8.2. WHITE SMOKE GENERATION

- 10.8.3. SUDDEN OIL DECREASE

- 10.8.4. DECREASE IN OUTPUT

- 10.8.5. POOR (SLOW) RESPONSE (STARTING) OF TURBOCHARGER

- 10.8.6. ABNORMAL SOUND OR VIBRATION

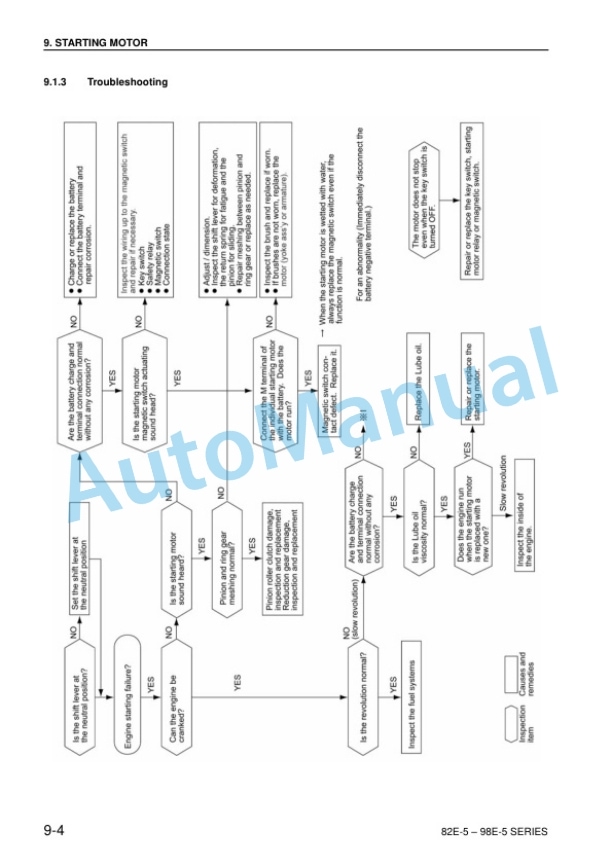

- 11. STARTING MOTOR

- 11.1. FOR 4D94LE/(S)4D98E

- 11.1.1. SPECIFICATIONS

- 11.1.2. COMPONENTS

- 11.1.3. TROUBLESHOOTING

- 11.1.4. NAMES OF PARTS AND DISASSEMBLY PROCEDURE

- 11.1.5. INSPECTION AND MAINTENANCE

- 11.1.6. SERVICE STANDARDS

- 11.1.7. ASSEMBLY

- 11.1.8. CHARACTERISTIC TEST

- 12. ALTERNATOR

- 12.1. THE 40A ALTERNATOR FOR 3D84E AND OTHER MODELS

- 12.1.1. COMPONENTS

- 12.1.2. SPECIFICATIONS

- 12.1.3. WIRING DIAGRAM

- 12.1.4. STANDARD OUTPUT CHARACTERISTICS

- 12.1.5. INSPECTION

- 12.1.6. TROUBLESHOOTING

- 13. ELECTRIC WIRING

- 13.1. ELECTRIC WIRING DIAGRAM

- 13.2. PRECAUTION ON ELECTRIC WIRING

- 13.2.1. ALTERNATOR

- 13.2.2. STARTING MOTOR

- 13.2.3. CURRENT LIMITER

- 13.2.4. SECTION AREA AND RESISTANCE OF ELECTRIC WIRE

- 14. SERVICE STANDARDS

- 14.1. ENGINE TUNING

- 14.2. ENGINE BODY

- 14.2.1. CYLINDER HEAD

- 14.2.2. GEAR TRAIN AND CAMSHAFT

- 14.2.3. CYLINDER BLOCK

- 14.3. LUBRICATING OIL SYSTEM (TROCHOID PUMP)

- 15. TIGHTENING TORQUE FOR BOLTS AND NUTS

- 15.1. TIGHTENING TORQUES FOR MAIN BOLTS AND NUTS

- 15.2. TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00